Professional Documents

Culture Documents

Accesspro4 Instalación

Uploaded by

Juan Pablo SosaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accesspro4 Instalación

Uploaded by

Juan Pablo SosaCopyright:

Available Formats

AccessPRO4 I nstallation and C onnection G uide 4.

Equipment Communication

The PC software communicate with the system through two protocols (RS485 and TCP/IP)

Vision:1. 0.1 Date: July, 2011 for data exchange and remote management. The communication cable should be away

from high-voltage lines as far as possible. Do not keep the communication cable in parallel

with power cords or bind them together.

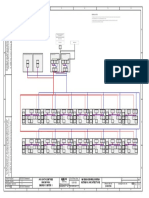

1) TCP/IP Mode:

1.Cautions

Please notice the following cautions. Mis-operation may lead to personal injury or

equipment failure: PC

1) Do not energize the system before installation is complete. Never carry out installation

activities when the system is energized. Card Reader

2) All peripheral devices must be grounded.

3) It is recommended that all wires run through casing pipes which may by PVC or galvanized

ones.

4) It is strongly recommended that the length of exposed part of any connection cable TCP/IP Ethernet S witch

should not be longer than 4 mm. Professional clamping tools may be used to avoid

unintentional contact of exposed wires to avoid short-circuit or communication failure.

5) It is recommended that card readers and buttons should be installed at height of 1.4m-1.5m

above ground.

6) It is recommended to use the power supply in case for control panel, and external power 1# Controller 2# Controller n# Controller

supply for each lock.

6

6

RS- 485 EXT

1

RS- 485 EXT

POWER

POWER

6

1

RS- 485 EXT

2.Equipment Installation

POWER

5

5

1

1

5

10

10

1

1

10

1

WIEGAND 3

WIEGAND 1

WIEGAND 3

WIEGAND 1

WIEGAND 3

WIEGAND 1

10

10

1

1

2

1

2

1

10

IN5

IN1 2

IN5

IN1 2

1

1 2

1 2

2

1

IN5

IN1 2

1

1

IN2 2

IN6

IN2 2

IN6

1 2

1

1

1

IN2 2

IN6

3

1

OUT5

OUT1 3

OUT5

OUT1 3

1

1

3

OUT5

OUT1 3

1

1

1

1

3

3

OUT2

OUT6

OUT2

OUT6

1

1

3

OUT2

OUT6

1

1

3

3

10

10

1

1

1

3

10

1

WIEGAND 2

WIEGAND 4

WIEGAND 2

WIEGAND 4

WIEGAND 2

WIEGAND 4

10

10

1

1

2

1

2

1

10

IN3 2

IN7

IN3 2

IN7

1

p

q

1 2

1 2

2

1

IN3 2

IN7

1

1

IN4 2

IN8

IN4 2

IN8

q

1 2

1

1

1

IN4 2

IN8

3

1

3

1

OUT3

OUT7

OUT3

OUT7

1

3

1

OUT3

OUT7

1

3 1

1

3 1

3

3

OUT4

OUT8

OUT4

OUT8

1

3 1

3

OUT4

OUT8

1

1

3

3

Reset

Reset

1

3

Reset

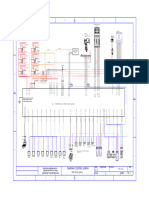

2) RS485 Mode:

1 Select two of the elliptical holes on 2 Hang the equipment on the upper 3 Push the equipment backward to hang

the rear iron cover. Drill two holes edge of the rear iron cover, and the entire equipment onto the rear cover. RS 485 Convertor

on the surface for fixing (Which may then press the equipment down.

485-

be on a distribution cabinet, ceiling 485+

G ND

or other weatherproof position).

Serial Bus

RS485 Ports

3. Lock Connection G N D 485+ 485-

4 3 2 1

G N D 485+485-

4 3 2 1

G N D 485+ 485-

4 3 2 1

PC

1)The access controller provides lock control output. For a lock which should be open when being energized and be closed 1# Controller 2# Controller 8# Controller

when being de-energized, the “COM” and “ NO” terminals should be used. For a lock which should be open when being

de-energized and be closed when being energized, the “COM” and “ NC” terminals should be used.

6

1

RS- 485 EXT

6

1

RS- 485 EXT

RS- 485 EXT

POWER

POWER

POWER

2) If the electrical lock is connected to the access control system, you need to parallel one FR107 diode (Equipped

5

5

1

1

in the package) to prevent the self-inductance EMF affect the system, do not reverse the polarities.

10

1

10

10

1

1

WIEGAND 3

WIEGAND 1

WIEGAND 3

WIEGAND 1

WIEGAND 3

WIEGAND 1

3) Each relay may work under the wet mode or dry mode by setting the jumper terminal. If the 12V power

10

10

10

1

1

2

1

IN5

IN1 2

2

1

2

supply inside the access controller uses external power supply, the output of each relay is under the “wet mode”. 1

IN5

IN1 2

IN5

IN1 2

1 2

1 2

1 2

1

IN2 2

IN6

1

IN2 2

IN6

IN2 2

IN6

1

1

1

3

OUT5

OUT1 3

3

OUT5

OUT1 3

OUT5

OUT1 3

If the external power supply uses potential free contacts, the “dry mode” should be used. please refer to

1

1

1

3

OUT2

OUT6

1

3

3

OUT2

OUT6

OUT2

OUT6

1

3

1

3

3

10

1

Instructions for Hardware of C4-200/400 Access Controller.

10

10

1

1

WIEGAND 2

WIEGAND 4

WIEGAND 2

WIEGAND 4

WIEGAND 2

WIEGAND 4

* It is recommended to short 2-3 ports, the output use the “dry mode”, the electronic lock use the external power supply.

10

10

10

1

1

2

1

IN3 2

IN7

2

1

2

1

IN3 2

IN7

IN3 2

IN7

q

1 2

p

1 2

1 2

1

IN4 2

IN8

1 2 3 4

1

1

IN4 2

IN8

IN4 2

IN8

1

1

3

1

OUT3

OUT7

3

1

OUT3

OUT7

OUT3

OUT7

1

3 1

1

3 1

1

3 1

3

OUT4

OUT8

3

OUT4

OUT8

OUT4

OUT8

-

1

3

Reset

1

3

1

Reset

Reset

L ock Power

+

6

1

RS- 485 EXT

POWER

FR107

Notes:

5

Unlock at power on

1

1) Internationally accepted RVSP (shielded twisted-pair) wires should be used for communication

10

1

Diode

WIEGAND 3

WIEGAND 1

L ock + - Enlar ged diag ram to effectively avoid interference. RS485 communication wires should be connected by means

- + of lock ports of bus cascade connection.

10

1

2

1

IN5

IN1 2

2) Theoretically, in RS485 communication, one bus may be connected with 64 access controllers.

1 2

1

IN2 2

IN6

1

NO

1

3

OUT5

OUT1 3

It is recommended to conenct with no more than 16 devices.

1

Unlock at power off

1

3

OUT2

OUT6

COM

3) The recommended bus length of RS485 communication is less than 600 meters.

1

3

10

1

Diode NC

WIEGAND 2

WIEGAND 4

- + 4) When the bus is longer than 300 m, to enhance the stability of communication, it is necessary

L ock

to change J24 on the first layer of PCB (see the figure below) inthe first and the last units (see

-

+

10

1

2

1

IN3 2

IN7

FR107

q

1 2

unit 8# as shown in the figure above) to short pins 2-3. This method is equivalent to connect

1

IN4 2

IN8

1

3

1

+

OUT3

OUT7

with a resistance of 120 ohm.

1

3 1

3

OUT4

OUT8

L ock Power

1

3

Reset

- Jumper terminals

External power supply for electronic lock 1234 RS485

J24

wet mode:

J24 Enlargement

1234 1234

123

123

123

Jumper terminals

1234

dry mode: Terminal resistance setting Factory default

R elay R elay

OUT8

OUT4

Jumping Terminals

Distribution 1234

OUT7

OUT3

R elay R elay diagram of the

factory default

jumper cap:

4 3 2 1 1 2 3 4

IN4

IN8

Terminal resistance setting diagram (The first layer of PCB)

R elay output por ts and j umper ter minals setting (The second layer of PCB)

5.Terminals Connection

Notes:

1) The auxiliary input may be connected to infrared body detectors, smoke detectors, gas detectors, window magnetic alarms, wireless exit switches, etc.

2) The auxiliary output may be connected to locks, monitors, alarms, door bells, etc.

3) The auxiliary input and the auxiliary output is set with iAccess4.0.

4) GPRS, WiFi and the following items indicated with "*" are optional. Please contact our business representatives or pre-sale technical

support for ordering machines with GPRS and WiFi functions.

5) Recommend use of wires

A. Use 2-conducotor power cord

B. According to the port you connected, choose such as 8,10 conductor cord communication twisted-pair sensor cable (RVVP 8*0.5mm)

C. Use 2-conducotor lock power cord (RVV 2*0.75mm)

D. Use 2-conducotor switch or magnetic power cord (RVV 2*0.5mm)

Fr ont V iew Fr ont Side V iew

A

6

+12V Data_Tx-

}*

1

{ GND

RS- 485 EXT

12V Power Input RS 422 Send

Data_Tx+ USB

POWER

U Disk

Shield Wire Shield GND

* AC Fail Detection AC Fail Data_RxTx-

}** or RS485 Comm.

RS422 Receive

* Battery Fail Detection Battery Fail Data_RxTx+

5

Shield Shield Wire

*

1

TCP/IP TCP/IP Comm.

B

B Card_present

VCC 12V *Card Present

10

{

1

12V Power Output Hold

GND

*Beep

Controlled Reader Hold

TXD232 RS 232 Send

*

{ BEEP

RS- 232

1

Wiegand Input D0 RXD232

*

}

WIEGAND 3

RS 232 Receive

WIEGAND 1

D1 LED_R Red Output

/ Idle

Sheild Wire Shield LED_G Green

GND RS 232 Ground

*

4

Green LED_G Shield Shield Wire

Output

{ Red

Beep

LED_R

BEEP

D1

D0

GND } Wiegand Input

* Controlled Reader Hold Hold

VCC 12V 12V Power Output

* Card Present Card_present

10

GND D

D Analog_input }Door Switch 3

2

1

{ Analog_input

IN5

IN1 2

Door Switch 1

GND

D

1 2

GND

D } Magnet 3

1

Analog_input Analog_input

IN6

IN2 2

Magnet 1

{GND 1

IN9

Analog_input

D

1

NC C Auxiliary Input

}

GND

1

2

3

NO COM Lock 3

OUT5

C

OUT1 3

Lock 1

{ COM NO Analog_input D

1

IN10

NC GND Auxiliary Input

1

NC

2

C

}

1

NO

3

C COM Auxiliary Output Analog_input D

OUT6

OUT2

{

IN11

Auxiliary Output COM NO Auxiliary Input

GND

B

2

NC

1

D

*Controlled Reader Hold

3

Card_present Card Present Analog_input

1

IN12

B

10

VCC 12V Auxiliary Input

{ Hold

1

12V Power Output

GND * Beep GND

2

BEEP

Wiegand Input

{ D0 LED_R Red

} Output

WIEGAND 4

WIEGAND 2

D1 LED_G Green

Shield Wire Shield Shield Shield Wire

Green LED_G D1

Output

{ LED_R D0

} NO C

OUT9

Red Wiegand Input

1

Beep BEEP GND COM Auxiliary Output

* ControlledCardReaderPresent

Hold Hold VCC 12V 12V Power Out NC

3

Card_present

* D

10

GND

1

NO

OUT10

}Door Switch 4

1

D Analog_input C

COM

2

1

Analog_input

{ Auxiliary Output

IN7

IN3 2

Door Switch 3

GND GND D NC

q

}

1 2

Magnet 4

D Analog_input

1

{Analog_input

IN8

IN4 2

Magnet 3

GND NC C

}

1

COM Lock 4

3

1

NO

OUT7

OUT3

{

C NO

Lock 2 COM

NC NC C

}

1

3 1

COM Auliliary Output

C NO

3

{

OUT8

OUT4

NO

Auliliary Output COM

NC

*

1

Shield

3

Shield Wire

Reset

1

RS- 485

RS 485-

RS 485+

GND

} RS485 Comm.

*

RS485 Ground

*

4

You might also like

- CDR1270 - Manual - Final Getting Started GuideDocument23 pagesCDR1270 - Manual - Final Getting Started GuidePaul WilkinsonNo ratings yet

- Beckhoff Main Catalog 2016 PDFDocument1,009 pagesBeckhoff Main Catalog 2016 PDFChi Lac PhungNo ratings yet

- SCADA Network ArchitectureDocument1 pageSCADA Network ArchitectureSlick72No ratings yet

- 564shj22-01-Gym-Tc-101 R1Document1 page564shj22-01-Gym-Tc-101 R1IbrahimUnesNo ratings yet

- Argus GT User ManualDocument1 pageArgus GT User ManualDian RusdianaNo ratings yet

- Opensprinkler Pi (Ospi) V1.43+ User Manual: Updated May 1, 2020Document7 pagesOpensprinkler Pi (Ospi) V1.43+ User Manual: Updated May 1, 2020Rui WangNo ratings yet

- A Complete Design Flow For Silicon PhotonicsDocument17 pagesA Complete Design Flow For Silicon PhotonicsnowdayNo ratings yet

- SOUTH Operation ManualDocument236 pagesSOUTH Operation ManualPrashanth Reddy TummuluriNo ratings yet

- B&K Front EndDocument24 pagesB&K Front Endzamri mohdNo ratings yet

- Argus User ManualDocument1 pageArgus User Manualanak gondrongNo ratings yet

- Digium Failover Appliances Application BriefDocument3 pagesDigium Failover Appliances Application Briefmaple4VOIPNo ratings yet

- Yur9hq1jki 1345213780Document2 pagesYur9hq1jki 1345213780Viktor GudymenkoNo ratings yet

- WA MelchiorriDocument70 pagesWA MelchiorriAbhishek DharNo ratings yet

- InBIO280 Installation and Connection Guide V2.0Document2 pagesInBIO280 Installation and Connection Guide V2.0fmanriquezarceNo ratings yet

- Publi 6615Document5 pagesPubli 6615Bhargav ChiruNo ratings yet

- CSC 398 Functional Programming: Instructor: Dr. Hao Wu Lecture 2 Haskell and Functional ProgrammingDocument24 pagesCSC 398 Functional Programming: Instructor: Dr. Hao Wu Lecture 2 Haskell and Functional ProgrammingCleo BrownNo ratings yet

- DefinitionDocument6 pagesDefinitionMaryanthony NamyaloNo ratings yet

- Smart Doorbell: User ManualDocument1 pageSmart Doorbell: User ManualCristhianNo ratings yet

- LAN & IPT Workshop - Melbourne: AgendaDocument45 pagesLAN & IPT Workshop - Melbourne: AgendaPaul YeoNo ratings yet

- NotnotDocument27 pagesNotnotDanica CamagongNo ratings yet

- Lecture 2 (EPANET 2.2)Document18 pagesLecture 2 (EPANET 2.2)17018 Md. Shahariar KabirNo ratings yet

- Drag 3 User ManualDocument1 pageDrag 3 User ManualR.PruittNo ratings yet

- Ahug-Ayv8vj R0 enDocument30 pagesAhug-Ayv8vj R0 enAmerico AndresNo ratings yet

- Control Solenid Main Mod Control Circuit High P0963Document4 pagesControl Solenid Main Mod Control Circuit High P0963Christian Ramos Alarcon100% (1)

- 21bce8457 CN Ass6Document3 pages21bce8457 CN Ass6roopa KowshiNo ratings yet

- Interface Technology in Modular Housings: Your Global Automation PartnerDocument16 pagesInterface Technology in Modular Housings: Your Global Automation PartnerJorge_Andril_5370No ratings yet

- GRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsDocument1 pageGRE - eec.D.99.CL.P.07576.12.014.01 Tracker Controller Cable ConnectionsJason DaNny FloResNo ratings yet

- AGU 03 TopkapiDocument1 pageAGU 03 TopkapiDanny Bendezú EstebanNo ratings yet

- Ericsson Spo 1400 Family: Packet Optical Transport-EtsiDocument4 pagesEricsson Spo 1400 Family: Packet Optical Transport-EtsiDanish RashidNo ratings yet

- W1 W3-B-C User ManualDocument1 pageW1 W3-B-C User Manualamad4youNo ratings yet

- 9971-1120 All eDocument3 pages9971-1120 All emohamad eslamiNo ratings yet

- Fttx/Pon Testing Reference PosterDocument3 pagesFttx/Pon Testing Reference PosterDjnsilva SilvaNo ratings yet

- Procedures or Subprograms: ObjectivesDocument65 pagesProcedures or Subprograms: ObjectivesFebwin VillaceranNo ratings yet

- iNUKE NU6000DSP: Service ManualDocument45 pagesiNUKE NU6000DSP: Service ManualHerberth BarriosNo ratings yet

- Micro Data Center Layout, Cable Management, Grounding/Bonding, Power and IDDocument2 pagesMicro Data Center Layout, Cable Management, Grounding/Bonding, Power and IDhgfdfg jhhNo ratings yet

- Multisim DIGITAl CircuitDocument22 pagesMultisim DIGITAl Circuitmichaeledem_royal100% (1)

- Development of An Animal-Component Free Electroporation and Recovery Formulation Using EX-CELL CHO Cloning MediumDocument1 pageDevelopment of An Animal-Component Free Electroporation and Recovery Formulation Using EX-CELL CHO Cloning MediumSAFC-GlobalNo ratings yet

- Tan 2001Document6 pagesTan 2001t123medNo ratings yet

- Enet pp005 - en eDocument4 pagesEnet pp005 - en esoayNo ratings yet

- UD19517B-E Baseline New Plastice Case Hybrid Security Control-Panel QSG V1.3 20201210Document4 pagesUD19517B-E Baseline New Plastice Case Hybrid Security Control-Panel QSG V1.3 20201210Ed SeguelNo ratings yet

- 1110 1600 1112 Schematics PDFDocument8 pages1110 1600 1112 Schematics PDFSumeet PandeyNo ratings yet

- TT710 (4GE+CATV+2WIFI xPON ONU) Datasheet-V1.0Document7 pagesTT710 (4GE+CATV+2WIFI xPON ONU) Datasheet-V1.0nguyenbaviet89No ratings yet

- Combivert: Instruction ManualDocument36 pagesCombivert: Instruction Manualruisengo100% (1)

- SIP To TCAP GatewayDocument2 pagesSIP To TCAP Gatewayrana_gpNo ratings yet

- 00 F 5 Sebk 320Document40 pages00 F 5 Sebk 320Mr.K chNo ratings yet

- Analisa Penyebab Kebakaran Dengan GCMSDocument7 pagesAnalisa Penyebab Kebakaran Dengan GCMSabdurahman143No ratings yet

- Model Tuning - Mentum PlanetDocument36 pagesModel Tuning - Mentum Planettomarnitin19833526No ratings yet

- QUBE-Servo MyRIO Quick Start GuideDocument4 pagesQUBE-Servo MyRIO Quick Start GuidealfredokpuNo ratings yet

- Robocup 2023 - RCT - Electrical PresentationDocument4 pagesRobocup 2023 - RCT - Electrical PresentationRevidadina Dwi JunitaNo ratings yet

- Manual Servicio Mini Component Sound System Noblex MNX 3000sDocument35 pagesManual Servicio Mini Component Sound System Noblex MNX 3000sNey TrajanoNo ratings yet

- Apple's CSAM Detection MechanismDocument12 pagesApple's CSAM Detection MechanismMike WuertheleNo ratings yet

- Gpon Ma5800Document42 pagesGpon Ma5800rommel salvadorNo ratings yet

- Instrument Hookup 9Document1 pageInstrument Hookup 9Wael ZakariaNo ratings yet

- 1.1.3.11 Lab - Draw A Process DiagramDocument4 pages1.1.3.11 Lab - Draw A Process DiagramJoshua ManalotoNo ratings yet

- Yieldsense: Operator'S ManualDocument24 pagesYieldsense: Operator'S Manuallaguna ag solutionsNo ratings yet

- Third Year: Practical Work Book For The Course EE-394 Communication SystemDocument22 pagesThird Year: Practical Work Book For The Course EE-394 Communication SystemMehmood ShahNo ratings yet

- Ocf - Pipe Rack 4 - Sheet-6Document1 pageOcf - Pipe Rack 4 - Sheet-6Suresh KannanNo ratings yet

- Samsung-led-monitor-SA300 Service ManualDocument41 pagesSamsung-led-monitor-SA300 Service ManualLuciano GerloNo ratings yet

- Lincoln LN25PRODocument6 pagesLincoln LN25PROmartinNo ratings yet

- Oxytome HPCDocument106 pagesOxytome HPCAnghelache RazvanNo ratings yet

- Fire Cable Installation MethodsDocument3 pagesFire Cable Installation MethodsHansika RajapakshaNo ratings yet

- MiCOM P139 TechnicalManual1Document806 pagesMiCOM P139 TechnicalManual1VanBan NguyenNo ratings yet

- RD7100-Guia UsuarioDocument43 pagesRD7100-Guia UsuariojuanchingarNo ratings yet

- GEA 71B/C: Installation ManualDocument61 pagesGEA 71B/C: Installation ManualВасилий ПавленкоNo ratings yet

- Polycab Cables Price List 2021Document4 pagesPolycab Cables Price List 2021Ulhas Vajre75% (4)

- Exhibitor 35804 PDFDocument36 pagesExhibitor 35804 PDFulton1237624No ratings yet

- 0 - Cover Page-Index (Section II A)Document3 pages0 - Cover Page-Index (Section II A)owngauravNo ratings yet

- Installation Instructions: Viewline 52 MMDocument6 pagesInstallation Instructions: Viewline 52 MMMaksim Panfilov100% (1)

- Sierra Wireless FX30S: User GuideDocument74 pagesSierra Wireless FX30S: User Guidehamdi galipNo ratings yet

- Hilti FS ManualDocument514 pagesHilti FS ManualHard T. Target100% (1)

- Fire Resistant Cables CatalogueDocument7 pagesFire Resistant Cables CatalogueSathis Kumar Naidu Thasnamoothy100% (2)

- Satrun 8000 Operation Manual (FXRD-3643VW4343VW2530VW) V1.0 - 1.3 - EN - 20211014 - NO GMP - Old AddressDocument76 pagesSatrun 8000 Operation Manual (FXRD-3643VW4343VW2530VW) V1.0 - 1.3 - EN - 20211014 - NO GMP - Old AddressArllette MeridaNo ratings yet

- 5500 HI Installation Guide (20111031)Document65 pages5500 HI Installation Guide (20111031)yocabezaNo ratings yet

- User Manual Part 2 3787009Document29 pagesUser Manual Part 2 3787009Yirgalem AddisNo ratings yet

- ATGofgao PDFDocument343 pagesATGofgao PDFWandencolk CoêlhoNo ratings yet

- 3927 - 01 - 00 - 02 - Follow-Up Amplifier AS, Type 139-158Document69 pages3927 - 01 - 00 - 02 - Follow-Up Amplifier AS, Type 139-158Marios Apostolou100% (2)

- Power Cable With PUR Jacket: Technical Data: BC428 - BC429Document1 pagePower Cable With PUR Jacket: Technical Data: BC428 - BC429fuchswebdeNo ratings yet

- SE10908 WD Catalogue WebDocument312 pagesSE10908 WD Catalogue WebZzzdddNo ratings yet

- E84AVSCx 8400 StateLine C v1-2 en Ma-2Document76 pagesE84AVSCx 8400 StateLine C v1-2 en Ma-2oscarNo ratings yet

- Anand Kumar Sinha: Phone Number: +91 7903371842 (M)Document2 pagesAnand Kumar Sinha: Phone Number: +91 7903371842 (M)Anand SinhaNo ratings yet

- The Phaserunner Motor Controller V2: User Manual - Rev2.0, ConnectorizedDocument16 pagesThe Phaserunner Motor Controller V2: User Manual - Rev2.0, Connectorizedbinouz24No ratings yet

- Tesla's Big Mistake (William Beaty)Document8 pagesTesla's Big Mistake (William Beaty)THE NIKOLA TESLA INSTITUTE100% (1)

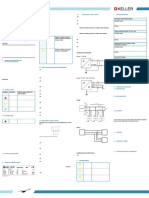

- Pressure Sensors and Systems: R&D With Kistler Solutions High-Precision Engine Indicating - Onboard and On The Test BenchDocument5 pagesPressure Sensors and Systems: R&D With Kistler Solutions High-Precision Engine Indicating - Onboard and On The Test BenchAlbertNo ratings yet

- Betriebsanleitung Pegelsonden eDocument1 pageBetriebsanleitung Pegelsonden ecesarjaramilloudeNo ratings yet

- ATOM GPS Quick Installation GuideDocument4 pagesATOM GPS Quick Installation GuideAZRA comNo ratings yet

- Color Echo Sounder: Operation ManualDocument41 pagesColor Echo Sounder: Operation ManualtchepssilveiraNo ratings yet

- ZXR10 8900 Series: Hardware Installation ManualDocument109 pagesZXR10 8900 Series: Hardware Installation ManualErnestoLopezGonzalezNo ratings yet

- DPS SMC ConfiguracionDocument76 pagesDPS SMC ConfiguracionAlejandro Armendáriz PérezNo ratings yet