Professional Documents

Culture Documents

Service Bulletin: © Honeywell International Inc. Do Not Copy Without Express Permission of Honeywell

Uploaded by

Juan Ruben GarciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Bulletin: © Honeywell International Inc. Do Not Copy Without Express Permission of Honeywell

Uploaded by

Juan Ruben GarciaCopyright:

Available Formats

Honeywell International Inc.

111 S. 34th Street

Phoenix, Arizona 85034-2802

U.S.A.

CAGE: 99193

Telephone: 800-601-3099 (Toll Free U.S.A./Canada)

Telephone: 602-365-3099 (International Direct)

Website: www.myaerospace.com

SERVICE BULLETIN

ENGINE - TURBINE SECTION - High Pressure (HP) and Low Pressure (LP) Turbine Blade Hour Tracking

and Recommended Blade Replacement Intervals for TFE731-2, -3, -4, -5 Series Engine Models

Legal Notice

NOTICE: This is a CATEGORY 2, RELIABILITY service bulletin.

Export Control

This document contains technical data and is subject to U.S. export regulations. These commodities,

technology, or software were exported from the United States in accordance with the export administration

regulations. Diversion contrary to U.S. law is prohibited.

ECCN: 9E991.

Proprietary Information

Honeywell - Confidential

THIS DOCUMENT AND ALL INFORMATION AND EXPRESSION CONTAINED HEREIN ARE THE

PROPERTY OF HONEYWELL INTERNATIONAL INC., ARE PROVIDED IN CONFIDENCE, AND MAY BE

USED BY PERSONS REQUIRED BY FEDERAL AVIATION REGULATION PART 21.50 TO COMPLY WITH

ANY OF THE TERMS OF THESE INSTRUCTIONS. EXCEPT AS SET FORTH ABOVE, NO PERSON MAY,

IN WHOLE OR IN PART, USE, DUPLICATE OR DISCLOSE THIS INFORMATION FOR ANY PURPOSE

WITHOUT THE PRIOR WRITTEN PERMISSION OF HONEYWELL INTERNATIONAL INC.

Honeywell Materials License Agreement

The documents and information contained herein ("the Materials") are the proprietary data of Honeywell

International Inc. These Materials are provided for the exclusive use of Honeywell Service Centers;

Honeywell-authorized repair facilities; operators of Honeywell aerospace products subject to an applicable

product support agreement, their wholly owned-subsidiaries or a formally designated third party service

provider; and direct recipients of Materials from Honeywell’s Aerospace Technical Publication Distribution.

The terms and conditions of this License Agreement govern your use of these Materials, except to the extent

that any terms and conditions of another applicable agreement with Honeywell regarding the operation,

maintenance, or repair of Honeywell aerospace products conflict with the terms and conditions of this License

Agreement, in which case the terms and conditions of the other agreement will govern. However, this License

Agreement will govern in the event of a conflict between its terms and conditions and those of a purchase

order or acknowledgement.

1. License Grant - If you are a party to an applicable product support agreement, a Honeywell Service Center

agreement, or an authorized repair facility agreement, Honeywell hereby grants you a limited, non-exclusive

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 1 of 29

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

license to use these Materials to operate, maintain, or repair Honeywell aerospace products only in accordance

with that agreement.

If you are a direct recipient of these Materials from Honeywell’s Aerospace Technical Publication Distribution

and are not a party to an agreement related to the operation, maintenance or repair of Honeywell aerospace

products, Honeywell hereby grants you a limited, non-exclusive license to use these Materials to maintain or

repair the subject Honeywell aerospace products only at the facility to which these Materials have been shipped

("the Licensed Facility"). Transfer of the Materials to another facility owned by you is permitted only if the

original Licensed Facility retains no copies of the Materials and you provide prior written notice to Honeywell.

2. Rights In Materials - Honeywell retains all rights in these Materials and in any copies thereof that are not

expressly granted to you, including all rights in patents, copyrights, trademarks, and trade secrets. No license

to use any Honeywell trademarks or patents is granted under this License Agreement.

3. Confidentiality - You acknowledge that these Materials contain information that is confidential and proprietary

to Honeywell. You agree to take all reasonable efforts to maintain the confidentiality of these Materials.

4. Assignment And Transfer - This License Agreement may be assigned to a formally designated service

designee or transferred to a subsequent owner or operator of an aircraft containing the subject Honeywell

aerospace products. However, the recipient of any such assignment or transfer must assume all of your

obligations under this License Agreement. No assignment or transfer shall relieve any party of any obligation

that such party then has hereunder.

5. Copies of Materials - Unless you have the express written permission of Honeywell, you may not make or

permit making of copies of the Materials. Notwithstanding the foregoing, you may make copies of only portions

of the Material for your internal use. You agree to return the Materials and any copies thereof to Honeywell

upon the request of Honeywell.

6. Term - This License Agreement is effective until terminated as set forth herein. This License Agreement

will terminate immediately, without notice from Honeywell, if you fail to comply with any provision of this

License Agreement or will terminate simultaneously with the termination or expiration of your applicable

product support agreement, authorized repair facility agreement, or your formal designation as a third party

service provider. Upon termination of this License Agreement, you will return these Materials to Honeywell

without retaining any copies and will have one of your authorized officers certify that all Materials have been

returned with no copies retained.

7. Remedies - Honeywell reserves the right to pursue all available remedies and damages resulting from a

breach of this License Agreement.

8. Limitation of Liability - Honeywell does not make any representation regarding the use or sufficiency of the

Materials. THERE ARE NO OTHER WARRANTIES, WHETHER WRITTEN OR ORAL, EXPRESS, IMPLIED

OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, (i) WARRANTIES ARISING FROM COURSE OF

PERFORMANCE, DEALING, USAGE, OR TRADE, WHICH ARE HEREBY EXPRESSLY DISCLAIMED, OR (ii)

WARRANTIES AGAINST INFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS OF THIRD PARTIES,

EVEN IF HONEYWELL HAS BEEN ADVISED OF ANY SUCH INFRINGEMENT. IN NO EVENT WILL

HONEYWELL BE LIABLE FOR ANY INCIDENTAL DAMAGES, CONSEQUENTIAL DAMAGES, SPECIAL

DAMAGES, INDIRECT DAMAGES, LOSS OF PROFITS, LOSS OF REVENUES, OR LOSS OF USE,

EVEN IF INFORMED OF THE POSSIBILITY OF SUCH DAMAGES. TO THE EXTENT PERMITTED BY

APPLICABLE LAW, THESE LIMITATIONS AND EXCLUSIONS WILL APPLY REGARDLESS OF WHETHER

LIABILITY ARISES FROM BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING BUT NOT LIMITED

TO NEGLIGENCE), BY OPERATION OF LAW, OR OTHERWISE.

9. Controlling Law - This License shall be governed and construed in accordance with the laws of the State of

New York without regard to the conflicts of laws provisions thereof. This license sets forth the entire agreement

between you and Honeywell and may only be modified by a writing duly executed by the duly authorized

representatives of the parties.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 2

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Safety Advisory

WARNING: BEFORE THE MATERIALS CALLED OUT IN THIS PUBLICATION ARE USED, KNOW THE

HANDLING, STORAGE AND DISPOSAL PRECAUTIONS RECOMMENDED BY THE MANUFACTURER OR

SUPPLIER. FAILURE TO OBEY THE MANUFACTURERS’ OR SUPPLIERS’ RECOMMENDATIONS CAN

RESULT IN PERSONAL INJURY OR DISEASE.

This publication describes physical and chemical processes which can make it necessary to use chemicals,

solvents, paints, and other commercially available materials. The user of this publication must get the Material

Safety Data Sheets (OSHA Form 174 or equivalent) from the manufacturers or suppliers of the materials to

be used. The user must know the manufacturer/supplier data and obey the procedures, recommendations,

warnings and cautions set forth for the safe use, handling, storage, and disposal of the materials.

Warranty/Liability Advisory

WARNING: HONEYWELL ASSUMES NO RESPONSIBILITY FOR ANY HONEYWELL EQUIPMENT

WHICH IS NOT MAINTAINED AND/OR REPAIRED IN ACCORDANCE WITH HONEYWELL’S PUBLISHED

INSTRUCTIONS AND/OR HONEYWELL’S FAA/SFAR 36 REPAIR AUTHORIZATION. NEITHER DOES

HONEYWELL ASSUME RESPONSIBILITY FOR SPECIAL TOOLS AND TEST EQUIPMENT FABRICATED

BY COMPANIES OTHER THAN HONEYWELL.

WARNING: INCORRECTLY REPAIRED COMPONENTS CAN AFFECT AIRWORTHINESS OR DECREASE

THE LIFE OF THE COMPONENTS. INCORRECTLY FABRICATED SPECIAL TOOLING OR TEST

EQUIPMENT CAN RESULT IN DAMAGE TO THE PRODUCT COMPONENTS OR GIVE UNSATISFACTORY

RESULTS.

Copyright - Notice

Copyright 1994, 2015 Honeywell International Inc. All rights reserved.

Honeywell is a registered trademark of Honeywell International Inc.

All other marks are owned by their respective companies.

THIS IS THE SB FOSI - DATE: 20121114

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 3

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Transmittal Information

ATA Number TFE731-72-3494 (Publication Number D199402000102)

Summary

The equipment changed in the revision(s) before this service bulletin may need additional changes. Refer to

Paragraph 3.

This revision is a FULL replacement. This revision includes the changes that follow:

• Changed Turbine Blade Life Limits to Recommended Blade Replacement Intervals and added engine

models to service bulletin title.

• Changed export control classification number from EAR99 to 9E991.

• Changed mark to service life, service life limits, and life limits to service marks, service mark limits, and

mark limits throughout service bulletin.

• Changed blade life to blade marking throughout service bulletin.

• Changed the content and format to agree with Honeywell processes in effect at the time of the release

of this revision.

The information that is identified with revision bars is listed in the Highlights section. Revision bars are not

used before Paragraph 1.A. The editorial changes and information that was moved or reformatted is not

identified with revision bars.

Refer to Paragraph 1.N. for a list of the acronyms and abbreviations used in this service bulletin.

Revision History

This service bulletin has had 13 revision(s) as shown in Table 1.

Table 1. Revision History

Revision Number Revision Date

0 18 Feb 1994

1 5 Aug 1994

2 21 Apr 1995

3 30 Apr 1998

4 19 Feb 1999

5 29 Nov 2001

6 21 Jan 2002

7 3 Mar 2004

8 21 Apr 2005

9 17 Aug 2007

10 23 Jul 2010

11 29 Jun 2011

12 24 Sep 2013

13 6 Aug 2015

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 4

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Highlights

This section issues Revision 13 to Service Bulletin, ATA Number TFE731-72-3494 (Publication Number

D199402000102), and contains these changes:

The list of highlights tells the users about the changes that the revision makes. The list has three columns. The

"Page" column shows the block of data that the revision changes and the page on which the block begins.

The block can be a section, subsection, graphic, table, etc. Revision marks give the location of the change in

the block. The "Description" column tells the user about the change or changes in each block. A paragraph,

table, or figure reference often comes before the description. The "Effectivity" column tells the user about

the part number(s) to which the block of information applies. The default value for this column is "All." "All"

means that the block applies to all parts.

Page Description Effectivity

9 Paragraph 1.C.(1).(a). Changed service life to blade replacement intervals. All

10 Paragraph 1.C.(1).(a).2. Changed service life to replacement intervals using All

turbine blade service mark limits and service life limits to replacement based on

blade service mark limits.

10 Paragraph 1.C.(3).(a). Changed service life to service mark limits and blade All

life mark limits to blade mark limits.

10 Paragraph 1.D.(1).(e). Changed service life mark limits to service mark limits. All

10 Paragraph 1.D.(1).(f). Changed blade life to blade marking. All

11 Paragraph 1.E.(3).(a). Changed service life limit to service mark limit. All

11 Paragraph 1.E.(3).(b).1. Changed service life mark limit to service mark limit. All

11 Paragraph 1.E.(3).(b).2. Changed service life mark limit to service mark limit. All

11 Paragraph 1.E.(3).(b).3. Changed service life mark limit to service mark limit. All

14 Paragraph 1.N. Added acronyms and abbreviations table. All

15 Paragraph 2.B.(1). Added reference for sending claims. All

15 Paragraph 2.B.(3). Changed footnote 2 for claims for Table 7. All

17 Paragraph 3.A. Added NOTES for publications and service bulletins listed. All

25 Paragraph 3.F. Changed section title from Service Life Limits to Blade Service All

Mark Limits.

25 Paragraph 3.F.(1). Changed service life limits to blade service mark limits. All

25 Paragraph 3.F.(3). Changed requirements blade marking factor. All

25 Paragraph 3.F.(4). Changed service life limits to service mark limits. All

25 Paragraph 3.F.(4).(a). Changed Service Life Limits to Service Mark Limits in All

title for Tables 9 through 18.

28 Paragraph 3.F.(4).(i). Changed blade life to blade marking in footnote 1 in All

Table 17.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 5

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Page Description Effectivity

29 Paragraph 3.G.(2). Changed service life limit to service mark limit. All

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 6

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

1. Planning Information

A. Effectivity

(1) This is a CATEGORY 2, RELIABILITY service bulletin.

NOTE: CATEGORY 2 service bulletins address substantial improvements to

reliability, usually by reducing the probability of experiencing an in-flight

shutdown or substantial repair costs associated with unscheduled

maintenance events. The compliance schedule stated in this service

bulletin provides a reasonable reduction in risk while minimizing engine

downtime.

(2) This service bulletin is applicable to the turbofan aircraft engines shown in Table 2.

Table 2. Applicable Engine(s)

Serial

PN Model Number Number Application

3070000-1 thru -14 TFE731-2-1C All Falcon 10/100

3070300-1 thru -9, -11, -12 TFE731-2-2B All Learjet 35/36

3073610-1, -3, -4 TFE731-2-3B All Learjet M31

3073610-2 TFE731-2-3B All Learjet M31

3070250-1 TFE731-2C-1C All Falcon 10/100

3070170-1 TFE731-2C-2B All Learjet 35/36

3070190-1 TFE731-2C-3B All Learjet M31

3070190-3 TFE731-2C-3B All Learjet M31

3072800-1, -2, -4, -5 TFE731-3-1C All Falcon 50

3072300-1, -2, -4 TFE731-3-1E All 731 Jetstar/L1329

3072600-1, -3 TFE731-3-1F All Jetstar II/L1329

3072500-1, -2, -4 TFE731-3-1G All Westwind 1124

3072900-2, -3, -4, -6, -7, -8 TFE731-3-1H All BAe HS125-SERIES

3074850-1, -3 TFE731-3-1K All Jetstar II/L1329 (Springfield)

3074100-3, -6, -9 TFE731-3A-2B All Learjet 55

3074100-4, -7, -10 TFE731-3A-2B1 All Learjet 55

3074550-1 thru -4 TFE731-3A-200G All IAI Astra 1125

3074560-1 thru -4 TFE731-3AR-200G All IAI Astra 1125

3074800-1, -4, -7 TFE731-3AR-2B All Learjet 55

3074800-2, -5, -8 TFE731-3AR-2B1 All Learjet 55

3074800-9 TFE731-3AR-2B2 All Learjet 55

3074800-10 TFE731-3AR-3B All Learjet 55

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 7

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Table 2. Applicable Engine(s) (Cont)

Serial

PN Model Number Number Application

3074800-11 TFE731-3AR-3B1 All Learjet 55

3074800-12 TFE731-3AR-3B2 All Learjet 55

3074800-13 TFE731-3AR-3B All Learjet 55

3074800-14 TFE731-3AR-3B1 All Learjet 55

3074800-15 TFE731-3AR-3B2 All Learjet 55

3074400-1, -2, -4, -5, -6, -8 TFE731-3B-100S All Citation III/VI

3073400-1, -2, -4, -5, -6, -8 TFE731-3BR-100S All Citation III/VI

3074080-1 TFE731-3C-100S All Citation III/VI

3074080-2, -3 TFE731-3C-100S All Citation III/VI

3074040-1 TFE731-3C-200G All IAI Astra 1125

3074040-2, -3 TFE731-3C-200G All IAI Astra 1125

3071880-1 TFE731-3C-3B All Learjet 55

3071880-2 TFE731-3C-3B1 All Learjet 55

3074070-1 TFE731-3CR-100S All Citation III/VI

3074070-2, -3 TFE731-3CR-100S All Citation III/VI

3074090-1 TFE731-3CR-200G All IAI Astra 1125

3074090-2, -3 TFE731-3CR-200G All IAI Astra 1125

3071890-1 TFE731-3CR-3B All Learjet 55

3071890-2 TFE731-3CR-3B1 All Learjet 55

3071890-3 TFE731-3CR-3B2 All Learjet 55

3074570-1 TFE731-3D-1C All Falcon 50

3073790-1 TFE731-3D-1G All Westwind 1124

3074580-1, -2, -3 TFE731-3D-1H All BAe HS125-SERIES

3074050-1, -2 TFE731-3D-1K All Jetstar II/L1329 (Springfield)

3070120-1 TFE731-3DR-1D All Sabreliner 65/65A (NA-265-65)

3074010-1, -2 TFE731-3DR-1G All Westwind 1124

3074590-1 TFE731-3DR-1H All BAe HS125-SERIES

3073750-2, -3 TFE731-3R-1D All Sabreliner 65/65A (NA-265-65)

3074910-1 thru -4 TFE731-3R-1G All Westwind 1124

3074000-1 thru -6 TFE731-3R-1H All BAe HS125-SERIES

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 8

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Table 2. Applicable Engine(s) (Cont)

Serial

PN Model Number Number Application

3075900-1 TFE731-4-1C All Falcon 50-4

3073640-2, -3 TFE731-4R-2S All Cessna Citation VII

3074860-1, -2 TFE731-5AR-1C All Falcon 900

3075360-1 TFE731-5AR-2C All Falcon 20-5

3075360-2 TFE731-5AR-2C All Falcon 20-5

3075330-3, -4, -5 TFE731-5BR-1C All Falcon 900B/900C

3075160-3, -4 TFE731-5BR-1H All Hawker 750/800XP/850XP

3075370-2, -3 TFE731-5BR-2C All Falcon 20-5

3074600-1, -2, -3 TFE731-5R-1H All Hawker 800

3074600-4, -5 TFE731-5R-1H All Hawker 800

B. Concurrent Requirements

(1) Review of the service bulletin(s) listed in Table 3 should be accomplished by the

operator for possible incorporation at the time this service bulletin is accomplished.

Table 3. Service Bulletin(s) To Be Reviewed

Service Bulletin Number Service Bulletin Title

TFE731-72-3219 ENGINE - TURBINE SECTION - Identification of LP and HP Turbine Rotor

Assemblies When Blades, Discs or Rotors Are Replaced

TFE731-72-3437 ENGINE - Convert Engine Model TFE731-5AR to TFE731-5BR

TFE731-72-3576 ENGINE - TURBINE SECTION - Replace First Stage LP Turbine Rotor

Assembly and Second Stage LP Turbine Rotating Seal on Specifically Identified

Engines

TFE731-72-3697 ENGINE - TURBINE SECTION - Install Screened (Specially Inspected) LP

Third Stage Turbine (LPT3) Blades, Part No. 3060788-1

TFE731-72-3768 ENGINE - TURBINE SECTION - Install First Stage Low Pressure Turbine

(LPT1) Rotor Assembly with Riveted Blade Retention

TFE731-72-3769 ENGINE - TURBINE SECTION - Install First Stage Low Pressure Turbine

(LPT1) Rotor Assembly with Riveted Blade Retention

C. Reason

(1) Problem:

(a) Turbine blades have finite lives, and while engine manufacturers have not

typically tracked turbine blade hours, they have, in some cases utilized blade

replacement intervals, micro examination, or other means in an effort to

preclude time related blade separations. Historically, Honeywell’s position

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 9

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

has typically been that turbine blades would be removed for other cause

prior to reaching their stress rupture or time at temperature related life.

However, occurrences of stress rupture blade separations in the TFE731

engine indicates that this is not always the case. Honeywell has addressed

this problem by:

1 Developing a procedure for tracking turbine blade hours, and

2 Establishing turbine blade replacement intervals using turbine blade

service mark limits. Implementation of turbine blade replacement

based on blade service mark limits will significantly reduce the

probability of these types of blade separations in TFE731 engines.

(2) Background:

(a) TFE731 engines have experienced a small number of turbine blade

separations, which metallurgical examination showed were related to stress

rupture. Because of this, older turbine blades are more susceptible to this type

of blade separation than newer turbine blades.

(3) Action:

(a) This service bulletin describes the procedure by which turbine blade hours will

be tracked and defines turbine blade service mark limits (refer to Table 9 thru

Table 18). The turbine blade markings and engine LMM will determine turbine

blade serviceability. If blade mark limits or marking factors were changed in

this revision, no action is required until the next scheduled MPI, at which time,

the revised marking factors and blade mark limits should be used.

D. Description

(1) This service bulletin provides instructions for:

(a) Initial compliance with turbine blade marking at MPI. Refer to Paragraph 3.C.

(b) Continuation of turbine blade marking at subsequent MPI. Refer to Paragraph

3.D.

(c) Unscheduled (repair) maintenance. Refer to Paragraph 3.E.

(d) How and where to mark turbine blades. Refer to Paragraph 3 and Figure 1

and Figure 2.

(e) Turbine blade service mark limits. Refer to Table 9 thru Table 18.

(f) (Post Service Bulletin TFE731-72-3437) Determining LPT first stage blade, PN

3074746-4 or PN 3075428-1, blade marking used.

(g) Engineering evaluation of separated turbine blades. Refer to Paragraph

3.E.(5).

E. Compliance

(1) Compliance addresses a substantial improvement to reliability.

(2) Honeywell recommends that turbine blade marking be initiated at the next MPI and

be updated at each subsequent MPI.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 10

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(3) This service bulletin provides maintenance instructions for marking turbine blades. The

maintenance action detailed in these instructions is required to be completed as a part

of each MPI. At time of inspection and after turbine blade marking, the following apply:

(a) Turbine blades which meet or exceed their service mark limit (refer to blade

mark limit, Table 9 thru Table 18) shall be scrapped and the turbine blade

airfoil rendered unserviceable.

(b) Turbine blades with marks less than the blade mark limit (refer to Table 9 thru

Table 18) may be returned to service (although turbine blades may exceed

blade mark limit prior to next MPI) with the following exception(s):

1 LPT first stage blade, PN 3074746 or PN 3075428, installed and

operated in Engine Model TFE731-5BR; replacement is recommended

if the turbine blade service mark limit will be exceeded prior to the next

scheduled MPI. Refer to Table 17 or Table 18.

2 HPT blade, PN 3072455 or PN 3072712, installed in Engine Model

TFE731-2-1C/-2B/-3B; replacement is recommended if the turbine

blade service mark limit will be exceeded prior to the next scheduled

MPI. Refer to Table 9 or Table 10.

3 LPT third stage blade, PN 3060788 and PN 3060690, replacement is

recommended if the turbine blade service mark limit will be exceeded

prior to the next scheduled MPI. Refer to Table 15 thru Table 18.

(4) Bank Engine Models TFE731-2-1C/-2B/-3B should utilize Engine Model TFE731-2-1C

marking factor for HPT blades, PN 3072455 and PN 3072712. Bank engines which

have been used exclusively as Engine Model TFE731-2-2B/-3B since the last MPI

may utilize Engine Models TFE731-2-2B/-3B marking factor.

F. Approval

(1) The accomplishment instructions of this service bulletin comply with applicable Federal

Aviation Regulations and are FAA approved.

G. Manpower

(1) An additional 3.0 man-hour(s) is/are required at time of scheduled maintenance.

H. Weight and Balance

(1) None.

I. Electrical Load Data

(1) Not applicable.

J. Software Accomplishment Summary

(1) Not applicable.

K. References

(1) The sources of information used in the preparation of this service bulletin include

Honeywell engineering documentation and the documents listed in Table 4.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 11

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Table 4. Sources of Information

Heavy Maintenance Light Maintenance Illustrated Parts

1 1

Part/Model Number Manual Manual Catalog

TFE731-2-1C NA 72-02-01 NA

TFE731-2-2B NA 72-02-01 NA

TFE731-2-3B NA 72-02-01 NA

TFE731-2C-1C NA 72-02-01 NA

TFE731-2C-2B NA 72-02-01 NA

TFE731-2C-3B NA 72-02-01 NA

TFE731-3-1C NA 72-02-15 NA

TFE731-3-1E NA 72-02-15 NA

TFE731-3-1F NA 72-02-15 NA

TFE731-3-1G NA 72-02-15 NA

TFE731-3-1H NA 72-02-15 NA

TFE731-3-1K NA 72-02-15 NA

TFE731-3A-200G NA 72-02-15 NA

TFE731-3A-2B NA 72-02-15 NA

TFE731-3A-2B1 NA 72-02-15 NA

TFE731-3AR-200G NA 72-02-15 NA

TFE731-3AR-2B NA 72-02-15 NA

TFE731-3AR-2B1 NA 72-02-15 NA

TFE731-3AR-2B2 NA 72-02-15 NA

TFE731-3AR-3B NA 72-02-15 NA

TFE731-3AR-3B1 NA 72-02-15 NA

TFE731-3AR-3B2 NA 72-02-15 NA

TFE731-3B-100S NA 72-02-15 NA

TFE731-3BR-100S NA 72-02-15 NA

TFE731-3C-100S NA 72-02-15 NA

TFE731-3C-200G NA 72-02-15 NA

TFE731-3C-3B NA 72-02-15 NA

TFE731-3C-3B1 NA 72-02-15 NA

TFE731-3CR-100S NA 72-02-15 NA

TFE731-3CR-200G NA 72-02-15 NA

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 12

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Table 4. Sources of Information (Cont)

Heavy Maintenance Light Maintenance Illustrated Parts

1 1

Part/Model Number Manual Manual Catalog

TFE731-3CR-3B NA 72-02-15 NA

TFE731-3CR-3B1 NA 72-02-15 NA

TFE731-3CR-3B2 NA 72-02-15 NA

TFE731-3D-1C NA 72-02-15 NA

TFE731-3D-1G NA 72-02-15 NA

TFE731-3D-1H NA 72-02-15 NA

TFE731-3D-1K NA 72-02-15 NA

TFE731-3DR-1D NA 72-02-15 NA

TFE731-3DR-1G NA 72-02-15 NA

TFE731-3DR-1H NA 72-02-15 NA

TFE731-3R-1D NA 72-02-15 NA

TFE731-3R-1G NA 72-02-15 NA

TFE731-3R-1H NA 72-02-15 NA

TFE731-4-1C NA 72-02-33 NA

TFE731-4R-2S NA 72-02-33 NA

TFE731-5R-1H NA 72-02-75 NA

TFE731-5AR-1C NA 72-02-75 NA

TFE731-5AR-2C NA 72-02-75 NA

TFE731-5BR-1C NA 72-02-96 NA

TFE731-5BR-1H NA 72-02-96 NA

TFE731-5BR-2C NA 72-02-96 NA

NOTE:

1. Affected Chapter/Section/Subject 72-50-04, 72-50-06, and 72-50-09 (as applicable).

(2) The service bulletin(s) listed in Table 5 is/are applicable to this service bulletin.

Table 5. Service Bulletin References

Service Bulletin Number Service Bulletin Title

TFE731-72-3417 ENGINE - TURBINE SECTION - Replacement of HP Turbine Rotor Blades,

Part No. 3072749-3, with More Than 1800 Operating Hours

L. Other Publications Affected

(1) Not applicable.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 13

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

M. Interchangeability or Intermixability of Parts

(1) Not applicable.

N. Acronyms and Abbreviations

(1) Refer to Table 6 for a list of the acronyms and abbreviations used in this service bulletin.

Table 6. List of Acronyms and Abbreviations

Term Full Term

ATA Air Transport Association

CAGE commercial and government entity

ECCN Export Control Classification Number

FAA Federal Aviation Administration

GSE ground support equipment

HP high pressure

HPT high pressure turbine

IN. inch

LMM light maintenance manual

LP low pressure

LPT low pressure turbine

mm millimeter

MPI major periodic inspection

MSP manufacturer’s suggested price

NA not applicable

OSHA Occupational Safety and Health Administration

PN part number

SFAR Special Federal Aviation Regulation

SIL service information letter

SPGM special program

TSN time since new

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 14

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

2. Material Information

A. Material - Price and Availability

(1) Not applicable.

B. Industry Support Information

(1) Send claims through the Honeywell MyAerospace web portal (www.myaerospace.com).

Select the Maintenance Plans tab and use the Claims-Maintenance Programs

sub-option.

(2) A special/warranty program may be available for this service bulletin, under

certain conditions, provided compliance recommendations of Paragraph 1.E.

are met. Information on special/warranty program and availability of parts

may be obtained from a Honeywell-authorized service facility. (Refer to SIL,

F731-3.) You can also use the “Dealer and Service Center Locator" tool at

https://myaerospace.honeywell.com/wps/myportal to find approved service locations.

(3) The warranty/program data is listed in Table 7.

NOTE: The procedures outlined in this service bulletin may be accomplished at the

Major Service Center level or greater.

Table 7. Warranty/Program Data

1 2

Warranty/Program Yes No

Commercial Warranty X

(Standard new engine warranty)

Spare Part Warranty X

(Standard new spare part warranty)

Special Extended Warranty Program Number X

(Extension of either standard commercial warranty or spare part warranty may apply)

3

Special Program Number 32 X X

(Programs in which special pricing and/or special conditions may apply)

Special Pricing Notice Number X

(Reduction from catalog list pricing, i.e., “P” condition pricing may apply)

MSP X

NOTES:

1. The costs of compliance with this service bulletin may be covered by Warranty, MSP, or other Programs

marked with an “X” in the “Yes” column, subject to the terms and conditions of the applicable Warranty, MSP,

or other Programs contracts. This service bulletin in no way alters, modifies, or extends the terms of any

Warranty, MSP, or other Programs contract. For clarification or questions, contact Honeywell Warranty

Department at 800-601-3099, Domestic or 602-365-3099, International and select Option # 2.

2. Send claims through the Honeywell MyAerospace web portal (www.myaerospace.com). Select the

Maintenance Plans tab and use the Claims-Maintenance Programs sub-option.

3. SPGM Number 32 is applicable for TFE731-4R and TFE731-5BR engine models only. No special program

coverage is available for other TFE731 engine models.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 15

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

C. Material Necessary for Each Engine

(1) Identify replaced parts (regardless of condition) as replaced/removed in accordance

with Service Bulletin TFE731-72-3494 on the shipping documents and ship to the

following address:

Honeywell International Inc.

Material Receiving

Attn.: Special Programs

1944 East Sky Harbor Circle

Phoenix, AZ 85034-3440

D. Material Necessary for Each Spare

(1) Not applicable.

E. Reidentified Parts

(1) Not applicable.

F. Tooling - Price and Availability

(1) The GSE in Table 8 is required to accomplish the instructions outlined in this service

bulletin in addition to tooling listed in publications referenced in Paragraph 1.K.(1).

Table 8. Tooling - Price and Availability

1 2

PN Nomenclature Unit List Price

CP-9361 vibro-etch tool (CAGE: 1P285)

NOTES:

1. Equivalent substitutes may be used for listed item(s).

2. Information regarding price and availability of GSE may be obtained from Honeywell

International, Ground Support Solutions (GSS), 3520 Westmoor St., Box 4 / Plant 26, South

Bend, IN 46628. Telephone: 1-866-810-8944 (U.S.A.), 1-574-231-3987 (International), or

http://aerospace.honeywell.com/services/maintenance-and-monitoring/ground-support-solutions.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 16

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

3. Accomplishment Instructions

A. General Information

NOTE: Publications listed in Paragraph 1.K.(1) provide applicable disassembly, cleaning,

inspection, reassembly, and testing instructions and shall be referred to during the

accomplishment of the following instructions.

NOTE: Service bulletins listed in Paragraph 1.B. shall be accomplished in addition to or in

conjunction with the following instructions.

NOTE: Turbine blades, in the following steps, will be referred to only as blade or blades.

B. General Rules for Blade Marking

(1) Blade marking is to be completed only when complying with an MPI or at unscheduled

maintenance only as defined in Paragraph 3.E.

(2) All blades will be marked prior to removal (if required) from disc, even if the removed

blades are to be considered as scrap.

(3) Blades, PN 3072450, which have been weld repaired shall have five marks applied to

the platform prior to being returned to service.

(4) Blades with unknown hours are not acceptable for use other than the one-time

compliance detailed in Paragraph 3.C.(1)(b).

(5) If blade replacement is required:

(a) Only serviceable blades with verified hours (i.e., no assumed identifier) are

acceptable for replacement use.

(b) Serviceable blades with an assumed hour identifier which are removed for

inspection, access to other blades in the rotor assembly, disc inspection, or

disc replacement are acceptable only for reinstallation into the same engine

from which they were removed.

(c) Blades with an assumed hour identifier which are removed for any other

reason cannot be returned to service and must be scrapped.

(d) Blades removed and not reinstalled on the same engine during unscheduled

maintenance will be marked per Paragraph 3.E.

NOTE: Blades reinstalled on the same engine they are removed from

during unscheduled maintenance do not require marking.

(6) Each mark is equivalent to a specified number of operating hours called the marking

factor. The specified number of hours is determined by the blade part number and the

engine model combination. Table 9 thru Table 18 specifies the marking factor for all

Model TFE731-2 thru -5BR engines versus blade part number installed.

(7) If accomplishing initial compliance of this service bulletin, continue with Paragraph 3.C.

If accomplishing continued compliance, proceed to Paragraph 3.D. If accomplishing

unscheduled maintenance, proceed to Paragraph 3.E.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 17

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

C. Instructions for Initial Compliance With This Service Bulletin

(1) General guidelines (rules) for initial compliance.

(a) Installed blades with known hours will receive marks based on the actual blade

hours. Blade hours may be different than engine hours.

(b) Installed blades with unknown hours, which have been operating in the engine

during the prior maintenance interval, can be assumed to match engine

hours ONE TIME ONLY.

(c) Installed blades with unknown hours will receive an additional identifier on

each blade aft platform indicating that the blade hours are assumed.

(2) Specific instructions for initiation of blade marking.

NOTE: Refer to the general rules in Paragraph 3.B.

(a) Determine blade set total hours.

1 If service bulletin is being complied with at the engines first MPI signoff,

and no prior turbine entry has occurred, all blades are considered to

have been new when engine was put into service. Blade set total

hours are equal to engine hours. Continue with Paragraph 3.C.(2)(b).

2 If service bulletin is being complied with after the engines first

MPI, review engine log book (disc Life Limited Part Log Card) to

determine the blade set total hours. If blade set total hours are known,

continue with Paragraph 3.C.(2)(b). If blade set total hours cannot be

determined from engine log book, assume blade set total hours are

equal to engine hours. Continue with Paragraph 3.C.(2)(b).

(b) Using the formula in Paragraph 3.C.(2)(b)1 to determine the dividend, round

the dividend up to the next integer if the decimal portion is greater than or

equal to 0.5. Round the dividend down to the same integer by truncating the

decimal portion if the decimal portion is less than 0.5.

1 To determine number of marks to be added, calculate the dividend:

• Dividend = Blade “Delta Hours” ÷ Marking Factor

2 Marking factor is shown in Table 16. Refer to the example below:

• Example.

LPT3 blade, PN 3074755, used in a Model TFE731-5A engine.

Marking Factor = 900

Hours since last MPI = 2150

Dividend = 2150 ÷ 900 = 2.38

0.38 is less than 0.5; therefore, round down.

Apply two marks for the initial interval.

(c) Mark blades.

1 Mark blades using a vibro-etch tool (refer to Table 8) to a depth of

0.005 to 0.010 inch (0.13 to 0.25 mm) maximum.

2 Each mark consists of a single vertical line which is vibro-etched on

the blade aft platform. Refer to Figure 1 and Figure 2.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 18

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Figure 1. (Sheet 1 of 1) HPT Blade (Typical) Showing Aft Platform Details N-N and P-P

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 19

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

Figure 2. (Sheet 1 of 1) LPT Blade (Typical) Showing Aft Platform Detail A-A

3 Marking should be initiated on the blade at the left-hand side of the aft

platform (13 to 15 marks can be entered). (Refer to Figure 1, Detail

N-N, and Figure 2, Detail A-A.) Careful placement of the marks will

ensure that the maximum usage is obtained.

a For blades, PN 3074746, PN 3075428, and PN 3060690 only,

the forward blade platform may be used for marking if the aft

platform has no room for additional marks. Refer to Figure 2.

4 Blades with unknown hours at time of initial compliance with this

service bulletin (assumed engine hours) must also be identified with

vibro-etch identifier on the right platform edge. Initiate identifier mark

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 20

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

no more than 0.100 inch (2.54 mm) in from right edge and etch

that portion of the platform completely. Refer to Figure 1, Detail

P-P, and Figure 2, Detail A-A.

(d) Inspect blades in accordance with the applicable engine LMM.

(e) Remove/install blades (if required) in accordance with the applicable engine

LMM.

(f) Enter maintenance action.

1 Enter the number of blades that were marked at the time of service

bulletin compliance and the number of marks etched on those

blades, the number (if any) of new replacement blades installed, and

engine TSN at the time of the maintenance action on the applicable

disc Life Limited Part Log Card in accordance with the applicable

engine LMM. If the disc is replaced at this maintenance action,

update replacement disc Life Limited Part Log Card with appropriate

blade marking information.

NOTE: Tracking blade hours (marks) on each disc Life Limited

Part Log Card will provide a means of predicting blade

usage at future MPIs.

D. Instructions for Continued Compliance with this Service Bulletin

(1) General rules for continued compliance.

(a) Replacement blades installed during the current MPI will receive marking at

the next MPI signoff.

(b) When determining the number of blade marks to apply at time of MPI

and different marking factors are defined for each MPI interval, use the

marking factor associated with the incoming MPI interval (the MPI interval

just completed).

(c) If unscheduled maintenance since the previous MPI resulted in replacement of

SOME of the blades in the assembly, the following rules apply:

1 All installed blades that have marks applied on the aft platform will be

assumed to have been in continuous service since the last MPI signoff.

2 All installed blades without marks applied to the aft platform will be

assumed to have been installed new at the last MPI signoff.

(d) If unscheduled maintenance since the previous MPI resulted in replacement of

ALL of the blades in the assembly, the delta hours may be computed from

the time of the unscheduled maintenance. Refer to Example 3 in Paragraph

3.D.(2)(b).

NOTE: The term “delta hours” used in this section refers to the number of

hours to be used for computing the number of marks that will be

added during the current MPI.

(e) Blades, PN 3072450, which have been weld repaired, shall have five marks

applied to the platform prior to being returned to service.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 21

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(2) Specific instructions for blade marking at MPI signoff.

NOTE: Refer to the general rules in Paragraph 3.B.

(a) Determine blade delta hours.

1 If review of engine log book indicates that no unscheduled

maintenance occurred since the previous MPI, the blade delta hours

are the number of hours the engine operated since the previous MPI.

Continue with Paragraph 3.D.(2)(b).

2 If review of the engine log book indicates that ALL blades in the

assembly were replaced during the unscheduled maintenance, then

the blade delta hours equal the number of hours operated since the

unscheduled maintenance. Continue with Paragraph 3.D.(2)(b).

3 If review of the engine log book indicates that only some of the blades

were replaced during unscheduled maintenance, refer to Paragraph

3.D.(1)(c)1 and Paragraph 3.D.(1)(c)2.

(b) Using the formula in Paragraph 3.D.(2)(b)1 to determine the dividend, round

the dividend up to the next integer if the decimal portion is greater than or

equal to 0.5. Round the dividend down to the same integer by truncating the

decimal portion if the decimal portion is less than 0.5.

1 To determine number of marks to be added, calculate the dividend:

• Dividend = Blade “Delta Hours” ÷ Marking Factor

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 22

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

2 Marking factor is shown in Table 10, Table 13, and Table 16. Refer

to the examples below:

• Example 1.

LPT3 blade, PN 3074755, used in a Model TFE731-5A engine.

Marking Factor = 900

Hours since last MPI = 2,100

Dividend = 2,100 ÷ 900 = 2.33

0.33 is less than 0.5; therefore, round down.

Apply two additional marks for the last interval.

• Example 2.

LPT1 blade, PN 3072311, used in a Model TFE731-3B engine.

Marking Factor = 500

Hours since last MPI = 1,400

Dividend = 1,400 ÷ 500 = 2.8

0.8 is greater than 0.5; therefore, round up.

Apply three additional marks for the last interval.

• Example 3.

HPT blade, PN 3072712, used in a Model TFE731-2-1C

engine, all blades were installed at unscheduled maintenance.

Marking Factor = 250

Hours since unscheduled maintenance where replacement

blades were installed = 840

Dividend = 840 ÷ 250 = 3.36

0.36 is less than 0.5; therefore, round down.

Apply three additional marks for the last interval.

(c) Apply appropriate marks to blades per Paragraph 3.C.(2)(c).

(d) Inspect blades in accordance with the applicable engine LMM.

(e) Remove/install blades (if required) in accordance with the applicable engine

LMM.

(f) Enter maintenance action.

1 Enter the number of blades that were marked at the time of service

bulletin compliance and the number of marks etched on those blades,

the number (if any) of new replacement blades installed, and engine

TSN at the time of the maintenance action on the applicable disc Life

Limited Part Log Card in accordance with the applicable engine

LMM. If applicable disc is replaced during this maintenance action,

update replacement disc Life Limited Part Log Card with appropriate

blade marking information.

NOTE: Tracking blade hours (marks) on each disc Life Limited

Part Log Card will provide a means of predicting blade

usage at future MPIs.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 23

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

E. Specific Instructions at Unscheduled (Repair) Maintenance

NOTE: Refer to the general rules in Paragraph 3.B.

(1) Inspect blades in accordance with the applicable engine LMM.

(2) Remove/install blades (if required) in accordance with the applicable engine LMM.

(3) Blades removed and not reinstalled on the same engine during unscheduled

maintenance shall be marked as follows:

NOTE: Blades reinstalled on the same engine they are removed from do not

require marking during unscheduled maintenance.

NOTE: The term “Delta Hours” used in this step refers to the number of hours

to be used for computing the number of marks that will be added to

account for either:

• Time from last marks applied at scheduled MPI to unscheduled

maintenance, or

• Time from unscheduled maintenance to scheduled MPI.

(a) Using the formula in Paragraph 3.E.(3)(a)1 to determine the dividend, round

the dividend up to the next integer if the decimal portion is greater than or

equal to 0.5. Round the dividend down to the same integer by truncating the

decimal portion if the decimal portion is less than 0.5.

1 To determine number of marks to be added, calculate the dividend:

• Dividend = Blade “Delta Hours” ÷ Marking Factor

2 Marking factor is shown in Table 17 and Table 18. Refer to the

example below:

• Example.

LPT2 blade, PN 3075424, used in a Model TFE731-5B engine.

Blades are being removed at unscheduled maintenance.

Marking Factor = 900

Hours since last MPI = 548

Dividend = 423 ÷ 333 = 1.27

0.61 is greater than 0.5; therefore, round up.

Apply one mark to blades being removed from the wheel.

(4) Enter maintenance action.

(a) Enter the number of blades that were replaced (if required) and the number

of marks etched on those blades, the number (if any) of new replacement

blades installed, and engine TSN at the time of the maintenance action on the

applicable disc Life Limited Part Log Card in accordance with the applicable

engine LMM. If applicable disc is replaced during this maintenance action,

update replacement disc Life Limited Part Log Card with appropriate blade

marking information.

NOTE: Tracking blade hours (marks) on each disc Life Limited Part Log

Card will provide a means of predicting blade usage at future MPIs.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 24

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(5) Engineering evaluation of separated blades.

(a) Any blades which are suspected to be the primary cause of an event (i.e.,

the separated blade), the adjacent blades should have an Orange Special

Handing Required Tag, Number AV 0398-1 (8-86), filled out, and the blades

routed to Honeywell Customer Support for evaluation.

F. Blade Service Mark Limits

(1) Blade service mark limits (blade mark limit) are based upon the engines being

operated within approved operating limits and maintained in accordance with

Honeywell published instructions.

(2) All blades must have an accounting of the hours accrued during operation.

(3) Blade marks are determined by using the marking factor per Table 9 thru Table 18

and the blade operating hours accumulated since new (if not previously marked)

or since the last MPI.

(4) Refer to Table 9 thru Table 18 to determine established turbine blade service mark

limits for the HPT and LPT blades. Blades which meet or exceed their service mark

limit (blade mark limit) shall be scrapped and the blade airfoil rendered unserviceable.

(a) Refer to Table 9 for Engine Model TFE731-2-2B/-3B.

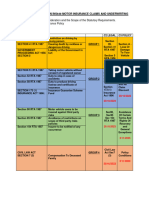

Table 9. HPT and LPT Blade Service Mark Limits for TFE731-2-2B/-3B Engines

Component Blade PN Marking Factor Blade Mark Limit

1

HPT 3072455 500 6

1

HPT 3072712 500 6

LPT1 3070019 1,000 9

LPT2 3072012 1,000 9

LPT3 3072014 1,000 9

NOTE:

1. Refer to Paragraph 1.E.(3)(b).

(b) Refer to Table 10 for Engine Model TFE731-2-1C.

Table 10. HPT and LPT Blade Service Mark Limits for TFE731-2-1C Engines

Component Blade PN Marking Factor Blade Mark Limit

1

HPT 3072455 250 6

1

HPT 3072712 250 6

LPT1 3070019 1,000 9

LPT2 3072012 1,000 9

LPT3 3072014 1,000 9

NOTE:

1. Refer to Paragraph 1.E.(3)(b).

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 25

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(c) Refer to Table 11 for Engine Model TFE731-2C.

Table 11. HPT and LPT Blade Service Mark Limits for TFE731-2C Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3074785 1,000 9

LPT1 3072311 1,000 9

LPT2 3072012 1,000 9

LPT3 3072014 1,000 9

(d) Refer to Table 12 for Engine Model TFE731-3/-3A/-3AR/-3R.

Table 12. HPT and LPT Blade Service Mark Limits for TFE731-3/-3A/-3AR/-3R Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3072450 1,000 9

LPT1 3072311 1,000 9

LPT2 3072012 1,000 9

LPT3 3072014 1,000 9

LPT3 3072845 1,000 9

(e) Refer to Table 13 for Engine Model TFE731-3B/-3BR.

Table 13. HPT and LPT Blade Service Mark Limits for TFE731-3B/-3BR Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3072749 1,000 2 (Refer to Service Bulletin

TFE731-72-3417)

HPT 3074785 1,000 9

LPT1 3072311 500 9

LPT2 3072012 1,000 9

LPT3 3072845 1,000 9

(f) Refer to Table 14 for Engine Model TFE731-3C/-3CR/-3D/-3DR.

Table 14. HPT and LPT Blade Service Mark Limits for TFE731-3C/-3CR/-3D/-3DR Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3074785 1,000 9

LPT1 3074098 1,000 9

LPT2 3074099 1,000 9

LPT3 3072845 1,000 9

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 26

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(g) Refer to Table 15 for Engine Model TFE731-4/-4R.

Table 15. HPT and LPT Blade Service Mark Limits for TFE731-4/-4R Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3074785 1,000 9

LPT1 3060612 1,000 10

LPT1 3074746 675 10

1

LPT1 3075428 675 10

LPT2 3075424 900 10

2

LPT3 3060690 210 10

2

LPT3 3060788 210 10

LPT3 3061823 900 10

LPT3 3074755 1,000 9

NOTES:

1. Refer to Service Bulletin TFE731-72-3576 for rotor assembly replacement.

2. Refer to Paragraph 1.E.(3)(b).

(h) Refer to Table 16 for Engine Model TFE731-5AR/-5R.

Table 16. HPT and LPT Blade Service Mark Limits for TFE731-5AR/-5R Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3074785 1,000 9

LPT1 3060612 1,000 10

LPT1 3074746 715 10

1

LPT1 3075428 715 10

LPT2 3074751 1,000 9

LPT2 3075424 900 10

2

LPT3 3060690 210 10

2

LPT3 3060788 210 10

LPT3 3061823 900 10

LPT3 3074755 1,000 9

NOTES:

1. Refer to Service Bulletin TFE731-72-3576 for rotor assembly replacement.

2. Refer to Paragraph 1.E.(3)(b).

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 27

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(i) Refer to Table 17 for Engine Model TFE731-5BR-1C/-2C.

Table 17. HPT and LPT Blade Service Mark Limits for TFE731-5BR-1C/-2C Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3074785 1,000 9

LPT1 3060612 1,000 10

1 3

LPT1 3074746 425 10

2 3

LPT1 3075428 425 10

LPT2 3075424 900 10

3

LPT3 3060690 210 10

3

LPT3 3060788 210 10

LPT3 3061823 900 10

LPT3 3074755 1,000 9

NOTES:

1. (Post Service Bulletin TFE731-72-3437) If new (zero time) LPT1 blades, PN 3074746 or PN 3075428 were

not installed at time of conversion to the Engine Model TFE731-5BR configuration, then LPT1 blades, PN

3074746 or PN 3075428 should be replaced once the blades have accumulated eight or more marks. The

removed blades, with eight or more marks, can be used only in Model TFE731-5R/-5AR engines to utilize the

remaining blade marking. If new blades, PN 3074746 or PN 3075428 were installed at the time of conversion

or subsequent, then the normal blade mark limit indicated in Table 17 should be used.

2. Refer to Service Bulletin TFE731-72-3576 for rotor assembly replacement.

3. Refer to Paragraph 1.E.(3)(b).

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 28

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

SERVICE BULLETIN

TFE731

(j) Refer to Table 18 for Engine Model TFE731-5BR-1H.

Table 18. HPT and LPT Blade Service Mark Limits for TFE731-5BR-1H Engines

Component Blade PN Marking Factor Blade Mark Limit

HPT 3074785 1,000 9

LPT1 3060612 1,000 10

1

LPT1 3074746 210 10

LPT2 3075424 900 10

1

LPT3 3060690 210 10

1

LPT3 3060788 210 10

LPT3 3061823 900 10

LPT3 3074755 1,000 9

NOTE:

1. Refer to Paragraph 1.E.(3)(b).

G. Enter Maintenance Action

(1) Enter the number of blades that were retired from service and engine TSN at the

time of the maintenance action on the applicable disc Life Limited Part Log Card in

accordance with the applicable engine LMM.

(2) If applicable disc is replaced during this maintenance action, update replacement disc

Life Limited Part Log Card with appropriate blade service mark limit information.

18 Feb 1994 TFE731-72-3494

Revision 13, 6 Aug 2015 Page 29

Publication Number D199402000102

© Honeywell International Inc. Do not copy without express permission of Honeywell.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cocke County SuitDocument65 pagesCocke County SuitWVLT NewsNo ratings yet

- FAA Issues AD for Learjet Flap Support StructureDocument8 pagesFAA Issues AD for Learjet Flap Support StructureJuan Ruben GarciaNo ratings yet

- 2109 GL Ak Aak 71-7Document3 pages2109 GL Ak Aak 71-7Juan Ruben GarciaNo ratings yet

- 2017-04-15Document7 pages2017-04-15Juan Ruben GarciaNo ratings yet

- Ati:F:Ht1: Service BulletinDocument42 pagesAti:F:Ht1: Service BulletinJuan Ruben GarciaNo ratings yet

- Employer Liability for Employee's Negligence Resulting in DeathDocument2 pagesEmployer Liability for Employee's Negligence Resulting in DeathMigoy DANo ratings yet

- Run Loop EmbeddedDocument5 pagesRun Loop EmbeddedpoojabadigerNo ratings yet

- 04-V1 (Q3E BW1316) - ECLOS Safety Instruction ManualDocument14 pages04-V1 (Q3E BW1316) - ECLOS Safety Instruction ManualJosé Manuel Valdez RevillaNo ratings yet

- Acc225 Business Law and RegulationsDocument201 pagesAcc225 Business Law and RegulationsJESSECA MARIE FERNANDEZNo ratings yet

- 2022.03.01 - OSH AmendmentsDocument98 pages2022.03.01 - OSH AmendmentsEZATI HANANI MURDINo ratings yet

- Criminal LawDocument177 pagesCriminal Lawyolanda paulNo ratings yet

- NLIU BHOPAL PROJECT ON ABSOLUTE LIABILITYDocument24 pagesNLIU BHOPAL PROJECT ON ABSOLUTE LIABILITYJatin MeenaNo ratings yet

- INS648 (Assignment 1) - Group PresentationDocument1 pageINS648 (Assignment 1) - Group Presentationazim02bunnyNo ratings yet

- Closely Held Business Org and Agency DutiesDocument85 pagesClosely Held Business Org and Agency DutiesnabarrowNo ratings yet

- Construction Development Corp. v. EstrellaDocument7 pagesConstruction Development Corp. v. Estrellajetzon2022No ratings yet

- Unit 1 Quantity Surveyors in ConstructionDocument11 pagesUnit 1 Quantity Surveyors in ConstructionLeon MendisNo ratings yet

- Liablity For Animals: by Sakshi BishtDocument7 pagesLiablity For Animals: by Sakshi BishtPrashant SharmaNo ratings yet

- Orion 910Document21 pagesOrion 910David DangNo ratings yet

- Accounting 9th Edition Hoggett Solutions ManualDocument35 pagesAccounting 9th Edition Hoggett Solutions Manualmellow.duncical.v9vuq100% (21)

- United Special Watchman Agency vs. CADocument6 pagesUnited Special Watchman Agency vs. CARona TumaganNo ratings yet

- 14 Landmark Medico Legal Philippine Jurisprudence 1946 To 2021 and Theory U Bunjing Transes in ProgressDocument6 pages14 Landmark Medico Legal Philippine Jurisprudence 1946 To 2021 and Theory U Bunjing Transes in ProgressJOHN PEARL FERNANDEZNo ratings yet

- Bailment & Pledge & Agency - Part 3Document14 pagesBailment & Pledge & Agency - Part 3Mehak KaushikkNo ratings yet

- G.R. No. 211535 (Bank Commerce v. Nite) Full CaseDocument6 pagesG.R. No. 211535 (Bank Commerce v. Nite) Full CaseEricha Joy GonadanNo ratings yet

- Memory aid for obligations and contracts sourcesDocument2 pagesMemory aid for obligations and contracts sourcesLeoni Francis Lagrama0% (1)

- Instant Download Solutions Manual To Accompany Stochastic Calculus For Finance II 9781441923110 PDF ScribdDocument14 pagesInstant Download Solutions Manual To Accompany Stochastic Calculus For Finance II 9781441923110 PDF ScribdToddNovakiqzmg100% (12)

- Student Copy PDF Seminar 9 AB1301 Lecture Notes - AgencyDocument40 pagesStudent Copy PDF Seminar 9 AB1301 Lecture Notes - AgencyJulianne Mari WongNo ratings yet

- GenICam License 20072005 PDFDocument11 pagesGenICam License 20072005 PDFÍcaro VianaNo ratings yet

- Types of Business Organization: Sole Proprietorships and PartnershipsDocument20 pagesTypes of Business Organization: Sole Proprietorships and PartnershipsAislinnNo ratings yet

- VICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco SalvaDocument4 pagesVICENTE CALALAS, Petitioner, Court of Appeals, Eliza Jujeurche Sunga and Francisco SalvaJude FanilaNo ratings yet

- Introduction To Law 6th Edition Ebook PDFDocument41 pagesIntroduction To Law 6th Edition Ebook PDFrobert.cervantes686100% (34)

- Proforma Invoice and Purchase Agreement No.1813972Document6 pagesProforma Invoice and Purchase Agreement No.1813972MauroRajaNo ratings yet

- Austria v. CADocument2 pagesAustria v. CAAvie UyNo ratings yet

- Drugs Week12-13 ReportingDocument24 pagesDrugs Week12-13 ReportingNyzell Mary S. ZablanNo ratings yet

- NOTES - Dec13 - Exceptions To Fortuitous EventsDocument2 pagesNOTES - Dec13 - Exceptions To Fortuitous Eventscmv mendozaNo ratings yet