Professional Documents

Culture Documents

1C Cu Epr-Pvc 35KV@133% 2017

Uploaded by

CarlosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1C Cu Epr-Pvc 35KV@133% 2017

Uploaded by

CarlosCopyright:

Available Formats

SPEC 46702

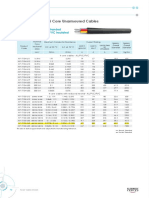

1/C CU 35KV 420 NL-EPR 133% TS SIMpull® PVC MV-105

Type MV-105 Single Conductor Copper, 420 Mils No Lead Ethylene Propylene Rubber (NL-EPR) 133% Insulation Level, Tape

Shield, SIMpull® Polyvinyl Chloride (PVC) Jacket, Dual Rated UL/CSA

1 3 6

6 5 4 3 2 1

Images not to scale. See Table 1 for Dimensions

CONSTRUCTION:

1. Conductor: Class B compressed stranded bare copper per ASTM B3 and ASTM B8

2. Conductor Shield: Semi-conducting cross-linked copolymer

3. Insulation: 420 Mils No Lead Ethylene Propylene Rubber (NL-EPR) 133% Insulation Level

4. Insulation Shield: Stripable semi-conducting cross-linked copolymer

5. Copper Tape Shield: Helically wrapped 5 mil copper tape with 25% overlap

6. Overall Jacket: Polyvinyl Chloride (PVC)

APPLICATIONS AND FEATURES:

Southwire’s 35KV cables are suited for use in wet and dry areas, conduits, ducts, troughs, trays, direct burial, and where su-

perior electrical properties are desired. These cables are capable of operating continuously at the conductor temperature not

in excess of 105°C for normal operation, 140°C for emergency overload, and 250°C for short circuit conditions. Rated at -35°C

for cold bend. ST1 (low smoke) Rated for sizes 1/0 and larger. PVC jacket is made with SIM technology and has a coefficient of

friction COF of 0.2. Cable can be installed in conduit without the aid of lubrication. Rated for 1000 lbs./FT maximum sidewall

pressure.

SPECIFICATIONS:

• ASTM B3 Soft or annealed copper

• ASTM B8 Concentric-lay-standard copper

• UL 1072 - Medium Voltage Power Cables

• ICEA S-97-682 5-46 KV Utility & ICEA S-93-639 (NEMA WC 74) 5-46 KV Shielded Power Cable

• UL 1685/FT4-ST1 Vertical-Tray Fire Propagation and Smoke Release Test (1/0 AWG and Larger)

• IEEE 1202 -Flame Test (70,000) BTU/hr Vertical Tray Test (1/0 AWG and Larger)

• AEIC CS-8 Specification for extruded dielectric shielded power cables rated for 5 through 46KV

• CSA C68.10 - Shielded Power Cables for Commercial and Industrial Applications - 5 to 46 KV

• CSA C22.2 No.230 - Tray Cables - Rated TC-ER (1/0 AWG and Larger)

• CSA C22.2 No. 2556 / UL 2556 - Cable Test Methods

SAMPLE PRINT LEGEND:

SOUTHWIRE [SYMBOL - LIGHTING BOLT] #P# (UL/CSA) 1/C [#AWG or #kcmil] CU 420 MILS NL-EPR 35KV 133% INS LEVEL

25% TS MV-105 For CT USE SUN. RES. TC-ER(CSA 1/0 LARGER) FOR DIRECT BURIAL FT4 -ST1 YEAR (NESC) [SEQUENTIAL

FEET MARKS]

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2016 Southwire Company, LLC. All Rights Reserved SPEC 46702_PSS DIVISION DATE: 04/13/2017 Rev:2.0.00C

SPEC 46702

Table 1 – Weights & Measurements

Diameter over

Cond. Insul. Insul. Jacket Approx. OD Approx. Max Pull Min Bend- Conduit

Stock Cond. Size (1) (3) Shield Thickness¹ (6) Weight Tension ing Radius Size*

Code AWG inches inches inches mils inches lbs./MFT lbs. inches inches

890065 ◊

1/0 0.362 1.239 1.299 80 1.479 1240 845 17.7 5

890082 2/0 0.405 1.282 1.342 80 1.522 1366 1065 18.3 5

TBA 3/0 0.456 1.333 1.393 80 1.573 1524 1342 18.9 5

890066 ◊

4/0 0.512 1.389 1.449 80 1.629 1713 1693 19.5 5

890083 250 0.558 1.444 1.504 80 1.684 1885 2000 20.2 5

890067 ◊

350 0.661 1.547 1.607 110 1.847 2394 2800 22.2 6

890068 ◊ 500 0.789 1.675 1.735 110 1.975 2988 4000 23.7 6

890084 750 0.968 1.863 1.923 110 2.163 3953 6000 26.0 6

890085 1000 1.117 2.012 2.072 110 2.312 4877 8000 27.7

All dimensions are nominal and subject to normal manufacturing tolerances

* Conduit size based on 3 phase 40% fill-factor without ground

¹ Comply with ICEA S-93-639 Appendix C for jacket thickness determination

◊ Standard stock item

Table 2 – Electrical and Engineering Data

Shield Short Allowable Ampacities

Resistance Reactance Positive Zero Circuit 900C/1050C

Cond. DC AC XC XL Sequence Sequence Current

Size @ 250C @ 900C @ 60Hz @ 60Hz Impedance* Impedance* 6 Cycles In Duct † In Air ‡

Stock Code AWG Ω/MFT Ω/MFT MΩ*MFT Ω/MFT Ω/MFT Ω/MFT Amps Amps Amps

890065 ◊

1/0 0.102 0.128 0.066 0.054 0.128 + j0.054 0.464 + j0.273 4259 200 / 215 260 / 290

890082 2/0 0.081 0.101 0.062 0.052 0.102 + j0.052 0.434 + j0.262 4398 230 / 245 300 / 330

TBA 3/0 0.064 0.080 0.058 0.050 0.081 + j0.050 0.408 + j0.249 4564 260 / 275 345 / 380

890066 ◊ 4/0 0.051 0.064 0.054 0.048 0.065 + j0.048 0.386 + j0.236 4747 295 / 315 395 / 445

890083 250 0.043 0.054 0.051 0.047 0.055 + j0.047 0.370 + j0.225 4926 325 / 345 440 / 490

890067 ◊

350 0.031 0.039 0.046 0.045 0.040 + j0.045 0.345 + j0.206 5261 390 / 415 545 / 605

890068 ◊ 500 0.022 0.028 0.041 0.043 0.029 + j0.043 0.321 + j0.186 5677 465 / 500 680 / 755

890084 750 0.014 0.019 0.035 0.040 0.020 + j0.040 0.295 + j0.161 6289 565 / 610 870 / 970

890085 1000 0.011 0.015 0.032 0.038 0.016 + j0.038 0.279 + j0.145 6773 640 / 690 1040 / 1160

* Calculations are based on three cables triplexed / 5 mil 25 % over lapping copper tape shield / Conductor temperature of 90°C / Shield temperature of 45°C /

Earth resistivity of 100 ohms-meter

† Ampacities are based on TABLE 310.60(C)(77) Detail 1. of the 2014 National Electrical Code (20°C Ambient Earth Temperature, Thermal Resistance ROH of 90)

‡ Ampacities are based on TABLE 310.60(C)(69) of the 2014 National Electrical Code (40°C Ambient Air Temperature)

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2016 Southwire Company, LLC. All Rights Reserved SPEC 46702_PSS DIVISION DATE: 04/13/2017 Rev:2.0.00C

You might also like

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNo ratings yet

- Origin 350 MCM o Kcmil o MamalonDocument2 pagesOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocument2 pages1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- 1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specDocument2 pages1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specEdgar Sierra RodriguezNo ratings yet

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- 1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105Document2 pages1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105RodNo ratings yet

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocument2 pages3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNo ratings yet

- Armor X 3C XHHW-2 Power 3GND 600V 2017 - CCDocument2 pagesArmor X 3C XHHW-2 Power 3GND 600V 2017 - CCpglv0210No ratings yet

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- SPEC83013 600 Volt UndergroundDocument3 pagesSPEC83013 600 Volt Undergroundakib javedNo ratings yet

- Ficha Técnica CABLE ERP SOUTHWIREDocument3 pagesFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNo ratings yet

- RhinoDocument2 pagesRhinoValeria Rendon NoyolaNo ratings yet

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Document2 pages3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNo ratings yet

- ACSR_TW.pdfDocument5 pagesACSR_TW.pdfJavier Soza DazaNo ratings yet

- Interlocked Armor Power Cable, 5000 VOLTSDocument1 pageInterlocked Armor Power Cable, 5000 VOLTSpedro perezNo ratings yet

- TDS Na2xyDocument5 pagesTDS Na2xyllruNo ratings yet

- K-Cs-216-Qa-Cer-155 Conductor 3C#8 +10G XHHW-2 Tc-ErDocument3 pagesK-Cs-216-Qa-Cer-155 Conductor 3C#8 +10G XHHW-2 Tc-ErKevind Jesse Castillo PereaNo ratings yet

- Cable 350 MCM-SouthwireDocument2 pagesCable 350 MCM-Southwiremariaelopez1988No ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- WELDING CableDocument2 pagesWELDING CableRezeki SimamoraNo ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- 5 ADocument2 pages5 AingenieuredwinNo ratings yet

- HT Cables - Leading China Cable ManufacturerDocument18 pagesHT Cables - Leading China Cable ManufacturerSIMON S. FLORES G.100% (1)

- Spec 45440Document2 pagesSpec 45440ger80No ratings yet

- AAAC - All Aluminum Alloy ConductorDocument5 pagesAAAC - All Aluminum Alloy ConductoralejandraNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Na2xy-O/ (J) : Din Vde 0276-603 (5G-2)Document3 pagesNa2xy-O/ (J) : Din Vde 0276-603 (5G-2)Asad Ali100% (1)

- Bostrig SC UnarmoredDocument3 pagesBostrig SC UnarmoredEnrique MartínezNo ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- Standard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Document7 pagesStandard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Bhagoo HatheyNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- Nexans 631101Document4 pagesNexans 631101JAIME INGA MORANNo ratings yet

- Me1.3.6-Me1.3.10 Cable XHHW SouthwireDocument2 pagesMe1.3.6-Me1.3.10 Cable XHHW SouthwireHenry MontenegroNo ratings yet

- Soow H07RN-F Aj 24.02.2022Document4 pagesSoow H07RN-F Aj 24.02.2022Tamara TrejosNo ratings yet

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFDocument2 pages15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezNo ratings yet

- Gaon Cable Catalogue (Eng.)Document54 pagesGaon Cable Catalogue (Eng.)harry jangNo ratings yet

- Muli Core Unarmoured CablesDocument4 pagesMuli Core Unarmoured Cablesمحمود الديبNo ratings yet

- Nyy 1CDocument1 pageNyy 1Chenry_gtNo ratings yet

- 35kV AL 133% TRXLPE One-Third Neutral LLDPE Primary UD: SPEC 81252Document5 pages35kV AL 133% TRXLPE One-Third Neutral LLDPE Primary UD: SPEC 81252Anonymous hxyW3v5QqVNo ratings yet

- Zero Halogen EP Welding Cable 105ºC Industrial Grade: Specifications & Standards ConstructionDocument1 pageZero Halogen EP Welding Cable 105ºC Industrial Grade: Specifications & Standards ConstructionAndri YunafrisonNo ratings yet

- Csvv-Swa PVC PDFDocument2 pagesCsvv-Swa PVC PDFahmad fauzanNo ratings yet

- Type TC Power Cable-THHN: ApplicationsDocument2 pagesType TC Power Cable-THHN: ApplicationsHenry MontenegroNo ratings yet

- General Wiring Price List - June 01st 2021Document1 pageGeneral Wiring Price List - June 01st 2021Hassan Iqbal WarraichNo ratings yet

- Anixter SPEC-44020 DLO-Cable PDFDocument3 pagesAnixter SPEC-44020 DLO-Cable PDFJoon LeeNo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- KabelmetaDocument1 pageKabelmetaLinda Soraya SeptianaNo ratings yet

- Nyy - Iec PDFDocument5 pagesNyy - Iec PDFbenryNo ratings yet

- N2XSB (Al) yDocument5 pagesN2XSB (Al) yWiraa FrihatmokoNo ratings yet

- Drift TableDocument3 pagesDrift TableRolly Hillz SochimNo ratings yet

- Texcan 13073130Document1 pageTexcan 130731306bngdz4xhkNo ratings yet

- TDS_Al_XLPE_SWA_PVC-_NA2XRYDocument3 pagesTDS_Al_XLPE_SWA_PVC-_NA2XRYvsumedhaNo ratings yet

- NYYDocument5 pagesNYYrioNo ratings yet

- Kabel Metal Nyy, Nym, Nya, NyfgbyDocument14 pagesKabel Metal Nyy, Nym, Nya, NyfgbyMitha Wahyu PangestiNo ratings yet

- Simpull XHHW/CT: SpecificationsDocument2 pagesSimpull XHHW/CT: SpecificationsrlaureanoNo ratings yet

- NYY 2 x (1.5-300) mm2 0.6/1 kV Cable SpecDocument5 pagesNYY 2 x (1.5-300) mm2 0.6/1 kV Cable SpecDen WhNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- 10194601-DS-0201 - B - SubstationDocument48 pages10194601-DS-0201 - B - SubstationCarlosNo ratings yet

- 101946-DS-0207 - 1 - Generator SetsDocument10 pages101946-DS-0207 - 1 - Generator SetsCarlosNo ratings yet

- LST 0704 - 0Document15 pagesLST 0704 - 0CarlosNo ratings yet

- LST 0702 - 0Document12 pagesLST 0702 - 0CarlosNo ratings yet

- Study Simple Steam Engine ModelDocument3 pagesStudy Simple Steam Engine ModelPradyot DeoliaNo ratings yet

- Hamworthy Topping Up GeneratorDocument2 pagesHamworthy Topping Up GeneratorHARISHNo ratings yet

- TSA-5 Electrical Wiring Installation Permit ApplicationDocument1 pageTSA-5 Electrical Wiring Installation Permit ApplicationMyrene Ambas-BoslengNo ratings yet

- Cummins: Fault Code: 488 PID: P105 SPN: 105 FMI: 0Document2 pagesCummins: Fault Code: 488 PID: P105 SPN: 105 FMI: 0Enrrique LaraNo ratings yet

- Wind Modeling Using WindPro and WAsP SoftwareDocument11 pagesWind Modeling Using WindPro and WAsP SoftwarensralmasiNo ratings yet

- Acid Base Lab ReportDocument16 pagesAcid Base Lab Reportapi-327713634100% (1)

- 1707 An253 Power Supply Design Basics ImpDocument6 pages1707 An253 Power Supply Design Basics ImpbmmostefaNo ratings yet

- GCP-HARP-1004 - College of Magics PDFDocument127 pagesGCP-HARP-1004 - College of Magics PDFMartin Gualdarrama50% (2)

- BS en 50160 2007Document24 pagesBS en 50160 2007Pepe Eulogio OrtízNo ratings yet

- Problem Set 3Document2 pagesProblem Set 3Dniel Suarez RNo ratings yet

- Nuclear Proliferation and The NPTDocument20 pagesNuclear Proliferation and The NPTgoricaaaPNo ratings yet

- Wind Turbines by UJJWAL NAUTIYALDocument14 pagesWind Turbines by UJJWAL NAUTIYALUjjwal NautiyalNo ratings yet

- Introduction To CommutationDocument45 pagesIntroduction To CommutationSobi67% (3)

- STrait Line Stud Finder ManualDocument1 pageSTrait Line Stud Finder ManualRob BrewsterNo ratings yet

- Microsoft Word - E003 Main QuizDocument6 pagesMicrosoft Word - E003 Main QuizwarrenronaldNo ratings yet

- Ams 3125 Bearing Vibration Monitor en 39920Document3 pagesAms 3125 Bearing Vibration Monitor en 39920EyuNo ratings yet

- ST Joseph'S College of EngineeirngDocument16 pagesST Joseph'S College of EngineeirngVignesshwar VenkatachalamNo ratings yet

- Magnetrol TD1Document16 pagesMagnetrol TD1mrizalygani99No ratings yet

- Benefits of Variable Speed Drives in Sugar Production: White PaperDocument12 pagesBenefits of Variable Speed Drives in Sugar Production: White PaperMashudi FikriNo ratings yet

- Applied Hydraulics LecturesDocument75 pagesApplied Hydraulics Lecturestubeline100% (1)

- CHE 110: Environmental Studies: Unit: 1 - Lecture: 5 - CHE110 - VKDocument17 pagesCHE 110: Environmental Studies: Unit: 1 - Lecture: 5 - CHE110 - VKAditya SajjaNo ratings yet

- Maleic Anhydride Plant CostDocument3 pagesMaleic Anhydride Plant CostIntratec SolutionsNo ratings yet

- DocumentDocument6 pagesDocumentManish KumarNo ratings yet

- 1LE1002-1DA33-4AA4-Z Q02 Datasheet en PDFDocument2 pages1LE1002-1DA33-4AA4-Z Q02 Datasheet en PDFhmfNo ratings yet

- Reverse Osmosis Model R4X40 Installation InstructionsDocument16 pagesReverse Osmosis Model R4X40 Installation InstructionsWattsNo ratings yet

- Analisa Setting Over Current Relay (Ocr) Dan Ground Fault Relay (GFR) Pada Trafo 60 MVA Di GIS 150 KV SimpangDocument8 pagesAnalisa Setting Over Current Relay (Ocr) Dan Ground Fault Relay (GFR) Pada Trafo 60 MVA Di GIS 150 KV Simpangmuhammad ikramNo ratings yet

- Solutions Manual For: Multiphase Flows With Droplets and ParticlesDocument80 pagesSolutions Manual For: Multiphase Flows With Droplets and ParticlesSarah Suelen100% (3)

- Concepts 2. Smart City 3. Smart Region 4. Smart Port 5. AnnexesDocument97 pagesConcepts 2. Smart City 3. Smart Region 4. Smart Port 5. AnnexesNataliaTeruyaNo ratings yet

- D 4762 - 04 Rdq3njiDocument16 pagesD 4762 - 04 Rdq3njicristina ramosNo ratings yet