Professional Documents

Culture Documents

Detailed Table of Contents

Detailed Table of Contents

Uploaded by

Maimouna CoulibalyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Detailed Table of Contents

Detailed Table of Contents

Uploaded by

Maimouna CoulibalyCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/259800926

CAD/CAM Principles and Applications

Book · May 2010

CITATIONS READS

12 24,145

1 author:

Nageswara Rao Posinasetti

University of Northern Iowa

210 PUBLICATIONS 1,206 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Diecasting View project

All content following this page was uploaded by Nageswara Rao Posinasetti on 09 February 2014.

The user has requested enhancement of the downloaded file.

CONTENTS

Preface vii

Acknowledgements xi

1. Introduction 1

Objectives 1

1.1 Computers in Industrial Manufacturing 1

1.2 Design Process 2

1.3 Computer Aided Design (CAD) 13

1.4 Computer Aided Manufacturing (CAM) 14

1.5 Computer Integrated Manufacturing (CIM) 15

Summary 16

Questions 17

Part - I Hardware and Software Components

2. CAD/CAM Hardware 21

Objectives 21

2.1 Basic Structure 21

2.2 Central Processing Unit (CPU) 22

2.3 Memory Types 25

2.4 Input Devices 28

2.5 Display Devices 32

2.6 Hard-Copy Devices 39

2.7 Storage Devices 41

2.8 Software 45

2.9 System Configuration 47

Summary 50

Questions 51

Problems 51

xiv Contents

3. Computer Graphics 53

Objectives 53

3.1 Raster-Scan Graphics 53

3.2 Coordinate Systems 59

3.3 Database Structures for Graphic Modelling 61

3.4 Engineering Data Management (EDM) System 66

3.5 Transformation of Geometry 70

3.6 3D Transformations 77

3.7 Mathematics of Projection 78

3.8 Clipping 80

3.9 Hidden Line/Surface Removal 83

3.10 Colour 86

3.11 Shading 87

Summary 90

Questions 91

Problems 92

Part - II Design of Industrial Products

4. Geometric Modelling 97

Objectives 97

4.1 Requirements of Geometric Modelling 97

4.2 Geometric Models 99

4.3 Geometric Construction Methods 102

4.4 Constraint-Based Modelling 113

4.5 Other Modelling Methods 116

4.6 Wireframe Modelling 118

4.7 Curve Representation 122

4.8 Surface-Representation Methods 139

4.9 Solid-Representation Methods 152

4.10 Modelling Facilities Desired 164

4.11 Rapid Prototyping (RP) 168

Summary 176

Questions 177

Problems 179

5. CAD Standards 180

Objectives 180

5.1 Standardisation in Graphics 180

5.2 Graphical Kernel System (GKS) 181

5.3 Other Graphic Standards 183

Contents

xv

5.4 Exchange of Modelling Data 184

Summary 196

Questions 197

6. Introduction to a Drafting System 198

Objectives 198

6.1 Basic Facilities in Autocad 198

6.2 Basic Geometric Commands 203

6.3 Layers 207

6.4 Display Control Commands 208

6.5 Editing a Drawing 212

6.6 Dimensioning 216

Summary 217

Questions 218

7. Introduction to Modelling Systems 219

Objectives 219

7.1 Introduction 219

7.2 Constraint-Based Modelling 220

Summary 229

Questions 230

8. Finite Element Analysis 231

Objectives 231

8.1 Introduction 231

8.2 FEM Software 232

8.3 Stiffness Matrices 236

8.4 Truss and Beam Analysis 242

8.5 Beam Analysis 247

8.6 Plane Stress/Strain Analysis 250

Summary 253

Questions 253

Problems 253

Part - III Manufacturing Aspects of Industrial Products

9. Introduction to Computer Numerical Control 257

Objectives 257

9.1 Introduction 257

9.2 Numerical Control 258

9.3 Numerical Control Modes 261

9.4 Numerical Control Elements 262

xvi Contents

9.5 NC Machine Tools 265

Summary 270

Questions 271

10. CNC Hardware Basics 272

Objectives 272

10.1 Structure of CNC Machine Tools 272

10.2 Spindle Design 274

10.3 Drives 276

10.4 Actuation Systems 279

10.5 Feedback Devices 283

10.6 Axes—Standards 286

Summary 289

Questions 290

11. CNC Tooling 291

Objectives 291

11.1 Cutting-Tool Materials 291

11.2 Turning-Tool Geometry 294

11.3 Milling Tooling Systems 297

11.4 Tool Presetting 298

11.5 Automatic Tool Changers 300

11.6 Work Holding 304

11.7 Cutting-Process Parameter Selection 306

Summary 312

Questions 312

12. CNC Machine Tools and Control Systems 314

Objectives 314

12.1 CNC Machining Centres 314

12.2 CNC Turning Centres 322

12.3 High-Speed Machine Tools 329

12.4 Machine Control Unit 333

12.5 Support Systems 341

12.6 Touch-Trigger Probes 342

Summary 346

Questions 347

13. CNC Programming 348

Objectives 348

13.1 Part-Programming Fundamentals 348

13.2 Manual Part-Programming Methods 354

Contents

xvii

13.3 Preparatory Functions 358

13.4 Miscellaneous Functions, M 367

13.5 Program Number 369

13.6 Tool-Length Compensation 372

13.7 Canned Cycles 372

13.8 Cutter-Radius Compensation 378

Summary 396

Questions 397

Problems 397

14. Turning-Centre Programming 402

Objectives 402

14.1 Comparison Between Machining Centres and Turning Centres 402

14.2 Tape Formats 403

14.3 Axes System 404

14.4 General Programming Functions 405

14.5 Motion Commands 410

14.6 Cut Planning 414

14.7 Thread Cutting 418

14.8 Canned Cycles 419

Summary 422

Questions 423

15. Advanced Part-Programming Methods 427

Objectives 427

15.1 Polar Coordinates 427

15.2 Parameters 428

15.3 Looping and Jumping 431

15.4 Subroutines 436

15.5 Mirror Imaging and Scaling 442

15.6 Special Canned Cycles 446

Summary 450

Questions 451

16. Computer-Aided Part Programming 452

Objectives 452

16.1 Concept of CAP 453

16.2 APT Language Structure 455

16.3 Geometry Commands 458

16.4 Motion Commands 474

16.5 Postprocessor Commands 482

xviii Contents

16.6 Compilation Control Commands 483

16.7 Repetitive Programming 484

16.8 Complete Part Program in APT 492

16.9 CAM Systems 494

Summary 509

Questions 510

Problems 510

Part - IV Role of Information Systems

17. Information Requirements of Manufacturing 515

Objectives 515

17.1 Discrete Part Manufacture 515

17.2 Information Requirements of a Production Organisaton 517

17.3 Manufacturing Strategies 519

17.4 Integration Requirements 520

Summary 521

Questions 521

18. Group Technology and Computer Aided Process Planning 522

Objectives 522

18.1 Group Technology 522

18.2 Classification and Coding 526

18.3 Production Flow Analysis 534

18.4 Cellular Manufacturing 542

18.5 Computer Aided Process Planning 547

18.6 CAPP: Implementation Techniques 547

Summary 552

Questions 553

Problems 554

19. Production Planning and Control 557

Objectives 557

19.1 Introduction 557

19.2 Production Planning 558

19.3 Capacity Planning 560

19.4 Master Production Schedule 561

19.5 Material Requirement Planning (MRP) 563

19.6 Production Activity Control (PAC) 569

19.7 Optimised Production Technology (OPT) 574

19.8 Manufacturing Resource Planning (MRP II) 575

19.9 Just In Time (JIT) 577

Contents

xix

Summary 578

Questions 579

Part - V Integration of Manufacturing Systems

20. Communications 583

Objectives 583

20.1 Communication Methods 583

20.2 Direct Numerical Control 587

20.3 Communication Standards 594

Summary 597

Questions 598

21. Material-Handling Systems 599

Objectives 599

21.1 Introduction 600

21.2 Automatic Guided Vehicles (AGV) 601

21.3 Robots 610

21.4 Automated Storage and Retrieval System 646

Summary 653

Questions 654

22. Flexible Manufacturing Systems 657

Objectives 657

22.1 Introduction to FMS 658

22.2 FMS Equipment 660

22.3 Tool-Management Systems 664

22.4 System Layouts 672

22.5 FMS Control 672

22.6 Development of the Concept 678

22.7 FMS Case Study 683

Summary 688

Questions 689

23. Computer Aided Quality Control 691

Objectives 691

23.1 Introduction 691

23.2 Inspection and Testing 692

23.3 Coordinate Measuring Machine 693

23.4 Non-Contact Inspection Methods 699

23.5 Statistical Quality Control 700

23.6 Statistical Process Control (SPC) 704

xx Contents

23.7 Total Quality Management (TQM) 705

23.8 Six Sigma 707

23.9 Integration of CAQC with CAD and CAM 709

Summary 711

Questions 712

24. Computer Integrated Manufacturing 713

Objectives 713

24.1 Historical Background 713

24.2 Integration 716

24.3 CIM Implementation 718

24.4 Benefits of CIM 724

24.5 Lean Manufacturing 725

Summary 728

Questions 728

Bibliography 731

Glossary of Terms 735

Standards Pertaining to CAM 751

Internet Addresses 754

Index 758

View publication stats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Caterpillar Cat 279D COMPACT TRACK LOADER (Prefix GTL) Service Repair Manual (GTL00001 and Up) PDFDocument7 pagesCaterpillar Cat 279D COMPACT TRACK LOADER (Prefix GTL) Service Repair Manual (GTL00001 and Up) PDFfksjdnkem0% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Annexes 033-CQB Release 10Document269 pagesAnnexes 033-CQB Release 10Eliezer Planes100% (7)

- Computer Implementation of An Optimal Conformal Mapping For Gear Tooth Stress AnalysisDocument9 pagesComputer Implementation of An Optimal Conformal Mapping For Gear Tooth Stress Analysisభుక్య వెంకటేష్No ratings yet

- An Experimental Investigation of High Contact Ratio Gear Tooth Behaviour PDFDocument199 pagesAn Experimental Investigation of High Contact Ratio Gear Tooth Behaviour PDFభుక్య వెంకటేష్No ratings yet

- Information Brochure Ph.D. Admissions 2017-18: Indian Institute of Technology DharwadDocument45 pagesInformation Brochure Ph.D. Admissions 2017-18: Indian Institute of Technology Dharwadభుక్య వెంకటేష్No ratings yet

- Me (Cadcam) 0708Document20 pagesMe (Cadcam) 0708భుక్య వెంకటేష్No ratings yet

- Til 1937-R1Document12 pagesTil 1937-R1BouazzaNo ratings yet

- (IJCST-V7I3P1) : Dr. Mumdouh Mirghani Mohamed Hassan, Dr. Yusuf Perwej, Dr. Awad Haj Ali Ahmed, Dr. Firoj ParwejDocument13 pages(IJCST-V7I3P1) : Dr. Mumdouh Mirghani Mohamed Hassan, Dr. Yusuf Perwej, Dr. Awad Haj Ali Ahmed, Dr. Firoj ParwejEighthSenseGroupNo ratings yet

- Boiler Controls and Boiler InterlocksDocument24 pagesBoiler Controls and Boiler InterlocksMohamed ShameemNo ratings yet

- Design and Construction of Potato Slicing MachineDocument4 pagesDesign and Construction of Potato Slicing MachineDr. Aung Ko LattNo ratings yet

- 3电气与信息系统 L958F英文Document106 pages3电气与信息系统 L958F英文gerallazo29No ratings yet

- Pamin, Michelle P.: BJT Modes of OperationDocument9 pagesPamin, Michelle P.: BJT Modes of OperationMitz PaminNo ratings yet

- eleganza 2 user manualDocument84 pageseleganza 2 user manualengngng1No ratings yet

- 1 s2.0 s1000936120300546 MainDocument11 pages1 s2.0 s1000936120300546 MainPai Gerdin HawkNo ratings yet

- XN PLC CanopenDocument54 pagesXN PLC CanopenPedro Henrique SantosNo ratings yet

- Project Report BFL2Document41 pagesProject Report BFL2quicksilver3593No ratings yet

- Ed024212 PDFDocument423 pagesEd024212 PDFImran Mr PerfectNo ratings yet

- Design of BeamsDocument112 pagesDesign of BeamskbkwebsNo ratings yet

- ASR User GuideDocument85 pagesASR User GuideJose TapiaNo ratings yet

- Quiz 10th CEDocument2 pagesQuiz 10th CEpankaj16fbNo ratings yet

- Leistritz Compounding ENGDocument9 pagesLeistritz Compounding ENGGustavoNo ratings yet

- Heavy Oil PDFDocument42 pagesHeavy Oil PDFRehan MansoorNo ratings yet

- Negative Resistance DevicesDocument4 pagesNegative Resistance DevicesHasitha Gayan JayasundaraNo ratings yet

- Micrometer and Slip GaugeDocument17 pagesMicrometer and Slip GaugeKrishh GuptaNo ratings yet

- 2005 Duramax Manual PDFDocument78 pages2005 Duramax Manual PDFmarcelo oliveira0% (2)

- DNV GL Sesam SoftwareDocument3 pagesDNV GL Sesam SoftwarearpitNo ratings yet

- ETW 400 BrochureDocument4 pagesETW 400 Brochurenimaboat4589No ratings yet

- 702a298d-f6f1-4a3c-96f9-33201d979748Document21 pages702a298d-f6f1-4a3c-96f9-33201d979748aklatreaderNo ratings yet

- Six Sigma Green Belt: (GB - 52 Batch)Document4 pagesSix Sigma Green Belt: (GB - 52 Batch)ashNo ratings yet

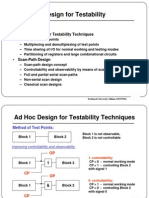

- 3 Testability DesignDocument65 pages3 Testability DesignMadhukumar KsNo ratings yet

- Physics Thermodynamics MCQsDocument2 pagesPhysics Thermodynamics MCQsMohammad Umair100% (1)

- What Are Available Drivers in JDBC?: JDBC-ODBC Bridge DriverDocument8 pagesWhat Are Available Drivers in JDBC?: JDBC-ODBC Bridge DriverMohan ChandraNo ratings yet

- Linux/Unix/Aix Discovery in IserveDocument5 pagesLinux/Unix/Aix Discovery in IserveppparmarNo ratings yet

- Safety Bulletin SB 409Document1 pageSafety Bulletin SB 409S Rao CheepuriNo ratings yet