Professional Documents

Culture Documents

PT-MCGDPL-MCGD-JP 07-Tie in

Uploaded by

ANURAG YADAVOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PT-MCGDPL-MCGD-JP 07-Tie in

Uploaded by

ANURAG YADAVCopyright:

Available Formats

JOB PROCEDURE

PT/MCGDPL/MCGD/JP-07/TIE-IN

LAYING & CONSTRUCTION OF 12”/8”/4” NB U/G STEEL P/L NETWORK & ASSOCIATED WORKS OF

PROJECT CITY GAS DISTRIBUTION N/W OF MCGDPL, MBNR (GA)

CLIENT MEGHA CITY GAS DISTRIBUTION PVT LTD

TPI IRCLASS SYSTEMS SOLUTION PVT LTD

PROCEDURE SPECIFICATION FOR

TIE - IN Welding

(Proposed For 12”, 8”& 4” Dia)

Review and Approval

Sign:

Name :

00 0 Reviewed By Approved By

Prepared By Checked By

Rev. Date IRCLASS MCGDPL

JP: TIE-IN WELDING PROCEDURE SPECIFICATION

REV:00 Page |1

JOB PROCEDURE

PT/MCGDPL/MCGD/JP-07/TIE-IN

LAYING & CONSTRUCTION OF 12”/8”/4” NB U/G STEEL P/L NETWORK & ASSOCIATED WORKS OF

PROJECT CITY GAS DISTRIBUTION N/W OF MCGDPL, MBNR (GA)

CLIENT MEGHA CITY GAS DISTRIBUTION PVT LTD

TPI IRCLASS SYSTEMS SOLUTION PVT LTD

Table of Contents

1.0 PURPOSE........................................................................................................................................................3

2.0 SCOPE.............................................................................................................................................................3

3.0 REFERENCE...................................................................................................................................................3

4.0 METHODOLOGY...........................................................................................................................................3

5.0 HEALTHY, SAFETY & ENVIRONMENT.......................................................................................................5

6.0 APPENDICES / FORMATS..............................................................................................................................5

JP: TIE-IN WELDING PROCEDURE SPECIFICATION

REV:00 Page |2

JOB PROCEDURE

PT/MCGDPL/MCGD/JP-07/TIE-IN

LAYING & CONSTRUCTION OF 12”/8”/4” NB U/G STEEL P/L NETWORK & ASSOCIATED WORKS OF

PROJECT CITY GAS DISTRIBUTION N/W OF MCGDPL, MBNR (GA)

CLIENT MEGHA CITY GAS DISTRIBUTION PVT LTD

TPI IRCLASS SYSTEMS SOLUTION PVT LTD

1.0 PURPOSE

The purpose of this work instruction is to establish guidelines and to establish a method or a

system to control the tie-in activity and inspection to be used in the CNG and City Gas Distribution

Project Mahabubnagar

2.0 SCOPE

The scope covers the TIE-IN joints for MEIL Pipeline Project

3.0 REFERENCE

Following documents in totality or in part shall form the reference documents: -

a. MEIL Spec. MEIL/Steel/TSP/02

b. Standard for welding of pipelines & related facilities- API 1104(Latest Edition)

c. ASME-SEC V

d. ASME SEC II PART C

e. Pipelines OISD 226

4.0 METHODOLOGY

Field welding of pipelines TIE-IN joints shall be done by SMAW process as per approved WPS.

Qualified welding procedure (WPS-02) shall be used for welding of TIE-IN joints after due

approval from MEIL.

A TIE-IN pit or bell hole of suitable length, depth and width shall be cut to enable to work freely inside the

trench. Proper care shall be taken so as not to allow pit to collapse or pit wall caving in. Necessary

supports shall be used wherever required. An angle of repose of 10º at such area is preferred.

In connecting pipes, special items, fittings on joints of differing material thickness as supplied transition

piece with 1:4 taper shall be used and the welds shall be subjected to Radiographic and Ultrasonic

(wherever applicable) examination.

Cut pipe ends shall be examined wherever applicable for laminations by Ultrasonic Testing & Dye

Penetrate Testing over distance of 25 mm minimum. Defective pipe length shall be cut back until

laminated section is removed and re-beveled for pipe which have been cut, Pipe No, Heat No. Coating

yard No, Balance length has to be transferred on to remaining pipe length. The cut piece which is used

JP: TIE-IN WELDING PROCEDURE SPECIFICATION

REV:00 Page |3

JOB PROCEDURE

PT/MCGDPL/MCGD/JP-07/TIE-IN

LAYING & CONSTRUCTION OF 12”/8”/4” NB U/G STEEL P/L NETWORK & ASSOCIATED WORKS OF

PROJECT CITY GAS DISTRIBUTION N/W OF MCGDPL, MBNR (GA)

CLIENT MEGHA CITY GAS DISTRIBUTION PVT LTD

TPI IRCLASS SYSTEMS SOLUTION PVT LTD

shall be designated by XA & the balance pipe length should designate by say pipe B specify XA, XB. Any

subsequent cutting of the pipe shall be designated as XBA, XBB.

Alignment of the TIE-IN joint shall be done using external hydraulic clamp capable of removing offset and

misalignment shall be minimized.

Seam orientation of welded pipe shall be selected to ensure that the longitudinal welds shall be staggered

in the top 90º of the pipeline or 150 mm. whichever is the less and shall be positioned in the upper half of

the pipe, not applicable with HSAW pipes. In case the seams come closer than as defined above, a pup

piece of minimum 1.0 m shall be used. For pipes of same wall thickness, the offset shall not exceed 3.0

mm.

ALL TIE-IN JOINTS SHALL BE WELDED IN ONE HEAT CYCLE.

TIE-IN shall be done in such a way as to leave minimum stress in the pipe. If any pup end is required for

TIE-IN, the minimum length shall not be less than 1.0 meter and two or more such pups shall not be

welded together. TIE-IN with two or more pups of length more than1.0 meter may be used providing a

space of entire length of pipe. In no case more than three welds shall be permitted in a 10-meter length

of pipeline.

TIE-IN joint welding including necessary cutting, beveling, grinding and line up etc. shall be carried out as

per this procedure and approved WPS.

The new field bevels shall be examined visually before offering for ultrasonic (wherever applicable)

testing. All reports of TIE-IN along with NDT reports shall be submitted to MCGDPL/TPIA for review and

approval. Cleaning, Priming, Coating and other activities shall be performed as per approved procedures.

The root gap shall be accurately checked and shall conform to the qualified welding procedure. All spaces

between bars or at least 60% of first pass shall be welded before the clamp is released and pipe

remaining adequately supported on each side of the joint.

Segments thus welded shall be equally spaced around the circumference of the pipe, Slag etc. shall be

cleaned off and the ends of the pass shall be prepared by grinding, so as to ensure continuity of the weld

bead.

Qualified welders shall carry out welding. While welding is in progress, care shall be taken to avoid any

kind of movement of the components / pipe, shocks vibration and stresses to prevent occurrence of weld

cracks.

Electrode starting and finishing points shall be staggered from pass to pass.

JP: TIE-IN WELDING PROCEDURE SPECIFICATION

REV:00 Page |4

JOB PROCEDURE

PT/MCGDPL/MCGD/JP-07/TIE-IN

LAYING & CONSTRUCTION OF 12”/8”/4” NB U/G STEEL P/L NETWORK & ASSOCIATED WORKS OF

PROJECT CITY GAS DISTRIBUTION N/W OF MCGDPL, MBNR (GA)

CLIENT MEGHA CITY GAS DISTRIBUTION PVT LTD

TPI IRCLASS SYSTEMS SOLUTION PVT LTD

Arc strikes outside the bevel on the pipe surface shall not be permitted. Accidental arc strikes shall be

repaired as per approved procedure.

All finished welds shall be visually inspected for parallel and axial alignment of the work, welds, surface

porosity and other surface defects.

Parts being welded and the welds shall be protected by windshields made of metallic frame covered by

Canvas, whenever necessary, to protect from rain and strong winds.

The completed welds shall be covered with asbestos cloth covered by GI sheets, whenever necessary, to

protect from bad weather conditions. The reports shall be submitted to MCGDPL/TPIA for review and

approval.

For TIE-IN of adjacent sections of pipeline already pressure tested also called golden joints and for final

joints, a single length pup or off cuts, which have been hydrostatically pre-tested shall be used.

All quality records generated during the welding of TIE-IN joints shall be reviewed and approved by

MCGDPL/TPIA.

5.0 HEALTHY, SAFETY & ENVIRONMENT

The approved procedure for Health, Safety & Environment shall be followed during execution.

1. It is to be noted that the special care to be adopted against snake / insects bite.

2. PPE is a must in this activity.

3. Only trained rigging personnel to be deployed for this activity.

4. All Measuring & Test Equipment used must be well maintained.

5. All lifting devices & Tools used shall be well maintained and approved by a competent authority.

6.0 APPENDICES / FORMATS

Inspection Test Plan - PT/MCGDPL/MCGD/JP-07/TIE-IN/ ITP REV.00

Inspection Report - PT/MCGDPL/MCGD/JP-07/TIE-IN/ IR REV.00

Note: In case of any conflict between the requirements of this procedure and MEIL specification; the later

shall govern.

JP: TIE-IN WELDING PROCEDURE SPECIFICATION

REV:00 Page |5

You might also like

- PT MCGPL MCGD JP 003Document6 pagesPT MCGPL MCGD JP 003ANURAG YADAVNo ratings yet

- Submission of Method Statement For Prestressing Works For T-Girder (Rev-01) From Dynamic Prestress Projects & Services Pvt. LTDDocument50 pagesSubmission of Method Statement For Prestressing Works For T-Girder (Rev-01) From Dynamic Prestress Projects & Services Pvt. LTDDinesh ChoudharyNo ratings yet

- 04 JP - WeldingDocument8 pages04 JP - WeldingShubhamShuklaNo ratings yet

- Procedure For WeldingDocument7 pagesProcedure For WeldingMecon Hyderabad100% (1)

- 04 JP - WeldingDocument8 pages04 JP - WeldingShubhamShuklaNo ratings yet

- Mos GRPDocument53 pagesMos GRPslxanto100% (3)

- 000 GPP GCX 00029 Welding and NDT MatrixDocument18 pages000 GPP GCX 00029 Welding and NDT MatrixGOPALAKRISHNAN SubramanianNo ratings yet

- Job Procedure For Mainline Welding: Document No.: CIPL-PNCPL-EIL-PL-WP-09Document7 pagesJob Procedure For Mainline Welding: Document No.: CIPL-PNCPL-EIL-PL-WP-09PNCPL PLANNINGNo ratings yet

- Rahman Heritage Tower, TangailDocument4 pagesRahman Heritage Tower, TangailHunter gamingNo ratings yet

- 1 Method Statement For Barapullah Post Tensioning Rev-CDocument20 pages1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhNo ratings yet

- ASTT - Guidelines For Horizontal DirectiDocument45 pagesASTT - Guidelines For Horizontal Directiamir_hayfa100% (1)

- Idc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingDocument18 pagesIdc-000-Mgp-Onp-Pro-005518en-01 Weld NumberingJovan Poznan100% (1)

- Expansion ProcedureDocument13 pagesExpansion ProcedureMani Tamil100% (1)

- G SM PPLT Pip 805Document12 pagesG SM PPLT Pip 805rokan123No ratings yet

- TS For Pipe-Duct DismantlingDocument10 pagesTS For Pipe-Duct DismantlingAmitava SilNo ratings yet

- Pipeline CoatingsDocument29 pagesPipeline Coatingstrpac100% (3)

- Repair Procedure CBR 3lpe 00Document3 pagesRepair Procedure CBR 3lpe 00Suresh KrishnanNo ratings yet

- Volime II of II Pipeline - JP KennyDocument199 pagesVolime II of II Pipeline - JP Kennyabhi_luvme03No ratings yet

- Repair Procedure - Zpi-3lpe-01Document3 pagesRepair Procedure - Zpi-3lpe-01Suresh KrishnanNo ratings yet

- Inspection Procedure SMALL BORE PIPINGDocument3 pagesInspection Procedure SMALL BORE PIPINGInspection jr100% (1)

- HFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ADocument14 pagesHFY-3800-0000-GEN-PD-0013 - 0 Welding and Welding Consumable Control Procedure-Code ANashaat DhyaaNo ratings yet

- DTTN DT2 PC MET EL 0011 A Method Statement For Hydraulic CrimpingDocument8 pagesDTTN DT2 PC MET EL 0011 A Method Statement For Hydraulic CrimpingTariq Ali SialNo ratings yet

- 8 KPM Duct SpecificationDocument9 pages8 KPM Duct SpecificationSAYYED RAHEELNo ratings yet

- 008 - Field Hydrotest ProcedureDocument17 pages008 - Field Hydrotest Procedurekaruna346100% (2)

- API 660 Vs TEMA RequirementsDocument3 pagesAPI 660 Vs TEMA Requirementstndeshmukh88% (8)

- Submittal 15890-001-000-mrDocument22 pagesSubmittal 15890-001-000-mrAlvin PermadiNo ratings yet

- Procedure For WeldingDocument7 pagesProcedure For Weldingshikh vasimNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- 028120-SPL-006 Linepipe and Riser Handling Rev. CDocument5 pages028120-SPL-006 Linepipe and Riser Handling Rev. CRokan PipelineNo ratings yet

- ASTT - Guidelines For Horizontal DirectiDocument45 pagesASTT - Guidelines For Horizontal DirectiFerdie TolosaNo ratings yet

- Rotary PipeCLADDocument7 pagesRotary PipeCLADsafari7No ratings yet

- Final TCP DesignDocument81 pagesFinal TCP DesignAbdul Wajid AliNo ratings yet

- Report On Industrial Training AT Dee Piping Systems Prithla (Palwal)Document20 pagesReport On Industrial Training AT Dee Piping Systems Prithla (Palwal)Amit PatelNo ratings yet

- الخليجDocument10 pagesالخليجmohamedNo ratings yet

- PFDDocument19 pagesPFDCyril JohnsonNo ratings yet

- BGRL (Satara-Sangli) - Spur Spread-3 - JP-Cold Bending - R0 - Code A - 26.02.2021Document9 pagesBGRL (Satara-Sangli) - Spur Spread-3 - JP-Cold Bending - R0 - Code A - 26.02.2021Aditya IngawaleNo ratings yet

- Method Statement For GRP Pipe InstallationDocument8 pagesMethod Statement For GRP Pipe Installationdj_holo100% (1)

- 10 Process Piping Welding Pipe To Flange, Weldolet, Fitting, If, Valve, Higher Thickness Pipe (Document11 pages10 Process Piping Welding Pipe To Flange, Weldolet, Fitting, If, Valve, Higher Thickness Pipe (Akhilesh KumarNo ratings yet

- Jacketed PipingDocument11 pagesJacketed PipingDhirendra Singh Rathore100% (7)

- Miller RMDDocument4 pagesMiller RMDRony Lesbt100% (1)

- Appendix E - Piping Material SpecsDocument6 pagesAppendix E - Piping Material Specssanjayt0100% (1)

- Hot Tap ProcedureDocument6 pagesHot Tap ProcedureNatarajan MurugesanNo ratings yet

- 002 Tipp-sct-Ahc-ms-002 Method Statment For GRP Pipe InstallationDocument30 pages002 Tipp-sct-Ahc-ms-002 Method Statment For GRP Pipe InstallationZishan AliNo ratings yet

- Piping Supervisor - AmbeDocument8 pagesPiping Supervisor - Ambesharan21v0% (1)

- Australasian Society For Trenchless Technologies - Guidelines For HDDDocument44 pagesAustralasian Society For Trenchless Technologies - Guidelines For HDDdiogenes_el_cinicoNo ratings yet

- 06 Fire Water Piping Welding ProcedureDocument10 pages06 Fire Water Piping Welding ProcedureAkhilesh Kumar100% (1)

- 006-MS For Purging of Stainless Steel PDFDocument18 pages006-MS For Purging of Stainless Steel PDFKöksal PatanNo ratings yet

- SPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionDocument14 pagesSPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionAbdul Hakam Mohamed YusofNo ratings yet

- MDPE WORK PROCEDURE For GailDocument59 pagesMDPE WORK PROCEDURE For GailSaravanan100% (1)

- Method Statement For Under CrossingDocument24 pagesMethod Statement For Under CrossingSaifur RahmanNo ratings yet

- Field Welding Procedures Manual - Contractor VersionDocument102 pagesField Welding Procedures Manual - Contractor Versionlaz_k100% (2)

- Hydraulics & Line SizingDocument20 pagesHydraulics & Line SizingM. Faisal Siddiqui100% (10)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- TGSPL Iocl Tepl C 5 01Document1 pageTGSPL Iocl Tepl C 5 01ANURAG YADAVNo ratings yet

- MDPE Work ProcedureDocument18 pagesMDPE Work ProcedureANURAG YADAVNo ratings yet

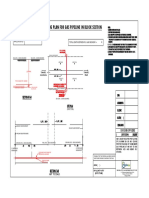

- Railway PlanDocument1 pageRailway PlanANURAG YADAVNo ratings yet

- GA 2063 Layout1Document1 pageGA 2063 Layout1ANURAG YADAVNo ratings yet

- Welding TERMINOLOGY DefinitionDocument33 pagesWelding TERMINOLOGY DefinitionrajuNo ratings yet

- New Microsoft Word DocumentDocument10 pagesNew Microsoft Word Documentkisan singhNo ratings yet

- QCS 2010 Section 17 Part 4 Architectural Metal Work PDFDocument4 pagesQCS 2010 Section 17 Part 4 Architectural Metal Work PDFbryanpastor106No ratings yet

- In-Service Welding of Pipelines Industry Action PlanDocument13 pagesIn-Service Welding of Pipelines Industry Action Planعزت عبد المنعم100% (1)

- Waterproofing: Waterstops For Expansion and Construction JointsDocument27 pagesWaterproofing: Waterstops For Expansion and Construction JointsgarusingheNo ratings yet

- Mechanical Technology Grade 12Document202 pagesMechanical Technology Grade 12Future Managers Pty Ltd95% (37)

- 2017 CatalogDocument16 pages2017 CatalognaelNo ratings yet

- Quality Control Manual Pt. BaraDocument51 pagesQuality Control Manual Pt. BaraMa'ruf firmansyah100% (1)

- E190.29610 AstmDocument4 pagesE190.29610 AstmMassab JunaidNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- SM Pc78uu-6 Sebm025118 PDFDocument1,025 pagesSM Pc78uu-6 Sebm025118 PDFarfa ujianto91% (34)

- Api 571 PDFDocument3 pagesApi 571 PDFumnartkhNo ratings yet

- Hastelloy B2 Welding Rod, Hastelloy Alloy B2 UNS N10665 Welding Rod Manufacturer in IndiaDocument3 pagesHastelloy B2 Welding Rod, Hastelloy Alloy B2 UNS N10665 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNo ratings yet

- Sterility Test Isolator en 2Document4 pagesSterility Test Isolator en 2aorustingNo ratings yet

- Objective Questions MaterialDocument14 pagesObjective Questions MaterialAshish AgarwalNo ratings yet

- WSS Welding Handbook 2013 Full Lowres PDFDocument552 pagesWSS Welding Handbook 2013 Full Lowres PDFsridharchowdary3490% (1)

- Asme Sa-358Document7 pagesAsme Sa-358Lora BoydNo ratings yet

- Auto Body Repairs and Spray Painting 1Document9 pagesAuto Body Repairs and Spray Painting 1HerbertNo ratings yet

- Xuper 2109Document2 pagesXuper 2109Brian HernandezNo ratings yet

- HL720 3Document471 pagesHL720 3Anonymous yjK3peI7100% (1)

- Astm A216-A216m-08Document4 pagesAstm A216-A216m-08selcukxNo ratings yet

- Visual TestDocument5 pagesVisual TestMohd Hafizan ZahariNo ratings yet

- Tech 7Document7 pagesTech 7Anum Zara (Zaari)No ratings yet

- Welding DesignDocument28 pagesWelding DesignSitaram JhaNo ratings yet

- Procedure - Hot TappingDocument6 pagesProcedure - Hot Tappingmanimaran_ratnam100% (4)

- Welding Filler MetalDocument1 pageWelding Filler MetalBharath KumarNo ratings yet

- Understanding Sour Service Performace of Coiled TubingDocument12 pagesUnderstanding Sour Service Performace of Coiled TubingMubeenNo ratings yet

- 005-WPS For Carbon Steel (1.6-4.6MM) PDFDocument7 pages005-WPS For Carbon Steel (1.6-4.6MM) PDFKöksal Patan0% (1)

- Unit V-Production Cost Estimation: Session 1 RecapDocument34 pagesUnit V-Production Cost Estimation: Session 1 RecapvengadeshNo ratings yet

- Pneumatic Structure-Vignesh SrinivasanDocument40 pagesPneumatic Structure-Vignesh SrinivasanVignesh SrinivasanNo ratings yet