Professional Documents

Culture Documents

1evaluation of The Causes of Flexible Pavement Failure Case Study

Uploaded by

MeleseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1evaluation of The Causes of Flexible Pavement Failure Case Study

Uploaded by

MeleseCopyright:

Available Formats

Nigerian

Nigerian Journal

Journal of Technology(NIJOTECH)

of Technology (NIJOTECH)

Vol. 40, Vol.

No. xx, No. xx

4 July, xxx,pp.558

2021, –6

xxx, pp.–1563

www.nijotech.com

www.nijotech.com

,

Print ISSN: 0331-8443

Print ISSN:

Electronic ISSN:0331-8443

2467-8821

Electronic ISSN: 2467-8821

http://dx.doi.org/10.4314/njt.v40ix.xx

http://dx.doi.org/10.4314/njt.v40i4.1

Evaluation of the Causes of Flexible Pavement Failure; Case Study

of Enugu/Port-Harcourt Expressway

E. C. Amanamba1, *, C. Chioke2, A. C. Ekeleme3

1,3Department of Civil Engineering, Abia State University, Uturu, Abia State, NIGERIA

2Department of Building and Woodwork Technology Education, Federal College of Education (Technical), Umunze, Anambra State, NIGERIA

Abstract

This study examined the causes of flexible pavement failure, taking the Enugu/Port-Harcourt expressway as a case study; to

understand possible peculiarities. Chainages 101+400 and 125+925 were the most critical, having potholes of 500mm in depth;

hence, soil samples were taken from these spots. The following tests were conducted: Particle size distribution, Atterberg limits,

Permeability, Compaction, and California Bearing Ratio (CBR). The results obtained showed evidence of presence of clay in the

subgrade; hence, concluding that the failure was mainly caused by poor soil material. From visual condition survey, it was noted

that there were no drainages even at the critical paths of the alignment, and there was a significant proportion of Heavy Goods

Vehicles (HGVs) which may not have been adequately considered during design.

Keywords: flexible pavement, pavement failure, clay, subgrade, soil test

1.0 INTRODUCTION similarly, [3,4,5,6,7] blamed soil materials of inadequate

The volume of infrastructure available to citizens strength for flexible pavement failures. According to [8],

is certainly an index for measuring national development. deterioration of flexible pavements is primarily caused by

In Nigeria, several billions are budgeted for road traffic loads exceeding the limits considered during the

construction annually. Ironically, as more roads are design of such roads. Studies by [9,10,11] suggested that

seemingly built, several more deteriorate; in fact, along these frequent flexible pavement failures are certainly a

several routes, while the contractor is still on site, some function of poor design. Amongst the several potential

sections of the alignment under construction would show causes of flexible pavement failure, [7,12,13] concluded

traces of imminent failure. The magnitude and frequency that poor drainage was the main culprit. Timely

of pavement failure in Nigeria is alarming, as virtually all rehabilitation of flexible pavements, however, can save

major highways are either being rehabilitated or in a state overall maintenance costs by over 50% [14].

of failure. This paper seeks to find justification to

Road maintenance is an integral component of the corroborate the findings of the several researchers who

entire process of highway construction and operation. have examined the causes of flexible pavement failure:

Highway maintenance is essential as it helps preserve the taking evidence from a different alignment.

highway in its original condition or nearly so; hence,

financial savings as less money would be voted for these 2.0 MATERIALS AND METHODS

highways, promote road user experience, and help 2.1 Materials

maintain the economy of the nation. Unfortunately, The road selected for this case study is the

adequate maintenance is often neglected resulting in rapid Enugu/Port-Harcourt expressway. The road is about

deterioration of the roadway and eventual failure from 200km in length, with the reference point commencing at

both environmental and vehicular impacts. ‘Naira triangle’ in Enugu state and terminating at ‘Eleme

There exist several researches on the causes of junction’ in Rivers state.

flexible pavement failure, some of the various factors Disturbed soil samples were collected at two

have been categorized. Evidence suggests that the most locations (CH 101+400 and CH 125+925) along the route.

common cause of flexible pavement failure is attributed These spots were the worst points of failure along the

to the pavement materials, especially the soil. [1,2] entire route; having absolute loss of pavement section.

suggested that attention should be paid to mixture of These samples were obtained at about 11:30hours on 10th

highway materials, to forestall flexible pavement failures, August, 2012, and soil testing began almost immediately.

The idea was to examine the subgrade soil, which would

*Corresponding author (Tel: +234 (0) 803 792 2088) usually be at a depth of 650-750mm from the wearing

Email addresses: engr.namba@gmail.com (E. C. course. It was considered that since these two test spots

Amanamba), educhioke@gmail.com (C. Chioke), had potholes of about 500mm depth, there was no point

chytony4real09@gmail.com (A. C. Ekeleme). having test pits which are beyond 500mm depth. Hence,

© FACULTY OF ENGINEERING, UNN, 2021

559 E.C. Amanamba, C. Chioke and A.C. Ekeleme

the samples were collected with a post-hole soil auger. A laboratory tests were conducted in accordance with

hole of 200mm was first dug right on the traffic bearing BS1377 Methods of Test for Soils for Civil Engineering

lanes of the carriageway, then with a soil auger, disturbed Purposes [16], and BS 6031 Codes of practice for earth

samples were taken. works [17]. The soil classification was based on

AASHTO system [18]. The sample from CH 125+925

2.2 Experimental Programme was labelled sample 1, and the sample from CH 101+400

Firstly, visual condition survey was carried out was labelled sample 2.

along the entire alignment to categorise the nature of

pavement failure. Chainages 101+400 and 125+925 were 3.0 RESULTS AND DISCUSSION

the most critical, having potholes of 500mm in depth. 3.1 Particle Size Distribution

Secondly, traffic survey was conducted to note the 200g of samples 1 and 2 were independently

composition of vehicular traffic; the traffic survey was characterised following the particle size distribution.

done for two days between the hours of 08:00 and 17:00, From table 1, the percentage passing sieve no. 200

to capture fairly, the morning and evening peak. Thirdly, (0.075mm), for sample 1 is 46.5%, and for sample 2, the

laboratory tests were conducted. The tests include: percentage passing sieve no. 200 (0.075mm) is 44.0%, as

Particle size distribution, Atterberg limits, Permeability, seen in table 2. From AASHTO classification, these

Compaction, and California Bearing Ratio (CBR), percentages show that there is presence of A-7-6 materials

following the methods adopted in a similar study [15]. All [18]; this indicates the presence of clay in the subgrade.

Table 1: Sample 1 Particle Size Distribution

Sieve size Mass Percentage Cumulative Percentage cumulative Percentage

(mm) retained (g) retained (%) mass (g) mass retained (%) passing (%)

4.760 0.0 0.0 0.0 0.0 100.0

2.380 2.0 1.0 2.0 1.0 99.0

1.190 8.0 4.0 10.0 5.0 95.0

0.600 8.0 4.0 18.0 9.0 91.0

0.425 8.0 4.0 26.0 13.0 87.0

0.300 13.0 6.5 39.0 19.5 80.5

0.150 35.0 17.5 74.0 37.0 63.0

0.075 33.0 16.5 107.0 53.5 46.5

Pan 93.0 46.5 200.0 100.0 0.0

Table 2: Sample 2 Particle Size Distribution

Sieve size Mass Percentage Cumulative Percentage cumulative Percentage

(mm) retained (g) retained (%) mass (g) mass retained (%) passing (%)

4.760 0.0 0.0 0.0 0.0 100.0

2.380 5.0 2.0 5.0 2.5 97.5

1.190 21.0 10.5 26.0 13.0 87.0

0.600 13.0 6.5 39.0 19.5 80.5

0.425 10.0 5.0 49.0 24.5 75.5

0.300 9.0 4.5 58.0 29.0 71.0

0.150 24.0 12.0 82.0 41.0 59.0

0.075 30.0 15.0 112.0 56.0 44.0

Pan 88.0 44.0 200.0 100.0 0.0

3.2 Atterberg Limit For sample 1, the liquid limit read off the plot obtained

The Casagrande apparatus method was employed was 79.8%, and for sample 2, the liquid limit read of the

in the determination of the liquid limit of the two samples. plot obtained was 85.2%. The plastic limit values were

Nigerian Journal of Technology (NIJOTECH) Vol. 40, No. 4, July 2021.

EVALUATION OF THE CAUSES OF FLEXIBLE PAVEMENT FAILURE; CASE STUDY OF ENUGU/PORT … 560

thus: 43.7% for sample 1, and 40.6% for sample 2 (see percentages show that there is presence of A-7-6 materials

table 3 and table 4). From AASHTO classification, these [18]; this indicates the presence of clay in the subgrade.

Table 3: Sample 1 Atterberg Limits

LIQUID LIMIT PLASTIC LIMIT

Container Number 1 2 3 4 5 6 7 8

Number of blows 12 19 28 38 49 - - -

Weight of wet soil + container (g) 34.4 31.8 34.0 30.7 34.3 25.2 26.0 25.7

Weight of dry soil + container (g) 26.1 24.6 26.1 24.2 26.1 22.6 23.0 22.6

Weight of water (g) 8.3 7.2 7.9 6.5 8.2 2.9 3.0 3.1

Weight of container (g) 16.1 15.7 16.1 15.9 16.1 15.9 16.1 15.6

Weight of dry soil (g) 10.0 8.9 10.0 8.3 10.0 6.7 6.9 7.0

Water content (%) 83.0 80.9 79.0 78.3 82.0 43.3 43.5 44.3

Table 4: Sample 2 Atterberg Limits

LIQUID LIMIT PLASTIC LIMIT

Container Number 1 2 3 4 5 6 7 8

Number of blows 12 20 27 38 49 - - -

Weight of wet soil + container (g) 35 33.5 34.6 33.3 34.3 26.6 25.9 25.2

Weight of dry soil + container (g) 26.1 25.2 26.1 25.4 26.1 23.4 23.1 22.5

Weight of water (g) 8.9 8.3 8.5 7.9 8.2 3.2 2.8 2.7

Weight of container (g) 16.1 15.7 16.1 15.9 16.1 15.9 16.1 15.6

Weight of dry soil (g) 10.0 9.5 10.0 9.5 10.0 7.5 7.0 6.9

Water content (%) 89.0 87.9 85.0 83.2 82.0 42.7 40.0 39.1

3.3 Permeability Test be taken as the substantive value. For sample 1, the

average of the two values obtained was 8.03×10-7, and for

The falling head method was adopted for the sample 2, the average of the two values obtained was

determination of the permeability value for both samples. 8.19×10-7. These values obtained are indicative of clay,

For each of the samples, the experiment was run twice (as according to standard chart of permeability coefficient for

recorded in table 5 and table 6), so that the average would various soil types [19].

Table 5: Sample 1 Permeability Tests

Run Initial Final Time Area of Area of Length of Permeability, K

Head, H0 Head, H1 (sec) burette, A sample, A sample, L (cm/sec)

2

(cm) (cm) (cm ) (cm2) (cm)

1 100 95 25200 1.33 23.76 7 7.97×10-7

2 95 90 26400 1.33 23.76 7 8.08×10-7

Table 6: Sample 2 Permeability Tests

Run Initial Final Time Area of Area of Length of Permeability, K

Head, Ho Head, H1 (sec) burette, A sample, A sample, L (cm/sec)

(cm) (cm) (cm2) (cm2) (cm)

1 100 95 23290 1.33 23.76 7 8.62×10-7

2 95 90 27270 1.33 23.76 7 7.76×10-7

Nigerian Journal of Technology (NIJOTECH) Vol. 40, No. 4, July 2021.

561 E.C. Amanamba, C. Chioke and A.C. Ekeleme

3.4 California Bearing Ratio adjusted with a ring factor of 4.72. For soil material to be

Table 7 shows that sample 1 had CBR value of suitable for use as subgrade, it must have a minimum CBR

3.0%, and the CBR value for sample 2 was taken to be value of 5% [20]; hence, these soil samples are clearly

3.0% too (see table 8). The tests were conducted and unsuitable as subgrade.

Table 7: Sample 1 CBR Test

Pen. (mm) 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

Dial reading 3.0 4.0 5.0 5.5 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0

Load (kN) 0.283 0.519

Dial reading 4.0 5.0 7.0 8.0 10.0 11.0 12.0 13.0 14.0 15.0 16.0 17.0

Load (kN) 0.472 0.708

Average CBR values (%) 2.8 3.0

Table 8: Sample 2 CBR Test

Pen. (mm) 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

Dial reading 1.0 2.0 3.0 4.0 5.0 6.0 8.0 9.0 10.0 12.0 13.0 14.0

Load (kN) 0.236 0.566

Dial reading 2.0 5.0 7.0 9.0 11.0 12.0 12.5 13.0 13.5 14.0 15.0 16.0

Load (kN) 0.519 0.661

Average CBR values (%) 2.8 3.0

3.5 Compaction Test For sample 1, the optimum moisture content

required to obtained maximum dry density of 1.92g/cm3

The compaction test experiment was conducted is 18.2% (see table 9); for sample 2, the optimum moisture

following the specifications of the modified proctor test: content 18.1% was achieved at dry density of

25 blows on each of 5 layers with 4.5kg rammer, 45cm 1.91g/cm3(see table 10). According to [21], soils with

drop, cylinder diameter of 15.24cm, height of 12.7cm, and optimum moisture content range between 18-20% are

volume of 2,315cm3. cohesionless soils.

Table 9: Sample 1 Compaction Test

Vol. of water added 360 120 120 120 120

Weight of cylinder + soil (g) 8090 8414 8553 8307 8145

Weight of cylinder (g) 4108 4108 4108 4108 4108

Weight of soil (g) 3983 4306 4445 4199 4037

Average water content (%) 13.6 16.1 18.2 20.4 21.4

Dry density (g/cm3) 1.720 1.860 1.920 1.814 1.744

Table 10: Sample 2 Compaction Test

Vol. of water added 360 120 120 120 120

Weight of cylinder + soil (g) 8256 8617 9033 9106 8998

Weight of cylinder (g) 4172 4172 4172 4172 4172

Weight of soil (g) 4084 4445 4861 4934 4826

Average water content (%) 14.8 16.4 18.1 20.0 21.8

Dry density (g/cm3) 1.652 1.771 1.907 1.903 1.832

4.0 CONCLUSION to assert that there are clay deposits in the

Following the surveys and experiments carried underlying layers of the pavement. The high

out on the two soil samples obtained from the worst water holding capacity of clay suggests that

portions of the deteriorated flexible pavement along the during rainy season, it will be difficult for rain

Enugu/Port-Harcourt expressway, the submissions are as water to infiltrate quickly into the earth. Clay

follows: remains saturated for a good length of time

i. Presence of clay deposits: all soil tests thereby resulting in soil volume fluctuations;

summarised in table 11 below, provide evidence cracks and potholes, a corollary.

Nigerian Journal of Technology (NIJOTECH) Vol. 40, No. 4, July 2021.

EVALUATION OF THE CAUSES OF FLEXIBLE PAVEMENT FAILURE; CASE STUDY OF ENUGU/PORT … 562

ii. Drainage: visual condition survey showed the significant presence of heavy trucks. The survey

absence of drainage along the entire route. It may results were not presented because it would be

be necessary to identify the critical portions of necessary to compare it to the traffic survey data

the alignment that requires drainage. used for the design of this highway, to ascertain

iii. Axle loading: traffic survey conducted showed if the design load has been exceeded.

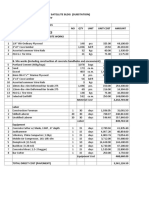

Table 11: Summary of Tests

PROPERTIES SAMPLE 1 SAMPLE 2

PARTICLE SIZE DISTRIBUTION A-7-6 Material A-7-6 Material

LIQUID LIMIT 79.8% 85.2%

PLASTIC LIMIT 43.7% 40.6%

PLASTICITY INDEX 36.1% 44.6%

-7

PERMEABILITY TEST 8.03×10 cm/sec 8.19×10-7cm/sec

CBR TEST 3% 3%

COMPACTION TEST 1.920g/cm3 (MDD) 1.910g/cm3 (MDD)

18.2% (OMC) 18.1% (OMC)

REFERENCE [8] Tarawneh, S. and Sarireh, M. “Causes of Cracks

[1] Sorum, N., Guite, T. and Martina, N. “Pavement and Deterioration of Pavement on Highways in

Distress: A Case Study,” International Journal of Jordan from Contractors’ Perspective,” Civil and

Innovative Research in Science, Engineering and Environmental Research, 3(10), (2013),16-27.

Technology, 3(4), (2014), 274-284. [9] Abubakar, S. “Bituminous Pavement Failures,”

[2] Nega, A., Nikraz, H., Herath, S. and Ghadimi, B. Journal of Engineering Research and

“Distress Identification, Cost Analysis and Application, 6(2), (2016), 94-100.

Pavement,” International Journal of Engineering [10] Adefemi, B. and Ajibola, I. “Flexible Pavement

and Technology, 7(4), (2015), 267-275. Assessment of Selected Highways in Ifelodun

[3] Onyelowe, K., Van, D., Igboayaka, C., Orji, F., Local Government, Ikirun-Osun, South –

and Ugwuanyi, H. “Rheology of Mechanical Western, Nigeria,” International Journal of

Properties of Soft Soil and Stabilization Protocols Engineering and Technology, 5(8), (2015), 475-

in the Developing Countries-Nigeria,” Materials 484.

Science for Energy Technologies, 2(1), (2019), 8- [11] Oguara, T. M. “Sustainable Development of High

14. Infrastructure in the Niger Delta Region,”

[4] Shere, T. K., Worku, A. and Keno, A. Proceedings of the Nigerian Society of Engineers

“Laboratory Investigations on the Causes of Road (NSE) Conference, (2002), 4-10.

Failures Constructed Along Asendabo to Deneba [12] Tijani, M. A. and Olawale, S. O. A. “Investigation

Road Section,” International Journal of of Flexible Pavement Failure along Ede – Akoda

Engineering Research and Technology, 7(12), Road, Osun State, Southwestern Nigeria,”

(2018),127-134. LAUTECH Journal of Civil and Environmental

[5] Rather, I. A. and Lateef, E. “Road Pavement Studies, 4(1), (2020),1-9.

Failure of Flexible Pavement from Sanat-Nagar [13] Adewoye, A. O. and Adegbola, A. A.

to Pantha-Chowk,” International Journal of “Engineering Properties of Foundational

Advanced Research in Education and Materials of Oyo-Ogbomoso Road in

Technology, 3(3), (2016), 135-137. Southwestern Nigeria,” Science Focus, 9, (2004),

[6] Oyediran, A. T. “Primary Cause of Highway 42-47.

Failure in Southwestern Nigeria and Lasting [14] Adeke, P. T., Atoo, A. A. and Orga, S. G.

Solution,” Nigeria Society of Engineers (NSE) “Assessment of pavement condition index: A

Technical Transaction, 36(3), (2001), 54-60. case of flexible road pavements on the university

[7] Jegede, G. “Pavement Failure Caused by Soil of agriculture Makurdi campus,” Nigerian

Physical Properties at a Section of the F209 Journal of Technology, 38(1), (2019) 15-21.

Highway at Ikole-Ekiti, Southwestern Nigeria,” [15] Ewa, D., Akeke, G. A. and Okoi, D. “Influence of

Journal of Biological and Physical Sciences, 1, rice husk ash source variability on road subgrade

(2000), 45-54.

Nigerian Journal of Technology (NIJOTECH) Vol. 40, No. 4, July 2021.

563 E.C. Amanamba, C. Chioke and A.C. Ekeleme

properties,” Nigerian Journal of Technology, [19] Evirgen, B., Onur, M. I., Tuncan, M. and Tuncan,

37(3), (2018), 582-586. A. “Determination of the Freezing Effect on

[16] British Standards Institute. BS 1377:1990, Unconfined Compression Strength and

Methods of Test for Soils for Civil Engineering Permeability of Saturated Granular Soils,”

Purposes, British Standards Institute, (1990), International Journal of GEOMATE, 8(2),

London. (2015), 1283-1287.

[17] British Standards Institute. BS 6031:2009, Code [20] Imafidon, D., Ogirigbo, O. R. and J. O. Ehiorobo,

of Practice for Earthworks, British Standards “Improvement of Deltaic Lateritic Soil using

Institute, (2009), London. River Sand and Cement for use as Pavement

[18] American Administration for State Highway Construction Material”, Nigerian Journal of

Officials (AASHTO). Guide for Design of Technology, 40(2), (2021), 168-176.

Pavement Structures, AASHTO, (1993), [21] Ataev, S. S. Construction Technology, Mir

California. Publishers, (1985), Moscow.

Nigerian Journal of Technology (NIJOTECH) Vol. 40, No. 4, July 2021.

You might also like

- Proceedings from the International Conference on Advances in Engineering and Technology (AET2006)From EverandProceedings from the International Conference on Advances in Engineering and Technology (AET2006)Jackson MwakaliNo ratings yet

- Pipeline DryingDocument27 pagesPipeline Dryingsiddiquiee7467% (3)

- 3causes of Failure of Flexible Pavement (A CaseDocument18 pages3causes of Failure of Flexible Pavement (A CaseMeleseNo ratings yet

- Manual - Otta SealDocument70 pagesManual - Otta SealJhossep David C. L100% (2)

- A Survey On Benchmark Defects Encountered in The Oil Pipe IndustriesDocument11 pagesA Survey On Benchmark Defects Encountered in The Oil Pipe IndustrieswdavidchristopherNo ratings yet

- Bridge Project Slum Upgrading, Agra, IndiaDocument10 pagesBridge Project Slum Upgrading, Agra, IndiaNicholas SocratesNo ratings yet

- AS Vs CBPDocument12 pagesAS Vs CBPakila47No ratings yet

- Powerpoint Presentation Road Pavement Failure (Coren Assembly) Revised FinalDocument110 pagesPowerpoint Presentation Road Pavement Failure (Coren Assembly) Revised FinalAdegboyega AdeyemiNo ratings yet

- Material Select. in Offshore IndustrDocument80 pagesMaterial Select. in Offshore IndustrRomul KNo ratings yet

- Material Offshore SelectionDocument80 pagesMaterial Offshore SelectionZaimatul SulfizaNo ratings yet

- Sintef PDFDocument80 pagesSintef PDFANILNo ratings yet

- Design Methodology Low-Cost MicrosurfacingDocument7 pagesDesign Methodology Low-Cost MicrosurfacingJohnEstevesSorianoCadilloNo ratings yet

- 2020 1910 Embedment Tests Nail Screws 3253RPTDocument8 pages2020 1910 Embedment Tests Nail Screws 3253RPTMiguel SaNo ratings yet

- Comparative review on sandcrete and laterite-cement building materialsDocument14 pagesComparative review on sandcrete and laterite-cement building materialsAsk 4olaNo ratings yet

- Esslinger-2004-The Railway Accident of Eschede-Published VersionDocument24 pagesEsslinger-2004-The Railway Accident of Eschede-Published VersionBiruk YifruNo ratings yet

- Design of Low-Cost Microsurfacing for Organic Sandy Silt SoilDocument7 pagesDesign of Low-Cost Microsurfacing for Organic Sandy Silt SoilJavier Anaya PinedaNo ratings yet

- Analysis of Lead Twist in Modern High-Performance Grinding MethodsDocument10 pagesAnalysis of Lead Twist in Modern High-Performance Grinding MethodsEralp tenderNo ratings yet

- Corrosion Propagation of Carbon Steel Rebar EmbeddDocument16 pagesCorrosion Propagation of Carbon Steel Rebar EmbeddAditya SutarNo ratings yet

- Engineering Properties of Bangkok Clay: January 2002Document7 pagesEngineering Properties of Bangkok Clay: January 2002Abdelmoez ElgarfNo ratings yet

- ARInt 2017 (8 4-05) PDFDocument11 pagesARInt 2017 (8 4-05) PDFNeven Ahmed HassanNo ratings yet

- 74 16 A ComparativeDocument7 pages74 16 A ComparativeSanjeev Kr. ThakurNo ratings yet

- Efective Leak DetectionDocument10 pagesEfective Leak DetectionEfren RamirezNo ratings yet

- PowerPoint Presentation ROAD PAVEMENT FAILURE (COREN ASSEMBLY) REVISED FINALDocument110 pagesPowerPoint Presentation ROAD PAVEMENT FAILURE (COREN ASSEMBLY) REVISED FINALSunil Bose100% (5)

- Evaluation of uphole seismic refraction data from Chad BasinDocument8 pagesEvaluation of uphole seismic refraction data from Chad BasinRenzo QuispeNo ratings yet

- Test Methods and in Uential Factors For Analysis of Bonding Between Bituminous Pavement LayersDocument12 pagesTest Methods and in Uential Factors For Analysis of Bonding Between Bituminous Pavement LayersSumanthNo ratings yet

- Ipc2010 31279 Ultrasoniccrack DetectionindemandingpipelineenvironmentsandlowDocument6 pagesIpc2010 31279 Ultrasoniccrack DetectionindemandingpipelineenvironmentsandlowMido Yehia100% (1)

- Project Material 3Document6 pagesProject Material 3Mhizta SoulmanNo ratings yet

- Combined MFD and Eddy Current Very Important1Document18 pagesCombined MFD and Eddy Current Very Important1sung quekNo ratings yet

- Jep20110800010 99970296Document7 pagesJep20110800010 99970296Elendu Emmanuel ChigozieNo ratings yet

- Van_den_Bergh_2019_IOP_Conf._Ser.__Mater._Sci._Eng._471_022031Document11 pagesVan_den_Bergh_2019_IOP_Conf._Ser.__Mater._Sci._Eng._471_022031andreystar1234No ratings yet

- Br-14 GTI ReportDocument67 pagesBr-14 GTI ReportNabendu KARMAKARNo ratings yet

- Evaluation of Collapse Mechanism of TelecommunicatDocument9 pagesEvaluation of Collapse Mechanism of TelecommunicatRossinie FometioNo ratings yet

- Infrared Imaging Reveals Temperature Differences Around Roadway ManholesDocument9 pagesInfrared Imaging Reveals Temperature Differences Around Roadway ManholesTanveshNo ratings yet

- Cor OMAE2006 92377Document9 pagesCor OMAE2006 92377iwanNo ratings yet

- Correlation of Tensile Strength of Split Cylinder Test and Double Punch Test of A Rubberized Asphalt Concrete Used in Flexible Pavement DesignDocument9 pagesCorrelation of Tensile Strength of Split Cylinder Test and Double Punch Test of A Rubberized Asphalt Concrete Used in Flexible Pavement DesignSheraz UllahNo ratings yet

- Water Infrastructure MaintainabilityDocument9 pagesWater Infrastructure MaintainabilityEvans UdomNo ratings yet

- AghameluandOkogbue2011 IJCEE PDFDocument14 pagesAghameluandOkogbue2011 IJCEE PDFKC TagleNo ratings yet

- A Comparative Study of Bs8110 and Eurocode 2 Standards For Design of A Continuous Reinforced Concrete BeamDocument10 pagesA Comparative Study of Bs8110 and Eurocode 2 Standards For Design of A Continuous Reinforced Concrete BeamHồ Anh PhiNo ratings yet

- MagbujosCharmaine LaboratoryReportNo.9 CE-3109Document4 pagesMagbujosCharmaine LaboratoryReportNo.9 CE-3109Prince RiveraNo ratings yet

- Nuclear Density Gauge Standard Count ProcedureDocument4 pagesNuclear Density Gauge Standard Count ProcedurePrince RiveraNo ratings yet

- Vibration Attenuation at Rail Joints Through UnderDocument7 pagesVibration Attenuation at Rail Joints Through UnderHossam AtifNo ratings yet

- Analysis of Tunnel For Different Subsoil Plaxis PDFDocument7 pagesAnalysis of Tunnel For Different Subsoil Plaxis PDFGuillermo MansillaNo ratings yet

- Ground Movement and Tunnel Stability in Sandy SoilDocument13 pagesGround Movement and Tunnel Stability in Sandy SoilAnonymous zpNy2bltNo ratings yet

- Mathematical Simulation of Pile Integrity Test (Pit) : November 2014Document7 pagesMathematical Simulation of Pile Integrity Test (Pit) : November 2014rivaldo wijayaNo ratings yet

- Barisua PaperDocument8 pagesBarisua PaperEBENEZER NGEKPENo ratings yet

- Effects of Sub-Grade and Sub-Base Materials QualitDocument12 pagesEffects of Sub-Grade and Sub-Base Materials Qualitbethelhem birassaNo ratings yet

- Effects of Sub-Grade and Sub-Base Materials QualitDocument12 pagesEffects of Sub-Grade and Sub-Base Materials Qualitbethelhem birassaNo ratings yet

- 2an Investigation Into The Cause of Road Failure AlDocument39 pages2an Investigation Into The Cause of Road Failure AlMeleseNo ratings yet

- Husaini 2018 IOP Conf. Ser. Mater. Sci. Eng. 352 012021Document7 pagesHusaini 2018 IOP Conf. Ser. Mater. Sci. Eng. 352 012021Andrei CanareicaNo ratings yet

- Paper Hanoi Metro ToSEAGS-AGSSEA VDDDocument7 pagesPaper Hanoi Metro ToSEAGS-AGSSEA VDDIngrid Irreño PalomoNo ratings yet

- Study On Breathe Bricks: International Research Journal of Engineering and Technology (IRJET)Document4 pagesStudy On Breathe Bricks: International Research Journal of Engineering and Technology (IRJET)Frida Faye LacsamanaNo ratings yet

- 1-New (1) .Uk - enDocument109 pages1-New (1) .Uk - enmarwa ghannamNo ratings yet

- Instrumen ProcedureDocument17 pagesInstrumen ProcedureSuswantoro ToroNo ratings yet

- Thesis AndreArsenio TUD FinalDocument166 pagesThesis AndreArsenio TUD FinalAmal KaNo ratings yet

- Optimising Resources for 10km Pipe Laying ProjectDocument11 pagesOptimising Resources for 10km Pipe Laying ProjectAytida OhorgunNo ratings yet

- E Pipe2000a 03Document2 pagesE Pipe2000a 03jack21abNo ratings yet

- Analysis of Sedimentation of Canals: March 2013Document28 pagesAnalysis of Sedimentation of Canals: March 2013jinkumalakarNo ratings yet

- Microstructural Analysis of Rail Tracks Defects: Case Study: IOP Conference Series: Materials Science and EngineeringDocument8 pagesMicrostructural Analysis of Rail Tracks Defects: Case Study: IOP Conference Series: Materials Science and EngineeringSpectro SinghNo ratings yet

- 179695-Article Text-458697-1-10-20181115Document8 pages179695-Article Text-458697-1-10-20181115minaNo ratings yet

- 5investigation of The Causes of Severe Asphalt Damagedon Road Pavement in Addis Ababa Jimma RoadDocument9 pages5investigation of The Causes of Severe Asphalt Damagedon Road Pavement in Addis Ababa Jimma RoadMeleseNo ratings yet

- Causes and Remedies of Flexible Pavement DeteriorationDocument15 pagesCauses and Remedies of Flexible Pavement DeteriorationMeleseNo ratings yet

- 2an Investigation Into The Cause of Road Failure AlDocument39 pages2an Investigation Into The Cause of Road Failure AlMeleseNo ratings yet

- Geotechnical Challenges in Highway Engineering in Twenty First CeDocument12 pagesGeotechnical Challenges in Highway Engineering in Twenty First CeCatalin VeghiuNo ratings yet

- Site Investigation Manual OverviewDocument4 pagesSite Investigation Manual OvervieweyerusalemhNo ratings yet

- International Journal of Information Technology, Control and Automation (IJITCA)Document2 pagesInternational Journal of Information Technology, Control and Automation (IJITCA)ijitcajournalNo ratings yet

- IGNOU - Examination Form AcknowledgementDocument2 pagesIGNOU - Examination Form Acknowledgementsinghabhithakur111No ratings yet

- The School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiDocument26 pagesThe School and The Community: Prepared By: Sen Xiao Jun Mohana Sundra Segaran Kaviyanayagi PonuduraiKaviya SKTDSNo ratings yet

- Os8 - XCVR 8.7r3 RevaDocument85 pagesOs8 - XCVR 8.7r3 RevaDouglas SantosNo ratings yet

- BG BG 202102080912862 User Manual - File (Long) BG BG-8Document1 pageBG BG 202102080912862 User Manual - File (Long) BG BG-8hofolo39No ratings yet

- Awareness On Biomedical Waste Management Among Dental Students - A Cross Sectional Questionnaire SurveyDocument8 pagesAwareness On Biomedical Waste Management Among Dental Students - A Cross Sectional Questionnaire SurveyIJAR JOURNALNo ratings yet

- Husserl - Amsterdam LecturesDocument13 pagesHusserl - Amsterdam LecturesPhilip Reynor Jr.No ratings yet

- Duobias M 200 TM Section02 Performance SpecificationDocument12 pagesDuobias M 200 TM Section02 Performance SpecificationtonytomsonNo ratings yet

- PROPOSED ARFF BUILDINGDocument27 pagesPROPOSED ARFF BUILDINGDale Bryan S DalmacioNo ratings yet

- Unit 3 Digital Documentation: Multiple Choice QuestionsDocument7 pagesUnit 3 Digital Documentation: Multiple Choice Questions07tp27652% (21)

- Registration Confirmation: 315VC18331 Aug 24 2009 7:47PM Devashish Chourasiya 24/05/1989 Mechanical RanchiDocument2 pagesRegistration Confirmation: 315VC18331 Aug 24 2009 7:47PM Devashish Chourasiya 24/05/1989 Mechanical Ranchicalculatorfc101No ratings yet

- Strategic ManagementDocument7 pagesStrategic ManagementSarah ShehataNo ratings yet

- Oisd STD 175Document59 pagesOisd STD 175yandiNo ratings yet

- Autodesk Revit 2014 ContentDocument6 pagesAutodesk Revit 2014 ContentGatot HardiyantoNo ratings yet

- Teaching Speaking: Daily Activities Lesson PlanDocument3 pagesTeaching Speaking: Daily Activities Lesson PlanMARCELANo ratings yet

- Adobe Scan 25 Dec 202Document1 pageAdobe Scan 25 Dec 202Jimit ShahNo ratings yet

- Autochief® C20: Engine Control and Monitoring For General ElectricDocument2 pagesAutochief® C20: Engine Control and Monitoring For General ElectricВадим ГаранNo ratings yet

- Alfa Laval DecanterDocument16 pagesAlfa Laval DecanterAKSHAY BHATKARNo ratings yet

- Galvanic CorrosionDocument5 pagesGalvanic Corrosionsatheez3251No ratings yet

- The Power ParadoxDocument27 pagesThe Power ParadoxKieran De PaulNo ratings yet

- Fif-12 Om Eng Eaj23x102Document13 pagesFif-12 Om Eng Eaj23x102Schefer FabianNo ratings yet

- Nasya - Paralellism - New Dengan Tambahan Dari LongmanDocument28 pagesNasya - Paralellism - New Dengan Tambahan Dari LongmannasyaayuNo ratings yet

- Netprobe 2000Document351 pagesNetprobe 2000Jordon CampbellNo ratings yet

- Net CallDocument2 pagesNet CallFerdinand Monte Jr.100% (2)

- Assignment 7Document1 pageAssignment 7sujit kcNo ratings yet

- Limit of Outside Usage Outside Egypt ENDocument1 pageLimit of Outside Usage Outside Egypt ENIbrahem EmamNo ratings yet

- Base Case Analysis Best CaseDocument6 pagesBase Case Analysis Best CaseMaphee CastellNo ratings yet

- BERGSTROM, Karl Jones. Playing For Togetherness (Tese)Document127 pagesBERGSTROM, Karl Jones. Playing For Togetherness (Tese)Goshai DaianNo ratings yet

- Einstein and Oppenheimer's Real Relationship Was Cordial and Complicated Vanity FairDocument1 pageEinstein and Oppenheimer's Real Relationship Was Cordial and Complicated Vanity FairrkwpytdntjNo ratings yet

- Time May Not Exist - Tim Folger in DiscoverDocument3 pagesTime May Not Exist - Tim Folger in DiscoverTrevor Allen100% (5)