Professional Documents

Culture Documents

E400NP Driver: Customer Product Manual Part 1038035C

Uploaded by

Oussama HobbiesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E400NP Driver: Customer Product Manual Part 1038035C

Uploaded by

Oussama HobbiesCopyright:

Available Formats

E400NP Driver

Customer Product Manual

Part 1038035C02

Issued 2/10

This equipment is regulated by the European

Union under WEEE Directive 2002/96/EC).

See www.nordson.com for information about

how to properly dispose of this equipment.

NORDSON CORPORATION • DULUTH, GEORGIA • USA

www.nordson.com

Nordson Corporation welcomes requests for information, comments, and inquiries about its products. General information

about Nordson can be found on the Internet using the following address: http://www.nordson.com.

Address all correspondence to:

Nordson Corporation

Attn: Customer Service

11475 Lakefield Drive

Duluth, GA 30097

Notice

This is a Nordson Corporation publication which is protected by copyright. Original copyright date 2003.

No part of this document may be photocopied, reproduced, or translated to another language without the prior written

consent of Nordson Corporation. The information contained in this publication is subject to change without notice.

Trademarks

AccuJet, AeroCharge, AquaGuard, Asymtek, Automove, Autotech, Baitgun, Blue Box, CanWorks, Century, CF, Clean Coat, CleanSleeve, CleanSpray,

Control Coat, Coolwave, Cross-Cut, Cyclo-Kinetic, Dispensejet, DispenseMate, Durafiber, Durasystem, Easy Coat, Easymove Plus, Econo-Coat, EFD, ETI,

Excel 2000, FlexiCoat, Flexi-Spray, Flex-O-Coat, Flow Sentry, Fluidmove, FoamMelt, FoamMix, Heli-flow, Helix, Horizon, Hot Shot, Isocoil, Isocore, Iso-Flo,

JR, KB30, Kinetix, Little Squirt, Magnastatic, MEG, Meltex, Microcoat, Micromark, MicroSet, Millennium, Mini Squirt, Moist-Cure, Mountaingate, MultiScan,

Nordson, OmniScan, OptiMix, Package of Values, PatternView, PermaFlo, Plasmod, PluraFoam, Porous Coat, PowderGrid, Powderware, Prism, ProBlue,

Pro-Flo, ProLink, Pro-Meter, Pro-Stream, RBX, Rhino, Saturn, SC5, S. design stylized, Seal Sentry, Select Charge, Select Coat, Select Cure, Slautterback,

Smart-Coat, Solder Plus, Spectrum, Speed-Coat, Spraymelt, Spray Squirt, Super Squirt, Sure Coat, Tela-Therm, Tracking Plus, Trends, Tribomatic,

Ultrasaver, UniScan, UpTime, Veritec, VersaBlue, Versa-Coat, Versa-Screen, Versa-Spray, Walcom, Watermark, and When you expect more.

are registered trademarks of Nordson Corporation.

AeroDeck, AeroWash, Apogee, ATS, Auto-Flo, AutoScan, BetterBook, CanNeck, Chameleon, Check Mate, ColorMax, Controlled Fiberization,

Control Weave, CPX, Dry Cure, DuraBlue, Dura-Coat, DuraPail, Dura-Screen, Easy Clean, Eclipse, EcoDry, e.DOT, E-Nordson, Equi=Bead, ESP, e

Stylized, Fillmaster, Fill Sentry, Gluie, HDLV, iControl, iFlow, Ink-Dot, iON, Iso-Flex, iTrend, KVLP, Lacquer Cure, March, Maxima, MicroFin, MicroMax,

Minimeter, Multifil, OptiStroke, Origin, PatternPro, PluraMix, Powder Pilot, Powercure, Primarc, Printplus, Process Sentry, Pulse Spray, PurTech, Ready

Coat, Scoreguard, Select Series, Sensomatic, Shaftshield, SheetAire, Spectral, Spectronic, Speedking, Spray Works, Summit, SureBead, Sure Brand,

Sure Clean, Sure-Max, Swirl Coat, Tempus, ThruWave, Trade Plus, Trak, Ultrasmart, Universal, Vantage, Viper, Vista, Web Cure,

and 2 Rings (Design) are trademarks of Nordson Corporation.

Designations and trademarks stated in this document may be brands that, when used by third parties for their own purposes,

could lead to violation of the owners’ rights.

Part 1038035C02 E 2010 Nordson Corporation

All rights reserved

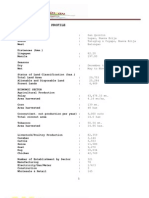

Table of Contents i

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Alert Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Responsibilities of the Equipment Owner . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instructions, Requirements, and Standards . . . . . . . . . . . . . . . . . . . . . . 2

User Qualifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Applicable Industry Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Intended Use of the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Instructions and Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance and Repair Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Equipment Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Equipment Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Safety Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Other Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

First Aid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Labels and Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Required Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mount the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect the Applicator to the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connect the Low Voltage Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect the AC Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install a Power On/Off Switch (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Test the Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Normal Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PURGE Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

E 2010 Nordson Corporation Part 1038035C02

ii Table of Contents

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Using the Illustrated Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Driver Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Applicator-to-Driver Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 1

E400NP Driver

WARNING: Allow only personnel with appropriate training and experience

to operate or service the equipment. The use of untrained or inexperienced

personnel to operate or service the equipment can result in injury, including

death, to themselves and others, and damage to the equipment.

Safety

Read this section before using the equipment. This section contains

recommendations and practices applicable to the safe installation,

operation, and maintenance (hereafter referred to as “use”) of the product

described in this document (hereafter referred to as “equipment”). Additional

safety information, in the form of task-specific safety alert messages,

appears as appropriate throughout this document.

WARNING: Failure to follow the safety messages, recommendations, and

hazard avoidance procedures provided in this document can result in

personal injury, including death, or damage to equipment or property.

Safety Alert Symbols

The following safety alert symbol and signal words are used throughout this

document to alert the reader to personal safety hazards or to identify

conditions that may result in damage to equipment or property. Comply with

all safety information that follows the signal word.

WARNING: Indicates a potentially hazardous situation that, if not avoided,

can result in serious personal injury, including death.

CAUTION: Indicates a potentially hazardous situation that, if not avoided,

can result in minor or moderate personal injury.

CAUTION: (Used without the safety alert symbol) Indicates a potentially

hazardous situation that, if not avoided, can result in damage to equipment

or property.

E 2010 Nordson Corporation Part 1038035C02

2 E400NP Driver

Responsibilities of the Equipment Owner

Equipment owners are responsible for managing safety information,

ensuring that all instructions and regulatory requirements for use of the

equipment are met, and for qualifying all potential users.

Safety Information

S Research and evaluate safety information from all applicable sources,

including the owner-specific safety policy, best industry practices,

governing regulations, material manufacturer’s product information, and

this document.

S Make safety information available to equipment users in accordance

with governing regulations. Contact the authority having jurisdiction for

information.

S Maintain safety information, including the safety labels affixed to the

equipment, in readable condition.

Instructions, Requirements, and Standards

S Ensure that the equipment is used in accordance with the information

provided in this document, governing codes and regulations, and best

industry practices.

S If applicable, receive approval from your facility’s engineering or safety

department, or other similar function within your organization, before

installing or operating the equipment for the first time.

S Provide appropriate emergency and first aid equipment.

S Conduct safety inspections to ensure required practices are being

followed.

S Re-evaluate safety practices and procedures whenever changes are

made to the process or equipment.

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 3

User Qualifications

Equipment owners are responsible for ensuring that users:

S receive safety training appropriate to their job function as directed by

governing regulations and best industry practices

S are familiar with the equipment owner’s safety and accident

prevention policies and procedures

S receive, equipment- and task-specific training from another qualified

individual

NOTE: Nordson can provide equipment-specific installation,

operation, and maintenance training. Contact your Nordson

representative for information

S possess industry- and trade-specific skills and a level of experience

appropriate to their job function

S are physically capable of performing their job function and are not

under the influence of any substance that degrades their mental

capacity or physical capabilities

Applicable Industry Safety Practices

The following safety practices apply to the use of the equipment in the

manner described in this document. The information provided here is not

meant to include all possible safety practices, but represents the best safety

practices for equipment of similar hazard potential used in similar industries.

Intended Use of the Equipment

S Use the equipment only for the purposes described and within the limits

specified in this document.

S Do not modify the equipment.

S Do not use incompatible materials or unapproved auxiliary devices.

Contact your Nordson representative if you have any questions on

material compatibility or the use of non-standard auxiliary devices.

Instructions and Safety Messages

S Read and follow the instructions provided in this document and other

referenced documents.

S Familiarize yourself with the location and meaning of the safety warning

labels and tags affixed to the equipment. Refer to Safety Labels and

Tags at the end of this section.

S If you are unsure of how to use the equipment, contact your Nordson

representative for assistance.

E 2010 Nordson Corporation Part 1038035C02

4 E400NP Driver

Installation Practices

S Install the equipment in accordance with the instructions provided in this

document and in the documentation provided with auxiliary devices.

S Ensure that the equipment is rated for the environment in which it will be

used and that the processing characteristics of the material will not

create a hazardous environment. Refer to the Material Safety Data

Sheet (MSDS) for the material.

S If the required installation configuration does not match the installation

instructions, contact your Nordson representative for assistance.

S Position the equipment for safe operation. Observe the requirements for

clearance between the equipment and other objects.

S Install lockable power disconnects to isolate the equipment and all

independently powered auxiliary devices from their power sources.

S Properly ground all equipment. Contact your local building code

enforcement agency for specific requirements.

S Ensure that fuses of the correct type and rating are installed in fused

equipment.

S Contact the authority having jurisdiction to determine the requirement for

installation permits or inspections.

Operating Practices

S Familiarize yourself with the location and operation of all safety devices

and indicators.

S Confirm that the equipment, including all safety devices (guards,

interlocks, etc.), is in good working order and that the required

environmental conditions exist.

S Use the personal protective equipment (PPE) specified for each task.

Refer to Equipment Safety Information or the material manufacturer’s

instructions and MSDS for PPE requirements.

S Do not use equipment that is malfunctioning or shows signs of a

potential malfunction.

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 5

Maintenance and Repair Practices

S Perform scheduled maintenance activities at the intervals described in

this document.

S Relieve system hydraulic and pneumatic pressure before servicing the

equipment.

S De-energize the equipment and all auxiliary devices before servicing the

equipment.

S Use only new factory-authorized refurbished or replacement parts.

S Read and comply with the manufacturer’s instructions and the MSDS

supplied with equipment cleaning compounds.

NOTE: MSDSs for cleaning compounds that are sold by Nordson are

available at www.nordson.com or by calling your Nordson

representative.

S Confirm the correct operation of all safety devices before placing the

equipment back into operation.

S Dispose of waste cleaning compounds and residual process materials

according to governing regulations. Refer to the applicable MSDS or

contact the authority having jurisdiction for information.

S Keep equipment safety warning labels clean. Replace worn or damaged

labels.

Equipment Safety Information

This equipment safety information is applicable to the following types of

Nordson equipment:

S hot melt and cold adhesive application equipment and all related

accessories

S pattern controllers, timers, detection and verification systems, and all

other optional process control devices

Equipment Shutdown

To safely complete many of the procedures described in this document, the

equipment must first be shut down. The level of shut down required varies

by the type of equipment in use and the procedure being completed.

If required, shut down instructions are specified at the start of the

procedure. The levels of shut down are:

Relieving System Hydraulic Pressure

Completely relieve system hydraulic pressure before breaking any hydraulic

connection or seal. Refer to the melter-specific product manual for

instructions on relieving system hydraulic pressure.

E 2010 Nordson Corporation Part 1038035C02

6 E400NP Driver

De-energizing the System

Isolate the system (melter, hoses, guns, and optional devices) from all

power sources before accessing any unprotected high-voltage wiring or

connection point.

1. Turn off the equipment and all auxiliary devices connected to the

equipment (system).

2. To prevent the equipment from being accidentally energized, lock and

tag the disconnect switch(es) or circuit breaker(s) that provide input

electrical power to the equipment and optional devices.

NOTE: Government regulations and industry standards dictate specific

requirements for the isolation of hazardous energy sources. Refer to the

appropriate regulation or standard.

Disabling the Guns

All electrical or mechanical devices that provide an activation signal to the

guns, gun solenoid valve(s), or the melter pump must be disabled before

work can be performed on or around a gun that is connected to a

pressurized system.

1. Turn off or disconnect the gun triggering device (pattern controller, timer,

PLC, etc.).

2. Disconnect the input signal wiring to the gun solenoid valve(s).

3. Reduce the air pressure to the gun solenoid valve(s) to zero; then

relieve the residual air pressure between the regulator and the gun.

General Safety Warnings and Cautions

Table 1 contains the general safety warnings and cautions that apply to

Nordson hot melt and cold adhesive equipment. Review the table and

carefully read all of the warnings or cautions that apply to the type of

equipment described in this manual.

Equipment types are designated in Table 1 as follows:

HM = Hot melt (melters, hoses, guns, etc.)

PC = Process control

CA = Cold adhesive (dispensing pumps, pressurized container, and

guns)

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 7

Table 1 General Safety Warnings and Cautions

Equipment

Type Warning or Caution

WARNING: Hazardous vapors! Before processing any polyurethane

reactive (PUR) hot melt or solvent-based material through a

compatible Nordson melter, read and comply with the material’s

MSDS. Ensure that the material’s processing temperature and

HM

flashpoints will not be exceeded and that all requirements for safe

handling, ventilation, first aid, and personal protective equipment are

met. Failure to comply with MSDS requirements can cause personal

injury, including death.

WARNING: Reactive material! Never clean any aluminum component

or flush Nordson equipment with halogenated hydrocarbon fluids.

Nordson melters and guns contain aluminum components that may

HM

react violently with halogenated hydrocarbons. The use of

halogenated hydrocarbon compounds in Nordson equipment can

cause personal injury, including death.

WARNING: System pressurized! Relieve system hydraulic pressure

before breaking any hydraulic connection or seal. Failure to relieve

HM, CA

the system hydraulic pressure can result in the uncontrolled release of

hot melt or cold adhesive, causing personal injury.

WARNING: Molten material! Wear eye or face protection, clothing

that protects exposed skin, and heat-protective gloves when servicing

HM equipment that contains molten hot melt. Even when solidified, hot

melt can still cause burns. Failure to wear appropriate personal

protective equipment can result in personal injury.

Continued...

E 2010 Nordson Corporation Part 1038035C02

8 E400NP Driver

General Safety Warnings and Cautions (contd)

Table 1 General Safety Warnings and Cautions (contd)

Equipment

Type Warning or Caution

WARNING: Equipment starts automatically! Remote triggering

devices are used to control automatic hot melt guns. Before working

on or near an operating gun, disable the gun’s triggering device and

HM, PC

remove the air supply to the gun’s solenoid valve(s). Failure to disable

the gun’s triggering device and remove the supply of air to the

solenoid valve(s) can result in personal injury.

WARNING: Risk of electrocution! Even when switched off and

electrically isolated at the disconnect switch or circuit breaker, the

equipment may still be connected to energized auxiliary devices.

HM, CA, PC De-energize and electrically isolate all auxiliary devices before

servicing the equipment. Failure to properly isolate electrical power to

auxiliary equipment before servicing the equipment can result in

personal injury, including death.

WARNING: Risk of fire or explosion! Nordson cold adhesive

equipment is not rated for use in explosive environments and should

not be used with solvent-based adhesives that can create an

explosive atmosphere when processed. Refer to the MSDS for the

CA

adhesive to determine its processing characteristics and limitations.

The use of incompatible solvent-based adhesives or the improper

processing of solvent-based adhesives can result in personal injury,

including death.

WARNING: Allow only personnel with appropriate training and

experience to operate or service the equipment. The use of untrained

HM, CA, PC or inexperienced personnel to operate or service the equipment can

result in injury, including death, to themselves and others and can

damage to the equipment.

Continued...

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 9

Equipment

Type Warning or Caution

CAUTION: Hot surfaces! Avoid contact with the hot metal surfaces of

guns, hoses, and certain components of the melter. If contact can not

HM be avoided, wear heat-protective gloves and clothing when working

around heated equipment. Failure to avoid contact with hot metal

surfaces can result in personal injury.

CAUTION: Some Nordson melters are specifically designed to

process polyurethane reactive (PUR) hot melt. Attempting to process

PUR in equipment not specifically designed for this purpose can

HM

damage the equipment and cause premature reaction of the hot melt.

If you are unsure of the equipment’s ability to process PUR, contact

your Nordson representative for assistance.

CAUTION: Before using any cleaning or flushing compound on or in

the equipment, read and comply with the manufacturer’s instructions

HM, CA and the MSDS supplied with the compound. Some cleaning

compounds can react unpredictably with hot melt or cold adhesive,

resulting in damage to the equipment.

CAUTION: Nordson hot melt equipment is factory tested with

Nordson Type R fluid that contains polyester adipate plasticizer.

HM Certain hot melt materials can react with Type R fluid and form a solid

gum that can clog the equipment. Before using the equipment,

confirm that the hot melt is compatible with Type R fluid.

Other Safety Precautions

S Do not use an open flame to heat hot melt system components.

S Check high pressure hoses daily for signs of excessive wear, damage,

or leaks.

S Never point a dispensing handgun at yourself or others.

S Suspend dispensing handguns by their proper suspension point.

E 2010 Nordson Corporation Part 1038035C02

10 E400NP Driver

First Aid

If molten hot melt comes in contact with your skin:

1. Do NOT attempt to remove the molten hot melt from your skin.

2. Immediately soak the affected area in clean, cold water until the hot melt

has cooled.

3. Do NOT attempt to remove the solidified hot melt from your skin.

4. In case of severe burns, treat for shock.

5. Seek expert medical attention immediately. Give the MSDS for the hot

melt to the medical personnel providing treatment.

Safety Labels and Tags

Figure 1 illustrates the location of the product safety labels and tags affixed

to the equipment. Table 2 provides an illustration of the hazard identification

symbols that appear on each safety label and tag, the meaning of the

symbol, or the exact wording of any safety message.

4212014

Figure 1 Safety labels and tags

Table 2 Safety Labels and Tags

Item Part Description

1. ------

Silkscreen, warning, electrical shock

2. 307838

Tag, warning, electrical shock

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 11

Description

The E400NP driver is a high-performance, single-channel,

current-controlling electric applicator driver. It is especially targeted for use

with E400 electric applicators, but it can also support other electric

applicators. The driver controls coil current, which is the driving force behind

the actuation of the module on an electric applicator. The driver electrical

output is a spiked waveform that applies a high-peak current to actuate the

module rapidly, followed by a lower holding current to reduce power

dissipation

The driver is shipped with factory default settings that should work for about

75 percent of all applications.

4212015

Figure 2 E400NP driver

The driver has a number of useful visual indicators that aid in

troubleshooting, such as the POWER, TRIGGER, OUTPUT, and thermal

fault LEDs. The thermal fault diagnostic is especially unique. The driver

monitors the power applied to the coil and communicates the coil power

level via three color-coded LEDs: green (OK), yellow (coil power

approaching coil rating), and red (coil power exceeds coil rating). In addition

to the visual indicators, an alarm contact is available for remote signaling.

The E400NP driver is just one part of an E400 adhesive-dispensing system.

When used together, the E400NP driver and the E400 electric applicator

provide a powerful, high-performance solution for many

adhesive-dispensing applications.

E 2010 Nordson Corporation Part 1038035C02

12 E400NP Driver

Specifications

Due to technological or quality improvements, specifications are subject to

change without notice.

Item Specification

Ambient temperature range 0−50 _C (32−122 _F)

Voltage 170−264 VAC (fuse- and transient-protected)

Enclosure rating IP20

Driver electrical output capacity S 1 E400 applicator at full performance

(current-controlling peak followed by S 2 or 3 E400 applicators in series at reduced performance

a reduced holding level)

Trigger input Opto-isolated by driver

Number of channels 1

Trigger levels S 5 VDC logic

S 10−30 VDC

Diagnostic LEDs S POWER

S TRIGGER

S OUTPUT

S Thermal (OK, WARNING, FAULT)

S OPEN (open circuit)

S SHORT (short circuit)

S DOT MODE

Alarm output Potential-free contact rated at 0.25 A @ 24 VDC, closes on

output fault (open circuit, short circuit, or thermal)

Terminal block connections Two-piece, quick-disconnect

Mounting DIN rail

Dimensions 64 mm (width) x 216 mm (height) x 147 mm (depth)

2.50 in. (width) x 8.50 in. (height) x 5.78 in. (depth)

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 13

Installation

Installation involves mounting the driver inside an enclosure, connecting

applicator and low-voltage signal wiring, and connecting power.

Required Items

You will need the following items to install the driver:

S wire cutter/stripper and ferrule crimper

S water- and dust-resistant enclosure with din rails

(customer-supplied)

S cable for connecting the driver to the applicator (refer to Parts for the

cable part number)

S 1.0−0.34 mm2 (18−22 AWG) wiring for the low-voltage signal wiring

(customer-supplied)

S 1.0 mm2 (18 AWG) wiring for the AC power connection

(customer-supplied)

Mount the Driver

See Figure 3. Mount the driver on a din rail inside an enclosure that will

protect it from dust and water. Make sure the front panel is visible and easily

accessible.

4212016

Figure 3 Mounting the driver

E 2010 Nordson Corporation Part 1038035C02

14 E400NP Driver

Connect the Applicator to the Driver

Electric applicators are connected to the driver via a cable. Refer to Parts

for the applicator-to-driver cable part number. Because the driver is

current-controlling, the modules are connected in series. Up to three

modules can be connected.

1. See Figure 4. Connect the cordset end of the applicator-to-driver cable

to the module control cordset on the applicator.

4212005

Figure 4 Connecting the applicator-to-driver cable to an E400 applicator

4212006

Figure 5 Location of terminal blocks on the driver

1. AC power inlet terminal block 3. Low-voltage signal wiring

2. Coil output terminal block terminal block

(applicator-to-driver cable connection)

2. Connect the other end of the applicator-to-driver cable to the driver as

shown in Table 3, 4, or 5. See Figure 5 for the location of the terminal

blocks on the driver.

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 15

Table 3 Terminal Block Connections for One Applicator Module

Designation Purpose

SHIELD Shield

Blank Not used

− COIL Coil terminal (−)

SERIES No connection

+ COIL Coil terminal (+)

Table 4 Terminal Block Connections for Two Applicator Modules

Designation Purpose

SHIELD Coil 1 and coil 2 shield

Blank Not used

− COIL Coil 1 terminal (−)

SERIES Coil 1 (+) and coil 2 (−)

+ COIL Coil 2 terminal (+)

Table 5 Terminal Block Connections for Three Applicator Modules

Designation Purpose

SHIELD Shield

Blank Not used

− COIL Coil 1 terminal (−)

SERIES No connection

+ COIL Coil 3 terminal (+)

NOTE: Wire three coils in series: join coil 1+ and coil 2−. Join coil 2+ and

coil 3−. Use wire nuts or other suitable means.

E 2010 Nordson Corporation Part 1038035C02

16 E400NP Driver

Connect the Low Voltage Signal Wiring

Connect 1.0−0.34 mm2 (18−22 AWG) low-voltage signal wiring from the

remotely located alarm and the pattern controller (trigger input) as shown in

the following table.

Designation Purpose

FAULT OUT Alarm contact

FAULT OUT Alarm contact

+ TRIG IN + Trigger input (10−30 VDC)

+5V TRIG IN +5 V Trigger (5 VDC)

− TRIG IN − Trigger input

Connect the AC Power Wiring

WARNING: Risk of serious injury or death. High voltage is present on the

AC power input terminal. Allow only qualified personnel to make electrical

connections. Follow electrical safety procedures and observe all

high-voltage indicators.

Connect 1.0 mm2 (18 AWG) wiring from the power source to the driver as

shown in the following table. The protective earth wiring is connected to the

terminal on the enclosure.

Designation Purpose

L1 AC L1

L2 AC L2 or N (neutral)

PE Earth ground

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 17

Install a Power On/Off Switch (Optional)

The switch must be a double-pole, double-throw (DPDT) type with a

minimum contact rating of 250 VAC, 6 A. It should be installed so that both

input power lines are turned off when the switch is turned off.

DPDT switch

L1

L2

PE

Power

source 4212007

Figure 6 Optional power on/off switch

Test the Driver

Perform these steps to ensure that the driver was properly installed.

1. Supply power to the driver and ensure that the POWER LED turns on.

2. Ensure that no faults are indicated (no red LEDs are on).

3. Press the PURGE button and ensure that the TRIGGER and OUTPUT

LEDs flash and that the applicator actuates.

Setup

Before placing the driver into routine operation, use the E400 Driver

Application Guide software to ensure that the driver’s default settings will

provide the desired performance and will not damage the applicator module

coil(s). The driver is shipped with factory default settings that should work

for about 75 percent of all applications.

E 2010 Nordson Corporation Part 1038035C02

18 E400NP Driver

Operation

Supply power to the driver and refer to Normal Operating Conditions,

PURGE Button, and Front Panel LEDs for information on operating the

driver.

WARNING: Hot! Risk of burns. Wear heat-protective clothing, safety

goggles, and heat-protective gloves when operating a hot melt system.

WARNING: The driver contains energized electrical components with

potentials that can cause death, serious injury, or equipment damage. Allow

only qualified personnel to operate the driver.

4212017

Figure 7 Front panel of the driver

1. PURGE button 2. Front panel LEDs

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 19

Normal Operating Conditions

See Figure 7. During normal operation:

S The POWER LED is on.

S The TRIGGER and OUTPUT LEDs flash when triggered. In the standard

mode, the LEDs flash at the same time.

S The THERMAL WARNING or THERMAL OK LED is on.

PURGE Button

See Figure 7. Use the PURGE button to manually operate the driver. The

driver electrical output is energized as long as the button is pressed.

When the PURGE button is pressed, the TRIGGER and OUTPUT LEDs

should illuminate.

E 2010 Nordson Corporation Part 1038035C02

20 E400NP Driver

Front Panel LEDs

Table 6 Meaning of LEDs on Front Panel of Driver

LED Color Meaning Action

POWER Green Advisory. Low-voltage control circuits None

have power and should be

operational.

TRIGGER Yellow Advisory. Trigger input has been None

activated and the module coil(s)

should be driven.

OUTPUT Yellow Advisory. Current is flowing to the None

module coil(s).

THERMAL Red Fault (See Note A). The power level Correct the cause of the excessive

FAULT in the module coil(s) has exceeded power. Programmed parameters may

the thermal rating of the coil(s). The be too aggressive or line speed may

alarm contact is activated. have increased over time. Use the

E400 Driver Application Guide

software to determine whether the

E400 gun system is appropriate for

the application.

THERMAL Yellow Advisory. The power level in the Continue operation, but monitor for a

WARNING module coil(s) is approaching the thermal fault if the driver parameters

thermal capability of the applicator. are changed or if the line speed

increases.

THERMAL Green Advisory. The power level in the None.

OK modules coil(s) is well within the

capabilities of the applicator.

OPEN Red Fault (See Note A). The driver’s Correct the cause of the open, loose,

electrical output has an open or or intermittent connection.

intermittent circuit. The alarm contact

is activated.

SHORT Red Fault (See Note A). The driver’s Correct the cause of the shorted

electrical output has a short or other output.

condition. The alarm contact is

activated.

DOT Yellow Not applicable. The E400NP does not None.

MODE allow DOT mode.

NOTE A: When a fault condition occurs, the driver continues to operate. However, Nordson Corporation

recommends diagnosing and correcting the cause of the fault as soon as is practical. Refer to

Troubleshooting.

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 21

Troubleshooting

Table 6 provides troubleshooting information based on the status of the

LEDs on the front panel. See Figure 7 for the location of the LEDs. The red

LEDs indicate fault conditions, as shown in Table 6. The alarm output

contact is activated whenever a red LED turns on, but the driver will

continue to operate (it will not disable the electrical output or shut down).

Nordson Corporation recommends diagnosing and correcting the cause of

the fault as soon as is practical.

Table 7 Troubleshooting Based on the Status of the Driver LEDs

Status of LED Action Note

POWER LED off Check the power source. If the power source is okay,

check for a blown fuse. Replace blown fuses. Refer to

Fuse Replacement.

TRIGGER LED does not S Verify that a trigger signal is being supplied by the

flash pattern controller.

S Check for loose or intermittent wiring connections.

S Check the trigger input terminal block.

S Check for use of the proper trigger input depending on

the voltage (+5 VDC logic vs. 10−30 VDC).

OUTPUT LED does not flash S Check the power source.

S Check for use of the proper trigger input depending on

the voltage (+5 VDC logic vs. 10−30 VDC).

S Check for loose or intermittent wiring connections.

S Check the driver settings.

THERMAL WARNING LED The heating power of the current being supplied by the

turns on driver has reached 80 percent of the rating for the coil

being controlled. Further increases in the line speed may A

cause the rating to be exceeded. Monitor the driver for a

thermal fault condition.

THERMAL FAULT LED turns The heating power of the current being supplied by the

on driver has exceeded the rating for the coil being controlled.

This can happen because of aggressive programming

parameters or because of line speed increases after A

installation. Use the E400 Driver Application Guide

software to determine whether the E400 gun system is

appropriate for the application.

NOTE A: Due to the thermal mass of the applicator, the driver’s thermal diagnostic responds to coil

heating conditions faster than the applicator itself, allowing the LEDs to function as leading

indicators. This is desirable because the LEDs provide a warning before the coil actually

overheats. The diagnostic is filtered to avoid false indications. Also, once an over-heating

condition has been corrected, the THERMAL FAULT LED will turn off before the applicator

actually cools. It is possible for two adjacent thermal diagnostic LEDs to be on at the same

time when the power level is near a transition. This is normal.

Continued on next page

E 2010 Nordson Corporation Part 1038035C02

22 E400NP Driver

Troubleshooting (contd)

Status of LED Action Note

OPEN LED turns on S Check all electrical connections between the driver

and the applicator(s). B, C

S Check the applicator output terminal block.

SHORT LED turns on S Check for loose or damaged coil wiring inside the

applicator.

S Check the applicator input terminal block.

S Check the applicator for internal failure. Refer to the B, D, E, F

applicator manual. (This type of failure is rare.)

S Check that the applicator is well-matched to the driver.

Some applicators may not work with the driver.

B: Some of the diagnostics require a switching trigger signal in order to function properly. The

OPEN and SHORT LEDs will not respond properly if the trigger signal is continuously on.

These diagnostics will function with frequencies as low as approximately 2−5 Hz

(120−300 cycles per minute).

C: When an open circuit is detected, the driver’s electrical output is disabled for approximately

one-half second (0.5 s) until the driver attempts to reactivate the output. When the coil is

reattached, the OPEN LED and the alarm contact reset after about 1 s.

D: The primary purpose of the SHORT LED is to indicate that there is a wiring problem between

the driver and the applicator. It can detect direct shorts in the driver electrical output as well

as shorts at the far end of the applicator-to-driver cable. It operates by detecting a response

that differs significantly from the response of the module. While the operation of this

diagnostic is reasonably robust, it could detect a false short when modules that are not well

matched to the driver are used.

E: The driver can operate with a shorted output indefinitely without damage. However, since the

driver can supply significant power into the short circuit, it is advisable to correct the situation

immediately.

F: The SHORT LED requires approximately 1.5 ms to respond. Accordingly, it does not operate

for on times (beads or dots) shorter than 1.5 ms.

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 23

Fuse Replacement

WARNING: The driver’s electrical output takes a short while to discharge

once power is shut off. The output decays rapidly when an applicator is

attached. However, if the output is disconnected, high voltage can remain

for several seconds. Exercise caution and wait until all LEDs are off before

touching the output circuit. Allow only qualified personnel to perform

electrical repairs. Follow electrical safety procedures and observe all

high-voltage indicators.

1. Disconnect and lock out electrical power to the driver.

2. Remove the driver cover.

3. Replace blown fuses. Refer to Parts for the fuse part number.

4. Reinstall the driver cover.

4212011

Figure 8 Location of fuses

E 2010 Nordson Corporation Part 1038035C02

24 E400NP Driver

This page intentionally left blank.

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 25

Parts

To order parts, call the Nordson Customer Service Center or your local

Nordson representative. Use this five-column parts list, and the

accompanying illustration, to describe and locate parts correctly.

Using the Illustrated Parts List

Numbers in the Item column correspond to numbers that identify parts in

illustrations following each parts list. The code NS (not shown) indicates that

a listed part is not illustrated. A dash (—) is used when the part number

applies to all parts in the illustration.

The number in the Part column is the Nordson Corporation part number. A

series of dashes in this column (- - - - - -) means the part cannot be ordered

separately.

The Description column gives the part name, as well as its dimensions and

other characteristics when appropriate. Indentions show the relationships

between assemblies, subassemblies, and parts.

S If you order the assembly, items 1 and 2 will be included.

S If you order item 1, item 2 will be included.

S If you order item 2, you will receive item 2 only.

The number in the Quantity column is the quantity required per unit,

assembly, or subassembly. The code AR (As Required) is used if the part

number is a bulk item ordered in quantities or if the quantity per assembly

depends on the product version or model.

Letters in the Note column refer to notes at the end of each parts list. Notes

contain important information about usage and ordering. Special attention

should be given to notes.

Item Part Description Quantity Note

— 0000000 Assembly 1

1 000000 S Subassembly 2 A

2 000000 S S Part 1

E 2010 Nordson Corporation Part 1038035C02

26 E400NP Driver

Driver Parts

See Figure 9.

Item Part Description Quantity Note

— 1045869 Driver, E400NP, high-viscosity —

1 1035937 S Base, enclosure 1

2 326947 S Mounting clip, DIN, 35 mm rail 2

3 983402 S Washer, flat, narrow, M4 2

4 983403 S Washer, lock, split, M4 2

5 982327 S Screw, chez, slotted, M4 x 12 2

6 ------ S Assembly, driver boards 1 A

NS 939775 S S Fuse, 2.0 A, fast-acting, 250 VAC 2

7 227317 S Washer, lock, spring, M3 5

8 982427 S Screw, pan, recessed, M3 x 6 16

9 1035938 S Cover, driver 1

10 173871 Terminal block plug, 5-position 1

11 182285 Terminal block plug, 8-position 1

NOTE A: The only replaceable components of this assembly are the fuses. To replace the entire assembly, order a

new driver. Boards are a matched set and must be replaced as an assembly.

NS: Not Shown

Applicator-to-Driver Cable

This cable is used to connect the driver to an E400 applicator.

Part Description

1015173 Cable, applicator-to-driver, E400, solenoid

Recommended Spare Parts

Part Description

939775 Fuse, 2.0 A, fast-acting, 240 VAC (two required)

Part 1038035C02 E 2010 Nordson Corporation

E400NP Driver 27

11

10

8

2

5

1

4

4212018

Figure 9 E400NP driver parts

E 2010 Nordson Corporation Part 1038035C02

28 E400NP Driver

Part 1038035C02 E 2010 Nordson Corporation

EC Declaration of Conformity

for Adhesive and Sealant Application Equipment

conforming to European Council Directives

PRODUCT:

400 Series Electric Gun Driver

APPLICABLE DIRECTIVES:

Low Voltage Directive: 2006/95/EC

Electromagnetic Compatibility Directive: 2004/108/EC

STANDARDS USED TO VERIFY COMPLIANCE:

EN 60204-1

EN 61000-6-2

EN 61000−6−4

PRINCIPLES:

This product has been manufactured according to good engineering practice.

The product specified conforms to the directives and standards described above.

Technical File Contact:

Dieter Ziesmer

Nordson Engineering GmbH

Peter Lambert, Vice President Lilienthalstrasse 6

Adhesives Dispensing Systems 21337 Lueneburg

GERMANY

Date: 10/June/2010

Nordson Corporation S 28601 Clemens Road S Westlake, Ohio

DOC035R3

You might also like

- Series H-200 Guns: Customer Product Manual Part 104457KDocument48 pagesSeries H-200 Guns: Customer Product Manual Part 104457KgunardiNo ratings yet

- Minibluet Guns: Customer Product Manual Part 1013124A02Document74 pagesMinibluet Guns: Customer Product Manual Part 1013124A02Carlos AguirreNo ratings yet

- LP90 Fluid Application System: Customer Product Manual Part 1041182 - 04Document60 pagesLP90 Fluid Application System: Customer Product Manual Part 1041182 - 04Oussama HobbiesNo ratings yet

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsFrom EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsNo ratings yet

- Fulfill Retrofit Kit ProBlue 4710Document68 pagesFulfill Retrofit Kit ProBlue 4710aliraazaa26No ratings yet

- LA844M Electric Applicator: Customer Product Manual Part 1062950A02Document52 pagesLA844M Electric Applicator: Customer Product Manual Part 1062950A02Oussama HobbiesNo ratings yet

- Durablue 4Document213 pagesDurablue 4arsya_agasNo ratings yet

- English ManualDocument287 pagesEnglish ManualJaka LiswaraNo ratings yet

- Nordson Prpblue ManualDocument300 pagesNordson Prpblue ManualDavid SolísNo ratings yet

- Machine 18 Glue Pot ManualDocument251 pagesMachine 18 Glue Pot ManualDaniel HoltNo ratings yet

- AltaBlue A15,30,50,100Document255 pagesAltaBlue A15,30,50,100Đỗ DuyNo ratings yet

- Spectra 30 Manual PDFDocument180 pagesSpectra 30 Manual PDFDaniel HoltNo ratings yet

- FP 200 Guns: Customer Product Manual Part 237478 - 03Document126 pagesFP 200 Guns: Customer Product Manual Part 237478 - 03a safaieNo ratings yet

- Nordson p4 p7 p10 PDFDocument319 pagesNordson p4 p7 p10 PDFRicardo CruzNo ratings yet

- Problue P4, P7 Et P10Document294 pagesProblue P4, P7 Et P10Tugay AlimanNo ratings yet

- Altablue™ Touch Series Adhesive Melters: Customer Product Manual Part 1120350 - 05Document306 pagesAltablue™ Touch Series Adhesive Melters: Customer Product Manual Part 1120350 - 05Jhonson Shut DownNo ratings yet

- Durablue IIDocument206 pagesDurablue IIoskar perezNo ratings yet

- ProBlue Flex ManualDocument418 pagesProBlue Flex ManualSakshi Sharma100% (1)

- AltaBlue™ TT Adhesive Melters Models A4, A10, and A16 Product ManualDocument256 pagesAltaBlue™ TT Adhesive Melters Models A4, A10, and A16 Product ManualKayc SilvaNo ratings yet

- Alta Slot IntermittentDocument51 pagesAlta Slot IntermittentHabib RajuNo ratings yet

- ProBlue Liberty Hot MeltDocument435 pagesProBlue Liberty Hot MeltCristian NastaseluNo ratings yet

- 05 ProBlue Flex Adhesive Melter With BBcon ControlsDocument492 pages05 ProBlue Flex Adhesive Melter With BBcon Controlsciarancrawford2No ratings yet

- AltaPail II Bulk Melters Product ManualDocument230 pagesAltaPail II Bulk Melters Product ManualGlobal DaechangNo ratings yet

- Manual Tanque VL500 321549Document337 pagesManual Tanque VL500 321549Eliaquin Moya BrenesNo ratings yet

- NodsonDocument319 pagesNodsonpatriciaNo ratings yet

- Problue ManualDocument320 pagesProblue ManualFrancisco MendozaNo ratings yet

- Durapailt Bulk Melters Dp020: Manual P/N 397983K EnglishDocument172 pagesDurapailt Bulk Melters Dp020: Manual P/N 397983K EnglishАндрей ПокровскийNo ratings yet

- 1072400 Universal Summit Spray Nozzles ManualDocument28 pages1072400 Universal Summit Spray Nozzles ManualjmbanadoNo ratings yet

- Nordson Applicator Head AD34Document26 pagesNordson Applicator Head AD34mahmoud ahmedNo ratings yet

- Manual DuraDrum Bulk Melters DD200Document174 pagesManual DuraDrum Bulk Melters DD200cantfixstupidNo ratings yet

- Model C-1 Electrostatic Airless Spray Gun: Customer Product Manual Part 104 326DDocument50 pagesModel C-1 Electrostatic Airless Spray Gun: Customer Product Manual Part 104 326DUlpianoxx19920% (1)

- Nordsonmeg DriverDocument20 pagesNordsonmeg DriverNinoslavSevicNo ratings yet

- Versablue ® Adhesive Melters Model VB C With Industrial PC: Manual P/N 7135228 - 04 - EnglishDocument264 pagesVersablue ® Adhesive Melters Model VB C With Industrial PC: Manual P/N 7135228 - 04 - EnglishDaniel FuentesNo ratings yet

- S7 ManualDocument308 pagesS7 ManualBenjamin MurphyNo ratings yet

- c-12+ manualDocument280 pagesc-12+ manuallegalmanager92No ratings yet

- Robotrac ManualDocument202 pagesRobotrac ManualadasrafalskiNo ratings yet

- Installation Manual: Simrad SP70 Low Frequency Long Range Fishery SonarDocument230 pagesInstallation Manual: Simrad SP70 Low Frequency Long Range Fishery SonarAlex BombayNo ratings yet

- Etec E115dplscr PDFDocument445 pagesEtec E115dplscr PDFEmil GrNo ratings yet

- Manual Drive NC-1 NordsonDocument19 pagesManual Drive NC-1 NordsonHeber MagdielNo ratings yet

- Manual VL110Document198 pagesManual VL110Gustavo GarridoNo ratings yet

- 237348g02web Series 3500V SP Piston Pump With Vista Control ManualDocument388 pages237348g02web Series 3500V SP Piston Pump With Vista Control ManualErick MaschiettoNo ratings yet

- Extec QJ340 C12 ManualDocument280 pagesExtec QJ340 C12 Manualdefiunikasungti100% (1)

- Dressta 560C99-1EDocument500 pagesDressta 560C99-1EMasterrNo ratings yet

- COLEIROSDocument116 pagesCOLEIROSJosiasNo ratings yet

- IOM - SBC ControllerDocument24 pagesIOM - SBC Controllernuraida hakikiNo ratings yet

- ThermostatsDocument48 pagesThermostatsRitlandNo ratings yet

- 3935 IomDocument37 pages3935 Iomcarlos andresNo ratings yet

- Evinrude E-Tech 200hp 225hp 250hp Service Repair Workshop Manual Download PDFDocument404 pagesEvinrude E-Tech 200hp 225hp 250hp Service Repair Workshop Manual Download PDFPavlos Michalios100% (2)

- KR Rotary Drum Cutter: Instruction ManualDocument44 pagesKR Rotary Drum Cutter: Instruction ManualhaythamNo ratings yet

- Flender GearboxesDocument98 pagesFlender GearboxesRahul RoyNo ratings yet

- Evinrude Etec g2 200 300 InstallationDocument164 pagesEvinrude Etec g2 200 300 InstallationJerry LoonNo ratings yet

- Evinrude 40-50-60 - 65 HP Service Manual - CompressedDocument369 pagesEvinrude 40-50-60 - 65 HP Service Manual - CompressedGaston BrigáNo ratings yet

- Liquid Adhesive Gun LS-T 373: Manual P/N 7135973B EnglishDocument56 pagesLiquid Adhesive Gun LS-T 373: Manual P/N 7135973B EnglishPandel LucianNo ratings yet

- Iscan Coreo Au User Manual PDFDocument230 pagesIscan Coreo Au User Manual PDFTài Lộc VươngNo ratings yet

- Controlador Sbs Ait 103 Sentry IsolokDocument27 pagesControlador Sbs Ait 103 Sentry Isolokelectronica73444939No ratings yet

- 4600en 0119fleDocument40 pages4600en 0119fledeni jakaNo ratings yet

- Evinrude 5007525 LoResDocument369 pagesEvinrude 5007525 LoResJulie Lafrance100% (2)

- Market Segmentation Targeting Strategy and Positioning Strategy Performance Effects To The Tourists Satisfaction Research in Pangandaran Beach Pangandaran DistrictDocument10 pagesMarket Segmentation Targeting Strategy and Positioning Strategy Performance Effects To The Tourists Satisfaction Research in Pangandaran Beach Pangandaran DistrictRizki Kurnia husainNo ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- Certificate of Analysis - Certified Reference Material: Cetyl PalmitateDocument6 pagesCertificate of Analysis - Certified Reference Material: Cetyl PalmitateRachel McArdleNo ratings yet

- Event Management Study Material Free PDFDocument2 pagesEvent Management Study Material Free PDFKim0% (1)

- TABS 6SellSheetDocument4 pagesTABS 6SellSheetHernando MontenegroNo ratings yet

- Municipal Profile of Umingan, PangasinanDocument51 pagesMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- OT Lawsuit CPDDocument20 pagesOT Lawsuit CPDDan LehrNo ratings yet

- Template Research ProjectDocument13 pagesTemplate Research ProjectTuấn Anh Đoàn CôngNo ratings yet

- TD2Document4 pagesTD2Terry ChoiNo ratings yet

- Price List 2014: Valid From 01.04.2014, Prices in Euro, Excluding VAT. Previous Price Lists Will Become InvalidDocument106 pagesPrice List 2014: Valid From 01.04.2014, Prices in Euro, Excluding VAT. Previous Price Lists Will Become InvalidarifNo ratings yet

- 5 Short MustWatch Motivational Videos For TeachersrccymDocument4 pages5 Short MustWatch Motivational Videos For Teachersrccymfoxpeak8No ratings yet

- TRAIN Briefing - Revised Personal Income Tax RatesDocument73 pagesTRAIN Briefing - Revised Personal Income Tax RatesElizaFaithEcleoNo ratings yet

- NOC Hardware Management SO.P. Derricks FormattedDocument3 pagesNOC Hardware Management SO.P. Derricks Formattedapi-27532183No ratings yet

- FLIX Booking 1068813091Document2 pagesFLIX Booking 1068813091Pavan SadaraNo ratings yet

- Agreement: /ECE/324/Rev.2/Add.127 /ECE/TRANS/505/Rev.2/Add.127Document29 pagesAgreement: /ECE/324/Rev.2/Add.127 /ECE/TRANS/505/Rev.2/Add.127Mina RemonNo ratings yet

- Instrument Landing SystemDocument35 pagesInstrument Landing SystemDena EugenioNo ratings yet

- Improved Line Maze Solving Algorithm For PDFDocument2 pagesImproved Line Maze Solving Algorithm For PDFRaja Joko MusridhoNo ratings yet

- Much NeedeDocument11 pagesMuch NeedeRijul KarkiNo ratings yet

- 229 PGTRB Commerce Study Material Unit 15 and 16Document16 pages229 PGTRB Commerce Study Material Unit 15 and 16shareena ppNo ratings yet

- College of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Document5 pagesCollege of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Industrial TechnologyNo ratings yet

- Differendial Pressure Flow MetersDocument1 pageDifferendial Pressure Flow Metersborn2engineerNo ratings yet

- B.Tech Digital Principles and System Design Exam Question BankDocument24 pagesB.Tech Digital Principles and System Design Exam Question Bankdigital1206No ratings yet

- UPT Unit 8 Vers ADocument12 pagesUPT Unit 8 Vers AValeria GarciaNo ratings yet

- Systemverilog Interview QuestionsDocument31 pagesSystemverilog Interview QuestionsDivya Dm100% (1)

- Manual Flowpet 5GDocument56 pagesManual Flowpet 5GRahkmat DanizarNo ratings yet

- Problem Solving 5Document4 pagesProblem Solving 5Raphael Pizarro ArceoNo ratings yet

- 001-Numerical Solution of Non Linear EquationsDocument16 pages001-Numerical Solution of Non Linear EquationsAyman ElshahatNo ratings yet

- Was Bali 2005Document786 pagesWas Bali 2005RoyOrtegaNo ratings yet

- Get started with Power BI DesktopDocument34 pagesGet started with Power BI Desktopbhargavc7No ratings yet

- Binders For: Architectural CoatingsDocument8 pagesBinders For: Architectural CoatingsAPEX SON100% (1)