Professional Documents

Culture Documents

HSE Alert - Toppling of Tipper Truck

HSE Alert - Toppling of Tipper Truck

Uploaded by

Zohaib Tahir0 ratings0% found this document useful (0 votes)

9 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageHSE Alert - Toppling of Tipper Truck

HSE Alert - Toppling of Tipper Truck

Uploaded by

Zohaib TahirCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

Health and Safety Department

HSE Alert

(On Monday 2208/2022 at 1.30 am, Serious Dangerous Occurence was teprted when a tipper tier prialy toppled when tipping the lod (subbase). The main causes

‘ofthis inden inching uneven grown, unsafe postioning of the track thi the trick head sn the semistrlewas not aligned, reekless driving with fly ried

Aotbod 0 ofa quickly, ond inadequate sperison

[No personal injury’ was epoted, However. the somites was pialy damaged.

iss cus

‘Trlr vas tipping on vo uneven and poorly compasted ground.

Root cuss:

(© tnadoquate planing and coordination resuked in an ineetive review of the associated rss and absence of prestat wotkplace inspection wo ensure the basic

safey precautions prior commencing the tipping atin.

1 Nonconformance tothe requitmonts of isk management, Wok Was cared out without proved method sae meat and isk asenoment

Inadoqutesubcontrictr management a the subcontractors subcontractor fond without vali contacts agreement deeds who has deployed the diver and

the tile, an HSE oriented commencement meeting between the main conrator and ub-conractor was mot conducted, HSE monitoring arrangements were not

stable, ee.

© Nonconformance to he training requirments ofthe projet: as subcontractor drivers found without ts specific tinings, projet induction ee.

Noncontormance tothe requirments of inepsction and mintranee wx mentioned in OSHAD SF CoP 360 and 440 incidingabsene of om rival inspection,

Ahly inspection bythe driver, pid inspection by a competent mechanic an planned prevertive maintenance as er the manufacturer reommnendatons"

(© madoquate supervision and HSE complies monitoring by the main contractor.

‘Lessons lear

11 esseatalw ensure sppeopite management of subcoteact/ supply chain when deploying its mailers wth divers Mai contractor ust comply with he

requirments of Element 3 of OSHAD SF andi cam be achieved by

1 Esalhing en approprate stb-contactrsuppy chain management procedure

(© rplemening the process with adequate routes inching but limited 1: prequalifiation for HSE, Wren Contract with lear scope

and SE

E obligations, Precommencerent meetings! communewion, sk manaperent taining requirements, supervision, HSE nioring, reporting and

(© Mainuining the procadure and its compliances with efectve supervision and monitoring.

yin compligce withthe Element 3 of OSHAD SF i extents and ican be achieved by:

2 Ensure management of HSE risk ti

(© Risk based thinking on every ctv business operations.

1 Establish ctivity specific method statement and isk assessment covering ll tine and non-outin tasks, which sto Meniyfresecable sks. and anticipated

«emerueeies with adequate contls and mitigation measures

5, Proatve planning and coordination of actos Between evant employees fom consition supervision and HSE tam, shall gurantee hase safety pressions

prior to commence physical activities tse

4. Pre-start inspection of al activities for basi safety precautions prior o star the sbi by competent supevisc foreman sl mse major non-conormances with HSE

quirements nd morsover create an opportunity 1 ge it ight fom the beginning”

5. Daily activity briing’ task spect training fr tht sida by the detiated sperisiom arn embed he riks an emergencies ticipated with he

cautions will impose workers morale, wareness and compionees

6. Deploynen of competent HSE sal evering al work locations, who shall conduct regular and appropriate inspections port all dings reuies improvement,

identify ott aus oral mr vnlaton and ensive appropriate coetive actin within senate tinea

Bost Rogards, ecb all gs

‘Musanada Health, Safety and Environment Team Adgally teal excell 5 ot

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Risk Assement - (Paint Work)Document6 pagesRisk Assement - (Paint Work)Zohaib TahirNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Emergency Plaining and ArrangmentsDocument6 pagesEmergency Plaining and ArrangmentsZohaib TahirNo ratings yet

- Objectives and TargetsDocument2 pagesObjectives and TargetsZohaib TahirNo ratings yet

- Emergency Drill April 2022Document5 pagesEmergency Drill April 2022Zohaib TahirNo ratings yet

- Incident Investigation ReportDocument4 pagesIncident Investigation ReportZohaib TahirNo ratings yet

- Daily Surprise DealsDocument13 pagesDaily Surprise DealsZohaib TahirNo ratings yet

- Domain 2 Management SystemDocument125 pagesDomain 2 Management SystemZohaib TahirNo ratings yet

- Confined Space - (November 2021)Document1 pageConfined Space - (November 2021)Zohaib TahirNo ratings yet

- CSP 11.09.2023Document2 pagesCSP 11.09.2023Zohaib TahirNo ratings yet

- Draft For Staff Shortage at SiteDocument1 pageDraft For Staff Shortage at SiteZohaib TahirNo ratings yet

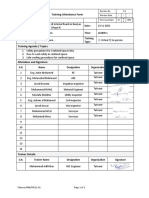

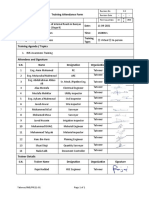

- Training Attendance - (January 2021)Document1 pageTraining Attendance - (January 2021)Zohaib TahirNo ratings yet

- IMS Awarness (September 2021)Document1 pageIMS Awarness (September 2021)Zohaib TahirNo ratings yet

- Waste Management (May 2021)Document1 pageWaste Management (May 2021)Zohaib TahirNo ratings yet

- Covid-19, Awarness & PrecautionsDocument1 pageCovid-19, Awarness & PrecautionsZohaib TahirNo ratings yet

- HSE Responsibilities - (October 2021)Document1 pageHSE Responsibilities - (October 2021)Zohaib TahirNo ratings yet

- HSE AgendaDocument2 pagesHSE AgendaZohaib TahirNo ratings yet

- HSE Plan & MSRADocument1 pageHSE Plan & MSRAZohaib TahirNo ratings yet

- Monitoring The Achievement of ObjectivesDocument1 pageMonitoring The Achievement of ObjectivesZohaib TahirNo ratings yet