Professional Documents

Culture Documents

Cable Cleats

Uploaded by

Ashraf BadrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Cleats

Uploaded by

Ashraf BadrCopyright:

Available Formats

Cable Cleats

Cable Cleats

CFX-1 Cable Tray Systems

Cable Cleats

Trefoil Cable Cleat with LSF Pad

1. Recommended for installations where the highest levels of short circuit withstand are required.

2. Short circuit current tested in accordance with BS EN 50368:2003 standard.

3. Available for single and trefoil cable applications.

4. LSF-pad incorporates an integral low smoke, low fume, zero halogen pad.

5. Hardware to attach cleat to rung attachment bracket is included with cleat. Bracket must be ordered separately.

55mm

BS EN 50368:2003 (Cable Cleats for Electric Installations) Technical Specifications

Classification

Frame 50mm x 2mm Marine grade, Non-magnetic 316L

Cleat Type Composite

Closure Hardware Captive 316 Stainless Steel M8 or M10 (M12 available)

Resistance to 130 kA peak / 50 kA RMS bolt and nylon-lock nut (Optional Hex Flange

Electromechanical Force 600 mm spacing Lock Nut available)

Lateral Load Test 3.439 kg average Integral Pad Low Smoke, Low Fume, Zero Halogen

Axial Load Test Pass Tools Required Impact Wrench

Operating Temperature Range -40°C to +60°C Mounting Bolt Provided with Cable Cleat

Impact Resistance Very Heavy

Needle Flame Test 30 seconds

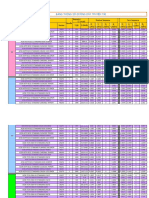

Cable Range (mm) Dimensions (mm) Cable Range (mm) Dimensions (mm)

Part No. Min. Dia. Max. Dia. H W Part No. Min. Dia. Max. Dia. H W

9SS6-CCT1323 13 22 74 66 9SS6-CCT6571 65 71 140 153

9SS6-CCT2125 21 25 77 70 9SS6-CCT6773 67 73 143 156

9SS6-CCT2329 23 29 81 78 9SS6-CCT6975 69 75 147 160

9SS6-CCT2531 25 31 84 81 9SS6-CCT7177 71 77 151 163

9SS6-CCT2733 27 33 86 83 9SS6-CCT7379 73 79 154 166

9SS6-CCT2935 29 35 90 89 9SS6-CCT7581 75 81 158 169

9SS6-CCT3238 32 38 94 95 9SS6-CCT7783 77 83 161 173

9SS6-CCT3541 35 41.5 98 100 9SS6-CCT7985 79 85 164 176

9SS6-CCT3844 38 44.5 101 104 9SS6-CCT8187 81 87 169 179

9SS6-CCT4248 42 48 105 111 9SS6-CCT8389 83 89 173 182

9SS6-CCT4551 45 51 109 117 9SS6-CCT8692 86 92 177 187

Cable Cleats

9SS6-CCT4753 47 53 111 120 9SS6-CCT8896 88 96 181 192

9SS6-CCT4955 49 55 114 124 9SS6-CCT9199 91 99 185 196

9SS6-CCT5157 51 57 116 127 9SS6-CCT96103 96 103 190 201

9SS6-CCT5359 53 59 119 133 9SS6-CCT99107 99 107 194 202

9SS6-CCT5561 55 61 127 137 9SS6-CCT103111 103 111 199 204

9SS6-CCT5763 57 63 126 140 9SS6-CCT107115 107 115 203 208

9SS6-CCT5965 59 65 128 144 9SS6-CCT111119 111 119 208 213

9SS6-CCT6167 61 67 132 147 9SS6-CCT115123 115 123 213 217

9SS6-CCT6369 63 69 136 150 9SS6-CCT119128 119 128 217 221

Cable Tray Systems CFX-2

Cable Cleats

Single Cable Cleat with LSF Pad

1. Recommended for installations where the highest levels of short circuit withstand are required.

2. Short circuit current tested in accordance with BS EN 50368:2003 standard.

3. Available for single and trefoil cable applications.

4. LSF-pad incorporates an integral low smoke, low fume, zero halogen pad.

5. Hardware to attach cleat to rung attachment bracket is included with cleat. Bracket must be ordered separately.

55mm

BS EN 50368:2003 (Cable Cleats for Electric Installations) Technical Specifications

Classification

Frame 50mm x 2mm Marine grade, Non-magnetic 316L

Cleat Type Composite

Closure Hardware Captive 316 Stainless Steel M8 or M10 (M12 available) bolt

Resistance to 130 kA peak / 50 kA RMS

and nylon-lock nut (Optional Hex Flange Lock Nut available)

Electromechanical Force 600 mm spacing

Integral Pad Low Smoke, Low Fume, Zero Halogen

Lateral Load Test 3.439 kg average

Axial Load Test Pass Tools Required Impact Wrench

Operating Temperature Range -40°C to +60°C Mounting Bolt Provided with Cable Cleat

Impact Resistance Very Heavy

Needle Flame Test 30 seconds

Cable Range (mm) Dimensions (mm) Cable Range (mm) Dimensions (mm)

Part No. Min. Dia. Max. Dia. H W Part No. Min. Dia. Max. Dia. H W

9SS6-CCS2832 28 32 61 55 9SS6-CCS6872 68 72 93 95

9SS6-CCS3034 30 34 63 57 9SS6-CCS7074 70 74 95 97

9SS6-CCS3236 32 36 65 59 9SS6-CCS7276 72 76 97 99

9SS6-CCS3438 34 38 67 61 9SS6-CCS7478 74 78 99 101

9SS6-CCS3640 36 40 71 63 9SS6-CCS7680 76 80 101 103

9SS6-CCS3842 38 42 69 65 9SS6-CCS7882 76 82 103 105

9SS6-CCS4044 40 44 71 67 9SS6-CCS8084 80 84 105 107

9SS6-CCS4246 42 46 72 69 9SS6-CCS8286 82 86 107 109

9SS6-CCS4448 44 48 74 71 9SS6-CCS8488 84 88 109 111

9SS6-CCS4650 46 50 75 73 9SS6-CCS8690 86 90 110 113

9SS6-CCS4852 48 52 77 75 9SS6-CCS8892 88 192 113 117

9SS6-CCS5054 50 54 79 77 9SS6-CCS9094 90 94 116 120

Cable Cleats

9SS6-CCS5256 52 56 80 79 9SS6-CCS9296 92 96 126 127

9SS6-CCS5458 54 58 81 81 9SS6-CCS94106 94 106 135 133

9SS6-CCS5660 56 60 83 83 9SS6-CCS100112 100 112 140 139

9SS6-CCS5862 58 62 85 85 9SS6-CCS106118 106 118 145 145

9SS6-CCS6064 60 64 86 87 9SS6-CCS112124 112 124 153 155

9SS6-CCS6266 62 66 88 89 9SS6-CCS118130 118 130 162 165

9SS6-CCS6468 64 68 90 91 9SS6-CCS127139 127 139 161 167

9SS6-CCS6670 66 70 91 93 9SS6-CCS132144 132 144 165 173

9SS6-CCS138150 138 150 170 179

CFX-3 Cable Tray Systems

Cable Cleats

Step 1: Know Your Cables

n What type of cable is being used?

• Single or Multi-conductor

n What is the outside diameter of the cable(s)?

n What is the cable arrangement (single conductor cables only)?

• Flat or Trefoil

n If a ground wire will be installed within the cleat, you will need the ground wire

outside diameter.

Step 2: Know Your System

n What is the available short circuit current (RMS or ip (peak))?

n What type of B-Line cable tray is installed?

Step 3: Select Your Cable Cleats

n See Pages CFX-2 & CFX-3

Step 4: Select Your Mounting Bracket

Mounting brackets are used to attach cable cleats to the rungs of the ladder type cable trays.

Your tray type will determine the mounting bracket used.

B-Line Tray Types Mounting Bracket

Aluminum welded rung trays with standard rungs.

Steel Series 2, 3, 4 or 5, trays with standard rungs 9SS6-CCB-C

Fiberglass trays with standard rungs

REDI-Rail™ Cable Tray 9SS6-CCB-D

Steel trays with strut rungs

9SS6-CCB-B

Aluminum trays with “Marine Rungs”

Steel Series 1 trays with standard rungs 9SS6-CCB-A

Use with rungs Use with rungs

9SS6-CCB-A 1” 9SS6-CCB-B

15/8”

1/2”

1”

11/2”

9SS6-CCB-C Use with rungs 9SS6-CCB-D Use with rungs

1”

Cable Cleats

1” 3/4”

11/2”

25/32”

1”

1”

11/2”

Cable Tray Systems CFX-4

Cable Cleats

Step 5: Determine Cleat Spacing for Installation

Your cable diameter is equal to the spacing between conductor centers shown below.

Find your cable diameter at the top of the table and look down at the column below it.

Find the value equal to or greater than the available short circuit for your system.

Single Conductor Short Circuit Withstand Table

Max. Cable Cleat Spacing Between Conductor Centers (mm)

Spacing (A) 23 25 27 29 31 33 35 37 39 41 43 45

mm In. ip peak (kA)

225 9 179 187 194 203 209 216 220 229 234 240 246 250

300 12 155 163 168 174 181 187 192 198 203 209 214 215

450 18 128 133 137 144 148 152 157 161 165 170 174 178

600 24 110 115 119 124 128 132 135 139 143 148 150 153

675 27 104 108 113 117 121 124 128 132 135 139 143 147

900 36 89 93 97 102 104 108 110 115 117 121 124 127

Changes of Direction

0.3M

A A A A A A

r)

max

(linea

ma M

0.3

(lin x

r)

ea

M

0.3 x

ma ear)

Trefoil Cables 0.3M (lin

max

)

(linear

IMPORTANT: Recommended Installation Procedures

It is important that the cleats are installed properly to secure your cables:

• It is not necessary for every cleat to be attached to the tray. Every other cleat ( ) must be

attached to the tray system to mount cable in tray. Unattached cleats ( ) provide additional

restraint to keep cables bundled.

Cable Cleats

• The bend radius should be 8 to 12 times the cable diameter.

• Cleats should always be installed at the beginning, middle and end of a bend ( ), and at no

time should the distance between cleats on a bend be more than 0.3M center to center.

CFX-5 Cable Tray Systems

Notes

Cable Cleats

Cable Tray Systems CFX-6

You might also like

- CableFixing PDFDocument6 pagesCableFixing PDFhumshkhNo ratings yet

- Schedules Updated As Per SoR 2022-23 For RDSSDocument41 pagesSchedules Updated As Per SoR 2022-23 For RDSSMohanraj SubramaniNo ratings yet

- All Dielectric Aerial Cable, ADSS Long Span 16 KNDocument3 pagesAll Dielectric Aerial Cable, ADSS Long Span 16 KNUdriste DanielNo ratings yet

- Triad 1.5mm2 Overall Shield SWA BlackDocument1 pageTriad 1.5mm2 Overall Shield SWA BlackDadang Ibnu SetyawanNo ratings yet

- Equipos A EntregarDocument6 pagesEquipos A EntregarJosueNo ratings yet

- 81 Yanfung Instalation CostingDocument1 page81 Yanfung Instalation CostingPradip ManeNo ratings yet

- Cleat WiringDocument8 pagesCleat WiringHaseeb NawazNo ratings yet

- Playing With HDTV AntennasDocument8 pagesPlaying With HDTV AntennasRobert GalargaNo ratings yet

- Polyrad Offshore Drill Cable 18AWG 4C XT125Document2 pagesPolyrad Offshore Drill Cable 18AWG 4C XT125GabrielNo ratings yet

- 01 Clampco CatDocument39 pages01 Clampco Cat900299gNo ratings yet

- Manual Maquina Soldar ESAB LKA-240-2Document23 pagesManual Maquina Soldar ESAB LKA-240-2Diego Ferreira FernándezNo ratings yet

- PC WireDocument7 pagesPC Wirejupe01No ratings yet

- E Docs Purchase Section Schedule of Rates Cds-50-60Document13 pagesE Docs Purchase Section Schedule of Rates Cds-50-60Nagaraju NayakNo ratings yet

- Type ST-C Cables: DescriptionDocument51 pagesType ST-C Cables: DescriptiongilmarquijanoNo ratings yet

- Servo Part ListDocument2 pagesServo Part ListahmetNo ratings yet

- 2c9 - MC & SC DetailsDocument47 pages2c9 - MC & SC DetailsKumarNo ratings yet

- Marking of SMD CapacitorDocument3 pagesMarking of SMD CapacitoragunghardonoNo ratings yet

- Short Circuit Current RatingsDocument1 pageShort Circuit Current Ratingsvanessa quispeNo ratings yet

- B1 PowerSafe TS Range SummaryDocument4 pagesB1 PowerSafe TS Range Summarylostris234No ratings yet

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFDocument2 pages15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezNo ratings yet

- Cat 3412 E Parts List With Gainwell QuotationDocument3 pagesCat 3412 E Parts List With Gainwell QuotationCwsNo ratings yet

- FP 400Document6 pagesFP 400kiranvankudre5802No ratings yet

- Combined HESCOM SoR 18-19Document172 pagesCombined HESCOM SoR 18-19Radhakrishna KPNo ratings yet

- JZ-600-Y-CY: Flexible, Number Coded, 0,6/1kV, Cu Screened Meter Marking, EMC-preferred TypeDocument2 pagesJZ-600-Y-CY: Flexible, Number Coded, 0,6/1kV, Cu Screened Meter Marking, EMC-preferred TypekaarefyhnNo ratings yet

- Industrial Low Voltage Cables: Acc. To CPR UE 305/11, EN 50575:2014 + A1:2016, Cca-S3, d1, A3Document3 pagesIndustrial Low Voltage Cables: Acc. To CPR UE 305/11, EN 50575:2014 + A1:2016, Cca-S3, d1, A3Yizhar Dwi GogaNo ratings yet

- MEDITOOL Parts For Oil Field Transportation Equipment (2020.10.01) - Sos StackerDocument8 pagesMEDITOOL Parts For Oil Field Transportation Equipment (2020.10.01) - Sos StackerRachid SmailiNo ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- US-dx-PS-AA 0217 WebDocument6 pagesUS-dx-PS-AA 0217 WebDeepak RajanNo ratings yet

- Senda Boq FinalDocument4 pagesSenda Boq Finalanildondapati1No ratings yet

- MTO Instrument Cables-10012017Document127 pagesMTO Instrument Cables-10012017Shankar KumarNo ratings yet

- RF & Microwave Cable Assemblies - 10MDocument51 pagesRF & Microwave Cable Assemblies - 10MBouhafs AbdelkaderNo ratings yet

- 44 CBL 21-09-2022Document15 pages44 CBL 21-09-2022Deelip ZopeNo ratings yet

- LKSM-HF: Armoured Power and Control Cable 0,6/1kVDocument4 pagesLKSM-HF: Armoured Power and Control Cable 0,6/1kVacastanopadilla4100No ratings yet

- Bs 6622 Xlpe PVC 12Kv CableDocument5 pagesBs 6622 Xlpe PVC 12Kv CableAnonymous EaCgJPfs41No ratings yet

- Procables Lista 75 22 Ene 2022Document4 pagesProcables Lista 75 22 Ene 2022jairo mahechaNo ratings yet

- Low Voltage Electrical Guide CatalogueDocument29 pagesLow Voltage Electrical Guide CatalogueAhmed ElsayedNo ratings yet

- Tabla IEC 62219Document5 pagesTabla IEC 62219ManuelNo ratings yet

- SN To THU Interchange 2012Document2 pagesSN To THU Interchange 2012prashant mishraNo ratings yet

- ADSSDocument19 pagesADSSMichalNo ratings yet

- Lista Precios ProcablesDocument4 pagesLista Precios ProcablesJuanEstebanCorreaDuqueNo ratings yet

- Reverse Circulation Hammer-Rc45Document1 pageReverse Circulation Hammer-Rc45hamed ShNo ratings yet

- Baterías DataSafe DXDocument2 pagesBaterías DataSafe DXLast Juan StandingNo ratings yet

- Materil Detail - UPPTCL Prayagraj GulabDocument76 pagesMateril Detail - UPPTCL Prayagraj GulabVimal SinghNo ratings yet

- Samsung Galaxy J1 Ace Neo (SM-J111F) Service ManualDocument81 pagesSamsung Galaxy J1 Ace Neo (SM-J111F) Service ManualLeonias Adrian100% (1)

- 077 Expansion JointsDocument7 pages077 Expansion Jointsoemlenovo1No ratings yet

- Branch - Param Power LinesDocument107 pagesBranch - Param Power LinesPhu LevanNo ratings yet

- PLS CADD PretensadoDocument10 pagesPLS CADD PretensadoJoaquin A. Vásquez TantaleánNo ratings yet

- Datasheet Sanicro 26mo For Wirelines enDocument3 pagesDatasheet Sanicro 26mo For Wirelines enafonsomlima_1No ratings yet

- UGD and HDPEDocument9 pagesUGD and HDPEAnkur JohriNo ratings yet

- Lista de Precios Publica NexansDocument10 pagesLista de Precios Publica NexansSantiago Mejía RNo ratings yet

- All ModelsDocument281 pagesAll Modelsmukesh_07thakkar89% (35)

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Schneider Electric - Tarifa Automatización y Control Industrial Marzo 01.03.2023PDocument674 pagesSchneider Electric - Tarifa Automatización y Control Industrial Marzo 01.03.2023PMarcos LledóNo ratings yet

- 220 KV Solar Power Sub-StationDocument5 pages220 KV Solar Power Sub-StationobayapalliNo ratings yet

- Standard Hook-Up Wires & Cables For ElectronicsDocument124 pagesStandard Hook-Up Wires & Cables For ElectronicsdlstoneNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- Product SpeDocument39 pagesProduct SpeТолон СабыркулуулуNo ratings yet

- N2XSYDocument5 pagesN2XSYRinda_RaynaNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- FE Exam TipsDocument17 pagesFE Exam TipsAshraf Badr100% (1)

- Job Connector - EnglishDocument1 pageJob Connector - EnglishAshraf BadrNo ratings yet

- FE Electrical and Computer CBT SpecsDocument3 pagesFE Electrical and Computer CBT SpecsAshraf BadrNo ratings yet

- APEGS Report StrcutureDocument5 pagesAPEGS Report StrcutureAshraf BadrNo ratings yet

- Competency Assessment Guide Apegs v182Document70 pagesCompetency Assessment Guide Apegs v182Ashraf BadrNo ratings yet

- Pumps SELWOODDocument8 pagesPumps SELWOODAshraf BadrNo ratings yet

- PTZ CameraDocument54 pagesPTZ CameraAshraf BadrNo ratings yet

- ASPE Cert Candidate BrochureDocument8 pagesASPE Cert Candidate BrochureAshraf BadrNo ratings yet

- Sigma CatalogDocument154 pagesSigma Catalogbakien-canNo ratings yet

- Din 6915 PDFDocument3 pagesDin 6915 PDFAnilNo ratings yet

- Melag Autoclave ManualsDocument32 pagesMelag Autoclave ManualsRasheed AhmadNo ratings yet

- Caterpillar3412 Manual Disassembly&Assembly PDFDocument181 pagesCaterpillar3412 Manual Disassembly&Assembly PDFlancaster2795% (22)

- S03 Drill Feed PDFDocument20 pagesS03 Drill Feed PDFIH MedranoNo ratings yet

- Troubleshooting (Rexton)Document31 pagesTroubleshooting (Rexton)francisca19100% (5)

- Mil DTL 1222jDocument51 pagesMil DTL 1222jPAOLO GIANNELLINo ratings yet

- Kete DrumDocument67 pagesKete DrumBart van TarelNo ratings yet

- cfm56-7 CAPDocument12 pagescfm56-7 CAPgarsi2346No ratings yet

- Sukho SPD List May 2019Document104 pagesSukho SPD List May 2019Inder SinghNo ratings yet

- Conestoga 2: Parts ListsDocument20 pagesConestoga 2: Parts ListsJonah RagleNo ratings yet

- Astm A36 1977Document6 pagesAstm A36 1977Ben Yie Min100% (1)

- Fluokit M24+: Instructions Assembly of The Internal Arc Kit 12.5 To 25 KaDocument12 pagesFluokit M24+: Instructions Assembly of The Internal Arc Kit 12.5 To 25 KaUsman SadikinNo ratings yet

- Volvo Penta Tamd61a-72j-A WM Fuelsystem PDFDocument44 pagesVolvo Penta Tamd61a-72j-A WM Fuelsystem PDFOzgyur MehmedovNo ratings yet

- Mounting Instructions: Cartridge Kit For Yamaha R25 R3 MT-03Document9 pagesMounting Instructions: Cartridge Kit For Yamaha R25 R3 MT-03Ivan TlNo ratings yet

- Work Study Lab ImplementsDocument10 pagesWork Study Lab ImplementsKailas Sree ChandranNo ratings yet

- Mak M25Document57 pagesMak M25Andrey Bogorodskiy100% (1)

- Fury 125 EnsamblajeDocument26 pagesFury 125 EnsamblajeMiguel Robles50% (4)

- Hardy Frame "STK" Washers Are Required in The Top of Panels WhenDocument1 pageHardy Frame "STK" Washers Are Required in The Top of Panels WhenJose Luis Velasco CadavidNo ratings yet

- Ecovent Vent Assembly Instructions: Revision: E Issued: March 31th, 2016Document36 pagesEcovent Vent Assembly Instructions: Revision: E Issued: March 31th, 2016Ciprian ColdaNo ratings yet

- 3 Rothe ErdeDocument173 pages3 Rothe ErdeOscar CruzNo ratings yet

- Homemade Bowstring JigDocument8 pagesHomemade Bowstring JigDean MyersNo ratings yet

- Parts Catalog Engine Generator SDG25S 3A3Document37 pagesParts Catalog Engine Generator SDG25S 3A3Вячелав ЕгоровNo ratings yet

- TrioTTH 6203D Horizontal Screen Parts Manual SN 226 PDFDocument23 pagesTrioTTH 6203D Horizontal Screen Parts Manual SN 226 PDFJoanMontillaNo ratings yet

- 04 - Howden - Installation-Maintenance D-Series Fans PDFDocument20 pages04 - Howden - Installation-Maintenance D-Series Fans PDFwilly12345120% (1)

- AIRMAN SDG125S 8B1 SDG Parts Catalog Engine Generator BTWDocument33 pagesAIRMAN SDG125S 8B1 SDG Parts Catalog Engine Generator BTWEd DugganNo ratings yet

- Frame EstructuresDocument84 pagesFrame EstructuresSERGIO CARDENAS CASTILLONo ratings yet

- CPM-SU-5012-B - Aluminizing of Stainless Steel FastenersDocument5 pagesCPM-SU-5012-B - Aluminizing of Stainless Steel FastenersNavneet YadavNo ratings yet

- Rivet Nut Insert CatalogDocument56 pagesRivet Nut Insert CatalogSAPTONo ratings yet

- 34-05198-6 v1.2 510 614 20141114 Blower Repair and MaintenanceDocument28 pages34-05198-6 v1.2 510 614 20141114 Blower Repair and Maintenanceadamnassir91No ratings yet