Professional Documents

Culture Documents

Data Sheet Southwire 3c#500kcmil

Uploaded by

Nestor-leoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet Southwire 3c#500kcmil

Uploaded by

Nestor-leoCopyright:

Available Formats

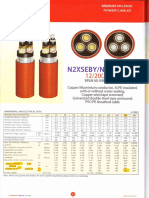

SPEC 46454

3/C CU 15KV 220 NL-EPR 133% TS ARMOR-X PVC MV-105

Type MV-105 Three Conductor Copper, 220 Mils No Lead Ethylene Propylene Rubber (NL-EPR) 133% Insulation Level, Tape

Shield, Continuous Corrugated Welded Armor (Armor-X), Polyvinyl Chloride (PVC) Jacket

B) Conductor

semi-con

1 3 9 10

10 9 8 7 6 5 4 3 2 1

Images not to scale. See Table 1 for Dimensions

CONSTRUCTION:

1. Conductor: Class B compressed stranded bare copper per ASTM B3 and ASTM B8

2. Conductor Shield: Semi-conducting cross-linked copolymer

3. Insulation: 220 Mils No Lead Ethylene Propylene Rubber (NL-EPR) 133% Insulation Level,

4. Insulation Shield: Stripable semi-conducting cross-linked copolymer

5. Copper Tape Shield: Helically wrapped 5 mil copper tape with 25% overlap

6. Grounding Conductor: 1 Class B compressed stranded bare copper ground per ASTM B3 and ASTM B8

7. Filler: Wax paper filler

8. Binder: Polypropylene tape

9. Armor: Continuous Corrugated Welded Armor (Armor-X)

10. Overall Jacket: Polyvinyl Chloride (PVC)

APPLICATIONS AND FEATURES:

Southwire’s 15KV ARMOR-X are armored cables for use in wet and dry areas, conduits, ducts, troughs, trays, direct burial,

and where superior electrical properties are desired. These cables are capable of operating continuously at the conductor

temperature not in excess of 105°C for normal operation, 140°C for emergency overload, 250°C for short circuit conditions,

and -50°C for cold bend. For uses in Class I, II, and III, Division 1 and 2 hazardous locations per NEC Article 501, 502, and 503.

SPECIFICATIONS:

• ASTM B3 Soft or annealed copper

• ASTM B8 Concentric-lay-standard copper

• UL 1072 - Medium Voltage Power Cables

• ICEA S-93-639 (NEMA WC 74) 5-46 KV Shielded Power Cable & ICEA S-97-682 5-46 KV Utility

• UL 1685/FT4 Vertical-Tray Fire Propagation and Smoke Release Test

• IEEE 1202 -Flame Test (70,000) BTU/hr Vertical Tray Test

• AEIC CS-8 Specification for extruded dielectric shielded power cables rated for 5 through 46KV

SAMPLE PRINT LEGEND:

SOUTHWIRE [SYMBOL - LIGHTING BOLT] #P# ARMOR-X (UL) 3/C [#AWG or #kcmil] CU 220 MILS NL-EPR 15KV 133% INS

LEVEL 25% TS MV-105 FOR CT USE SUN. RES. FOR DIRECT BURIAL FT4 [-50°C] YEAR (NESC) [SEQUENTIAL FEET MARKS]

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2018 Southwire Company, LLC. All Rights Reserved SPEC 46454_PSS DIVISION DATE: 07/23/2018 Rev:2.0.07C

SPEC 46454

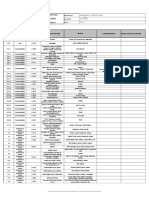

Table 1 – Weights & Measurements

Diameter over Dia. Over Approx. Min

Cond. Cond. Insul. Insul. Armor Jacket OD Approx. Max Pull Bending

Stock Size (1) (3) Shield Ground (9) Thickness (10) Weight Tension Radius

Code AWG inches inches inches No. x AWG inches mils inches lbs./MFT lbs. inches

890663 2 0.283 0.760 0.820 1x6 2.290 75 2.440 2529 1593 17.1

TBA 1 0.322 0.799 0.859 1x4 2.290 75 2.440 2811 2009 17.1

890664 1/0 0.362 0.839 0.899 1x4 2.430 75 2.580 3142 2534 18.1

890665 2/0 0.405 0.882 0.942 1x4 2.550 75 2.700 3527 3194 18.9

TBA 3/0 0.456 0.933 0.993 1x3 2.670 75 2.820 4033 4027 19.7

890666 4/0 0.512 0.989 1.049 1x3 2.880 75 3.030 4630 5078 21.2

890667 250 0.558 1.044 1.104 1x3 2.880 75 3.030 5109 6000 21.2

890668 ◊

350 0.661 1.147 1.207 1x2 3.220 85 3.390 6839 8400 23.7

890669 ◊

500 0.789 1.275 1.335 1x1 3.540 85 3.710 8731 12000 26.0

550439 750 0.968 1.463 1.523 1x0 3.850 85 4.020 11729 18000 28.1

All dimensions are nominal and subject to normal manufacturing tolerances

◊ Standard stock item

Table 2 – Electrical and Engineering Data

Shield Short Allowable Ampacities

Resistance Reactance Positive Zero Circuit 900C/1050C

Cond. DC AC XC XL Sequence Sequence Current Directly

Size @ 250C @ 900C @ 60Hz @ 60Hz Impedance* Impedance* 6 Cycles Buried † In Air ‡

Stock Code AWG Ω/MFT Ω/MFT MΩ*MFT Ω/MFT Ω/MFT Ω/MFT Amps Amps Amps

890663 2 0.162 0.203 0.053 0.047 0.203 + j0.047 0.577 + j0.419 2700 185 / 200 165 / 185

TBA 1 0.129 0.161 0.049 0.045 0.162 + j0.045 0.535 + j0.401 2827 210 / 225 185 / 210

890664 1/0 0.102 0.128 0.045 0.043 0.128 + j0.043 0.499 + j0.383 2957 240 / 255 215 / 240

890665 2/0 0.081 0.101 0.042 0.042 0.102 + j0.042 0.471 + j0.366 3097 270 / 290 245 / 275

TBA 3/0 0.064 0.081 0.039 0.040 0.081 + j0.040 0.446 + j0.346 3263 305 / 330 285 / 315

890666 4/0 0.051 0.064 0.036 0.039 0.065 + j0.039 0.426 + j0.327 3445 350 / 375 325 / 360

890667 250 0.043 0.054 0.034 0.038 0.055 + j0.038 0.411 + j0.309 3624 380 / 410 360 / 400

890668 ◊

350 0.031 0.039 0.030 0.036 0.040 + j0.036 0.386 + j0.279 3959 460 / 495 435 / 490

890669 ◊

500 0.022 0.028 0.026 0.034 0.028 + j0.034 0.362 + j0.247 4376 550 / 590 535 / 600

550439 750 0.014 0.020 0.022 0.032 0.020 + j0.032 0.335 + j0.209 4987 665 / 720 670 / 745

* Calculations are based on 5 mil 25 % over lapping copper tape shield / Conductor temperature of 90°C / Shield temperature of 45°C / Earth resistivity of 100

ohms-meter

† Ampacities are based on TABLE 310.60(C)(83) of the 2014 National Electrical Code (20°C Ambient Earth Temperature, Thermal Resistance ROH of 90)

‡ Ampacities are based on TABLE 310.60(C)(71) of the 2014 National Electrical Code (40°C Ambient Air Temperature)

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2018 Southwire Company, LLC. All Rights Reserved SPEC 46454_PSS DIVISION DATE: 07/23/2018 Rev:2.0.07C

You might also like

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocument2 pages3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNo ratings yet

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosNo ratings yet

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNo ratings yet

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- Ficha Técnica CABLE ERP SOUTHWIREDocument3 pagesFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNo ratings yet

- Origin 350 MCM o Kcmil o MamalonDocument2 pagesOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraNo ratings yet

- 1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specDocument2 pages1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specEdgar Sierra RodriguezNo ratings yet

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocument2 pages1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Document2 pages3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNo ratings yet

- RhinoDocument2 pagesRhinoValeria Rendon NoyolaNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- ACSR_TW.pdfDocument5 pagesACSR_TW.pdfJavier Soza DazaNo ratings yet

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFDocument2 pages15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezNo ratings yet

- SPEC83013 600 Volt UndergroundDocument3 pagesSPEC83013 600 Volt Undergroundakib javedNo ratings yet

- Spec 45440Document2 pagesSpec 45440ger80No ratings yet

- Zero Halogen EP Welding Cable 105ºC Industrial Grade: Specifications & Standards ConstructionDocument1 pageZero Halogen EP Welding Cable 105ºC Industrial Grade: Specifications & Standards ConstructionAndri YunafrisonNo ratings yet

- Armor X 3C XHHW-2 Power 3GND 600V 2017 - CCDocument2 pagesArmor X 3C XHHW-2 Power 3GND 600V 2017 - CCpglv0210No ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- THHN TC FuerzaDocument2 pagesTHHN TC Fuerzajuan pablo castro gallegoNo ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Type TC Power Cable-THHN: ApplicationsDocument2 pagesType TC Power Cable-THHN: ApplicationsHenry MontenegroNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- 1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105Document2 pages1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105RodNo ratings yet

- Soow H07RN-F Aj 24.02.2022Document4 pagesSoow H07RN-F Aj 24.02.2022Tamara TrejosNo ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- Conductor Technical CatalogDocument22 pagesConductor Technical CatalogKarna Satish KumarNo ratings yet

- HT Cables - Leading China Cable ManufacturerDocument18 pagesHT Cables - Leading China Cable ManufacturerSIMON S. FLORES G.100% (1)

- 35kV AL 133% TRXLPE One-Third Neutral LLDPE Primary UD: SPEC 81252Document5 pages35kV AL 133% TRXLPE One-Third Neutral LLDPE Primary UD: SPEC 81252Anonymous hxyW3v5QqVNo ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- Interlocked Armor Power Cable, 5000 VOLTSDocument1 pageInterlocked Armor Power Cable, 5000 VOLTSpedro perezNo ratings yet

- Pages From PowerPlusLowres2Document50 pagesPages From PowerPlusLowres2veljal6317No ratings yet

- NA2XY cable powers industries and networksDocument5 pagesNA2XY cable powers industries and networksnoviaNo ratings yet

- IEC 60502-2 Technical Data TablesDocument6 pagesIEC 60502-2 Technical Data TablesKumar NagarajanNo ratings yet

- AAAC - All Aluminum Alloy ConductorDocument5 pagesAAAC - All Aluminum Alloy ConductoralejandraNo ratings yet

- Nyy 1CDocument1 pageNyy 1Chenry_gtNo ratings yet

- PVC Insulated Copper and Aluminum Wire Armored Power CablesDocument5 pagesPVC Insulated Copper and Aluminum Wire Armored Power CablesAhmad Arif SaktiNo ratings yet

- Renewable Energy Webiste Standard Product List V4Document4 pagesRenewable Energy Webiste Standard Product List V4Alireza AhmadimaneshNo ratings yet

- Technical Specification: Single Core Unarmoured Cables Copper Conductors XLPE Insulated 0.6/1KVDocument4 pagesTechnical Specification: Single Core Unarmoured Cables Copper Conductors XLPE Insulated 0.6/1KVMohammed A. Al NabulsiNo ratings yet

- PVC Insulated, Concentric Conductor Power Cables Rated 0.6/1kVDocument2 pagesPVC Insulated, Concentric Conductor Power Cables Rated 0.6/1kVJerrykid NguyenNo ratings yet

- 5 ADocument2 pages5 AingenieuredwinNo ratings yet

- TDS_Al_XLPE_SWA_PVC-_NA2XRYDocument3 pagesTDS_Al_XLPE_SWA_PVC-_NA2XRYvsumedhaNo ratings yet

- Bostrig 125 Type P-VFD Power CableDocument2 pagesBostrig 125 Type P-VFD Power CableJAY SINGHAMNo ratings yet

- 4 MC Armored 5 8 KV Epr 3 ConductorsDocument1 page4 MC Armored 5 8 KV Epr 3 ConductorsJavier MaldonadoNo ratings yet

- Drift TableDocument3 pagesDrift TableRolly Hillz SochimNo ratings yet

- N2Xfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesN2Xfgby 2 X (1.5-300) MM 0.6/1 KVRince OktavianaNo ratings yet

- Bostrig Type P VFD 2kVDocument3 pagesBostrig Type P VFD 2kVEnrique MartínezNo ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- MV Cable Current Carrying Capacity NA2XSEYBY SucacoDocument1 pageMV Cable Current Carrying Capacity NA2XSEYBY SucacoharisNo ratings yet

- N2XSERY 33xx(25-300) mm2 3.6/6 kV and 6/10 kV Cable SpecificationDocument5 pagesN2XSERY 33xx(25-300) mm2 3.6/6 kV and 6/10 kV Cable SpecificationArthurNo ratings yet

- (1C X 95mm) N2XSYDocument3 pages(1C X 95mm) N2XSYRahmawan fiberhomeNo ratings yet

- NYRY 1core PVC AWA PVCDocument5 pagesNYRY 1core PVC AWA PVCYulian Dea ZollaNo ratings yet

- FELTOFLEX NTMCWOEU 20kV - enDocument2 pagesFELTOFLEX NTMCWOEU 20kV - enPhilippe SingletonNo ratings yet

- Utility Distribution Cable SpecificationsDocument1 pageUtility Distribution Cable SpecificationsFrancisco ChanaNo ratings yet

- Acsr PDFDocument1 pageAcsr PDFAUGUSTA WIBI ARDIKTANo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- NYFGbY cable specificationsDocument4 pagesNYFGbY cable specificationsSaung KuringNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Marcas Aprobadas Por PamDocument8 pagesMarcas Aprobadas Por PamNestor-leoNo ratings yet

- 8777 Techdata PDFDocument3 pages8777 Techdata PDFNestor-leoNo ratings yet

- 8777 Techdata PDFDocument3 pages8777 Techdata PDFNestor-leoNo ratings yet

- Product:: Electronic, 2 C #16 STR TC, PE Ins, OS, PVC JKT, CMDocument2 pagesProduct:: Electronic, 2 C #16 STR TC, PE Ins, OS, PVC JKT, CMNestor-leoNo ratings yet

- For More Information Please Call 1-800-Belden1: General DescriptionDocument3 pagesFor More Information Please Call 1-800-Belden1: General DescriptionNestor-leoNo ratings yet

- Application Information For Busway Rated 600 Volts or Less: NEMA Standards Publication BU 1.2-2002Document17 pagesApplication Information For Busway Rated 600 Volts or Less: NEMA Standards Publication BU 1.2-2002Nestor-leoNo ratings yet

- Precautionary Labeling For Arc-Welding and Cutting Products: NEMA Standards Publication EW 6-1998Document30 pagesPrecautionary Labeling For Arc-Welding and Cutting Products: NEMA Standards Publication EW 6-1998Nestor-leoNo ratings yet

- NEMA BU1 2 - EspañolDocument17 pagesNEMA BU1 2 - EspañolNestor-leoNo ratings yet

- Precautionary Labeling For Arc-Welding and Cutting Products: NEMA Standards Publication EW 6-1998Document30 pagesPrecautionary Labeling For Arc-Welding and Cutting Products: NEMA Standards Publication EW 6-1998Nestor-leoNo ratings yet

- NEMA BU1 2 - EspañolDocument17 pagesNEMA BU1 2 - EspañolNestor-leoNo ratings yet

- Application Information For Busway Rated 600 Volts or Less: NEMA Standards Publication BU 1.2-2002Document17 pagesApplication Information For Busway Rated 600 Volts or Less: NEMA Standards Publication BU 1.2-2002Nestor-leoNo ratings yet

- NEMA BU1 2 - EspañolDocument17 pagesNEMA BU1 2 - EspañolNestor-leoNo ratings yet

- Module 6 (Materials & Hardware) SubModule 6.6 (Pipes and UnDocument22 pagesModule 6 (Materials & Hardware) SubModule 6.6 (Pipes and UnInterogator5No ratings yet

- HE10044 RW MedicalBrochure E 02Document12 pagesHE10044 RW MedicalBrochure E 02Th NattapongNo ratings yet

- Contoh PatentDocument12 pagesContoh PatentMaya RamlahNo ratings yet

- Rubber Examination Gloves: Standard Specification ForDocument5 pagesRubber Examination Gloves: Standard Specification ForNguyễn Bảo TrâmNo ratings yet

- 4088 Natural Golf Grip DesignDocument20 pages4088 Natural Golf Grip DesignAjay ThakurNo ratings yet

- Wheels & Castors: Carrying Industrial Loads Since 1976Document32 pagesWheels & Castors: Carrying Industrial Loads Since 1976GM HerbalsNo ratings yet

- Corporate History MRFDocument6 pagesCorporate History MRFvampire_sushyNo ratings yet

- Eth Brochure Flooring and CoatingDocument84 pagesEth Brochure Flooring and CoatingRiian ApriansyahNo ratings yet

- SPC-FD-00-G00-Part 09 of 12-Division 23 (2 of 2)Document256 pagesSPC-FD-00-G00-Part 09 of 12-Division 23 (2 of 2)marco.w.orascomNo ratings yet

- Emeca Pile Joint UserguideDocument16 pagesEmeca Pile Joint UserguideKevin LimNo ratings yet

- Choice of MaterialDocument3 pagesChoice of Materialprabhath mahelaNo ratings yet

- Avk Gate Valve PN 10 or PN 16 06/30 - 26/00Document2 pagesAvk Gate Valve PN 10 or PN 16 06/30 - 26/00Popescu OctavianNo ratings yet

- 6002 Rex Conveyor Idlers CatalogDocument104 pages6002 Rex Conveyor Idlers CatalogNur Yanto100% (1)

- Pioneer Pro Builders Bond ConstructionDocument8 pagesPioneer Pro Builders Bond ConstructionPaul Andrew Relucano IINo ratings yet

- Practical Guide To Hydrogenated Nitrile PDFDocument8 pagesPractical Guide To Hydrogenated Nitrile PDFSid ShahNo ratings yet

- Ashi and Bushnag Co. LTD: Tensile Fabric Playgrounds and KG AreaDocument1 pageAshi and Bushnag Co. LTD: Tensile Fabric Playgrounds and KG AreausmanNo ratings yet

- Apollo Tyres Research ProjectDocument8 pagesApollo Tyres Research Projectdarshan jainNo ratings yet

- Catalogo Parker CAT 4660 PDFDocument420 pagesCatalogo Parker CAT 4660 PDFpelcarNo ratings yet

- Cases 1Document26 pagesCases 1yagayNo ratings yet

- MP TSP CuplaDocument4 pagesMP TSP CuplaSaveli Paul FlorinNo ratings yet

- 3M™ Cold Shrink QT-III Silicone Rubber Termination 7673-S-8-JCNDocument10 pages3M™ Cold Shrink QT-III Silicone Rubber Termination 7673-S-8-JCNiamlpNo ratings yet

- Cricri Material List WordDocument7 pagesCricri Material List WordScribblerNo ratings yet

- Expansion Joints - FabricDocument44 pagesExpansion Joints - Fabricibson045001256No ratings yet

- Mould BaseDocument8 pagesMould BaseMould Base ManufacturerNo ratings yet

- Mustang Monthly - November 2014 USADocument84 pagesMustang Monthly - November 2014 USABaggio YesudasNo ratings yet

- Cost Accounting DEER Factory VisitDocument17 pagesCost Accounting DEER Factory VisitHashm HussainNo ratings yet

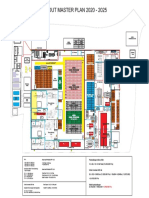

- Layout Master Plan 2020 - 2025: Jalur ForkliftDocument1 pageLayout Master Plan 2020 - 2025: Jalur ForkliftIanNo ratings yet

- Ref. 4 - Akrochem Technical Bulletein Carbon - BlackDocument10 pagesRef. 4 - Akrochem Technical Bulletein Carbon - BlackSDawNo ratings yet

- Flanged Basket Strainers IOMDocument4 pagesFlanged Basket Strainers IOMSteve NewmanNo ratings yet

- Chatham AW15 Mens CollectionDocument72 pagesChatham AW15 Mens CollectionromyluleNo ratings yet