Professional Documents

Culture Documents

26 63

26 63

Uploaded by

Abdallah Elhendy0 ratings0% found this document useful (0 votes)

25 views44 pagesOriginal Title

26-63

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views44 pages26 63

26 63

Uploaded by

Abdallah ElhendyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 44

Part Number 26-63

MDTotco ne

ILLUSTRATED PARTS BREAKDOWN

CRANE LOAD INDICATOR SYSTEM

Printed in USA. February 15, 1981

Manual 26-63 contains 44 pages as follows:

Cover

i through vi

4-1 through 1-7

2:0 through 2-11

3-0 through 3-8

4-4 through 4-6

5-1 through 5-2

6-1 through 6-2

All product, brand, or trade names used in this publication are the trademarks or registered trade:

marks of their respective owners.

February 1981

February 1981

February 1981

. February 1981

February 1981

February 1981

February 1981

February 1981

Information in this manual is subject to change without notice.

IMPORTANT SAF! NOTICE

Proper service and repair is important to the sate, reliable operation of all W/D TOTCO equipment.

‘The service procedures recommended by M/D TOTCO and described in the technical manuals are

recommended methods of performing service operations. When these service operations require

the use of tools specially designed for the purpose, those special tools should be used as recom:

mended. Warnings against the use of specific service methods that can damage equipment or

render it unsafe are stated in the manuals. These warnings are not exclusive, as M/D TOTCO

could not possibly know, evaluate and advise service people of all conceivable ways in which ser-

vice might be done or of all possible associated hazardous consequences. Accordingly, anyone

who uses service procedures or tools which are not recommended by M/D TOTCO must first sat-

isfy themselves thoroughly that neither personnel safety nor equipment safety will be jeopardized

by the method selected

February 1981

MWD Totco

LIMITED PRODUCT WARRANTY

‘THE FOLLOWING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER,

EXPRESS, IMPLIED OR STATUTORY, INCLUDING, BUT NOT BY WAY OF LIMITATION, ANY WARRANTY

(OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

Martin-Decker TOTCO ("Company") warrants to Buyer (“Purchaser of new products manufactured or

supplied by the Company that such products are, at the time of delivery to the Purchaser, free of material and

workmanship defects, subject to the following excoptions:

‘A. Any product which has been repaired or altered in such a way, in the Company's judgement, as to affect

the product adversely, including any repairs, rebuilding, welding or heat treating outside of Company

authorized facility

Any product which has, in the Company's judgement, been subject to negligence, accident, or improper

storage.

. Any product which has not been installed, operated and maintained in accordance with normal practice

‘and within the recommendations of the Company.

D. For all items of special order by Buyer which are not manufactured by Company, Buyer should submit

warranty claims directly to the manufacturer thereof.

The Company's obligation under this warranty is limited to repairing, or at ts option, replacing any products

which in its judgement proved not to be as warranted within the applicable warranty period, All costs of

transportation of products claimed not to be as warranted to authorized Company service facility shall bo

borne by Buyer. Costs of return transportation to Buyer of products accepted for repair or replacement by

‘Company under the warranty provisions of the Sales Agreement shall be borne by the Company. Company

‘may, at its sole option elect to refund the purchase price of the products, and Company shall have no further

obligation under the Sales Agreement.

The cost of labor for installing a repaired or replacement part shall be borne by Buyer. Replacement parts

provided under the terms of this warranty are warranted for the remainder ofthe warranty period of the

product upon which installed to the same extent as if such parts were original components thereof.

‘The warranty periods for various products are:

‘A. Hydraulic, Mechanical, Electronic Equipment: one (1) year from date of installation or fiteen (15) months

from date of shipment from Company, whichever occurs firs.

B. All Elastomer Diaphragms: six (6) months from date of shipment from Company.

No doviations from the Company's standard warranty terms or period as stated herein will be honored unloss.

‘agreed to in writing by an authorized Company representative prior to acceptance of the order.

EXCLUSIVITY OF REMEDY AND LIMITATION OF LIABILITY. THE REMEDIES PROVIDED FOR IN THIS

WARRANTY SHALL CONSTITUTE THE SOLE RECOURSE OF BUYER AGAINST COMPANY FOR

BREACH OF ANY OF COMPANY'S OBLIGATIONS UNDER THE SALES AGREEMENT WITH BUYER,

WHETHER THE CLAIM IS MADE IN TORT OR IN CONTRACT, INCLUDING CLAIMS BASED ON

WARRANTY, NEGLIGENCE, OR OTHERWISE,

IN NO EVENT SHALL COMPANY BE LIABLE FOR DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, REGARDLESS OF THE FORM OF ACTION, WHETHER IN CONTRACT,

‘STRICT LIABILITY OR IN TORT (INCLUDING NEGLIGENCE), NOR FOR LOST PROFITS,

Page iv February 1981

MID Totco

INSTRUCTION MANUAL 26-63

TABLE OF CONTENTS

Section Page

T INTRODUCTION © ee ee eee

a1 Introduction»... 0. oo

4 Group Assembly Parts List Section) 2.212.100

6 + Figure and Index Number Column... see eee

7 + Part Number Colum 2. eee eee ee ee eee

-8 + Description Colum . 2... ee ee eee

1

1

“10. Units Per Assembly Colum. 2... . 04

“11. Use on Code Colum...

1-12 Numerical Index Section... .

1-14, Second and Succeeding Position Arrangement

1-15 Additional Parts Lists... ee eee as

1-17 How to Use the Illustrated Parts Breakdown

1-20 Catalog Numbers Versus Part Numbers

Ir GROUP ASSEMBLY PARTS LIST (ENGLISH)... see ee eee eee

ur GROUP ASSEMBLY PARTS LIST (SI) 2...) ee eee ee

Iv NUMERICAL INDEX oe ee ee ee ee ee

v Spame(PARTSSL TOTS fe) ee ee

Sei General’ Intornacion 9) 9 0 fa ests eee

vr ADDITIONAL DATA. eee ee ee ee

6-1 Crane Load Indicator Systems Listing... +

LIST OF ILLUSTRATIONS

Figure Page

ast How to Use the Illustrated Parts Breakdown... 2-54-24. + 1-2

12 Crane Load Indicator Catalog Numbering System... . 1.4... - 1-6

a1 Crane Load Weight Indicator System Details, Typical... +... + 2-0

(English)

2-2 Load Cell Assembly, 6.53 Sq In. Non-Spin Piston... 2-2 +

2-3 Load Cell Assembly, 10.8 Sq In. Non-Spin Piston... .-. + +

24 Weight Gauge Assembly, Typical (Mnglish). ...-.- +. ++

2-5 Short Linkage Assembly ...-.--+---- fees

2-6 7

3-1 5

3-2 6

Damper Assembly, High-Pressure, Gauge Mount .- +--+ ++ -

Crane Load Weight Indicator System Details, Typical (SI Units)

Weight Gauge Assembly, Typical (SI Units)... + +e ee ee

LIST OF TABLES

Table Page

Sel Recommended Spare Parts List... ee eee ee ee OF

6-1 CL System Configurations... ee ee

INSTRUCTION MANUAL 26-63

INSTRUCTION MANUAL 26-63

SECTION |

INTRODUCTION

INTRODUCTION

‘This manual contains an illustrated parts breakdown for the Crane Load

Weight Indicator System manufactured by TOTCO.

1-3 This section describes how to use the Group Assembly Parts List, Numerical

Index (when included), Recommended Spare Parts List (when included), and

any other parts identification and ordering data.

GROUP ASSEMBLY PARTS LIST SECTION

The Group Assembly Parts List Section (Figure 2-1 and subsequent) includes

detailed or exploded views accompanied by parts lists keyed to the index

numbers on the illustrations, Each assenbly is listed in its order of disassembly.

Detail parts descriptions are indented to show relationship to their assenblies.

Attaching parts are listed inmediately following the parts they attach and are

identified by the abbreviation (AP) following the descriptions. Attaching parts

are indented at the same level as the items they attach. The relationship of each

part to its next higher assembly or main group is shown either by indention or by

cross reference notes.

1-6 FIGURE AND INDEX NUMBER COLUMN. In this column the digit(s) preceding the

dash refer to the figure in the parts breakdown on which a part or assembly

is illustrated (See Figure 1-1). Digit(s) following the dash are the figure numbers

for the parts. An asterisk(*) following dash indicates the part is not illustrated.

1-7? PART NUMBER COLUMN. This column lists TOTCO part numbers, part numbers of

suppliers to TOTCO and also standard items. Part numbers are used ex-

clusively to identify parts. The entry STD HDWE in this colum means hardware,

without an assigned part number, and available from normal commercial sources.

Information for purchase of these items is contained in the DESCRIPTION column.

1+8 DESCRIPTION COLUMN. This column lists each assembly, its attaching parts

(AP) and detail parts of the assembly indented to show their relationship

to the assembly. Where vendor-supplied parts are used by TOTCO, the manufacturers’

names are included in this column. Parts identified with (AP) are attaching parts

for items and assemblies. Where it is impractical to show completely in one il-

lustration all detail parts of any one subassembly, the subassembly is illustrated

completely assembled on this illustration and a separate view of the subassembly

is furnished. A notation in parentheses following the part description, cross

refers the subassembly to its illustration. A notation in parentheses following

the description of the part on the subassembly view refers to the figure and index

number of the subassembly on the next higher assembly (NHA) illustration.

1-9 Listed parts are indented to indicate item relationship of next higher

assembly. The description of each assembly is followed in the list (except

for attaching parts) by its detail parts indented one column to the right (See 4,

Figure 1-1). To determine the next higher assembly of a part or assembly, note the

column in which the first word of the nomenclature appears. The first item directly

above which appears one column to the left (except for attaching parts) is the next

higher assembly.

INSTRUCTION MANUAL 26-63

Identifying and locating parts

information in the parts list

and associated illustration.

1 Fg number. oe

2. Index number of a part on the

illustration and accompanying

parts list. Index number in

parts tat ara assigned in

disassembly order [BE

3 Part number of assomblies 6! lea

illustrated detail parts.

4 Description of parts indented a EEE

to show relationship to the

assembly of which it is a part.

Tew elevis, 8, ig a detail part :

of cylinder assembly, part number

26-1890, Spring, =18, is @ port of

piston rod and calibration spring

fesembly, part number 28-0899,

5 Attaching parts (AP) are always .

indented at the same level as.

and directly beneath, the item

they secure.

Noxt higher assembly (NHA}

ces indicate the

iMlustration and index number on

Which the assembly is shown in

2 completely assembled condition}

‘and also the assembly of which

itis a part

‘Quantity of parts used in one,

fF to attach one, part or

assembly

8 ‘Use on Codes’ define specific

differences between similar

‘assemblies. For example,

dented parts bearing code A

‘are used only in the assembly

bearing the same A code.

Where there is no code lettor

assigned in the USE ON CODE

column, uncoded detail parts

parts List.

FIGURE 1-1. HOW TO USE THE ILLUSTRATED PARTS BREAKDOWN (Sheet 1 of 3)

INSTRUCTION MANUAL 26-63

To identify a part when the

part number IS known:

1 hon the part number is known,

refer to the Numerical

\Section VIN). Locate the part

umber and note the figure and

Index number on which the part

2 Turn to the figute number indicated)

‘and locate the index umber that

was referonced in the Numerical

Index.

3. Ita pictorial representation of the

OF its location is desired.

refer to the same index number on

the accompanying illustration.

FIGURE 1-1. HOW TO USE THE ILLUSTRATED PARTS BREAKDOWN (Sheet 2 of 3)

INSTRUCTION MANUAL 26-63

To identify a part when the a

part number is NOT known:

1. Determine the function and

applications of the part required. aes

Turn to the List of Mlusteations

‘and select the most appropriate

title. Note the illustration page |

umber.

2 urn to the page indicated and

locate the part on the illustration

3. From the illustration, obtain the

indox number assigned to the part. :

Refer to the accompanying description

for specific information regarding a

the part.

FIGURE 1-1.

HOW TO USE THE ILLUSTRATED PARTS BREAKDOWN (Sheet 3 of

3)

INSTRUCTION MANUAL 26-63

UNITS PER ASSEMBLY COLUMN. This column lists the number of units required

for one next higher assembly. The quantities specified, therefore, are

not necessarily the total number used per installation or end item. AR denotes

that parts should be selected as required. ‘The term REF denotes parts which are

listed for reference purposes. Units per assembly for other REF items are shown

on the appropriate figures referenced in the DESCRIPTION column. NP denotes parts

which are not procurable.

1 USE ON CODE COLUMN. Code letters in this column show variations in parts

on two or more similar assemblies. Parts peculiar to a particular assembly

are identified by the same code letter as the main assembly; common parts are un-

coded.

2 NUMERICAL INDEX SECTION (when Included)

1-13 The Numerical Index Section contains an alphanumerical listing of parts

and/or drawings that are listed in the Group Assembly Parts List. Standard

hardware items are not included. Alphabetical part identifiers are listed first,

followed by numerical listing. The index is arranged in order of precedence

beginning on the extreme left-hand (first) position as follows:

Letters A through Z

Numbers 0 through 9

1-14 SECOND AND SUCCEEDING POSITION ARRANGEMENT. The order of precedence in

continuing the part number arrangement in the second and succeeding posi-

tions of the part number from left to right is as follows:

(@) Space (blank column) (5) Letters A through Z

(2) Diagonal (slant) (6) Numbers 0 through 9

(3) Point (period)

(4) Dash (-)

1+15 ADDITIONAL PARTS LISTS (SECTIONS) (When Included)

1:16 Additional informative lists, such as Recommended Spare Parts List and

Fuse List, follow the Group Assembly Parts List Section or Numerical Index

Section (as applicable).

1+17 HOW TO USE THE ILLUSTRATED PARTS BREAKDOWN

18 If the item part number is known, turn to the Numerical Index for the

applicable figure and index number. Locate the illustration and descrip-

tion of the part in the Group Assembly Parts List, using the figure and index number.

1-19 If the item part number is unknown, turn to the List of Illustrations and

locate the figure and breakdown on which the part appears. Identify the

part on the illustration and use its figure and index number to find the part number

and description in the Illustrated Parts Breakdown.

1-5

INSTRUCTION MANUAL 26-63

1-20 CATALOG NUMBERS VERSUS PART NUMBERS

1:21 Certain product line equipment systens are coded with catalog numbers in

addition to part nunbers, These catalog numbers are listed in parentheses

under the system part numbers In the Group Assembly Parts List Section(s). Catalog

numbers are also cross-referenced in the Numerical Index Section. (See Figure 1-2

for catalog numbering systen.)

1-6

INSTRUCTION MANUAL 26-63

CRANE LOAD INDICATOR SYSTEM, ENGLISH AND SI UNITS

EACH CRANE LOAD SYSTEM INCLUDES

‘© 6’ Fuie-filed Gauge with Zero Adjust Dial for specitic number of lines strung, mounted in a steel box

'¢ Hydraulic Piston Type Cylinder

¢ 2 Shackles

‘# 25" of 5,000 psi WP Hose

Hand Pump and Fluid

SPECIFICATION VARIABLES

Single Line Pull Capacity

‘Number of Lines Strung

AVAILABILITY CHART

Single Line Pull Capacity

Lbs.) (é Number of Lines Strung

10.000 5.000

ee | 2 |

20,000 8.000 24

L —_____ 4

| 11.000 46

6

30,000

‘SPECIFYING CATALOG NUMBER FOR ORDERING PURPOSES,

(1) Verity that your requirement can be met by reterring to the availabilty chart above

(2) Using the example below as a guice, develop your own catalog number using the ordering codes table.

EXAMPLE: cL—020~24

ee

SingiéTine Number of

Pull Capacty Lines Strung

CL = Crane Load

(020 ~ 20,000 Ib. Single Line Pull Capacity

24 = Number of Lines Sung

All Crane Load System catalog numbers should begin with CL. and be followed by § identilying numbers as shown.

NOTE: For Si configurations add SI to the catalog number For example: CL-020-24-SI

ORDERING CODES

Single Line Number of

Pull Capacity (Lbs.) _ Code Lines Strung Code

10,000 010 2 02

20,000 020 4 04

25,000 025 24 24

30,000 030 46 46

6 06

FIGURE 1-2. CRANE LOAD INDICATOR CATALOG NUMBERING SYSTEM

INSTRUCTION MANUAL 26-63

SECTION 11

GROUP ASSEMBLY PARTS LIST

CRANE LOAD INDICATOR SYSTEM (ENGLISH)

20

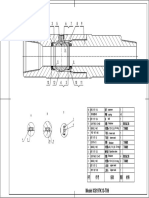

FIGURE 2-1.

CRANE LOAD WEIGHT INDICATOR SYSTEM DETAILS, TYPICAL

(ENGLISH)

INSTRUCTION MANUAL 26-63

NOTE

Refer to Table 6-1 for system configurations

and capabilities, The following listed Crane

Load (CL) Weight Indicator Systems (English)

all include:

a. A box-mounted, 6-inch weight gauge.

b. A cylindrical, tension-type, load cell

(6.53 or 10.8 sq in,, non-spin piston,

with two shackles.

c. A hydraulic hose assembly with quick-

disconnect fittings.

d. A fluid hand pump and one quart of

instrument fluid.

UNITS: USE

PART NUMBER DESCRIPTION PER on

(CATALOG NO.) 1234567 ASsY CODE

2a 213266 CL SYSTEM, Two lines, 10,000 Ib per... 1 A

(cL-010-02) line, 6.53 load cell

213267 CL SYSTEM, Four lines, 10,000 1b per -. 1 B

(CL~010-04) line, 6.53 load cell

213268 CL SYSTEM, Six lines, 10,000 1b per... 1 c

(cL-010-06) line, 6.53 load cell

213269 CL SYSTEM, Two and four lines , 10,000 . 1 D

(CL-010-24) Ib per line, 6.53 load cell

213270 CL SYSTEM, Four and six lines, 10,000... 1 E

(CL~010-46) 1b per line, 6.53 load cell

213281, CL SYSTEM, Two Lines, 20,000 Ib per... 1 F

(CL-020-02) line, 6.53 load cell

213282 CL SYSTEM, Four lines, 20,000 1b per .. 1

(CL~020-04) Line, 6.53 load cell

213283, CL SYSTEM, Six lines, 20,000 1b per... 1 u

(CL-020-06) line, 6.53 load cell

213284 CL SYSTEM, Two and four ines, 20,000 .. 1 I

(CL-020-24) 1b per line, 6.53 load cell

213285 CL SYSTEM, Four and six lines, 20,000... 1 J

(CL~020-46) 1b per line, 6.53 load cell

213296 CL SYSTEM, Two lines, 25,000 1b per... 1 K

(CL~025-02) line, 6.53 load cell

213297 CL SYSTEM, Four lines, 25,000 1b per. . 1 L

(cL-025-04) line, 6.53 load cell

213298 CL SYSTEM, Six lines, 25,000 1b per... 1 ™

(cL-025-06) Line, 6.53 load cell

213299 CL SYSTEM, Two and four lines, 25,000... 1 N

(CL-025-24) 1b per line, 6.53 load cell

213300 CL SYSTEM, Four and six lines, 25,000... 1 °

(c1-025-46) Ip per line, 6.53 load cell

INSTRUCTION MANUAL 26-63

FIG. & UNITS USE

INDEX PART NUMBER DESCRIPTION PER ox

No. (CATALOG NO.) 1234567 Assy CODE

al 213311 CL SYSTEM, Two Lines, 30,000 1b per... 1 P

(CL-030-02) line, 10.8 load cell

213312 CL SYSTEM, Four lines, 30,000 1b per... 1 Q

(CL-030-04) Line, 10.8 load cell

213313 CL SYSTEM, Six lines, 30,000 1b per... 1 R

(C1-030-06) line, 10.8 load cell.

213314 CL SYSTEM, Two and four lines, 30,000... 1 s

(CL-030-24) Ib per line, 10.8 load cell

213315 CL SYSTEM, Four and six lines, 30,000... 1 T

(CL=030~46) Ab per line, 10.8 load cell

ol 970621-012. DUST CAP, Male... 2... 1

-2 970621-008 | COUPLING, Female... ea

3 210658-125 | HOSE ASSY, Hydraulic, 25 feet | aa

m4 9205-205 . SHACKLE, 1 in., 1-1/8 in. pin. 2 A thru 0

(16 tons)

999205-206 SHACKLE, 1-1/8 in., 1-1/4 in. pin. « 2 P thru

(17.5 tons)

5 212371-102 «. LOAD CELL ASSY, Tension type, non- - sl A thru 0

spin, 6.53 Sq in, (See Figure

2-2 for details)

212360-102 —-. ‘LOAD CELL ASSY, Tension type, non- - 1 P thru T

spin, 10.8 sq in. (See Figure

2-3 for details)

~6 970621-013 «=. : DUST CAP, Temale +--+ +--+ +++ 2

-7 970621-009 . COUPLING, Male»... eee e ee 2

-8 968202-002 NIPPLE, Hex, 1/4 NPT... +. se 2

-9 210366 2 ELBOW, Street, hex se. ee ee ee 2

-10 210368 Bo rretcercet neste eee)

=i 212985-101 |, WEIGHT GAUGE ASSY, ‘Tuo lines,» 2... 1 A

10,000 1b per line (See Figure

2-4 for details)

212985-102 —-. WEIGHT GAUGE ASSY, Four lines, .. ~~ 1 B

10,000 1b per line (See Figure

2-4 for details)

212985-103 WEIGHT GAUGE ASSY, Six lines, . - 5 c

10,000 1b per line (See Figure

2-4 for details)

212985-104 WEIGHT GAUGE ASSY, Two and four... . 1 D

lines, 10,000 1b per line (See

Figure 2-4 for details)

212985-105 «WEIGHT GAUGE ASSY, Four and six « 1 E

lines, 10,000 1b per line (See

Figure 2-4 for details)

212988-101 «WEIGHT GAUGE ASSY, Two lines, 20,000. . 1 F

1b per line (See Figure 2-4 for

details)

212988-102 =~. WEIGHT GAUGE ASSY, Four lines, 20,000. 1 G

1b per line (See Figure 2-4 for

details)

INSTRUCTION MANUAL 26-63

FIG. &

INDEX

No.

PART NUMBER

1

DESCRIPTION

234567

UNITS

PER

Assy

USE

oy,

cope

QeLell

-13

“14

-15

-16

212988-103

212988-104

212988-105,

212991101

212991-102

212991-103,

212991-104

212991-105,

212994~101

212994-102

212994-103,

212994-104

212994-105

999393-025

1999321-320

210017

212450-102

214359-101,

. WEIGHT GAUGE ASSY, Six lines, 20,000.

Ib per Tine (See Figure 2-4 for

details)

WEIGHT GAUGE ASSY, Two and four. .

Lines, 20,000 ib per line (See

Figure 2-4 for details)

. WEIGHT GAUGE ASSY, Four and six...

Lines, 20,000 ib per line (See

Figure 2-4 for details)

. WEIGHT GAUGE ASSY, Two lines, 25,000.

1b per line (See Figure 2-4 for

details)

WEIGHT GAUGE ASSY, Four lines, 25,000

1b per line (See Figure 2-4 for

details)

. WEIGHT GAUGE ASSY, Six lines, 25,000.

Ub per Line (See Figure 2-4 for

details)

WEIGHT GAUGE ASSY, Two and four . «

lines, 25,000 1b per line (See

Figure 2-4 for details)

. WEIGHT GAUGE ASSY, Four and six. - «

lines, 25,000 1b per Line, (See

Figure 2-4 for details)

WEIGHT GAUGE ASSY, Two lines, 30,000

1b per line (See Figure 2-4 for

details)

. WEIGHT GAUGE ASSY, Four lines, 30,000

1b per line (See Figure 2-4 for

details)

WEIGHT GAUGE ASSY, Six lines, 30,000

Lb per line (See Figure 2-4 for

details)

WEIGHT GAUGE ASSY, Two and four . . -

Lines, 30,000 1b per line (See

Figure 2-4 for details)

WEIGHT GAUGE ASSY, Four and six -

Lines, 30,000 ib per line (See

Figure 2-4 for details)

~ SCREW, Hex hd, 1/420 x 1/2... .

cd pl (AP)

« LOCKWASHER, Split, 1/4, cd pl (AP)-

1 BOX ASSY, Steel, 6-in. gauge...»

\ HAND PUMP, Hydraulic fluid... ~~

+ INSTRUMENT FLUID, M-15, hy- + + + + +

draulic, 1 qt can

1

INSTRUCTION MANUAL 26-63

FIGURE 2-2. LOAD CELL ASSEMBLY, 6.53 SQ IN. NON-SPIN PISTON

FIG

UNITS USE

INDEX. DESCRIPTION PER ox,

No. PART NUMBER 1.234567 ass¥ CODE

212371-102 LOAD CELL ASSY, CYLINDRICAL, Tension~. . . REF

type, non-spin piston, 6.53 sq in.

(See'5, Figure 2-1 for NHA)

-1 210440 + IDENTIFICATION PLATE. 2... 1

-2 999241-008 + DRIVE SCREW, No. 2 x 3/16, sst (AP). 2

-3 210366 + ELBOW, Street, hex, 1/4-18 NPT . el

“4 999324-230 + SETSCREW, Skt hd, 3/8-24 x 3/8 cp pt. - 1

5 212370-302 + CYLINDER HEAD, 6.53... .-...-- 1

6 7-023 + GASKET, Flange, 35/8 x4x1/8 2... 1

-7 999334-100 + SCREW, Rd hd, 1/4-20 x 3/8, brass... 1

-8 933206-106 = SEA beoauge 1

212372-102 | PISTON AND ROD Assy |) 12 teed

999324~202 1. SETSCREW, 1/4-20 x 1/2, cp pt 1... NP

212373, +. PISTON (incl dowels PN 999259-310) . . XP

212368 2. ROD, Piston see eee ee eee MP

979456~222 TORING... ell cee seers d

979456-336 © O-RING. Fe ee ee ee ee ee

979456-127 LORINGS . oe eee ee eee

979453-070 DSEAL. oe ce ee eee ee eee

212374 CYLINDER BODY, 6.53. . 22. eee ee 1

210984 REPAIR KIT, 6.53 load cell (includes » 1

index nos. 6, 8, 12 thru 15)

INSTRUCTION MANUAL 26-63

FIGURE 2-3. LOAD CELL ASSEMBLY, 10.8 SQ IN. NON-SPIN PISTON

FIC. & uNITs ust

INDEX DESCRIPTION PER On

no. PART NUMBER 1234567 ASSY CODE |

23+ 212360-102 “LOAD CELL ASSY, CYLINDRICAL, Tension-, | , REF

type, non-spin piston, 10.8 sq in.

(See 5, Figure 2-1 for NHA)

a1 210440 + IDENTIFICATION PLATE: - - ss ss 1

-2 999241-008 | DRIVE SCREW, No. 2 x 3/16, sst (AP) 1

3 210366 : ELBOW, Street, hex, 1/4-18 NPT... . 1

“4 999324-230 | SETSCREW, Skt hd, 3/8-24 x 1/2 ep pt». 1

-5 210398 B cru riemen\enean toffee et eee meee:

~6 7-076 GASKET, Flange, 4°5/8 x 5x 1/8...) 1

-7 999334-100 SCREW, "Rd hd, i/4-20 x 3/8, brass 1

-8 933206-106 SEAL tte te ee ee ee ee l

212361-102 PISTON AND ROD ASSY. » 2. 1

-9 999324-202 .. SETSCREW, 1/4-20 x 1/2, brass D1 NP

-10 212362 + + PISTON (incl dowels PN’ 999259-310) | | NP.

= 212363 + ROD, Piston... ........., 8P

-12 979456-222 | O-RING. » +e se st : 1

13 979456-432 O-RING eee 1

-14 979456-127 O-RING. eee DT 1

-15 979453-070 SEAL. + eee I

-16 212364 Seviinper wooy, 10.8 222) 22 Dla

210979 REPAIR KIT, 10.8 load cell (includes | 1

index nos. 6,8,12 thru 15)

INSTRUCTION MANUAL 26-63

FIGURE 2-4, WEIGHT GAUGE ASSENBLY, TYPICAL (ENGLISH)

2-6

INSTRUCTION MANUAL 26-63

FIG. & UNITS USE

INDEX DESCRIPTION PER on

No. PART NUMBER 1234567 ASSY CODE

2oh- 212985-101 WEIGHT GAUGE ASSY, Two lines, 10,000. . . REF A

1b per line (See 11, Figure 2-1 for NHA)

212985-102 WEIGHT GAUGE ASSY, Four lines, 10,000. . . REF B

Ib per line (See 11, Figure 2-1 for NHA)

212985-103 WEIGHT GAUGE ASSY, Six lines, 10,000. . . REF c

1b per line (See 11, Figure 2-1 for NHA)

212985-104 WEIGHT GAUGE ASSY, Two and four... . . REF D

lines, 10,000 1b per line (See 11,

Figure 2-1 for NHA)

212985-105 WEIGHT GAUGE ASSY, Four and six . . . REF E

Lines, 10,000 1b per line (See 11,

Figure 2-1 for NHA)

212988-101 WEIGHT GAUGE ASSY, Two lines, 20,000 . . . REF F

Ab per line (See 11, Figure 2-1 for NHA)

212988-102 WEIGHT GAUGE ASSY, Four lines, 20,000. . . REF c

ib per line (See 11, Figure 2-1 for NHA)

212988-103 WEIGHT GAUGE ASSY, Six lines, 20,000 . . . REF ®

Ib per line (See 11, Figure 2-1 for NHA)

212988-104 WEIGHT GAUGE ASSY, Two and four... . . REF I

Lines, 20,000 1b per line (See 11,

Figure 2-1 for NHA)

212988-105 WEIGHT GAUGE ASSY, Four and six... . . REF J

Lines, 20,000 1b per line (See 1i,

Figure 2-1 for NHA)

212991-101 WEIGHT GAUGE ASSY, Two lines, 25,000. . . REF K

Ib per line (See 11, Figure 2-1 for NHA)

212991-102 WEIGHT GAUGE ASSY, Four lines, 25,000. . . REF L

Ub per line (See 11, Figure 2-1 for NHA)

212991-103 WEIGHT GAUGE ASSY, Six lines, 25,000. . . REF M

Ib per line (See 11, Figure 2-1 for NHA)

212991-104 WEIGHT GAUGE ASSY, Two and four... . . REF N

lines, 25,000 1b per Line (See 11,

Figure 2-1 for NHA)

212991-105 WEIGHT GAUGE ASSY, Four and six . ... . REF 0

Lines, 25,000 1b per line (See 11,

Figure 2-1 for NHA)

212994-101 WEIGHT GAUGE ASSY, Two lines, 30,000. . . REF Pp

1b per line (See 11, Figure 2-1 for NHA)

212994-102 WEIGHT GAUGE ASSY, Four lines, 30,000. . . REF Q

1b per line (See 11, Figure 2-1 for NHA)

212994-103 WEIGHT GAUGE ASSY, Six lines, 30,000. . . REF R

lb per line (See 11, Figure 2-1 for NHA)

212994-104 WEIGHT GAUGE ASSY, Two and four... . . REF s

Lines, 30,000 1b per line (See 11,

Figure 2-1 for NAA)

212994-105 WEIGHT GAUGE ASSY, Four and six... . . REF i

lines, 30,000 1b per line (See 11,

Figure 2-1 for NHA)

27

INSTRUCTION MANUAL 26-63

FIG. & UNITS USE.

INDEX DESCRIPTION PER ow.

NO. PART NUMBER 1234567 assy CODE

Qab-L 210022 + RING, Case, 6-in. gauge...

-2 999383-056 | SCREW, Fil hd, 10-32 x 1/2 sst (AP) - 4

213458 : GLASS ASSY, Gauge, 6-in, with red. . 1

pointer

-3 210176 KNOB, Knurled... eee ee MP

~4 999324-195, + SETSCREN, Skt, hd, No. 8-32 x. : 1P

1/4, blk, sel (AP)

-35 979456-110, Oe ORING te : XP

6 213776 + POINTER, Target, red... 2. NP

7 211452 +. GLASS, Gauge, plexiglass, clear . NP

“8 979456-259 1 O-RING, ‘Case | RGljoodo ©

-9 212462 | POINTER, 4.12 in. ig, bik | 1

-10 999287~101 + SNAP RING... 5 0

-u 214261 { DIAL, Two Lines, 10,000 1b’per line |) 1 A

214240, { DIAL, Four lines, 10,000 1b per line . 1 B

214242 1 DIAL, Six Lines, 10,000 1b per line.» 1 c

211020 + DIAL, Two and four lines, 10,000... . 1 D

Ib per line

211047 + DIAL, Four and six lines, 10,000,... 1 E

1b per line

214243 . DIAL, Two lines, 20,000 1b per line, . 1 F

214245 : DIAL, Four lines, 20,000 1b per line . 1 c

214246 + DIAL, Six lines, 20,000 1b per line, . 1 H

214244 + DIAL, Two and four lines, 20,000, 1 1

1b per line

211635, . DIAL, Four and six lines, 20,000,... 1 J

1b per line

213087 . DIAL, Two lines, 25,000 1b per line . a K

214247 + DIAL, Four lines, 25,000 1b per line 1 1

214248 + DIAL, Six lines, 25,000 1b per line . 1 M

212256 : DIAL, Two and four lines, 25,000... . 1 N

1b per line

213077 + DIAL, Four and six lines, 25,000... . 1 0

1b per line

212249 . DIAL, Two lines, 30,000 1b per line 1 Pp

214250 : DIAL, Four lines, 30,000 1b per line. 1 Q

212263, . DIAL, Six lines, 30,000 1b per line. . 1 R

213042 + DIAL, Two and four lines, 30,000... . 1 8

ib per Line

214251, « DIAL, Four and six lines, 30,000... . 1 T

1b per Line

“12 212595-106 + BOURDON TUBE ASSY, 1300 to 1800 psig.» 1 A thru E

212595-109 + BOURDON TUBE ASSY, 2800 to 3900 psig. ee cira

212595-108 + BOURDON TUBE ASSY, 2200 to 3000 pats. oe oeebrult

-13 210359 + SCREW, Tube mounting (AP) - - - 3

-14 979456-456 DO-RING G@P) see ee eee 3

-15 210172 + MOUNT, Dial . Bee

-16 999391-150 { SCREW, Truss hd, 6-32 x 1/2 sst (AP), | 2

“7 999338-113 { LOCKWASHER, Inti t, No. 6, cad pl (AP), 2

2-8

INSTRUCTION MANUAL 26-63,

FIG. & uNITS USE

INDEX DESCRIPTION PER on

NO. PART NUMBER 1234567 Assy CODE

24-18 210924 . LINKAGE ASSY, Short, with mtg hdw. . . 1

(See Figure 2-5 for details)

-19 210363, « . NUT, Slotted (AP) (See 1, Figure . . . -REF

2-5 for details)

-20 210538~301 . » SCREW, Shidr (See 3,4, Figure 2-5 . . REF

for details)

-21 220540 . . WASHER, (AP) (See 2, Figure 2-5 for. . .REF

details)

22 210528 MOVEMENT ASSY . 5 pocgooH

-23 999368-775 1 SCREW, Ske hd, 8-32 x 1/4sse 2 2 2

(AP)

24 210929 . DAMPER ASSY, High-pressure, gauge... . 1

mount (See Figure 2-6 for details)

-25 999393~248 «SCREW, Hex hd, 1/4-20 x 1/4, st. . .REF

(AP) (See 1, Figure 2-6 for details)

26 999321120 . . LOCKWASHER, Split, 1/4, sst (AP) . . -REF

(See 2, Figure 2-6 for details)

214560 / TUBING. 2... ee ce!

971107-012 D CONNECTOR, “Nale, 1/8 dia'x 1/8 Nbr... 2

(with ferrule and nut)

~29 212940 - TBE STOP. 2... Be

30 999387-014 1D SCREW, Pan'hd, 6-32 x 1/4, 02 e ed

est (AP)

211139 + BACK ZERO ADJUST ASSY, 2.2... wD

-31 999338-113 - LOCKWASHER, Intl t, No. 6, cd pl (AP). 22

-32 999324~185 +. SETSCREN, Skt hd, No. 6........1

-33 210126 : . DRIVE ASSY, Back zero adjust... - + 1

34 979456-006 Se OcRTnC Mee

35 210171, 2. MY, Housing 5... ee ee eee ed

36 979456-115 ++ O-RING... pe et

-37 210036 11 GEAR, Zero adjust

38 999334100 | SCREW, Rd hd, 1/4-20 x 3/8, brass... - 1

-39 933206106 cua tse ee

~40 211492 1 CASE, Gauge, 6-in, 2 ee ee ee ed

-418 ——214358-101 + INSTRUMENT FLUID, Gauge, N-8,.- . - . + 1

1 qt can

Not Illustrated

INSTRUCTION MANUAL 26-63

FIGURE 2-5. SHORT LINKAGE ASSEMBLY

FIG. 6 uNrTs USE

INDEX DESCRIPTION PER oN

No PART NUMBER 1.234567 Assy CODE

2-5- 210924 SHORT LINKAGE ASSY (See 15, Figure . REF

2-4)

1 210363 plumule Inacascocgeccoo #

-2 210540 By acerca ee ete 2

3 Ale Stents e Aaa gaaaaccaoo |

“4 210538-301 «SCREW, Shldr . . . . 1

-5 999399-004 | NUT, Elastic stop, No. oe

~6 212420 DWASHER 0 le ee eee 2

-7 210349 | LINKAGE BAR, Slide 222. 1

-8 210936 [ LENKAGE BAR'ASSY.. FDS ae 1

-9 999334-505 |. SCRE, Rd hd, 2-56 x 5/16... 2

sst (secured to linkage bar)

INSTRI

ION MANUAL 26-63

FIGURE 2-6. DAMPER ASSEMBLY, HIGH PRESSURE, GAUGE MOUNT

UNITS USE

DES¢RIPTION PER ox

Xo. PART NUMBER 123.4567 con)

210929 DAMPER ASSY, High pressure, gauge... . REF

nount (See 34, Figure 2-4 for NHA)

a 999393-248 , SCREW, Hex hd, 1/4-20 x 1/4 set (AP). . 2

2 999321-120 | LOCKWASHER, split, 1/4, sat (AP). 2

3 211137 DGasker, Damper... ed

a4 969141- 002 . PLUG, Hex hd, 1/8 NPT... ese 1

5 971107-01: « CO ‘TOR, Male, 1/8 tube x |

1/8 NPT

210930-101 «=. «STEM ASSY, High pressure»... 0-1

~6 979456456 |. O-RING ee ee]

-7 979401-006 | | BACK UP SEAL, Teflon, No. 6.2... 1

“8 999395-265 | | ROLL PIN, Long, 5/32'dia x 1

2.0 ed pl

-9 210149 . STEN CAP, High pressures... 2. NP

=10 211261 LL MUI, High pressure 2.01). MP

1110146 Dl srt, High pressure |) 221 21 P

m2 211498 1 BODY, Gauge mount damper Sv LL... I

INSTRUCTION MANUAL 26-63

SECTION Ill

GROUP ASSEMBLY PARTS LIST

CRANE LOAD INDICATOR SYSTEMS (SI UNITS)

3-0

FIGURE

3-1.

CRANE LOAD WEIGHT INDICATOR SYSTEM DETAILS,

TYPICAL (ST UNTTS)

INSTRUCTION MANUAL 26-63

NOTE

Refer to Table 6-1 for system configurations

and capabilities, The following listed Crane

Load (CL) Weight Indicator Systems (SI Units)

all include:

a. A box-mounted, 6-inch weight gauge.

b, A cylindrical, tension-type, load cell

(6.53 or 10.8 sq in., non-spin piston,

with

c. A hydraulic hose assembly with quick~

two shackles.

disconnect fittings.

d. A hydraulic fluid hand pump and one

quart of instrument fluid.

FIG. & UNITS USE

INDEX PART NUMBER DESCRIPTION PER on.

No. (CATALOG NO.) 123.4567 Assy CODE

Ble 213276 CL SYSTEM, Two lines, 4500 daN per 1 A

(CL-010-02-S1) line, 6.53 load cell

213277 CL SYSTEM, Four lines, 4500 daN per 1 B

(CL-010-04-S1) line, 6.53 load cell

213278 CL SYSTEM, Six lines, 4500 daN per . . a c

(CL-010-06-S1) line, 6.53 load cell

213279 CL SYSTEM, Two and four lines, 4500 1 D

(CL-010-24-ST) daN per line, 6.53 load cell

213280 CL SYSTEM, Four and six lines, 4500 1 E

(CL-010-46-ST) daN per line, 6.53 load cell

213291 CL SYSTEM, Two lines, 9000 daN per . . 1 F

(CL-020-02-S1) line, 6.53 load cell

213292 CL SYSTEM, Four lines, 9000 daN per . 1 G

(cL-020-04-ST) line, 6.53 load cell

213293 CL SYSTEM, Six lines, 9000 daN per . . 1 W

(CL~020-06-S1) Line, 6.53 load cell

213294 CL SYSTEM, Two and four lines, 9000... 1 1

(CL-020-24-81) daN per line, 6.53 load cell

213295, CL SYSTEM, Four and six lines, 9000 . at J

(CL-020-46-S1) daN per line, 6.53 load cell

213306 CL SYSTEM, Two Lines, 11,000 daN per . 1 K

(CL-025-02-81) line, 6.53 load cell

213307 CL SYSTEM, Four lines, 11,000 daN per 5 L

(CL-025-04-ST) line, 6.53 load cell,

213308 CL SYSTEM, Six lines, 11,000 daN per . i) u

(CL-025-06-ST) line, 6.53 load cell

213309 CL SYSTEM, Two and four lines, 11,000 1 Nx

(CL-025-24-ST) daN per line, 6.53 load cell

213310 CL SYSTEM, Four and six lines, 11,000 .. 1 °

(CL-025-46-S1)

daN per line, 6.53 load cell

31

INSTRUCTION MANUAL 26-63

FIG. & UNITS USE

INDEX PART NUMBER DESCRIPTION PER ON

No. (CATALOG NO.) 1234567 ASSY CODE

Bele 213321 CL SYSTEM, Two lines, 14,000 daN per... 1 P

(CL~030-02-s1) line, 10,8 load cell

213322 CL SYSTEM, Four Lines, 14,000 daN per. . 1 °

(CL~030-04-ST) line, 10.8 load cell

213323 CL SYSTEM, Six lines, 14,000 daN per... 1 R

(CL~030-06-81) Line, 10.8 load cell

213324 CL SYSTEM, Two and four lines, 14,000 .. 1 8

(CL-030-24-S1) daN per line, 10.8 load cell

213325, CL SYSTEM, Four and six lines, 14,000 .. 1 T

(CL-030-46-ST) daN per line, 10.8 load cell

1 970621-012 DUST CAP, Males ee ee ee 1

2 970621-008 + COUPLING, Female . . oe

3 210658-125 1 HOSE ASSY, Hydraulic, 25-feet 11. 1

“4 999205-205 + SHACKLE, 1 in., 1-1/8 in. pin 2 A thru D

(6 tons)

999205~206 + SHACKLE, 1-1/8 in., 1-1/4 in. pin . 2 P thro T

(17.5 tons)

-5 212371-102 . LOAD CELL ASSY, Tension type, non-. 1 A thru 0

spin, 6.53 5q in. (See Figure

2-2 for details)

212360-102 + LOAD CELL ASSY, Tension type, non--- + 1 P thru T

spin, 10.8 sq in. (See Figure 2

for details)

~6 970621-013 .~DUST CAP, Female... +--+ see eee 2

7 970621-009 | COUPLING, Male. 12st ee 2

-8 968202-002 | NIPPLE, Hex, 1/4 NPT.) ss ee 2

“3 210366 I ELBOW, Street, hex. 2) 2 oe 1

-10 210368 I TEE, Street, hex sey e eee

oi 212987-101 | WEIGHT GAUGE ASSY, Two lines, 4500 . 1 4

daN per line (See Figure 3-2 for

details)

212987-102—-.- WEIGHT GAUGE ASSY, Four lines, 4500 . . 1 B

daN per line (See Figure 3-2 for

details)

212987-103 —-. WEIGHT GAUGE ASSY, Six limes, 4500... 1 c

GaN per line (See Figure 3-2 for

details)

212987-104 WEIGHT GAUGE ASSY, Two and four»... 1 D

Lines, 4500 da per line (See

Figure 3-2 for details)

212987-105 —-. WEIGHT GAUGE ASSY, Four and six... 1 E

lines, 4500 daN per line (See

Figure 3-2 for details)

212990-101. . WEIGHT GAUGE ASSY, Two lines, 9000... 1 F

daN per line (See Figure 3-2

for details)

212990-102 . WEIGHT GAUGE ASSY, Four lines, 9000 . . 1 c

daN per line (See Figure 3-2 for

details)

342

INSTRUCTION MANUAL 26-63

FIG. &

INDEX

No.

PART NUMBER 1

UNITS. USE

DESCRIPTION PER ow.

BYOGGD Assy CODE

3-1-1

-13

“14

-15

-16

212990-103,

212990-104

212990-105

212993-101

212993-102

212993-103

212993-104 :

212993-105 :

212996-101 5

212996-102 :

212996-103

212996-104

212996-105,

999393-025,

999321-320 :

210017 :

212450-102 :

214359-101 :

. WEIGHT GAUGE ASSY, Six lines, 9000... 1 x

daN per line (See Figure 3-2 for

details)

. WEIGHT GAUGE ASSY, Two and four... + 1 I

lines, 9000 daN per line (See

Figure 3-2 for details)

. WEIGHT GAUGE ASSY, Four and six... . 1 J

lines, 9000 daN per line (See

Figure 3-2 for details)

. WEIGHT GAUGE ASSY, Two lines, 11,000. . 1 K

daN per line (See Figure 3-2 for

details)

. WEIGHT GAUGE ASSY, Four lines, 11,000. 1 L

aN per line (See Figure 3-2 for

details)

. WEIGHT GAUGE ASSY, Six lines, 11,000 - 1 M

daN per line (See Figure 3-2 for

details)

IGHT GAUGE ASSY, Two and four +--+ 1 N

Lines, 11,000 daN per line (See

Figure 3-2 for details)

WEIGHT GAUGE ASSY, Four and six- ++ 1 °

limes, 11,000 daN per line (See

Figure 3-2 for details)

WEIGHT GAUGE ASSY, Two lines, 14,000 . 1 P

daN per line (See Figure 3-2 for

details)

WEIGHT GAUGE ASSY, Four Lines, 14,000. 1 a

daN per line (See Figure 3-2 for

details)

WEIGHT GAUGE ASSY, Six lines, 14,000 - 1 R

daN per line (See Figure 3-2 for

details)

. WEIGHT GAUGE ASSY, Two and four +++ 1 s

Lines, 14,000 daN per line (See

Figure 3-2 for details)

. EIGHT GAUGE ASSY, Four and six. +. 1 t

lines, 14,000 daN per line (See

Figure 3-2 for details)

= SCREW, Hex hd, 1/4-20 x 1/2, ed +» ++ 3

pl (AP)

LOCKWASHER, Split, 1/4, cd pl (AP)

BOX ASSY, Steel, 6-in. gauge - + + + +

HAND PUMP, Hydraulic fluid + + ++ + +

INSTRUMENT FLUID, M-15, 0. 7s ee +

hydraulic, 1 qt can

33

INSTRUCTION MANUAL 26-63

FIGURE 3-2. WEIGHT GAUGE ASSEMBLY, TYPICAL (SI UNITS)

a4

INSTRUCTION MANUAL 26-63

FIG.

INDEX

No.

&

PART NUMBER

DESCRIPTION

1234567

UNITS

PER

ASsY

USE

on

CODE

32>

212987-101

212987102

212987-103

212987104

212987105

212990-101.

212990-102

212990-103,

212990-104

212990-105

212993-101

212993-102

212993-103

212993-104

212993-105

212996-101

212996-102

WEIGHT GAUGE ASSY, Two lines, 4500 .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Four lines, 4500 . .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Six lines, 4500. .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Two and four... .

Lines, 4500 daN per line (See

Ll, Figure 3-1 for NHA)

WEIGHT GAUGE ASSY, Four and six

lines, 4500 daN per line (See

ll, Figure 3-1 for NHA)

WEIGHT GAUGE ASSY, Two lines, 9000. . .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Four lines, 9000 . .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Six lines, 9000 . .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Two and four... .

Lines, 9000 daN per line (See

ll, Figure 3-1 for NHA)

WEIGHT GAUGE ASSY, Four and six .

Lines, 9000 daN per line (See

1l, Figure 3-1 for NHA)

WEIGHT GAUGE ASSY, Two lines, 11,000 . .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Four lines, 11,000 .

daN per line (See 11, Figure 3-1

for NRA)

WEIGHT GAUGE ASSY, Six lines, 11,000 .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Two and four... «

Lines, 11,000 daN per line (See

U1, Figure 3-1 for NHA)

WEIGHT GAUGE ASSY, Four and six . .

Lines, 11,000 daN per line (See

ll, Figure 3-1 for NHA)

WEIGHT GAUGE ASSY, Two lines, 14,000 .

daN per line (See 11, Figure 3-1

for NHA)

WEIGHT GAUGE ASSY, Four lines, 14,000 .

daN per line (See 11, Figure 3-1

for NHA)

. REF

+ REF

. REF

. REF

» REF

. REF

+ REF

+ + REF

. REF

. REF

+ REF

+ REF

+ REF

+ REF

+ REF

+ REF

. REF

3

M

°

INSTRUCTION MANUAL 26-63

FIG. & UNITS USE

INDEX DESCRIPTION PER ow

XO. PART NUMBER 1234567 aSSY CODE

32. 212996-103 «WEIGHT GAUGE ASSY, Six lines, 14,000. . . REF R

daN per line (See 11, Figure 3-1

for NHA)

212996-104 WEIGHT GAUGE ASSY, Two and four... . . REF s

Lines, 14,000 daN per line (See

Li, Figure 3-1 for NEA)

212996-105 WEIGHT GAUGE ASSY, Four and six... . . REF 1

Lines, 14,000 daN per line (See

11, Figure 3-1 for NHA)

-1 210022 . RING, ’Case, 6-in. gauge .

2 999383-056 | SCREW, Fil’hd, 10-32 x 1/2 est (AP) 4

213458 2 GLASS’ ASSY, Gauge, 6-in. with red xP

pointer

3 210176 = KNOB, Knurled .. 2. cee

4 999324-195 . SETSCREW, Skt hd, 8-32 x 1/4... + ‘NP

blk, sti

+5 979456-110 LORING cee eee eee WP

-6 213774 ) POINTER, Target, red. eee NP

-7 211452 + + GLASS, Gauge, plexiglass, clear NP

-8 979456-259 | O-RING, Case. ee ee ee ee ee eT

-9 212462 { POINTER, 4.12 in. 1g, blk Ll 1

=10 999287-101 | SNAP RING... pes

“a 214112 1 DIAL, Two Lines, 4500 daN per line. + 1 A

(8000 aax)

21413 . DIAL, Four lines, 4500 daN per line. . 1 B

(8,000 dan)

2144 | DIAL, Six lines, 4500 daN per line... 1 c

(37,000 daw)

214115 = DIAL, Two and four lines, 4500 daN - 1 D

per line (9000 and 18,000 daN)

210116 . DIAL, Four and six lines, 4500 daN - a E

per line (18,000 and 27,000 dav)

214107 | DIAL, Two lines, 9000 daN per line... 1 F

(18,000 daN)

214108 « DIAL, Four lines, 9000 daN per line - 1 c

(36,000 daN)

214109 . DIAL, Six lines, 9000 daN per line « 1 i

(54,000 dan)

21410 | DIAL, Two and four Mines, 9000 daN.. . 1 1

per line (18,000 and 36,000 daN)

2ualld = DIAL, Four and Six lines, 9000 daN. . - 1 J

per line (36,000 and 54,000 daN)

247 | DIAL, Two Lines, 11,000 daN per line. . 1 K

(22,000 dan)

21aus = DIAL, Four lines, 11,000 daN per line. . 1 L

(44,000 daN)

214119 | DIAL, $ix Lines, 11,000 daN per line. . 1 ™

(66,000 daX)

214120 | DIAL, Two and four lines, 11,000 daN. . 1 N

per Line (22,000 and 44,000 daw)

214121 | DIAL, Four and six lines, 11,000 daN. . 1 °

36

per Line (44,000 and 66,000 daN)

INSTRUCTION MANUAL 26-63

UNITS USE

DESCRIPTION PER ox

XO. PART NUMBER 123.4567 ASSY cove

aad 214122 . DIAL, Two lines, 14,000 daN per line». 1 P

(28,000 dax)

214123 . DIAL, Four lines, 14,000 daX per lines » 1 Q

(56,000 dan)

214124 + DIAL, Six Lines, 14,000 daN per line. . 1 R

(84,000 da)

214126 . DIAL, Four and six lines, 14,000 dav. . 1 T

per line (56,000 and 84,000 daN)

12 212595-106 «BOURDON TUBE ASSY, 1300 to 1800 psig. . 1 A thro E

212595-109 |-BOURDON TUBE ASSY, 2800 to 3900 psig. . 1 F thru 0

212595-108 BOURDON TUBE ASSY, 2200 to 3000 pate.» 1 P thru T

-13 210359 2 SCREW, Tube mounting (AP). see 3

-14 979456-456 O-RING (AP) Be000006 a

-15 210172 ff aon sty eee a

-16 999391-150 | SCREW, Truss hd, 6-32 x 1/2, ost (AP). + 2

-17 999338-113 | LOCKWASHER, Inti t, No. 6, cd pl (AP) . 2

-18 210924 D LINKAGE ASSY, Shore, with mtg... 2. 1

hdw (See Figure 3-5 for details)

-19 210363, . NUT, Slotted (AP)(See 1, Figure 2-5

for details)

-20 210538-301 —«.-- ‘SCREW, Shidr (See 3, 4, Figure 2-5. . REF

for details)

-21 210540 . . WASHER, (AP) (See 2, Figure 2-5... . REF

for details)

22 210528 | MOVEMENT ASSY 2. ssw 5

-23 999368-775 | SCREW, Skt hd, 8-32 x 1/4, ast (AP). . + 2

~2u 210929 | DAMPER ASSY, High-pressure, gauge». + 1

mount (See Figure 2-6 for details)

-25 999393-248 + SCREW, Hex hd, 1/4-20 x 1-1/4 set. - REF

(AP) (See 1, Figure 2-6 for details)

-26 999321-120 . . LOCKWASHER, Split, 1/4 sst (AP). . - REF

(See 2, Figure 2-6 for details)

-27 214560 LTUBING. See ee ee ee 1

28 971107-012 | CONNECTOR, Male, 1/8 dia x 1/8 NPT... 2

(sich ferrule and nut)

-29 212940 WBE STOP 2. eee ee ee ee eee ee 2

-30 999387-014 . SCREN, Pan hd, 6-32 x 1/4 sst (AP)... 1

31 999338-113 | LOCKWASHER, Intl t, No. 6, cd pl (AP). . 1

211139 J BACK ZERO ADJUST ASSY . . . 1

32 999324-185 + SEISCREW, Skt hd, No. 6 .. +. + 1

-33 210126 1 1 DRIVE ASSY, Back’ zero adjust... 6. 1

-34 979456-006 —. . O-RING . Booo

-35 210171 Lnur, Housing | se eee ee

=36 979456-115 1 L O-RING. eee ee ee eee ee OD

-37 210036 11 GEAR, Zero adjust +... eee zl

-38 999334-100 | SCREW, Rd hd, 1/4-20 x 3/8, brass 1

=39 933206-106 | SEAL wee ee eee 1

=40 211492 1 CASE, Gauge, Bins se ee 1

male 24358-2101 |“ INSTRUMENT FLUID, Gauge, M-8, 2 2... 1

‘Not Illustrated

1 qt can

3-7/3-8

INSTRUCTION MANUAL 26-63

SECTION IV

NUMERICAL INDEX

PART NUMBER

FIGURE &

INDEX NO.

FIGURE &

PART NUMBER INDEX NO.

cL-010-02

CL-010-02-St

cL-010-04

L-010-04-S1

CL-010-06

CL-010-06-ST

cL-010-24

CL~010-24-ST

cL-010~46

CL-010~46-ST

cL-020-02

CL-020-02-ST

CL-020-04

CL-020-04-ST

cL-020-06

CL~020-06-S1

CL-020-24

CL-020-24-ST

CL-020-46

CL-020-46-ST

CL~025-02

CL~025-02-ST

eL~025+04

CL-025-04~SI

L-025-06

CL~025-06-81

cL~025-24

CL~025-24-S1

CL~025-46

CL-025-46-ST

cL-030-02

CL~030-02-SI

CL~030-04

CL=030-04-ST

CL=030-06

CL-030-06-ST

CL-030~24

CL-030-24-ST

cL-030-46

CL-030-46-ST

THIS COLUMN INTENTIONALLY LEFT BLANK.

4d

INSTRUCTION MANUAL 26-63

FIGURE AND

PART NUMBER INDEX NUMBER

PART NUMBER

FIGURE AND

INDEX NUMBER

210017

210022

210036

210126

210146

210149

210171,

210172

210176

210359

210363

210366

210368

210398

220440

210528

210538-301

210540

210549

210658-125

210658-135

210658-150

210924

210929

210936

210979

210984

211020

211137

211261

211452

211492

211498

211635,

211702

212256

212263

212360-102

212362

212363,

212364

212368

212370~302

212371-102

212373,

212374

212420

212450-102

212462

212595-106

212595-108

212595109

3

2

2

2

2

2

3

2

3

2

2

3

2

2

2

2

3

2

2

4-2

INSTRUCTION MANUAL 26-63

FIGURE AND FIGURE AND

PART NUBER INDEX NUMBER PART NUMBER INDEX NUMBER

212980 24-31 212991-105 21-11

32-31 24

212985-101 21 212993-101 31-11

24 3-2 |

212985-102 pin 212993-102 3-1-1 |

3-2

212985-103 212993-103 3-1-1 |

3-2

212985-104 212993-104 3-1-1 |

342 |

212985-105 212993-105 31-11 i

342

212987-101 212994101 2-111

2-4

21.2987-102 212994102 21-11

24

212987-103 212994103 21-11

24

212987-104 212994-104 2-1-1

24

212987-105 212994-105 2-1-11

24

212988-101 212996101 3-1-1

3-2

212988-102 212996-102 3e1-al

3-2

212988-103 212996-103 3-1-1

3-2

212988-104 212996-104 3-1-11

3-2

212988-105 212996-105 3-111

3-2

212990-101 213042 24-11

213077 2-11

212990-102 213087 Qed

213266 21

212990-103 213267 2-1

213268 21

212990-104 213269 2-1

213270 2-1

212990-105 213276 Bel

213277 3-1

212991-101 213278 Bl

213279 3-1

212991-102 213280 3-1

213281 2-1

212991-103 213282 2-1

213283 2-1

212991-104 213284 2-1

| 213285 2-1

INSTRUCTION MANUAL 26-63

FIGURE AND FIGURE AND

PART NUMBER INDEX NUMBER PART NUMBER INDEX NUMBER

213291 341 214243,

213292 3-1 214244,

213293, 3-1 214245,

213294 3-1 214246

213295, 3-1 214247

213296 2-1 214248

213297 2-1 214249

213298 2-1 214250,

213299 2-1 214251,

213300 2-1 214359-101

213306 3-1

213307 3-1 214560

213308 1

213309 3-1 7-023

213310 3-1 7-076

213311, 2-1 933206-106

213312 2-1

213313 2-1

213314 2-1

213315, 2-1 968202-002

213321, a1

213322 a1 969141-003

213323 a1 970621-001

213324 3-1

213325, 341 970621-005

213774 2-6-6

3-2-6 970621-012

214107 32-11

214108 3-2-1 970621-013,

214109 32-11

214110 3-2-1 979453-070

2uaiit 32-11

214112 362-11 979456-006

214113, 3-2-1

214114 342-11

214115 342-11 979456-110

214116 32-11

214117 342-11 979456-115

214118 3-2-11

214119 3-2-11 979456-127

214120 3-2-1

214121 3-2-11 979456-222

214122 3-2-11

214123, 3-2-11 979456-259

214124 342-11

214125, 3-2-11 979456-336

214126 3-2-1 979456~342

214240, 2-4-1 979456-456

214241, 24-11

214242 2a4-1L

999205-205

INSTRUCTION MANUAL 26-63

FIGURE AND

PART NUMBER INDEX NUMBER

PART NUMBER

FIGURE AND

INDEX NUMBER

999241~008

999287-101

999321120

999321-320

999324-185

999324-195

9324-202

999324-230

999334100

999334~505

999338-113

9368-775

9383-056

999387-014

999391-150

999393-025

999393-248

1999395-265,

999399-004

INSTRUCTION MANUAL 26-63

SECTION V

SPARE PARTS LIST

5-2 This section contains information for parts which are recommended as a

beginning quantity for stocking as spares at each using facility. Part

numbers and quantities will depend on each facility's experience. An inventory

of readily available spare parts will reduce the equipment down time when replace-

ment of parts is necessary. Standard hardware items are not included, Sufficient

information for obtaining these items is contained in the parts listing in the

Group Assembly Parts List in Section Il and Ill. For convenience, spare parts

are arranged in ascending nunerical order by Figure and Index Numbers.

TABLE 5-1. RECOMMENDED SPARE PARTS LIST

FIGURE AND PART ] qn

INDEX NO, | __ NUMBER DESCRIPTION USED

970621-008 | COUPLING, Fenale 2

210658-125 | HOSE ASSY, Hydraulic, 1/4-in. 1D, 25 fe | 2

| srzsra-102 oan cxia Assy, Teneton-type, noneepiny 6.53 | 2

212360-102 | LOAD CELL ASSY, Tension-type, non-spin, 10.8 | 1

970621-009 | COUPLING, Male 4

212450-102 | HAND PUNP ASSY, Hydraulic fluid 1

214359101 | INSTRUMENT FLUID, 4-25, Hydraulte, 1 qt can | 1

| 210984 | REPAIR KIT, 6.53 Load celL joa

| 210979 REPAIR KIT, 10.8 load cell fea

213458 |GLASS ASSY, Gauge, 6-in. with red pointer

| o11a39 BACK ZERO ADJUST ASSY 1

979456-259 | 0-RING, Case 2

212462 POINTER, Black 2

| a0924 SHORT LINKAGE ASSY 2

210528 MOVEMENT ASSY, Gauge, 6-in., simple | 2

212595-109 | BOURDON TUBE ASSY, 2800-3800 psig fa

212595-108 | BOURDON TUBE ASSY, 2200-2000 psig 1

INSTRUCTION MANUAL 26-63

TABLE 5-1. RECOMMENDED SPARE PARTS LIST (Cont'd)

fFrcure AND || PART Jory |

INDEX No. NUMBER DESCRIPTION |useo

1

2-4-29 210359 SCREW, Tube mounting 6 |

3-2-29 |

2-4-30 979456-456 O-RING | 8

2-6-6 |

3-2-30 |

2-434 210929 DAMPER ASSY, High pressure 2 |

aa |? |

2-420 214358-101 _| INSTRUMENT FLUID, Gauge, M+B, 1 gt can 1]

p-2-40 |

2-6-3 211137 GASKET, Damper

INSTRUCTION MANUAL 26-63

SECTION VI

ADDITIONAL DATA

NE_LOAD INDICATOR SYSTEMS LISTING

6-2 Crane Load Indicator Systems configurations are listed in Table 6-1 by

weight capabilities and numbers of lines.

TABLE 6-1. CL SYSTEM CONFIGURATIONS

NuvpeR | weicur PER | WETGNT PER

ceane Loap | GAUGE ann paper | oF LINES LINE LINE

SYSTEM ony (orat) | enottsucay* | sr (daxys

(213266-125 212985-101 2 10,000

213276-125 | 212987-101 2 4500

213267-125 212985-102 | 4 10,000 j

(213277-125 212987-102 } 4 4500,

213283-125 | 212985-102 6 10,000

213278-125 | 212987-103 6 4500

213265-125 | 212985-104 264 10,000

nazzy3-125 | 212987-104 a 4500

213270-125 | 212985-105 | 10,000

213280-125 | 212987-105 a 4500

213281-125 212988-104 2 20,000 |

213291-125 | 212990-101 2 9000

213282-125 212988-102 } 4 20,000 |

aisee2125 | 212990-102 4 so00 |

213283-125 | 212986-103 6 20,000 |

213293125 | 212990-103 6 3000

nu3ze4-125 | 212988-104 264 20,000

213294-125 | 212990-104 264 9000

213085-125 | 212988-105 466 20,000

213095125 | 212990-105 486 9000

213096125 | 212991-101 2 25,000

213306125 | 212993-101 2 | 11,000

213297-125 | 212991-102 4 25,000

pis3o7—125 | ig993—102,— | 11,000

di3298-125 | © iz991-103. | 25,000

213308-125 212993-103 6 11,000

213299-125 | 212256-204 264 25,000

213309125 | 212993-104 264 11,000

213300-125 | 213077-105 ase 25, 000

213310-125 212993-105 4&6 10,000 |

pisaii-i2s | 212994101 2 30,000

213321-125 212996-101 2 14,000

213312-125 | 212994-102 : 30,000

213322-125 | 212996-102 : 14,000

pig3i3-125 | 212994-102 6 30,000

INSTRUCTION MANUAL 26-63

TABLE 6-1. CL SYSTEM CONFIGURATIONS (Cont'd)

CRANE LoAD | GAUGE AND DANPER | OF LINES ie LINE

ene peat cae en egssege | eg ure | eeeran rine Penta

nt ee ae oa

Pests te ceseiore aye alee coo

(213324-125 212996-104 1 264 | 14,000

(213315-125 212994-105 466 | 30,000 14,000

| |

10,000, 20,000, and 25,000 1b (4500, 9500, and 11,000 daN) systems use 6.53

sq in, load cell assembly, PN 212371102. 30,000 1 (14,000 daN) si/stems use

10.8 sq in. load cell assembly, PN 212360-102.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Single Output Current Sensor Assembly: Service ManualDocument40 pagesSingle Output Current Sensor Assembly: Service ManualAbdallah ElhendyNo ratings yet

- Gcep09075 (Po13175)Document10 pagesGcep09075 (Po13175)Abdallah ElhendyNo ratings yet

- Part Number 26-73: Illustrated Parts BreakdownDocument150 pagesPart Number 26-73: Illustrated Parts BreakdownAbdallah ElhendyNo ratings yet

- Hydro-Mast Weight Indicator System: Service ManualDocument64 pagesHydro-Mast Weight Indicator System: Service ManualAbdallah Elhendy100% (1)

- Air Supply SystemDocument31 pagesAir Supply SystemAbdallah ElhendyNo ratings yet

- Electric-to-Pneumatic (E/P) Transducer Assembly: 26-56-MAN (P/N 10075275-001) CDocument44 pagesElectric-to-Pneumatic (E/P) Transducer Assembly: 26-56-MAN (P/N 10075275-001) CAbdallah ElhendyNo ratings yet

- XS197K13-T89-00 DrawingDocument1 pageXS197K13-T89-00 DrawingAbdallah ElhendyNo ratings yet

- Joint Torque System: Service ManualDocument52 pagesJoint Torque System: Service ManualAbdallah ElhendyNo ratings yet

- Hydro-Weight Master Indicator System: Service ManualDocument39 pagesHydro-Weight Master Indicator System: Service ManualAbdallah ElhendyNo ratings yet

- Electronic Pressure Transducer: For Two Inch 1502 WECO Type Unions (P/N: 221212-Series)Document20 pagesElectronic Pressure Transducer: For Two Inch 1502 WECO Type Unions (P/N: 221212-Series)Abdallah ElhendyNo ratings yet

- Full Bore Safety Valve Assembly Guide BookDocument8 pagesFull Bore Safety Valve Assembly Guide BookAbdallah ElhendyNo ratings yet