Professional Documents

Culture Documents

Drift Table

Uploaded by

Rolly Hillz SochimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drift Table

Uploaded by

Rolly Hillz SochimCopyright:

Available Formats

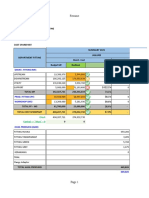

WT/FT ID BBL/FT DRIFT SEAL NO GO NIPPLE STD V

BORE PACKING

2 3/8 4.6 – 4.7 1.995 0.00387 1.901 1.875 1.791 X STD 91V310

2 7/8 6.4 –6.5 2.441 0.0058 2.347 2.313 2.205 X STD 91V318

3½ 10.3 2.922 0.0083 2.797 2.750 2.635 X STD 91V3378

3½ 10.3 2.922 0.0083 2.867 2.813 2.760 X OPT 91V330

4 10.9 - 11 3.476 0.0117 3.361 3.313 3.135 X STD 91V3317

4 13.4 3.4 0.0112 3.215 3.125 2.907 R SDT

4½ 12.75 3.958 0.0152 3.833 3.813 3.725 X &R 91V320

4½ 13.5 3.92 0.015 3.796 3.688 3.456 R STD 91V3334

5 13 4.494 0.01963 4.389 4.313 X STD 91V3422

5 13 4.494 0.01963 4.389 4.126 3.913 R STD 91V375

5 15 4.408 0.01888 4.283 4.126 3.912 R STD 91V375

5½ 17 4.892 0.02326 4.787 4.562 4.456 X&R 91V3309

5½ 23 6.67 0.04324 4.545 4.313 3.967 R STD 91V3422

7 17.32 ------- ------- 5.962 5.760 R STD 91V322

4-Types of Plug

1. XN X Nipple Uses Plug & prong

2. XX Installed without Prong

3. RN R-Nipple Not in use, core accumulate debris at bottom

Mostly used for heavy weight Tubing.

4. XXN Not in use, core accumulate debris at bottom

Conversion Factors

Multiply By To Obtain Multiply By To Obtain

Barrels 0.15898 Cu Meters Cu Inches 16.3900 Cu. Meters

Foot 0.3048 Metres Cu Meters 0.0160 Cu. Inches

Gal. Liq. N2 93.12 SCF N2 Gas. Cu Meters 35.3100 Cu. Feet

Gal (US) 0.8327 Gal-Imp’ Cu Metres 6.2897 Barrels

Gal (US) 0.0238 Barrels Cu Meters 1.3080 Cu. Yards

Gal (US) 3.785 Litres Cu Inches 0.0163 Liters

Gal -Imp’ 4.546 Litres Cm 0.3937 Inches

Grams 15.4300 Grains Hectares 2.4710 Acres

Inch 2.54 CM Ounces 28.3500 Grams

Km 0.6214 Miles Sq. Yards 0.8361 Sq. Meters

Kp 0.1451 PSI Sq. Meters 10.7600 Sq. Feet

Kg 2.2046 Pounds Sq. Inches 0.4520 Sq. Cm

Kg/sq.cm. 14.22 PSI Sq. Km 0.3861 Sq. Miles

Metre 3.281 Feet Tons 1016.000 Kilograms

Miles 1.609 Km Yards 0.9144 Metres

PSI 0.0703 Kg/sq.cm.

PSI 6.895 Kp Pounds 453.6000 Grams

Wire Minimum Breaking Strength Area

API 9A UHT API 9A UHT

inches 75% 50% 75% 50%

0.066 811 1100 608.25 405.5 825 550 0.0034

0.072 961 1270 720.75 480.5 952.5 635 0.0040

0.082 1239 1610 929.25 619.5 1207.5 805 0.0052

0.092 1547 1980 1160.25 773.5 1485 990 0.0066

0.108 2120 2720 1590 1060 2040 1360 0.0090

Swab-Line 9-6-1 9-9-1 9-6-1 9-9-1

Dyform 75% 50% 75% 50%

4298 6172 3223.5 2149 4629 3086 0.0275

Max. working strength of wires

75% of breaking Strength strain @ slow pull with hay pulley at 900 angle

50% of breaking strength strain for fast jarring with hay pulley at 90 0 angle.

AMOUNT WIRE-LINE WILL FALL BACK PER 1000’ WHEN BROKEN

Tubing Size 2 3/8 3½ 4½ 5½ 7

Wire-Line OD Fall Back per 100’

0.092 12 16

0.108 15 27 40 90

3/16 20 35 50 100

API = 141.5 divide by sg , minus 131.5

0

F = centigrade x 1.8 + 320.

0

C = Fahrenheit – 320 x .5666

Draw-down = Static BHP – Flowing BHP

Productivity Index –PI = BBLS per Day divide by ( static BHP – flowing BHP)

FREE POINT CALCULATIONS AND COILED TUBING STRETCH TABLE

Size (in.) Cross Sectional Free Point Size (in.) Cross Sectional Free Point

Area (sq. in.) Constant Area (sq. in.) Constant

1.000 X 0.080 0.221 552

1.000 0.087 0.239 598

1.000 0.095 0.257 643

1.000 0.102 0.275 688

1.000 0.109 0.293 732

You might also like

- Design of Cylindrical Shell Under Internal PressureDocument51 pagesDesign of Cylindrical Shell Under Internal PressurevikramNo ratings yet

- BITS Vulnerability Management Maturity ModelDocument19 pagesBITS Vulnerability Management Maturity ModelJack JacksonNo ratings yet

- Propeller Design CalculationDocument8 pagesPropeller Design CalculationDave Carter100% (7)

- DNV OS-B101 Metallic MaterialsDocument48 pagesDNV OS-B101 Metallic MaterialsBoni Luck100% (1)

- Cosmos Carl SaganDocument18 pagesCosmos Carl SaganRabia AbdullahNo ratings yet

- 22-02-13 Samsung Answer To Staton Techniya Complaint & CounterclaimsDocument72 pages22-02-13 Samsung Answer To Staton Techniya Complaint & CounterclaimsFlorian MuellerNo ratings yet

- Marine Biofouling (LIBRO)Document316 pagesMarine Biofouling (LIBRO)Laura Alejandra Montaño100% (1)

- Chapter 5 PresentationDocument35 pagesChapter 5 PresentationSabeur Dammak100% (1)

- Teachers Book - Smarty 4 PDFDocument77 pagesTeachers Book - Smarty 4 PDFFlorenciaRivichini50% (2)

- Shell and Head Dimensions in mmDocument69 pagesShell and Head Dimensions in mmLaskar PejuangNo ratings yet

- Design of Slab: Two WayDocument3 pagesDesign of Slab: Two WaySyeda NafeezaNo ratings yet

- DESIGN OF TWO WAY SLABDocument3 pagesDESIGN OF TWO WAY SLABSyeda NafeezaNo ratings yet

- Equilibrium CalculationDocument38 pagesEquilibrium CalculationvijayNo ratings yet

- Building EstimationDocument22 pagesBuilding EstimationchanakyaNo ratings yet

- SANLAU1 Mong Coc Thanh UyDocument20 pagesSANLAU1 Mong Coc Thanh Uylam phuNo ratings yet

- AAAC - All Aluminum Alloy ConductorDocument5 pagesAAAC - All Aluminum Alloy ConductoralejandraNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- THHN TCDocument5 pagesTHHN TCjuan pablo castro gallegoNo ratings yet

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNo ratings yet

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocument2 pages3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNo ratings yet

- Determinação Da Taxa Mínima de Armadura de Flexão em Vigas Com Seção RetangularDocument9 pagesDeterminação Da Taxa Mínima de Armadura de Flexão em Vigas Com Seção RetangularPatrícia MouraNo ratings yet

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosNo ratings yet

- Low Voltage Cable - 1101230820Document102 pagesLow Voltage Cable - 1101230820Mouath AlraoushNo ratings yet

- Ship Design (Practical Task 1)Document4 pagesShip Design (Practical Task 1)Aiman AriefNo ratings yet

- Pitagoras 1Document42 pagesPitagoras 1Andres De la cruzNo ratings yet

- Nexans 631101Document4 pagesNexans 631101JAIME INGA MORANNo ratings yet

- HidraulicaDocument42 pagesHidraulicaJuan Camilo Muñoz CarmonaNo ratings yet

- 5 ADocument2 pages5 AingenieuredwinNo ratings yet

- Pressure Conversion Wet Well Intake Pipe Sizing: 173.4 Amps 1.24x1.25x65a + 65A + 7.6ADocument2 pagesPressure Conversion Wet Well Intake Pipe Sizing: 173.4 Amps 1.24x1.25x65a + 65A + 7.6AMark Joey David100% (1)

- Comparação Entre NBR-AISC-Eurocode - LigaçõesDocument2 pagesComparação Entre NBR-AISC-Eurocode - LigaçõesAnderson GuerraNo ratings yet

- Viscometer Model 35Document5 pagesViscometer Model 35Aji Sentosa PramonoNo ratings yet

- 5 lps q: Manning 'n' value n = 0.01 φ 200 mm A = 0.0314 m2 0.0050 m3/s R = 0.050Document2 pages5 lps q: Manning 'n' value n = 0.01 φ 200 mm A = 0.0314 m2 0.0050 m3/s R = 0.050navneet3bawaNo ratings yet

- Confinement Check d0Document15 pagesConfinement Check d0Srishti Project ConsultantsNo ratings yet

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocument2 pages1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- 1200 1300Document18 pages1200 1300wyerengrNo ratings yet

- OMSHRINIWAS EXTRUSIONS ROUND AND FLAT BAR SPECIFICATIONSDocument1,310 pagesOMSHRINIWAS EXTRUSIONS ROUND AND FLAT BAR SPECIFICATIONSSONAL VFSLLPNo ratings yet

- SD Reinforcing Mesh Q131Document12 pagesSD Reinforcing Mesh Q131Mohand EliassNo ratings yet

- SD Reinforcing Mesh Q131Document12 pagesSD Reinforcing Mesh Q131Mohand EliassNo ratings yet

- Torque Tech Prod CatalogDocument38 pagesTorque Tech Prod CatalogPrayoga Muhamad BudimanNo ratings yet

- 02.INTERNAL-EXTERNAL PressureDocument53 pages02.INTERNAL-EXTERNAL PressureGaurav BedseNo ratings yet

- Prel. Results Wake DistributionDocument10 pagesPrel. Results Wake Distributionaun7328No ratings yet

- Properties of steel pipesDocument11 pagesProperties of steel pipesjonasNo ratings yet

- Axv PDFDocument5 pagesAxv PDFramel sigueNo ratings yet

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- Technical Guide e I PDFDocument32 pagesTechnical Guide e I PDFNicuVisanNo ratings yet

- Bolt Torque Requirements Chart for Flange GasketsDocument16 pagesBolt Torque Requirements Chart for Flange GasketsfrdnNo ratings yet

- Material Apoio Calculo Metasa - R05Document1 pageMaterial Apoio Calculo Metasa - R05Anderson GuerraNo ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- Abaco ModyDocument195 pagesAbaco ModyDo IsidroNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- MODULO 6 Analisis Sismico EstaticoDocument11 pagesMODULO 6 Analisis Sismico EstaticoLUIZ FERNANDO ALARCÓN ROJASNo ratings yet

- Cheese Winding Production ReportDocument9 pagesCheese Winding Production ReportSatish K SinghNo ratings yet

- Calculo de caida de tension y regulacion en circuitos electricosDocument7 pagesCalculo de caida de tension y regulacion en circuitos electricosJaime Hernandez MateusNo ratings yet

- Cópia de 3 GrupoDocument1 pageCópia de 3 GrupoNataniel Naerte DomingosNo ratings yet

- Wheatland - ASTM F1043 WT 40 and ASTM F1083 FlyerDocument2 pagesWheatland - ASTM F1043 WT 40 and ASTM F1083 FlyerKurt WolfeNo ratings yet

- PE Pipe Data SheetDocument3 pagesPE Pipe Data SheetNisarg PandyaNo ratings yet

- Origin 350 MCM o Kcmil o MamalonDocument2 pagesOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraNo ratings yet

- Scantling Calc SpreadsheetDocument73 pagesScantling Calc SpreadsheetTapan KhandelwalNo ratings yet

- Calculo de Acero Viga: Verificar O.KDocument7 pagesCalculo de Acero Viga: Verificar O.KAlex ChavarriNo ratings yet

- Ibm 6550-t3n Chassis d99 PDFDocument44 pagesIbm 6550-t3n Chassis d99 PDFCaretta Caretta LNo ratings yet

- Catatan Satuan Dalam Meter (M), Misal R 100 R NO Sudut (A) X Y T - T Hasil T - M 1-COS A Hasil 1 2 3 4 5 6 7 8 9 10Document4 pagesCatatan Satuan Dalam Meter (M), Misal R 100 R NO Sudut (A) X Y T - T Hasil T - M 1-COS A Hasil 1 2 3 4 5 6 7 8 9 10Wal RusNo ratings yet

- Acsr PDFDocument1 pageAcsr PDFAUGUSTA WIBI ARDIKTANo ratings yet

- Utility Distribution Cable SpecificationsDocument1 pageUtility Distribution Cable SpecificationsFrancisco ChanaNo ratings yet

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- Controles PracticasDocument23 pagesControles PracticasChristian Santa Cruz MoraNo ratings yet

- RESEARCH PROJECT: Ac 4079 / A9 - 2.3.1. Resistance and Propulsion TestsDocument4 pagesRESEARCH PROJECT: Ac 4079 / A9 - 2.3.1. Resistance and Propulsion TestsTudor ChirilaNo ratings yet

- Seepco Nitrogen Purge VolumeDocument1 pageSeepco Nitrogen Purge VolumeRolly Hillz SochimNo ratings yet

- Completion Accessories and Functions GuideDocument40 pagesCompletion Accessories and Functions GuideRolly Hillz SochimNo ratings yet

- CT Hydraulic Syetem Schematics For PP and CCDocument12 pagesCT Hydraulic Syetem Schematics For PP and CCRolly Hillz SochimNo ratings yet

- BCTC Job Preperation 3Document2 pagesBCTC Job Preperation 3Rolly Hillz SochimNo ratings yet

- N2 Calculations SpreadsheetDocument15 pagesN2 Calculations SpreadsheetRolly Hillz SochimNo ratings yet

- ouchureIC 7000Document4 pagesouchureIC 7000iti_na8567No ratings yet

- Install and Configure Computer Networks Training Session PlanDocument9 pagesInstall and Configure Computer Networks Training Session PlanMarvin AlcantaraNo ratings yet

- The Effective of Geothermal Energy in BuDocument8 pagesThe Effective of Geothermal Energy in BuMeziane YkhlefNo ratings yet

- jrc122457 Dts Survey Deliverable Ver. 5.0-3Document46 pagesjrc122457 Dts Survey Deliverable Ver. 5.0-3Boris Van CyrulnikNo ratings yet

- Physics ProjectDocument12 pagesPhysics ProjectRita SharmaNo ratings yet

- Overview of Common Communication Challenges and TipsDocument7 pagesOverview of Common Communication Challenges and TipsTinyEYE Therapy ServicesNo ratings yet

- Substitution in The Linguistics of Text and Grammatical ThoughtDocument17 pagesSubstitution in The Linguistics of Text and Grammatical ThoughtThảo HanahNo ratings yet

- Cesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingDocument7 pagesCesp 105 - Foundation Engineering and Retaining Wall Design Lesson 11. Structural Design of Spread FootingJadeNo ratings yet

- Practical Training Seminar Report FormatDocument8 pagesPractical Training Seminar Report FormatShrijeet PugaliaNo ratings yet

- QP 7721-Sobha-B+g+8-2town-Pahse IiDocument2 pagesQP 7721-Sobha-B+g+8-2town-Pahse IirajatNo ratings yet

- Engine Parts Location GuideDocument4 pagesEngine Parts Location GuidevarenziaNo ratings yet

- Lanco Solar EPC leaderDocument19 pagesLanco Solar EPC leaderShabir TrambooNo ratings yet

- P0880 TCM Power Circuit InspectionDocument5 pagesP0880 TCM Power Circuit InspectionLojan Coronel José HumbertoNo ratings yet

- G8 - Light& Heat and TemperatureDocument49 pagesG8 - Light& Heat and TemperatureJhen BonNo ratings yet

- DRAFT RoA (TSBINUANG) TSB 12 PDFDocument1 pageDRAFT RoA (TSBINUANG) TSB 12 PDFAchwan FebNo ratings yet

- Intro To Factor AnalysisDocument52 pagesIntro To Factor AnalysisRawnak JahanNo ratings yet

- Foundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureDocument1 pageFoundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureJosé CallisayaNo ratings yet

- SpinView Getting StartedDocument16 pagesSpinView Getting StartedRicardo SequeiraNo ratings yet

- C 60 A/XF: The Siam Refractory Industry Co.,LtdDocument1 pageC 60 A/XF: The Siam Refractory Industry Co.,LtdGaluhNo ratings yet

- The World in Which We Believe in Is The Only World We Live inDocument26 pagesThe World in Which We Believe in Is The Only World We Live inYusufMiddeyNo ratings yet

- Ett 531 Motion Visual AnalysisDocument4 pagesEtt 531 Motion Visual Analysisapi-266466498No ratings yet

- Resume summary of monthly sparepart costs and production in 2021Document590 pagesResume summary of monthly sparepart costs and production in 2021winda listya ningrumNo ratings yet

- # Micro Pelton Turbines ! $Document93 pages# Micro Pelton Turbines ! $Nathaniel E. Barrios Fuentes100% (1)