Professional Documents

Culture Documents

Full Bore Safety Valve Assembly Guide Book

Uploaded by

Abdallah ElhendyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Full Bore Safety Valve Assembly Guide Book

Uploaded by

Abdallah ElhendyCopyright:

Available Formats

Tianhe Oil Group Huifeng petroleum Equipment Co.

,Ltd

Full bore safety valve assembly guide book

Full bore safety valve

Assembly guide book

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

1、Operation and application

Full bore safety valve is hand control valve in the drill string

circulating system , it's an effective tool to prevent blowout, well kick.

The design of full bore safety valve accord with API SPEC 7-1

requirement, use the safety valve between the bottom of kelly and top of

drill pipe or down side of the kelly saver sub. During the drilling

operation to avoid blowout and vicious accident happen, should be

connect the safety valve in the drill string.

Full bore safety valve is simple construction, easy maintenance ball

valve, the valve with full bore and big full bore feature, that reduce

greatly the drilling fluid erosive wear to the key parts. Full bore safety

valve adopt separated structure, when same connecting guarantee large

drift diameter requirement and meet API specification.

1.1、Application overview

Full bore safety valve is one important drill string internal

prevention blowout tool, install it on the upper of drill pipe is called top

safety valve, install it on the bottom of drill pipe is called bottom safety

valve. Rotating ball valve with a special wrench to achieve valve opening

-1-

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

and closing. When the overflow or blowout occur, close full bore safety

valve, cut off the drill tool inner channel to achieve drill tool internal

blowout prevention purpose.

1.2、Full bore safety valve structure and working principle

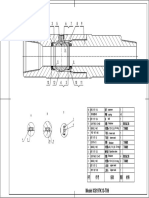

1.2.1、Full bore safety valve structure

Full bore safety valve is composed of top sub, top ball seat, seal ring,

operational key, ball, lower ball seat, spring, lower sub and accessories

wrench, see figure 1.

1 2 3 4 5 6 7

D2

D1

8 4 4

L t

1、top sub 2、top ball seat 3、operational key 4、sealing element repair

kit 5、ball 6、lower ball seat 7、lower sub 8、spring

Figure1 Full bore safety valve structure

-2-

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

2.2 Full bore safety valve specification and technical

parameter

Table 1 Full bore safety valve technical parameters

Specification Part connect OD ID Length Weight Hexagona Working

(mm) (mm) (mm) l size pressure

Model number thread (kg) (mm) (Mpa)

D1 D2 d L t

XS225-T104 F072251 5 VAM TOP 225 146 104 950 27 35(70)

XS210-T100 F072102 4 1/2 EUE 210 141 100 765 115 27 35(70)

XS197-T89A F071977 5 1/2 FH 197 178 89 960 160 27 35(70)

XS197C-T89 F071978 XT57 197 184 89 960 152 27 35(70)

XS190-T82.6 F071902 NC50 190 168 82.6 895 123 27 35(70)

XS152-T76 F071521 3 1/2 EUE 152 114 76 617 51 19.3 35(70)

XS140-T62 F071401 NC40 140 140 62 750 69 13 35(70)

XS134B-T62 F071348 NC38 134 121 62 800 62 13 35(70)

XS134A-T62 F071347 2 7/8 EUE 134 93 62 800 62 13 35(70)

XS134D-T62 F071349 XT38 134 124 62 800 63 13 35(70)

XS127K-T51 F0712713 XT39 127 127 50.8 812 58 16 35(70)

XS121F-T51 F071216 NC38 121 121 50.8 711 44 16 35(70)

XS118-T54 F071181 NC31 118 105 54 760 40 16 35(70)

XS118A-T54 F071186 2 7/8EUE 118 93 54 550 27 16 35(70)

XS114A-T51 F071142 2 3/8EUE 114 78 51 546 25 13 35(70)

XS105A-T44 F071052 NC26 105 89 44 732 34 13 35(70)

XS89C-T38 F070892 2 7/8" 89 79.4 38 760 29 13 35(70)

HTPAC

-3-

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

3、Preparation before assembly

3.1 Read it carefully about the full bore safety valve structure drawing

( Figure 1 ) to make sure needed components, standard parts, know

assembly relationship.

3.2 Make an inventory according the assembly drawing and put it in

order.

3.3 Checking , coping , cleaning the components.

3.4 Clean the inner hole dust, iron chip etc by air pump.

3.5 Ball and ball seat with grinding.

4、Full bore safety valve assembly

4.1 Put the spring into the lower sub spring hole one by one,then put the

O-ring and relevant check ring into the lower ball seat O-ring groove in

turn and smear suitable engine oil to lubricate. After finished it, put the

lower ball seat into lower sub according to assembly drawing, see

Figure2.

Figure 2 Spring and lower ball seat assembly

-4-

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

4.2 Put the O-ring and relevant check ring into the top ball seat O-ring

groove in turn and smear suitable engine oil to lubricate. After finished it,

put the top ball seat into top sub according to assembly drawing, see

Figure 3.

Figure 3 Spring and top ball seat assembly

4.2 Put the O-ring and relevant check ring into the operational key O-ring

groove in turn and smear suitable engine oil to lubricate, After finished it,

put the operational key into top sub cross hole, during the assembly, use

wrench slowly rotated the operational key to the assembly position to

prevent ruined the rubber ring, rotary the operational key to close position,

see Figure 4.

-5-

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

Figure 4 Operational key assembly

4.3 Smear suitable engine oil on ball surface, then put the ball into top

sub along operational key direction, see Figure 5.

Figure 5 Ball assembly

4.4 Smear the suitable thread compound on lower sub thread, then

connect the lower sub and top sub together, tight it by bucking unit. See

Figure 6.

Figure6 top、lower sub connect

4.5 After tighten the thread check the operational key rotary free or not,

hereto the product finish assembly, can do the pressure testing, the

pressure is qualified then dry the tool, smear anti-rust oil on surface of

drill pipe thread, with thread protector, see Figure 7.

-6-

PDF created with pdfFactory Pro trial version www.pdffactory.com

Tianhe Oil Group Huifeng petroleum Equipment Co.,Ltd

Full bore safety valve assembly guide book

Figure7 Full bore safety valve

5 Full bore safety valve disassembly process is assembly

inverse process.

-7-

PDF created with pdfFactory Pro trial version www.pdffactory.com

You might also like

- LF90LS Operations and Service Manual PDFDocument154 pagesLF90LS Operations and Service Manual PDFDavid Fino Y. Seguro100% (1)

- Inlet and Exhaust Valves - Remove and Install: Shutdown SIS Previous ScreenDocument5 pagesInlet and Exhaust Valves - Remove and Install: Shutdown SIS Previous ScreenbejoythomasNo ratings yet

- Operation Manual: Ahfq Series Douple-Flap Butterfly ValveDocument12 pagesOperation Manual: Ahfq Series Douple-Flap Butterfly Valvehamann97No ratings yet

- Kelly Valve: When Ordering Please SpecifyDocument8 pagesKelly Valve: When Ordering Please SpecifyAhmad Reza FarokhiNo ratings yet

- Swivel (水龙头)Document16 pagesSwivel (水龙头)Omar Fathy100% (1)

- Prosedure Installation Eui c9Document5 pagesProsedure Installation Eui c9Un'galluNo ratings yet

- UB Type Butterfly Valve (Wafer Type)Document35 pagesUB Type Butterfly Valve (Wafer Type)rizkydjonhansemitNo ratings yet

- Operation and Maintenance Manual-Floating Ball Valves-2011Document9 pagesOperation and Maintenance Manual-Floating Ball Valves-2011engineeringikptNo ratings yet

- RG Petro Machinery YG 180Document18 pagesRG Petro Machinery YG 180Alfred Hernandez Mendoza75% (4)

- F84L Series Liquid Relief Valve: Installation, Operation, & Maintenance ManualDocument15 pagesF84L Series Liquid Relief Valve: Installation, Operation, & Maintenance ManualMoe MozhganNo ratings yet

- Data Sheet: Clean Agent Nitrogen Actuator Completer KitsDocument2 pagesData Sheet: Clean Agent Nitrogen Actuator Completer KitsMagderson CorreaNo ratings yet

- 450╦«┴·═╖╦╡├≈╩Θ003ok engDocument27 pages450╦«┴·═╖╦╡├≈╩Θ003ok engGabriel IbarraNo ratings yet

- Varco Ibop Valves PDFDocument50 pagesVarco Ibop Valves PDFAnonymous MxwCc4100% (3)

- 160.75-RP1 (210) - Yk (G)Document92 pages160.75-RP1 (210) - Yk (G)JayashtonNo ratings yet

- Maint. Instr. MF Piston 50 100 and 200 DA Pnuem ActDocument24 pagesMaint. Instr. MF Piston 50 100 and 200 DA Pnuem ActJosé Daniel ArenasNo ratings yet

- Vetec 62.7 Sanson Plug Tipo CanflexDocument12 pagesVetec 62.7 Sanson Plug Tipo CanflexAnderson SiqueiraNo ratings yet

- ZQ127-25 Operation Manual (English)Document37 pagesZQ127-25 Operation Manual (English)corvin volocaruNo ratings yet

- FT14 IM, IFT14, FTGS14 and IFTGS14Document2 pagesFT14 IM, IFT14, FTGS14 and IFTGS14Henrry LingNo ratings yet

- Ep-01 enDocument8 pagesEp-01 enMikeNo ratings yet

- Disassembly/Assembly Manual Ro Iii 4X3: Excellent Engineering SolutionsDocument36 pagesDisassembly/Assembly Manual Ro Iii 4X3: Excellent Engineering SolutionsErica HenryNo ratings yet

- DP Series Wafer Check Valve CiDocument2 pagesDP Series Wafer Check Valve CiAerox neoNo ratings yet

- SERVICE MANUAL TUBE SEALER Model SE250Document38 pagesSERVICE MANUAL TUBE SEALER Model SE250silictronic100% (1)

- Manual ZB400II Catalogo de Repuestos PDFDocument31 pagesManual ZB400II Catalogo de Repuestos PDFDAVID GUTIERREZ POLONo ratings yet

- Unit Injector - InstallDocument4 pagesUnit Injector - InstallJose PichinteNo ratings yet

- Manual de ZB400Document35 pagesManual de ZB400marthos ericson muñoz castilloNo ratings yet

- Rease SystemDocument82 pagesRease Systemsundya100% (1)

- F70Pr Series Pilot-Operated Pressure Relief Valve: Installation, Operation, & Maintenance ManualDocument22 pagesF70Pr Series Pilot-Operated Pressure Relief Valve: Installation, Operation, & Maintenance ManualMoca PhoenixNo ratings yet

- Rotary Lobe ManualDocument19 pagesRotary Lobe ManualKamal UddinNo ratings yet

- Unit Injector - Install: Disassembly and AssemblyDocument5 pagesUnit Injector - Install: Disassembly and AssemblyJoze 23No ratings yet

- 727 PosrvDocument7 pages727 Posrvtxlucky80No ratings yet

- Thunder Tiger ManualDocument49 pagesThunder Tiger ManualOle Kristian FlatøyNo ratings yet

- Spec Bias CuttingDocument4 pagesSpec Bias Cuttingandri putrantoNo ratings yet

- PT - Toyota Astra Motor: Installation ManualDocument16 pagesPT - Toyota Astra Motor: Installation ManualArdi AgusmanNo ratings yet

- TDTG Bucket ElevatorDocument20 pagesTDTG Bucket ElevatorVictor Julio Torres Daza0% (1)

- F80 Manual RevE PDFDocument17 pagesF80 Manual RevE PDFNaseer HydenNo ratings yet

- Vibration Damper and Pulley - Remove and InstallDocument3 pagesVibration Damper and Pulley - Remove and Installbejoythomas100% (1)

- Curtis Se40-Se50 Parts ListDocument26 pagesCurtis Se40-Se50 Parts ListrobertNo ratings yet

- 2008 - 8 - DIN Threaded FittingsDocument10 pages2008 - 8 - DIN Threaded FittingsandytuorNo ratings yet

- Hook Block (游车大钩)Document18 pagesHook Block (游车大钩)Omar FathyNo ratings yet

- FT16 Ball Float Steam TrapDocument8 pagesFT16 Ball Float Steam Trapdoni mikaNo ratings yet

- c15 Inlet and Exhaust Valve RemovalDocument5 pagesc15 Inlet and Exhaust Valve RemovalMUHSIN MTNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- Figure 1. Service ValveDocument2 pagesFigure 1. Service ValvejuanchingarNo ratings yet

- BVR BOP: Technical Instruction ManualDocument9 pagesBVR BOP: Technical Instruction ManualGregory StewartNo ratings yet

- Manual For Pneumatic Automatic Feeder SpecificationDocument18 pagesManual For Pneumatic Automatic Feeder SpecificationhaisamnagyNo ratings yet

- Biodiesel Pump - 115V - 20 GPMDocument4 pagesBiodiesel Pump - 115V - 20 GPMOrganic MechanicNo ratings yet

- AAFs - v1.10-OmegaAir - enDocument10 pagesAAFs - v1.10-OmegaAir - enMột Lằn QuangNo ratings yet

- Pulper Rotor ManualDocument10 pagesPulper Rotor ManualhenryhariyadiNo ratings yet

- Ajin SMT - Operating Manual-1Document38 pagesAjin SMT - Operating Manual-1henry vegaNo ratings yet

- JISKOOT 710 EL MC Sampler Rev 0Document19 pagesJISKOOT 710 EL MC Sampler Rev 0rendi saputroNo ratings yet

- Manual Horizontal IOM Envirotech ESPDocument67 pagesManual Horizontal IOM Envirotech ESPOmar RodriguezNo ratings yet

- Jar IntensifierDocument2 pagesJar IntensifierMicNo ratings yet

- WOT - Tech Data Sheets PDFDocument43 pagesWOT - Tech Data Sheets PDFAmbroise RICHARDNo ratings yet

- ENVOY RAZOR-regulator-valve-service-manualDocument37 pagesENVOY RAZOR-regulator-valve-service-manualDon SheensNo ratings yet

- SE260SM CeDocument41 pagesSE260SM CeAnnuar Rais100% (3)

- Interchangeable Spindle Users Guide 4C v0311 WebDocument21 pagesInterchangeable Spindle Users Guide 4C v0311 WebMynor SGNo ratings yet

- Weber 55 DCODocument2 pagesWeber 55 DCOPatrick StivénNo ratings yet

- Air Handling Units 39 GDocument42 pagesAir Handling Units 39 Gthanh_79No ratings yet

- Grafica de Medidas para Recesion de Valvulas G3400Document3 pagesGrafica de Medidas para Recesion de Valvulas G3400carlos angelNo ratings yet

- Gcep09075 (Po13175)Document10 pagesGcep09075 (Po13175)Abdallah ElhendyNo ratings yet

- Single Output Current Sensor Assembly: Service ManualDocument40 pagesSingle Output Current Sensor Assembly: Service ManualAbdallah ElhendyNo ratings yet

- Part Number 26-73: Illustrated Parts BreakdownDocument150 pagesPart Number 26-73: Illustrated Parts BreakdownAbdallah ElhendyNo ratings yet

- Hydro-Mast Weight Indicator System: Service ManualDocument64 pagesHydro-Mast Weight Indicator System: Service ManualAbdallah Elhendy100% (1)

- Electric-to-Pneumatic (E/P) Transducer Assembly: 26-56-MAN (P/N 10075275-001) CDocument44 pagesElectric-to-Pneumatic (E/P) Transducer Assembly: 26-56-MAN (P/N 10075275-001) CAbdallah ElhendyNo ratings yet

- Joint Torque System: Service ManualDocument52 pagesJoint Torque System: Service ManualAbdallah ElhendyNo ratings yet

- Hydro-Weight Master Indicator System: Service ManualDocument39 pagesHydro-Weight Master Indicator System: Service ManualAbdallah ElhendyNo ratings yet

- Electronic Pressure Transducer: For Two Inch 1502 WECO Type Unions (P/N: 221212-Series)Document20 pagesElectronic Pressure Transducer: For Two Inch 1502 WECO Type Unions (P/N: 221212-Series)Abdallah ElhendyNo ratings yet

- Air Supply SystemDocument31 pagesAir Supply SystemAbdallah ElhendyNo ratings yet

- XS197K13-T89-00 DrawingDocument1 pageXS197K13-T89-00 DrawingAbdallah ElhendyNo ratings yet

- Aicte Internship Approval Pending 1Document7 pagesAicte Internship Approval Pending 1Anisha KumariNo ratings yet

- Pamphlet 89 Chlorine Scrubbing SystemsDocument36 pagesPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- National Pension System (NPS) - Subscriber Registration FormDocument3 pagesNational Pension System (NPS) - Subscriber Registration FormPratikJagtapNo ratings yet

- Hexoloy SP Sic TdsDocument4 pagesHexoloy SP Sic TdsAnonymous r3MoX2ZMTNo ratings yet

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- Namagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishDocument10 pagesNamagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishMonydit santinoNo ratings yet

- Romano Uts Paragraph Writing (Sorry For The Late)Document7 pagesRomano Uts Paragraph Writing (Sorry For The Late)ទី ទីNo ratings yet

- FPGA Implementation For Humidity and Temperature Remote Sensing SystemDocument5 pagesFPGA Implementation For Humidity and Temperature Remote Sensing SystemteekamNo ratings yet

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocument61 pagesSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASNo ratings yet

- Er6f Abs 2013Document134 pagesEr6f Abs 2013Calibmatic JobNo ratings yet

- Sop GC6890 MS5973Document11 pagesSop GC6890 MS5973Felipe AndrinoNo ratings yet

- Make Yeast StarterDocument2 pagesMake Yeast StarterAlexandraNo ratings yet

- 00.diesel Engine Power Plant Design PDFDocument4 pages00.diesel Engine Power Plant Design PDFmardirad100% (1)

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- All Worksheets MYSQLDocument33 pagesAll Worksheets MYSQLSample1No ratings yet

- Unit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Document147 pagesUnit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Madhan MNo ratings yet

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDocument10 pagesBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275No ratings yet

- 61annual Report 2010-11 EngDocument237 pages61annual Report 2010-11 Engsoap_bendNo ratings yet

- Hypothesis Testing Random MotorsDocument8 pagesHypothesis Testing Random MotorsLinn ArshadNo ratings yet

- En 1993 09Document160 pagesEn 1993 09Vio ChiNo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxNo ratings yet

- Admission: North South University (NSU) Question Bank Summer 2019Document10 pagesAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- Types of ComputersDocument7 pagesTypes of ComputersSyed Badshah YousafzaiNo ratings yet

- Shift Registers NotesDocument146 pagesShift Registers NotesRajat KumarNo ratings yet

- Powerplant QuestionsDocument19 pagesPowerplant QuestionsAshok KumarNo ratings yet

- ANNEXESDocument6 pagesANNEXESKyzer Calix LaguitNo ratings yet

- ALTS150-12P Datasheet1Document2 pagesALTS150-12P Datasheet1mamloveNo ratings yet

- Nissan Note E-Power 2022 Quick Guide ENDocument57 pagesNissan Note E-Power 2022 Quick Guide ENSarita EmmanuelNo ratings yet

- DA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Document6 pagesDA-I Question Bank From Module 1-3 of PHY1701 Course, Winter Semester 2020-21Likith MallipeddiNo ratings yet