Professional Documents

Culture Documents

8L (G.V) Canister Vessel - R01 - For Vendor

8L (G.V) Canister Vessel - R01 - For Vendor

Uploaded by

Chethan Nagaraju KumbarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8L (G.V) Canister Vessel - R01 - For Vendor

8L (G.V) Canister Vessel - R01 - For Vendor

Uploaded by

Chethan Nagaraju KumbarCopyright:

Available Formats

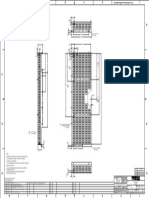

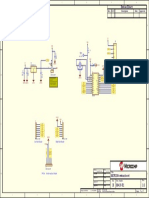

1 2 3 4 5 6 7

Changes Via CAD Only DESIGN DATA

Equipment Name 8L (G.V) Canister Vessel

Inspected By Self inspected

H/D Ratio ~ 1.3:1

Ø7.5

Ø6.5 Vessel Working Volume 6L

A Ø5 Chamber Vessel Jacket A

OD 119 Geometric Volume 8L NA

Design Pressure -1 to 1.5 bar(g) NA

NTH02 Design Temperature 0°C to 150°C NA

NTH03 NTH01 Ø8 Ø7.5 Hydro Test Presure 2.0 bar(g) NA

Ø6.5

Joint Efficiency 0.85 (1 For Dish & Shell Joint)

Ø5

Dye Penetration Test For All Fillet Weld

Product Contact Area NON-Product Contact Area

Ø12 Surface Finish (Ra)

1t ≤0.6µm ≤1.2µm

Ø8 Surface Roughness Internal: Electropolished External: Matt Finish, MP

Insulation NA

Elastomer EPDM

Lifting Arrangement Type Handles

MATERIAL LIST

Area Material

B B

Product Contact Parts SS316L(1.4404)

Non-Product Contact Parts SS304

OD 8 All Nozzles Parts SA 182 F Gr 316L(1.4404)

01

1 thk

W.V.L W.V.L 01 NOZZLE SCHEDULE

TAG NO SERVICE SIZE TYPE OF CONNECTOR

01 NTH01 Dip Tube port ID 15.75 Tri Clamp(OD25)

~ 359

NTH02 Hose Nipple Port -01 ID 5 Hose connector (OD 8)

Vessel OD 219.1 NTH03 RTD ID 10 Pipe with Blind End(OD 12)

2.77 t NTH04 Hose Nipple Port -02 ID 5 Hose connector (OD 8)

NTH05 Hose Nipple Port -03 ID 5 Hose connector (OD 8)

Vessel OD 219.1

277

156

307

C C

This drawing is the property of VMARS Biopharma Pvt. Ltd. Any replica in design or transmitted or passed to other without permission by VMARS Biopharma Pvt. Ltd is prohibited.

01

30

T.L T.L

01

'A'

55

120 120

SECTION Y-Y Bottom Dish

FRONT VIEW SECTION X-X

D D

Drain Hole

(invert Position)

270°

Ø7.5

Ø6.5

Y

Ø5

Bottom Support

45

Detail - A

4t

Ø8

NTH05 01

NTH04

E E

180° 0°

NTH01 150

X X

NTH03

GENERAL NOTS:-

1. All dimensions are in mm unless otherwise specifed. NTH02

2. All gasket & O-Rings shall be of single piece construction only. CONTROLLED COPY

3. All fillet welds shall be DP tested.

4. All butt welds shall be full penetration weld joints.

5.Shell flange & top lid should be fabricated from one piece only. 01 30 SEP 2022 --- GKV MM SM

45°

6.All O Rings & Gaskets are USP Class VI or FDA Complained.

7.Root runs of butt welds shall be DP tested. 00 18 OCT 2022 --- GKV MM SM

8.All internal weld joints, fillets & sharp corners shall be ground smooth.

9.There shall be no radial tool marks in o-ring grooves or other sealing surfaces. Rev.No DATE --- DRAWN BY CHECKED BY APPROVED BY

18

F F

10.All weld joints shall be thoroughly wire brushed & cleaned to remove loose scales, slags,

01 TITLE 8L (G.V) Canister Vessel

oil, grease, & foreign matters

Y

22

11.All weld metal shall have equal or better mechanical properties than the parent metal. 90° PROJECTION

12.All electrodes & fluxes should be selected as per part SFA-5.9 ASME Sec. IIC . CLIENT NAME ***

Qty :- 04Nos

13.Jacket to shell weld joint shall not foul with any circumferential shell joint (If Applicable).

DRAWING NO TBD

14.All surfaces are free from cavities,burrs,chattering,black spots waviness etc.

15.All weld joints shall be located in such a way that they are clear off

PROJECT NO Enq SHEET: 1 of 1 REV NO : 01

nozzles/cleats/pads/lifting lugs/brackets etc.

1 2 3 4 5 6 7

You might also like

- Flue Gas Outlet DamperDocument1 pageFlue Gas Outlet Damperprth valveNo ratings yet

- Report On Issues Observed in Waterproofing Apllication at B6 L07 Cleaning Room and Disable BathroomDocument4 pagesReport On Issues Observed in Waterproofing Apllication at B6 L07 Cleaning Room and Disable BathroomYasith AbeywickramaNo ratings yet

- Treaties MapDocument1 pageTreaties MapGateway Education TeamNo ratings yet

- E D F A A: Propiedad PrivadaDocument1 pageE D F A A: Propiedad PrivadaJenica Zarina Calderon HolgadoNo ratings yet

- Fabio Lima: Standard TuningDocument3 pagesFabio Lima: Standard TuningKaina PortoNo ratings yet

- Flowmeter With ReedswitchDocument1 pageFlowmeter With ReedswitchKaye TrishaNo ratings yet

- 0G29170ST03Document1 page0G29170ST03Alejandro NietoNo ratings yet

- GA of LV Cabinet PDFDocument1 pageGA of LV Cabinet PDFSoporte ANDET SACNo ratings yet

- Black Sabbath - N.I.BDocument6 pagesBlack Sabbath - N.I.Bzika77100% (2)

- TRAYDocument1 pageTRAYMarko PetrovicNo ratings yet

- Tarrega MarietaDocument3 pagesTarrega Marietawooki97No ratings yet

- Hurry X Mas Bass TabDocument5 pagesHurry X Mas Bass TabSean HardyNo ratings yet

- Z 1081053 - GPD Dimensions - Customer Drawing PDFDocument1 pageZ 1081053 - GPD Dimensions - Customer Drawing PDFkospi46No ratings yet

- 212 189th ST Sunny Isles FL - FEMA FULL FIRMDocument1 page212 189th ST Sunny Isles FL - FEMA FULL FIRMcivil.jdriveroincNo ratings yet

- InsensatezDocument2 pagesInsensatezmatiaszloto4118No ratings yet

- Historia de Un Amor: Arranged by Thu LeDocument3 pagesHistoria de Un Amor: Arranged by Thu LeTuan Pham100% (1)

- Lake 701361 Site PlanDocument1 pageLake 701361 Site PlanadsourceNo ratings yet

- Joquebede - Israel Santos - Contrabaixo (Tablatura & Partitura)Document3 pagesJoquebede - Israel Santos - Contrabaixo (Tablatura & Partitura)JONATHAS RICARDONo ratings yet

- Gigabyte Gallery: GV-N970G1 GAMING-4GD GV-N970G1 GAMING-4GD GV-N970G1 GAMING-4GDDocument34 pagesGigabyte Gallery: GV-N970G1 GAMING-4GD GV-N970G1 GAMING-4GD GV-N970G1 GAMING-4GDRafael SenaNo ratings yet

- Romane - DanubeDocument3 pagesRomane - Danubejoaquin.ca.garciaNo ratings yet

- Bluest Blues Alveen LeeDocument9 pagesBluest Blues Alveen LeePhilippeNo ratings yet

- Typical Car Parking - Elevation-Option-1 6Document1 pageTypical Car Parking - Elevation-Option-1 6GreenNo ratings yet

- Typical Car Parking - Elevation-Option-1 6Document1 pageTypical Car Parking - Elevation-Option-1 6GreenNo ratings yet

- Are You Gonna Be My Girl: Standard TuningDocument3 pagesAre You Gonna Be My Girl: Standard TuningArtem SemeshkoNo ratings yet

- Sayonara BassDocument2 pagesSayonara BassChatphon ManeepongNo ratings yet

- 1-Bodega Fabrica Dulcesita Panela - Oiba - 14-12-20 (1) - ModeloDocument1 page1-Bodega Fabrica Dulcesita Panela - Oiba - 14-12-20 (1) - ModeloJuan SebastianNo ratings yet

- Independent Hotel Show 2018 - Floor Plan 13.03.2018 PDFDocument1 pageIndependent Hotel Show 2018 - Floor Plan 13.03.2018 PDFDiana MihaelaNo ratings yet

- Gigabyte GTX970 - GV-N970G1 GAMING-4GD PDF1 - 230309 - 104705 PDFDocument35 pagesGigabyte GTX970 - GV-N970G1 GAMING-4GD PDF1 - 230309 - 104705 PDFEdersonCassianoNo ratings yet

- AFS..Gigabyte GTX970 - GV-N970G1 GAMING-4GD PDFDocument34 pagesAFS..Gigabyte GTX970 - GV-N970G1 GAMING-4GD PDFЕвгений КуценкоNo ratings yet

- Stand byDocument5 pagesStand byrussettNo ratings yet

- Grinding Mill Drawings PDFDocument1 pageGrinding Mill Drawings PDFBender Doblador Rodriguez100% (1)

- Tea1751 150W Schematic 05022008Document1 pageTea1751 150W Schematic 05022008pekiilicNo ratings yet

- Archi Plan Sample DoorsDocument1 pageArchi Plan Sample DoorsKatPalaganasNo ratings yet

- Slow Blues: (A.R Power Trio)Document2 pagesSlow Blues: (A.R Power Trio)pacomoyaguitarraNo ratings yet

- STP, GWT, R.pompa-E2-StpDocument1 pageSTP, GWT, R.pompa-E2-StpilhamNo ratings yet

- M3M CornerWalkDocument40 pagesM3M CornerWalkNidhi YadavNo ratings yet

- Lifecycle: M Iti G at in G Ri SKDocument1 pageLifecycle: M Iti G at in G Ri SK757rustamNo ratings yet

- B N Đ Phân Lô Thăng Long ResidenceDocument1 pageB N Đ Phân Lô Thăng Long ResidenceDũng XuânNo ratings yet

- As Built Plan Final-A3Document1 pageAs Built Plan Final-A3anonymousupldr666No ratings yet

- 3.plano de Redes de Agua PotableDocument1 page3.plano de Redes de Agua Potablealbertofer123No ratings yet

- Report On Substandard Floor Tiling Work in B6 Male BathroomDocument3 pagesReport On Substandard Floor Tiling Work in B6 Male BathroomYasith AbeywickramaNo ratings yet

- Diagrama Eletrico Hawk 405Document1 pageDiagrama Eletrico Hawk 405eduardocasarim1604No ratings yet

- Badge Badge: Robben Ford Solo Robben Ford SoloDocument2 pagesBadge Badge: Robben Ford Solo Robben Ford SoloCarlo Romano GrillandiniNo ratings yet

- The Sound - Lead GuitarDocument2 pagesThe Sound - Lead GuitarAnonymous D7fUKbTGNo ratings yet

- Dragonball Z - Rock The DragonDocument2 pagesDragonball Z - Rock The Dragonignacio caballeroNo ratings yet

- Parts List Item No. RPN Description QTY NameDocument1 pageParts List Item No. RPN Description QTY Namearthur9mozoNo ratings yet

- Romane - Fill in GuitarDocument3 pagesRomane - Fill in Guitarjoaquin.ca.garciaNo ratings yet

- Astro Chart2Document1 pageAstro Chart2bal1976No ratings yet

- DD-N-00426-3-01-DDCMS-C-15-STRU-312-2-P-01 - First Floor - Slab Layout & Details (Sh-2) - RA-312-2Document1 pageDD-N-00426-3-01-DDCMS-C-15-STRU-312-2-P-01 - First Floor - Slab Layout & Details (Sh-2) - RA-312-2SivaAgathamudiNo ratings yet

- R 1 - 420x594 3ex Negru PDFDocument1 pageR 1 - 420x594 3ex Negru PDFconstantin ciobanuNo ratings yet

- Thats's My DesireDocument1 pageThats's My Desiresaxly gordNo ratings yet

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

- PDF CropDocument1 pagePDF CropAditiNo ratings yet

- C-Tech Basin Agartaa STPDocument1 pageC-Tech Basin Agartaa STPSwapan Kumar BoseNo ratings yet

- Heat Exchange Piston ExhaustDocument1 pageHeat Exchange Piston ExhaustCốGắngNàoNo ratings yet

- Tổng hợp bản vẽ TKNMDocument27 pagesTổng hợp bản vẽ TKNMYến Nhi LêNo ratings yet

- Ruler 30cm Scale2 A4 Transparent PDFDocument1 pageRuler 30cm Scale2 A4 Transparent PDFKish FauneNo ratings yet

- Rencana Fireprotection Lantai 1Document1 pageRencana Fireprotection Lantai 1R Rayhan ZahriNo ratings yet

- Pomiso: PIU202 PIX102Document1 pagePomiso: PIU202 PIX102beivee123No ratings yet

- Digital Inclinometer - 2022-15-FM1Document1 pageDigital Inclinometer - 2022-15-FM1Chethan Nagaraju KumbarNo ratings yet

- Mesuring Tape HE - mt.001Document2 pagesMesuring Tape HE - mt.001Chethan Nagaraju KumbarNo ratings yet

- DTF 11-21 001 002Document1 pageDTF 11-21 001 002Chethan Nagaraju KumbarNo ratings yet

- MTCs 7Document1 pageMTCs 7Chethan Nagaraju KumbarNo ratings yet

- MTCs 4Document1 pageMTCs 4Chethan Nagaraju KumbarNo ratings yet

- MTCs 8Document1 pageMTCs 8Chethan Nagaraju KumbarNo ratings yet

- MTCs 6Document1 pageMTCs 6Chethan Nagaraju KumbarNo ratings yet

- 2.APQP Timing Plan - R01Document11 pages2.APQP Timing Plan - R01Chethan Nagaraju KumbarNo ratings yet

- DTF 11-21 001 003Document2 pagesDTF 11-21 001 003Chethan Nagaraju KumbarNo ratings yet

- Hydro Test (Air Heat Exchanger)Document1 pageHydro Test (Air Heat Exchanger)Chethan Nagaraju KumbarNo ratings yet

- MTCs 1Document1 pageMTCs 1Chethan Nagaraju KumbarNo ratings yet

- Goa Trip PlanDocument15 pagesGoa Trip PlanChethan Nagaraju KumbarNo ratings yet

- Material Test Report: Cse. Chiang Sung Enterprise Co., LTDDocument3 pagesMaterial Test Report: Cse. Chiang Sung Enterprise Co., LTDChethan Nagaraju KumbarNo ratings yet

- Material Heat Chart - Air Heat ExchangerDocument1 pageMaterial Heat Chart - Air Heat ExchangerChethan Nagaraju KumbarNo ratings yet

- Quality Gurus - Kaoru IshikawaDocument1 pageQuality Gurus - Kaoru IshikawaChethan Nagaraju KumbarNo ratings yet

- All Connectors Status 13.10.2022Document6 pagesAll Connectors Status 13.10.2022Chethan Nagaraju KumbarNo ratings yet

- Quality Guru William Edwards DemingDocument1 pageQuality Guru William Edwards DemingChethan Nagaraju KumbarNo ratings yet

- Team FeasibilityDocument3 pagesTeam FeasibilityChethan Nagaraju KumbarNo ratings yet

- Dalmia 5S Standardization ManualDocument65 pagesDalmia 5S Standardization ManualChethan Nagaraju KumbarNo ratings yet

- Quality Gurus Philip B. CrosbyDocument1 pageQuality Gurus Philip B. CrosbyChethan Nagaraju KumbarNo ratings yet

- 5S Audit Score Average For 2020 To Bala To Update in SoftwareDocument4 pages5S Audit Score Average For 2020 To Bala To Update in SoftwareChethan Nagaraju KumbarNo ratings yet

- Mvrla 5s Ppt-SustenanceDocument185 pagesMvrla 5s Ppt-SustenanceChethan Nagaraju KumbarNo ratings yet

- 5S Over ViewDocument108 pages5S Over ViewChethan Nagaraju KumbarNo ratings yet

- Session 84 - 5S Common SenseDocument34 pagesSession 84 - 5S Common SenseChethan Nagaraju KumbarNo ratings yet

- 5s PPT NewDocument39 pages5s PPT NewChethan Nagaraju KumbarNo ratings yet

- Sartorius Stedim India: Bioprocess Solutions 5S JourneyDocument53 pagesSartorius Stedim India: Bioprocess Solutions 5S JourneyChethan Nagaraju KumbarNo ratings yet

- ArkaprakashaDocument18 pagesArkaprakashaChethan Nagaraju KumbarNo ratings yet

- Dokumen - Tips - Quality Function Deployment and Lean Six Sigma Applications in Public HealthDocument24 pagesDokumen - Tips - Quality Function Deployment and Lean Six Sigma Applications in Public HealthChethan Nagaraju KumbarNo ratings yet

- 003 - ABK AOTS 5S LA Part - 3 June 2018Document49 pages003 - ABK AOTS 5S LA Part - 3 June 2018Chethan Nagaraju KumbarNo ratings yet

- Iso Astm 52903-2-2020Document14 pagesIso Astm 52903-2-2020Chethan Nagaraju KumbarNo ratings yet

- Client Information Ethel Stamer 01Document27 pagesClient Information Ethel Stamer 01ethelNo ratings yet

- 01-Article - Per. STR. Gedung 5 LantaiDocument8 pages01-Article - Per. STR. Gedung 5 Lantaimuh khalifardiNo ratings yet

- Procurement Schedule210719Document5 pagesProcurement Schedule210719Anonymous Xb3zHioNo ratings yet

- VECTA001 - Tank Selection Guide PDFDocument28 pagesVECTA001 - Tank Selection Guide PDFYogi Yugan100% (1)

- 10 1 3 RMDDocument5 pages10 1 3 RMDRay GalfianNo ratings yet

- Mud Gas Separator DesignDocument10 pagesMud Gas Separator Designsaa6383No ratings yet

- VersionDocument38 pagesVersionMukesh SharmaNo ratings yet

- Dynamic Analysis of A Monorail Beam For An Overhead Crane: February 2015Document10 pagesDynamic Analysis of A Monorail Beam For An Overhead Crane: February 2015Sudhanshu PalNo ratings yet

- L9 - Construction Methodology - 1Document20 pagesL9 - Construction Methodology - 1J. Kumar Infraprojects LtdNo ratings yet

- Viking Conveyor REMA Tip TopDocument5 pagesViking Conveyor REMA Tip TopLutfi IsmailNo ratings yet

- Progress ReportDocument3 pagesProgress Reportapi-610888061No ratings yet

- Analysis and Design of Multi Storeyed Building Using Autodesk Robot Structural Analysis Professional 2016 2Document7 pagesAnalysis and Design of Multi Storeyed Building Using Autodesk Robot Structural Analysis Professional 2016 2AHSANNo ratings yet

- Standard Specification For WBM & Asphalt RoadsDocument26 pagesStandard Specification For WBM & Asphalt RoadsSachin Pawar100% (3)

- The Fabulous 22 of 1992Document4 pagesThe Fabulous 22 of 1992David PreeceNo ratings yet

- Upgrading of Falaj Al Qabail Roundabout TENDER NO. 51/2012Document61 pagesUpgrading of Falaj Al Qabail Roundabout TENDER NO. 51/2012muneerpmhNo ratings yet

- VK41../VK81..SERIES: Gas Controls For Combined Valve and Ignition SystemDocument34 pagesVK41../VK81..SERIES: Gas Controls For Combined Valve and Ignition SystemThaynar BarbosaNo ratings yet

- Schedule For Ordinary Hazard OccupanciesDocument1 pageSchedule For Ordinary Hazard OccupanciesMostafa El-BalashonyNo ratings yet

- GRP Pre Insulated PipesDocument2 pagesGRP Pre Insulated PipesSubin AnandanNo ratings yet

- LECTURE 6 - Truss Bridge Details and ConnectionsDocument49 pagesLECTURE 6 - Truss Bridge Details and ConnectionsMohamed NourNo ratings yet

- 14 Material and Heat Treatment of Jigs &Document18 pages14 Material and Heat Treatment of Jigs &GV RagunathanNo ratings yet

- Boiler Drum Erection ProcedureDocument6 pagesBoiler Drum Erection Procedureer_sanjaypatel100% (1)

- Unit Storage and Distribution Reservoirs: StructureDocument20 pagesUnit Storage and Distribution Reservoirs: StructurewapcosrajkotNo ratings yet

- Prestressed Wall ConcreteDocument20 pagesPrestressed Wall ConcreteKiara Ticangan ArgelNo ratings yet

- The Grand Mosque of QairawanDocument20 pagesThe Grand Mosque of QairawanFree lancerNo ratings yet

- Concrete Mix Design As Per Indian Standard CodeDocument10 pagesConcrete Mix Design As Per Indian Standard Codeਤਨ੍ਹਾ ਰਾਜੀਵ ਮਾਯੂਸNo ratings yet

- Vishnu's Premium ProposalDocument11 pagesVishnu's Premium ProposalVamsi Pavan Kumar SankaNo ratings yet

- Lovol TB2SA604-002K Wheeled Tractor Parts Catalogue PDFDocument160 pagesLovol TB2SA604-002K Wheeled Tractor Parts Catalogue PDFLiv CBNo ratings yet

- 2-MUTO On Seismic Analysis of BuildingsDocument1 page2-MUTO On Seismic Analysis of BuildingsBAMOUROU SANOGONo ratings yet

- Public Review Draft 2404Document115 pagesPublic Review Draft 2404Said100% (1)

- SSM Winding Machines - XENO - YWDocument23 pagesSSM Winding Machines - XENO - YWyogesh kumawat100% (1)