Professional Documents

Culture Documents

04 ISO 19443 Introduction To Risk-Based Thinking

Uploaded by

Roberto Eduardo HilalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 ISO 19443 Introduction To Risk-Based Thinking

Uploaded by

Roberto Eduardo HilalCopyright:

Available Formats

ISO 19443 Training

Introduction to Risk-Based Thinking (Products & Processes)

www.tuv-sud.com/nucleartraining

nucleartraining@tuvsud.com

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022

Motivation

▪ Get to know more about Risk-Based Thinking

▪ Learn how risk based thinking enables an organization to

optimize its results

▪ Learn about methods used like preventive controls,

risk analysis etc.

Source: TÜV SÜD

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 2

Introduction to Risk-Based Thinking

1 Introduction

2 Risk-Based Thinking

3 Methods of Risk-Based Thinking

4 Risk Analysis

5 Summary

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 3

Risk-Based Thinking in ISO 9001 / ISO 19443

Risk-Based

Thinking

Preventive action to Analysing any

eliminate potential nonconformity that

nonconformities does occur

Plan and implement

Taking actions to actions to address

prevent recurrence risks and

opportunities

Source: TÜV SÜD ET

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 4

Introduction to Risk-Based Thinking

1 Introduction

2 Risk-Based Thinking

3 Methods of Risk-Based Thinking

4 Risk Analysis

5 Summary

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 5

Risk-Based Thinking

▪ Risk-Based Thinking is generally included in ISO 9001

▪ It is essential for achieving an effective quality management system

▪ Risk-Based Thinking also has a high importance in the Nuclear Supply Chain, since safety regulations and considerations

in this area are especially high.

▪ Risk-Based Thinking can be applied to planning and implementing quality management system processes

▪ key purposes of a quality management system is to act as a preventive tool

▪ the organization shall plan actions to address risks

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 6

Risk-Based Thinking

Purpose of

Risk-Based

Thinking

Determine factors

that could cause the Make maximum use

QMS to deviate from Put in place of opportunities

planned results preventive controls

to minimize negative

effects

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 7

Introduction to Risk-Based Thinking

1 Introduction

2 Risk-Based Thinking

3 Methods of Risk-Based Thinking

4 Risk Analysis

5 Summary

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 8

Actions to address risks and opportunities

Issues (4.1) 6.1.1

Consider

Requirements (4.2)

When planning for the risks and opportunities

Quality Management 6.1.1

that need to be addressed to:

System, the • give assurance that the quality management system can

organization shall… Determine achieve its intended result(s);

• enhance desirable effects;

Maintain • prevent, or reduce, undesired effects;

and • achieve improvement.

Retain 6.1.2

• actions to address risks and opportunities

. Plan

• how to: integrate and implement actions into its QMS

related documented information.. processes evaluate the effectiveness of these actions.

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 9

Methods of Risk-Based Thinking

▪ Guidance on ISO 19443:

▪ Gives examples of good practice for actions to address risks and opportunities (6.1.1, 6.1.2)

Goal: Development of a documented risk management method, related to the achievement of applicable requirements,

including:

a. assignment of responsibilities for risk management,

b. definition of risk criteria

c. identification, assessment and communication of risks throughout product realization including supply chain,

d. identification, implementation and management of actions to mitigate risks that exceed the defined risk acceptance

criteria.

e. tolerability of risks remaining after implementation of actions

▪ different types of risk analysis and assessment methods are listed in CEI/ISO 31010

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 10

CEI/ISO 31010

Risk Management – Risk Assessment Techniques

▪ Guidance on selection and application of risk assessment techniques

Risk assessment techniques:

− Categorization of techniques according to their primary application in assessing risks

− Elicting views from stakeholders and experts

Risk Identification

− Identifying risk

− Determining sources, causes and drivers of risk

− Analysing existing controls

Risk Analysis

− Understanding consequences and likelihood

− Analysing dependencies and interations

− Providing measures of risk

− Evaluating the significance of risk

− Selecting between options Risk Evaluation

− Recording and reporting

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 11

Introduction to Risk-Based Thinking

1 Introduction

2 Risk-Based Thinking

3 Methods of Risk-Based Thinking

4 Risk Analysis

5 Summary

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 12

Risk Analysis

▪ Suppliers within the nuclear industry have to conduct a risk analysis. The organizations have to identify the

impact of failures or malfunctions of their products or activities with respect to nuclear safety. One particular

challenge can be the consideration of items and activities, which have been provided by external sub-suppliers.

▪ Determination of ITNS items and activities: base for the graded approach to the application of quality requirements.

▪ Annex B ISO/TR 4450:2020‐05 gives an example how to conduct a risk analysis

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 13

Teamwork: How to perform a risk analysis

(1) Identification of the dangerous situations

(2) Risk assessment

(3) Hierarchical organization of risks

(4) Mitigation of risks

(5) Record of risk management, data, steps

and results

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 14

Step 1: Identification of dangerous situations

▪ Chose one topic and identify possible dangerous situations concerning the topic

(1) Financial

(2) Contractual

(3) Purchasing

(4) Project Management

(5) Technical and Realization

(6) Human aspects

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 15

Step 1 – Exemplary Answers

TOPIC Examples

(1) Financial Unrealistic cost esimates

Variation of unfavourable exchange rate

Too low profitability of the project/order

TOPIC Examples

(2) Contractual Poor understanding of customer needs or specifications

Difficult to meet contractual obligations in the project or order

Poor analysis of the impact of changes

Poor analysis of requirements for quality assurance

Poor analysis of the impact of documentary constraints

Constraints imposed for unrealistic calendar or without margins

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 16

Step 1 – Exemplary Answers

TOPIC Examples

(3) Purchasing Unavailability of materials/components

Purchase price of materials/components incompatible with the budget

Poor transmission of contractual requirements to subcontractors

Suppliers are imposed or not permitted by the customer

Unfavourable political developments in the country of the subcontractor

Supply „single source“

Misunderstanding of the projects needs by subcontractors

Insufficient ability of the supplier as part of projects requirements or order

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 17

Step 1 – Exemplary Answers

TOPIC Examples

(4) Project Management Industrial organization unclear or inadequate

Restructuring, planned or expected

Organizational functions non-existent or inadequate

Inconsistent schedules of different stakeholders

Loss of knowledge and know-how

Safety culture of the company (incl. questioning attitude toward the

customer) not addressed

Method and communication tools not addressed

Insufficient or unavailable human or technical resources

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 18

Step 1 – Exemplary Answers

TOPIC Examples

(5) Technical and Realization Inadequate industrial base

Production logistics difficult to implement

The technologies considered are immature or poorly controlled

Principles or concepts proposed are not validated (by the owner, the

customer, the authorities, etc.)

Production process inappropriate against constraints on nuclear safety

False or incomplete input data

Not sufficient or inappropriate computing resources

Test facilities unsuitable or absent

Simulation models or tests not validated for condition of use

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 19

Step 1 – Exemplary Answers

TOPIC Examples

(6) Human aspects Cultural differences which may cause misunderstandings

Poor control of the contractual language

Poor communication within the company (needs, data, information)

Trainings in safety culture insufficient or absent

Training time required for the project or order is too large relative to the

constraints of schedule completion

Poor management of skills and/or qualifications

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 20

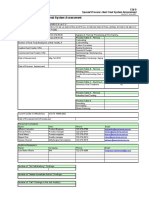

Step 2 – Assessment of the risk occurrence

Assessment

Occurrence Qualitative Quantitative

Level (P=likelihood)

1 Low P < 20%

2 Medium 20% ≤ P < 40%

3 High 40% ≤ P < 60%

4 Critical P > 60%

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 21

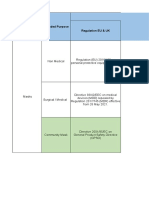

Step 2 – Assessment of the severity of the impact of risks

Impact on

Severity Safety Conformity Performance Delivery Planning (D) Costs

Level (C)

1 Low Low D < 5% C < 2%

2 Medium Medium 5% ≤ D < 10% 2% ≤ C < 5%

unacceptable

3 High High 10% ≤ D < 20% 5% ≤ C < 10%

4 Critical Critical D > 20% C > 10%

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 22

Step 3 – Hirarchical organization of risks

Severity Level

Occurrence 1 2 3 4

Level

1

2

3

4

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 23

Step 4 – Mitigation of risks

The risks have not to be mitigated but should be kept in mind.

The risks should be examined again for reduction action (by

acting on the occurrence or severity) = moving from orange to

yellow or placed under observation in case of impossibility of

reduction

The risks should be addressed and a solution should be found

to eliminate them = moving from red to orange

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 24

Step 5 – Record of risk management data, steps and results

Risk Initial risk assessment Mitigation action Final risk assessment

identified Occurrence Severity Criticality What Who When Occurrence Severity Criticality

#1: …

#2: …

Source: ISO/TR 4450

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 25

Introduction to Risk-Based Thinking

1 Introduction

2 Risk-Based Thinking

3 Methods of Risk-Based Thinking

4 Risk Analysis

5 Summary

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 26

Summary

▪ Risk-Based Thinking is generally included in the ISO 9001: it enables an organization to determine the factors that could

cause its processes and results to deviate. Preventive controls have to be installed to eliminate potential nonconformities,

analyzing any nonconformity that occurs, and taking action to prevent reoccurrence.

▪ Suppliers within the nuclear industry have to conduct a risk analysis. The organizations have to identify the

impact of failures or malfunctions of their products or activities with respect to nuclear safety. One particular

challenge can be the consideration of items and activities, which have been provided by external sub-suppliers.

▪ As part of the ITNS determination, this risk analysis has to demonstrate whether the item or activity is important

to nuclear safety or not (ITNS or non-ITNS).

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 27

Copyright

‘‘ The contents of the training materials are protected by copyright.

TÜV SÜD Energietechnik GmbH Baden-Württemberg reserves all rights resulting

thereof, especially with regard to reprinting, publication by photomechanical

reproduction or other means, and storage in data processing systems (in whole

or in part).

This document and any information it contains shall not be used for any other

purpose than the one for which they were provided.

’’

Stock photos and ClipArt's: Licensed by TÜV SÜD.com Image Database.

TÜV SÜD Academy UK | ISO 19443 Training 21-23/06/2022 28

You might also like

- 00 ISO 19443 Welcome Introduction Organisation - HandoutDocument17 pages00 ISO 19443 Welcome Introduction Organisation - HandoutRoberto Eduardo HilalNo ratings yet

- 01 ISO 19443 Motivation and Development HistoryDocument20 pages01 ISO 19443 Motivation and Development HistoryRoberto Eduardo HilalNo ratings yet

- 02 ISO 19443 Fundamentals HandoutDocument52 pages02 ISO 19443 Fundamentals HandoutRoberto Eduardo HilalNo ratings yet

- 06 ISO 19443 FMEA Practical Application HandoutDocument45 pages06 ISO 19443 FMEA Practical Application HandoutRoberto Eduardo Hilal100% (1)

- 03 ISO 19443 Structure and Requirements - HandoutDocument92 pages03 ISO 19443 Structure and Requirements - HandoutRoberto Eduardo HilalNo ratings yet

- Polyolefin Monofilaments: Standard Specification ForDocument9 pagesPolyolefin Monofilaments: Standard Specification Forgoodcharacter1No ratings yet

- Environmental Management Study MaterialDocument175 pagesEnvironmental Management Study MaterialTalha NaeemNo ratings yet

- Pas 00110-2010Document60 pagesPas 00110-2010Ivan TtofimchukNo ratings yet

- ISO 9001 2015 QMS Lead Auditor Training Course 2Document2 pagesISO 9001 2015 QMS Lead Auditor Training Course 2mohdshamboulNo ratings yet

- Customer Complaints Management Drive Loyality and Mitigate Risk Across Your OrganizationDocument10 pagesCustomer Complaints Management Drive Loyality and Mitigate Risk Across Your Organizationtolga aktasNo ratings yet

- WANO Guidelines Traits of A Healthy Nuclear Safety Culture Addendum GL 2013-01-1Document52 pagesWANO Guidelines Traits of A Healthy Nuclear Safety Culture Addendum GL 2013-01-1M. Ammad ul HassanNo ratings yet

- 196-Material Supplier Pre-Qualification ChecklistDocument70 pages196-Material Supplier Pre-Qualification ChecklistSyed Mohammed ZakariaNo ratings yet

- Q2-Intro To Internal AuditingDocument6 pagesQ2-Intro To Internal AuditingSantos Gigantoca Jr.No ratings yet

- Preview - ISO 10001 2018Document7 pagesPreview - ISO 10001 2018Mauricio CardenasNo ratings yet

- IAEA Nuclear Security Series 7 - Nuclear Security CultureDocument48 pagesIAEA Nuclear Security Series 7 - Nuclear Security Culturemadalina_troneaNo ratings yet

- Consolidated ISO IEC Part-1 (E) 2022Document163 pagesConsolidated ISO IEC Part-1 (E) 2022Mohammed BndawdawNo ratings yet

- Application of The Management System For NF - Draft Safety Guide DS349, IAEA, Vienna (2008)Document147 pagesApplication of The Management System For NF - Draft Safety Guide DS349, IAEA, Vienna (2008)HopeNo ratings yet

- Role of Wisdom in Decision Making Styles Among ManagersDocument6 pagesRole of Wisdom in Decision Making Styles Among ManagersDr. Muhammad Azizur Rahman RamliNo ratings yet

- NEBOSH IGC1 Past Exam Paper September 2012 PDFDocument3 pagesNEBOSH IGC1 Past Exam Paper September 2012 PDFAmeen UllahNo ratings yet

- Implementing Integrated Management Systems Using A Risk Analysis Based ApproachDocument10 pagesImplementing Integrated Management Systems Using A Risk Analysis Based ApproachLuisa Fernanda Quiceno GiraldoNo ratings yet

- Validation ServicesDocument3 pagesValidation ServicesDeepakNo ratings yet

- IAFID1QMS EMS Codes20140610 PDFDocument8 pagesIAFID1QMS EMS Codes20140610 PDFJohn RajeshNo ratings yet

- CQI-9 Heat Treat System Assessment - Bomba Gen IVDocument19 pagesCQI-9 Heat Treat System Assessment - Bomba Gen IVANONIMONo ratings yet

- Work Process and ProceduresDocument6 pagesWork Process and ProceduresDiverfied CorporationNo ratings yet

- Kurt Lewin's Process Model For Organizational Change: The Role of Leadership and Employee Involvement: A Critical ReviewDocument6 pagesKurt Lewin's Process Model For Organizational Change: The Role of Leadership and Employee Involvement: A Critical ReviewJiana NasirNo ratings yet

- SOP004 General Laboratory HousekeepingDocument16 pagesSOP004 General Laboratory Housekeepingratna puspita sariNo ratings yet

- Bouchard 2014Document6 pagesBouchard 2014Linda Alejandra PerezNo ratings yet

- IPIECA - IOGP - Controlled In-Situ Burning of Spilled Oil - 2016Document52 pagesIPIECA - IOGP - Controlled In-Situ Burning of Spilled Oil - 2016seawolf50No ratings yet

- Quality Manual SASB - APR - 2019 FinalDocument34 pagesQuality Manual SASB - APR - 2019 FinalVasudevan GovindarajNo ratings yet

- Ghg-Assurance-Statement-2020 ANZDocument3 pagesGhg-Assurance-Statement-2020 ANZKevin MuliaNo ratings yet

- Safety Culture TransformationDocument17 pagesSafety Culture TransformationLuqman MuhammadNo ratings yet

- Manage Operational PlanDocument11 pagesManage Operational Planneha100% (1)

- Iso 14731 2019Document18 pagesIso 14731 2019djalalhemNo ratings yet

- Office 365 - ISO 22301 - 2012 - Assessment Report - 01.11.2019Document20 pagesOffice 365 - ISO 22301 - 2012 - Assessment Report - 01.11.2019Steve CastroNo ratings yet

- Iso 45001Document16 pagesIso 45001parthaNo ratings yet

- Awareness Session On Environmental Management System (EMS) Based On ISO 14001:2015 RequirementsDocument23 pagesAwareness Session On Environmental Management System (EMS) Based On ISO 14001:2015 RequirementsRahul SharmaNo ratings yet

- FAD 4.0 - IsO-IEC 17065 GAC Application DocumentDocument44 pagesFAD 4.0 - IsO-IEC 17065 GAC Application Documentsadbad6No ratings yet

- BS Iso Iec 20000-1-2018Document42 pagesBS Iso Iec 20000-1-2018shailendraNo ratings yet

- IOSH Managing Safely v5 - Detailed ChangesDocument1 pageIOSH Managing Safely v5 - Detailed ChangesMunavir kNo ratings yet

- ISO 22000 - 2018 A Brief OverviewDocument28 pagesISO 22000 - 2018 A Brief OverviewGenNo ratings yet

- RACS SOP43 Rev02 Product Certification Scheme HALAL ProductsDocument10 pagesRACS SOP43 Rev02 Product Certification Scheme HALAL ProductsrahmathNo ratings yet

- HSS COSH Day 3 - Delegate's HandoutDocument118 pagesHSS COSH Day 3 - Delegate's HandoutNicole SalemNo ratings yet

- CertificationDocument10 pagesCertificationdiaa sinanNo ratings yet

- Iaf MD 17:2019Document20 pagesIaf MD 17:2019My DocumentNo ratings yet

- TUV SUD Webinar ISO 19443 PresentationDocument23 pagesTUV SUD Webinar ISO 19443 PresentationIqfal ZulhendriNo ratings yet

- CDC UP Requirements Traceability Matrix TemplateDocument2 pagesCDC UP Requirements Traceability Matrix TemplateFelicia GhicaNo ratings yet

- ISO 45001 2018 Amd 1 2024 (En)Document6 pagesISO 45001 2018 Amd 1 2024 (En)cmorabitoNo ratings yet

- SGS MIN TP2003 10 Coal Quality Management PDFDocument4 pagesSGS MIN TP2003 10 Coal Quality Management PDFDavid SimanungkalitNo ratings yet

- Nucleus E ProfileDocument4 pagesNucleus E ProfileRajesh ThiyagarajanNo ratings yet

- Iso 22003 1 and Iso 22003 2 Presentation GeneralDocument25 pagesIso 22003 1 and Iso 22003 2 Presentation Generaldenisenko.marina2017No ratings yet

- 002 Icei2021 w1c HuwylerDocument27 pages002 Icei2021 w1c HuwylerRUDINo ratings yet

- Iso TS 16949 - 6 May 2010 - AdexDocument29 pagesIso TS 16949 - 6 May 2010 - Adexsudar1477No ratings yet

- PPE Testing and Certifications V 1.2Document50 pagesPPE Testing and Certifications V 1.2Karthi ThiyagarajanNo ratings yet

- Broker3 Guideline ENDocument40 pagesBroker3 Guideline ENAnonymous XfIF3HdNo ratings yet

- Iso Iec 17021 2011 OverviewDocument27 pagesIso Iec 17021 2011 OverviewAlex Ramadhan SabananyoNo ratings yet

- Quality Manual: Table of ContentsDocument5 pagesQuality Manual: Table of Contentsanon_217857558No ratings yet

- MOTIVATIONDocument25 pagesMOTIVATIONArabelle GONo ratings yet

- ISO 9001:2015 Quick Reference: 4. Context of The OrganizationDocument2 pagesISO 9001:2015 Quick Reference: 4. Context of The Organizationhasanali unibrushNo ratings yet

- ISO 31000 and Integrated Risk ManagementDocument36 pagesISO 31000 and Integrated Risk Managementfrakuk91% (11)

- Risk Management TrainingDocument23 pagesRisk Management TrainingDANY SUJINo ratings yet

- New Jubilee Internship ReportDocument92 pagesNew Jubilee Internship ReportYasir Ayaz100% (11)

- Business Continuity Frameworks: Presented by You ExecDocument32 pagesBusiness Continuity Frameworks: Presented by You ExecMohannadNo ratings yet

- Itto SpreadsheetDocument19 pagesItto Spreadsheetrbbaker67% (3)

- PraxisIFM Group LTDDocument51 pagesPraxisIFM Group LTDAmer MohdNo ratings yet

- General Guide For CranesDocument17 pagesGeneral Guide For CranesHewa Wedage Niroshan AnuruddhaNo ratings yet

- Inspection Personnel ExamDocument9 pagesInspection Personnel ExamRafael_YevgenyNo ratings yet

- THE EFFECT OF RISK MANAGEMENT ON FINANCIAL PERFORMANCE OF INSURANCE COMPANIES IN KENYA Chapter 1Document20 pagesTHE EFFECT OF RISK MANAGEMENT ON FINANCIAL PERFORMANCE OF INSURANCE COMPANIES IN KENYA Chapter 1Dennis NziokiNo ratings yet

- Iii Semester, Insurance and Risk Management ModuleDocument10 pagesIii Semester, Insurance and Risk Management ModuleSofi KhanNo ratings yet

- Monitoring and Evaluation Final ReportDocument41 pagesMonitoring and Evaluation Final ReportjekulNo ratings yet

- A Comparative Review of Risk Management Standards - Tzvi Raz & David Hillson - Risk Management Journal - 2005 PDFDocument14 pagesA Comparative Review of Risk Management Standards - Tzvi Raz & David Hillson - Risk Management Journal - 2005 PDFHubert BonamisNo ratings yet

- PMI - Risk Management Professional (PMI-RMP) - 1 PDFDocument4 pagesPMI - Risk Management Professional (PMI-RMP) - 1 PDFefeNo ratings yet

- Risk Assessment and Management in Chemical Industry in Vietnam - SINHDocument24 pagesRisk Assessment and Management in Chemical Industry in Vietnam - SINHMinh Hoàng Nguyễn HữuNo ratings yet

- Corporate Governance SlideDocument11 pagesCorporate Governance SlideRajkishor YadavNo ratings yet

- Issues of Managing ICT Projects in Construction EnvironmentDocument10 pagesIssues of Managing ICT Projects in Construction EnvironmentNagenthara PoobathyNo ratings yet

- A Methodology For Project Risk Analysis Using Bayesian Belief Networks Within A Monte Carlo Simulation EnvironmentDocument243 pagesA Methodology For Project Risk Analysis Using Bayesian Belief Networks Within A Monte Carlo Simulation EnvironmentJustin LeeNo ratings yet

- The Impact of Information Technology On Internal Auditing PDFDocument17 pagesThe Impact of Information Technology On Internal Auditing PDFIndra Pramana100% (2)

- Job Safety Analysis Peondasi BangunanDocument14 pagesJob Safety Analysis Peondasi BangunanWahyu FebriantoNo ratings yet

- The Senior Manager's Role in SMSDocument15 pagesThe Senior Manager's Role in SMSEdgar ChávezNo ratings yet

- Further and Higher Education Building Design GuideDocument48 pagesFurther and Higher Education Building Design GuideSyamsul HadiNo ratings yet

- What Is A Key Risk Indicator (KRI) and Why Is It ImportantDocument4 pagesWhat Is A Key Risk Indicator (KRI) and Why Is It ImportantJaveed A. KhanNo ratings yet

- 7.13 - Defradar - ISO27k GDPR Mapping Release - v2Document12 pages7.13 - Defradar - ISO27k GDPR Mapping Release - v2Jakobović DomagojNo ratings yet

- FNCE90046 Subject Guide Sem 2 2020-1Document9 pagesFNCE90046 Subject Guide Sem 2 2020-1Sana BajpaiNo ratings yet

- Due Diligence: ChecklistDocument16 pagesDue Diligence: ChecklistRichard L. Dunnam100% (2)

- Iso - Iec A1 PDFDocument12 pagesIso - Iec A1 PDFRushikaNo ratings yet

- English Draft GSR 999 (E) - Upgradation of SCH M GMP PDFDocument166 pagesEnglish Draft GSR 999 (E) - Upgradation of SCH M GMP PDFMv Patel100% (4)

- Iso 12849-2013Document268 pagesIso 12849-2013Juan Diego Garcia Esquen67% (3)

- Shaking Tables Around The WorldDocument15 pagesShaking Tables Around The Worlddjani_ip100% (1)

- Earthquake Engineering Course OutlineDocument2 pagesEarthquake Engineering Course OutlineMISKIR TADESSENo ratings yet

- Manage Program DeliveryDocument42 pagesManage Program DeliveryNata Lia80% (5)

- WPS HQ Construction Project Audit ReportDocument56 pagesWPS HQ Construction Project Audit ReportTessa VanderhartNo ratings yet