Professional Documents

Culture Documents

High-Temperature Hydrawrap: Hydratech

Uploaded by

Luis Carlos Balcazar0 ratings0% found this document useful (0 votes)

16 views3 pagesOriginal Title

HighTemperatureHydraWrapTDS10.4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views3 pagesHigh-Temperature Hydrawrap: Hydratech

Uploaded by

Luis Carlos BalcazarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

®

HydraTech High-Temperature HydraWrap

Structural Composite Repair System for High-Temperature Applications

Issue 10.14

The HydraWrap system is a performance driven product that PERFORMANCE DATA

provides a chemical and corrosion resistant structural repair.

The HydraWrap system is backed by our engineering staff CHEMICAL RESISTANCE ASTM D543 (30 day immersion)

that services each application with assessment and technical

support. It offers a low cost, long term solution to the most Water No effect

challenging demands of the industry.

Sodium Hydroxide 5% No effect

Ammonium Hydroxide 5% No effect

PRODUCT DESCRIPTION Sodium Hypochlorite (bleach) No effect

Ferric Chloride 1% No effect

HydraWrap is Carbon Fiber Reinforced Polymer (CFRP)

Sulfuric Acid 20% No effect

repair system engineered to restore or enhance the

structural integrity of pipe and infrastructure. Nitric Acid 1% No effect

Each HydraWrap product is a uniquely designed high Detergent Solution No effect

performance system that consists of a 100% solids high Gasoline No effect

build epoxy Primer, a 100% solids epoxy Wet-Out resin, and Toluene No effect

carbon fiber fabric.

The Primer provides excellent adhesion to a variety of ADHESION ASTM D4541 (psi)

substrates while allowing a sag free application at high film Cold Rolled Steel >2,000

builds. Hot Rolled Steel >2,000

The Wet-Out resin is designed to thoroughly wet out the Cast Iron >2,000

fiber forming a composite matrix with a very high tensile and 304 Stainless Steel >2,000

flexural properties. 316 Stainless Steel >2,000

The High-Temperature HydraWrap System is designed to Concrete Concrete Failure

provide a structural repair that will withstand elevated

temperatures with minimal post-cure. (Testing reflects results after 24 hour cure)

Advantages Composite System Hoop Hoop Axial

High Temperature resistance with minimal post-cure (two ply bidirectional ) 200C 300C 300C

Chemical and Corrosion Resistant Structural Repair Tensile Strength

41.08 88.3 13.79

High Tensile / Flexural Modulus and Strength ASTM D3039 (ksi)

Tensile Modulus

100% Solvent-Free, Zero V.O.C. ASTM D3039 (msi) 4.48 8.44 2.32

Restores Maximum Allowable Operating Pressure (MAOP) % Elongation

Installed by fully trained application specialists ASTM D3039 0.95 1.03 0.68

Full contract support services available Flexural Strength

ASTM D790 (ksi) 64.4 106 19

Flexural Modulus

ASTM D-790 (msi) 3.16 4.18 0.98

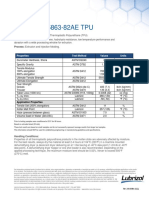

PHYSICAL PROPERTIES CTE

ASTM E831 (x10-6/°F) 16.8

Primer Wet-Out Maximum Operating

Color Steel Red Clear Temperature (°F) 350 / 400

Working Life – 200ºF (93ºC) 60 minutes 60 minutes Continuous / Intermittent

Dry Times – 68ºF (20ºC) >24 Hours >24 Hours

% Vol Solids (ASTM 2369) 100 100 Conforms to DOT regulations • PCC-2 Art 4.1,

Shore D Hardness (ASTM D2240) 75 80 4.2 ASME B31.1•.3•.4•.8 • API 570 • ISO15649

Mix Ratio Pre-measured 1:1 ISO13623 • ACI 440.2R08

Flash Point > 200ºF (93ºC)

Storage Life Twelve months when stored For details regarding the testing associated with the provided data refer to

the HydraWrap Testing and Design Sheet.

in original sealed containers,

between 50-77ºF (10-25ºC)

HydraTech Engineered Products LLC

10448 Chester Road, Cincinnati, OH 45215 Phone (513) 827-9169 Fax (513) 827-9171

www.hydratechllc.com

1

®

HydraTech High-Temperature HydraWrap Issue 10.14

APPLICATION RECOMMENDATIONS INSTALLATION PROCEDURE

Minimum Application Temp 40ºF (4.4ºC) Prep substrate according to NACE / SSPC spec.

Maximum Relative Humidity 85% Measure fabric around pipe to ensure proper length.

Substrate Temperature 5ºF (3ºC) above dew point Mechanically mix together both primer components until

Thinning Do not thin uniform.

Cleaning Fluid Universal Equipment Apply primer to prepared substrate via brush or spreader.

Cleaner Mix both Wet-Out components for two minutes.

To aid application at low temperatures, both components Apply Wet-Out to fabric via spreader or impregnator

should be warmed to 60-68ºF (15.5-20ºC) prior to mixing. ensuring complete wet out of fabric.

Apply saturated fabric to wet primer ensuring a consistent,

smooth wrap free of voids.

SUBSTRATE PREPARATION System must be post-cured @ 350°F for 2 hours

minimum, for best results a total of 6 hours.

Substrate preparation dictates the adhesion performance of If exposed to sunlight, top coat the wrap with a light stable

any coatings system. A properly prepped surface will ensure top coat.

maximum life and performance of the system.

For details regarding application refer to the HydraWrap Installation Procedure

Concrete: NACE No.6* / SSPC-SP 13*

Steel: NACE No.2* / SSPC-SP 10*

NACE No.3 / SSPC-SP 6 COVERAGE

NACE No.5 / SSPC-SP 12

UNIT SIZE COVERAGE

*indicates recommended method PRIMER Pt 4.5 sqft

Qt 9 sqft

NOTE Hg 23.5 sqft

The HydraTech High Temperature HydraWrap System is WET-OUT Pt 4 sqft of fabric

intended for short-term repairs in critical applications and Qt 8 sqft of fabric

some long-term applications. The High Temperature Primer coverage based on 32mil film build.

HydraWrap system is not intended for applications with Wet-Out coverage based on 99.36gg/sqft of 300C fabric.

exposure to strong acids, organic acids, strong solvents

(MEK, Acetone, Alcohol) or temperatures exceeding 350°F.

To be applied by certified personnel only. See MSDS for

safety information.

ORDER INFORMATION

Part No. for standard kits consist of: System Code – Pipe Size – Pipe Style

ex. SH-12-W (Standard HydraWrap for 12” Weld Repair)

SYSTEM CODE PIPE SIZE PIPE STYLE

SH = Standard 2 = will wrap up to one 2” pipe 14 = will wrap up to one 14” pipe W = Weld

A = Acid 4 = will wrap up to one 4” pipe 16 = will wrap up to one 16” pipe E = Elbow

M = Mid-Temperature 6 = will wrap up to one 6” pipe 20 = will wrap up to one 20” pipe T = Tee

H = High Temperature 10 = will wrap up to one 10” pipe 22 = will wrap up to one 22” pipe SS = Spiral

SS = SubSea 12 = will wrap up to one 12” pipe 24 = will wrap up to one 24” pipe U = Universal

*** NOTE: Custom kits are available to accommodate nearly any installation. ***

Add an M for the Marine Kit Option. Marine Kits includes tools for mixing and applying the HydraWrap System. ex. SH-12-W-M

HydraTech Engineered Products LLC

10448 Chester Road, Cincinnati, OH 45215 Phone (513) 827-9169 Fax (513) 827-9171

www.hydratechllc.com

2

HydraTech Engineered Products LLC

10448 Chester Road, Cincinnati, OH 45215 Phone (513) 827-9169 Fax (513) 827-9171

www.hydratechllc.com

3

You might also like

- Compilado Fichas Técnicas HYDRAWAPDocument12 pagesCompilado Fichas Técnicas HYDRAWAPLuis Carlos BalcazarNo ratings yet

- PETRONAS Global Compressor A M6 Master EN18Document3 pagesPETRONAS Global Compressor A M6 Master EN18Mujeeb SiddiqueNo ratings yet

- PETRONAS Compressor A M4 Series v2. 23-11-2016Document3 pagesPETRONAS Compressor A M4 Series v2. 23-11-2016Mujeeb SiddiqueNo ratings yet

- ESystemHydraWrapTDS10 4Document2 pagesESystemHydraWrapTDS10 4Luis Carlos BalcazarNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Compressor AM2Document3 pagesCompressor AM2Hendra KurniawanNo ratings yet

- Petronas Hydrocer Series: Anti-Wear Hydraulic FluidsDocument3 pagesPetronas Hydrocer Series: Anti-Wear Hydraulic FluidsRamy El GammalNo ratings yet

- PETRONAS Hydraulic Series v2. 23-05-2016Document4 pagesPETRONAS Hydraulic Series v2. 23-05-2016Roter DiamNo ratings yet

- PETRONAS Slideway Series v2. 13 07 2016Document3 pagesPETRONAS Slideway Series v2. 13 07 2016Isay Quiroga VargasNo ratings yet

- Petronas Gear MepDocument3 pagesPetronas Gear MepLetíciaMendesNo ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- Ethafoam 400 Polyethylene Foam: Density 4.0 PCF (64.1 KG/M) Maximum Loading 5.0 Psi (34.5 Kpa) Color Black, NaturalDocument2 pagesEthafoam 400 Polyethylene Foam: Density 4.0 PCF (64.1 KG/M) Maximum Loading 5.0 Psi (34.5 Kpa) Color Black, NaturalMina MagdyNo ratings yet

- PETRONAS - Jenteram G Series - v2. 21 08 2018Document3 pagesPETRONAS - Jenteram G Series - v2. 21 08 2018Hazrul ImaginariumNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- Airtop HTDocument1 pageAirtop HTtribolasNo ratings yet

- Petronas Jenteram G 32 TDS en 2020Document3 pagesPetronas Jenteram G 32 TDS en 2020galuh prabandariNo ratings yet

- Caulking - Silco SIL-BOND RTV 4500Document1 pageCaulking - Silco SIL-BOND RTV 4500Estevan huertasNo ratings yet

- FlexPipe Linepipe HT Product Data SheetDocument2 pagesFlexPipe Linepipe HT Product Data SheetSaidNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- RapidFix HD CompositeDocument2 pagesRapidFix HD CompositeHeramb TrifaleyNo ratings yet

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Document3 pagesTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananNo ratings yet

- Vetotop Doc Technical Map en 3573Document4 pagesVetotop Doc Technical Map en 3573Rebel XNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Tech Data Sheet Siltech 100HV: Typical PropertiesDocument2 pagesTech Data Sheet Siltech 100HV: Typical PropertiesVictor Rocha ZavaletaNo ratings yet

- DOWSIL™ 896 PanelFixDocument7 pagesDOWSIL™ 896 PanelFixChris Hung WeiNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- LH-3750 - Daelim IndustrialDocument2 pagesLH-3750 - Daelim IndustrialAkoyoNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- Dymonic 100 Data SheetDocument2 pagesDymonic 100 Data SheetDavid LuongNo ratings yet

- CYCLON HYDRAULIC - EN - Vja21Document1 pageCYCLON HYDRAULIC - EN - Vja21Jolie AbarcaNo ratings yet

- Atlantic Air Compressor OilsDocument1 pageAtlantic Air Compressor OilsOsman QaasimNo ratings yet

- Texaco Randon HDZDocument3 pagesTexaco Randon HDZRonald José Silva CostaNo ratings yet

- Tectyl HF 46 PDS ENDocument1 pageTectyl HF 46 PDS ENAdham TunggalNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- Urethane Coating 165 PWDocument3 pagesUrethane Coating 165 PWANIBALLOPEZVEGANo ratings yet

- Hercules EngDocument1 pageHercules EngTAREK HAMADNo ratings yet

- FT Grease 22Document2 pagesFT Grease 22Edgar Leonel CortésNo ratings yet

- Shock Oil ChangeDocument1 pageShock Oil Changevobleris makitaNo ratings yet

- Perfecto T Range: DescriptionDocument2 pagesPerfecto T Range: Descriptiondforsythe639No ratings yet

- Mobil Dte 20Document3 pagesMobil Dte 20alexander900616No ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetDaya Shanker PalNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- Aeroshell Fluid 31Document2 pagesAeroshell Fluid 31mertaktayNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- Prorox WM 950 SaDocument1 pageProrox WM 950 SaHanief AnsharNo ratings yet

- Sikaflex 252 TDSDocument3 pagesSikaflex 252 TDSxingobuilderNo ratings yet

- HydraulicDocument1 pageHydraulicTAREK HAMADNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- Aeroshell Ascender: Performance, Features & Benefits Main ApplicationsDocument3 pagesAeroshell Ascender: Performance, Features & Benefits Main ApplicationsRicardo LacskoNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Hyspin ZZ Range: DescriptionDocument2 pagesHyspin ZZ Range: DescriptionDaniel VuletaNo ratings yet

- Dirax PDFDocument2 pagesDirax PDFTom Henry Bernabe Castro100% (1)

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Electrolysis ProcessesDocument180 pagesElectrolysis ProcessesEngineering Office Shahrak100% (1)

- Example Chemical and Biological CompositionDocument8 pagesExample Chemical and Biological CompositioniskandarNo ratings yet

- Process Flow Chart Dairy ProductsDocument5 pagesProcess Flow Chart Dairy Productslokesh jainNo ratings yet

- Food Che. W1-4Document177 pagesFood Che. W1-4mihael jhnsNo ratings yet

- CH 21Document32 pagesCH 21Indro ParmaNo ratings yet

- KIMO HQ210 BrochureDocument4 pagesKIMO HQ210 BrochurebolsjhevikNo ratings yet

- Lett 2c03388Document5 pagesLett 2c03388Vũ LưuNo ratings yet

- 3330604Document3 pages3330604dhwaniNo ratings yet

- Elec6063 Optoelectronics and Lightwave Technology: Part 2: Leds and Lasers - 1 (Leds)Document43 pagesElec6063 Optoelectronics and Lightwave Technology: Part 2: Leds and Lasers - 1 (Leds)wanxin zhouNo ratings yet

- Sol Gel Synthesis of Nanocrystalline Magnesium Fluoride Its Use in The Preparation of MgF2 Films and MgF2 SiO2 Composites 1996 Chemistry of MaterialsDocument8 pagesSol Gel Synthesis of Nanocrystalline Magnesium Fluoride Its Use in The Preparation of MgF2 Films and MgF2 SiO2 Composites 1996 Chemistry of MaterialskarthikdhadalaNo ratings yet

- Space WeatherDocument36 pagesSpace WeatherMat MinNo ratings yet

- 2D Simulations and Electro-Thermal Analysis of Micro-Heater Using COMSOLDocument4 pages2D Simulations and Electro-Thermal Analysis of Micro-Heater Using COMSOLshobiiiscNo ratings yet

- SG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323Document10 pagesSG Unit6ProgressCheckMCQ 63fd8804e35951.63fd880808f2a9.47859323vDraqNo ratings yet

- SorptionDocument44 pagesSorptionluckyprimeNo ratings yet

- Fundamentals of Automotive Electricity & ElectronicsDocument83 pagesFundamentals of Automotive Electricity & ElectronicsJohnny Ym100% (1)

- Introduction To Turbulence1Document28 pagesIntroduction To Turbulence1Mustafa YılmazNo ratings yet

- Behavior DS MM247LC (Bae2001)Document6 pagesBehavior DS MM247LC (Bae2001)Alex CostaNo ratings yet

- Salama YoussefDocument1 pageSalama YoussefYoussef SalamaNo ratings yet

- Electrolysis O LevelDocument17 pagesElectrolysis O LevelInnocent EbilNo ratings yet

- CPP & Cqa PDFDocument71 pagesCPP & Cqa PDFanon_695264516100% (1)

- Ishrae PPT On RefrigerantDocument9 pagesIshrae PPT On RefrigerantJigar ShahNo ratings yet

- Prospectus Syllabus: Post Graduate Diploma Course in Food Analysis and Quality AssuranceDocument19 pagesProspectus Syllabus: Post Graduate Diploma Course in Food Analysis and Quality Assurancepriyanka thapliyal100% (1)

- Keep 512Document17 pagesKeep 512rajaijahNo ratings yet

- BS en Iso 23936-2-2011Document78 pagesBS en Iso 23936-2-2011Franklin Osorio Sanchez67% (3)

- Ecofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaDocument22 pagesEcofriendly Finishing of Textile: by Dr. Pintu Pandit Asst. Professor, NIFT PatnaARYAN RATHORENo ratings yet

- Fiitjee: Solutions To JEE (Main) - 2020Document36 pagesFiitjee: Solutions To JEE (Main) - 2020srijan jhaNo ratings yet

- Gelatin Zymography For Detection of Matrixmetalloproteinase-2 and - 9 (MMP-2, MMP-9) From Myocardiam SamplesDocument21 pagesGelatin Zymography For Detection of Matrixmetalloproteinase-2 and - 9 (MMP-2, MMP-9) From Myocardiam SamplesItrux JonathanNo ratings yet

- Offshore Oil & GasDocument27 pagesOffshore Oil & GasArash HamidiNo ratings yet

- Chemical Engineering CommunicationsDocument16 pagesChemical Engineering CommunicationsMichelle Quilaqueo NovoaNo ratings yet

- REVISE Final 1-5Document23 pagesREVISE Final 1-5Kobe VasquezNo ratings yet