Professional Documents

Culture Documents

Deublin en

Deublin en

Uploaded by

Juan Caceres0 ratings0% found this document useful (0 votes)

25 views2 pagesOriginal Title

Deublin_en

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views2 pagesDeublin en

Deublin en

Uploaded by

Juan CaceresCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

DEUBLIN GmbH

Nesoavstrabe 10

10-6256 Hotheim-Wallau

Telefon 0612212018

Telex 04182 624

Installation and maintenance of Deublin:unions

Installation: ee Seen

Bepause of Deublit’s balanced seal. design no exterior bracing and/or torque restraint’ should be used:

to prevent the-housirig from ‘otatina. : : “ 5 so . =

Tocoimpensate for any eccetricites occuring throug

is being used.

installation it:

imperative that a flexible connection:

Be not pipe solid,

‘To.avoid wrench torque damage 16 the bearing during installation, the following proceckire is recommended:

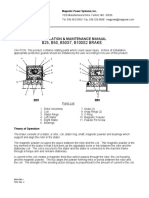

Retation

Fig Hig. 2 Fi. 9 :

Grasp the rear of the Install rotating’ = ‘Cohnect flexible hose to supaly-

rousing ina oench vise union into line: Uae a a8 dean elbow and

tnd instal fexibto hace. / machina shaft bibs union on te ser making

Sure there isa slight curve a

age and hose te not

ietatled taut.

Note: Be sure hose is ‘not taut nor becomjes taut when pressurized. Monofiow plugs, elbows’ and, rotor

connections (for.exampie on tandem unions 2117) are only tightened by hand when shipped frort- our

factory. Make sure, you ratighten these before final installation by proceeding as shown in Fig. 1

Start up

Attention: Keep your air and/or hydiaulic system ag clean as possible during installation and start-up.

3

E

é

=

3

3

2

5

:

2

2

z

i

:

2

Experience. has. shown that. almost ‘all-leakages which occur’ shortly’ after: start up. are’ caused: by dirt

Or impurities inthe flow media, Therefore it is most important to.intemally rinse oF clean out all-system

components before operating media gets inta the system so that a problem free start up of operation ~

is assured. We strongly recommend to rinse the whole- system thoroughly before installing the union.

‘Warranty oe

Every Deublin union is subject fo our warranty (eee last page of Deublin Enginoering Catalog)

For warranty claims

Do not open the union, Feturi it transport prepaid dlrectly to the ridarest representative: and ‘enclose.

8 detailed Hist with all Sperating data such as medium, pressure, temperature, RPM, time In ‘operation; ~

feasons forretur 4

Lubrication (Use good quality lubricants only)

Lubrication of the .ball bearings or seal faces is periodically. required:. The, union models which are not

equipped with d grease fitting of all cup are lubricated for Ife and require no maintenance other than periodic

inspection to. determine if normal wear has-caused: ‘eso ‘to: leak: 2

“motor oil, approximately once-a month or it extreme: severe ridtions where high RPM's are ve erenunered

once'a week : : : . z

Rotating unions which are. equipped with grease fittings should te labricated with’ a good quality ball

bearing grease. We recommend Chevron Oil company SRI-groase for temperatires up to"177° C or 360°.

Only enough grease should be applied to the ball bearings to replace that which has dissipated.

Overgreasing increases interfal friction and cari be es damagiiig to the union as under-greasiig, Paiticulany

‘on high RPM -applications, grease should’be used sparingly. The chart bélow provides the approximate.

+ frequency of uerigation depending on ‘temperature or as experience dictates:

- Operating Temperature. =." ~*~ Frequency oF Lubrication

BC OF OPO M4OR ‘At most once every six months.

: : (Factory iubrication may iast for union life)

60° C.(140°F) to 120°C (250°F) ‘Once every three months,

120°C (250° F) to 160°C (800° Fy ‘Once monthly.

180°C (200? F) to 175°C (350° F} - ‘Once weekly.

° {in extreme cases use a High Temperature

- ‘grease and consult supplier for propér greasing

schedule, e, g, Kiliber Lubrication.)

The mictodapped sealing faces are lubricated by the flow medium, Compressed air as. flow medlumi

should carry oil. mist for lubrication. Carbon graphite seals have only limited self-lubricating properties and

should not run dry for ‘an extended period of time, Therefore it is important, if shut-off valves aré installed,

that they are ited info the return pipe. This way you are sure that the unions earnot drain‘empty and

‘always are tubrloated through the flow médium,

Filtering.

‘Seal life is largely detormined hy filtering quality. Testing confirmed tat an improvement of fitering quality:

. fom 5 ys (micron) to 3 y.can increase systerm life up to 40 tines. This considerable extension alone pays

off many-times:the additional cost for higher quality fiters, Standard fitteing requirement for hydraulic,

systems presently calls for 5p.

Sometimes it fs impissible to improve the fering quality in existing systems, Then it miay.be convenient

to lise a tungsten carbide/ceremic seal combination. Instead of the standard: carbon graphite/bronze.

Some unions, such-as the “All-Purpose” models and those for "Gun-driling” are available with these-special

seals, Most of the time the tungsten carbide/coramic seals improve the service life significantly, provided al

other installation requirements are correct and only:abrasive. media has caused premature séal wear. ~~

: Quality control .

Every Deublin Union is factory tested before ‘shipment for, ieeroot ana pioper operation.

‘Repair. service . ay » : ce

Repair and rebuilding service is’availatlé at the. Deublin factories. Factory repaired andor factory rebuitt

unions carry a."NEW-UNIO! WARRANTY”: If repair cosis exceed 60 % of "New Unionsprice”: then we.” ”

* recotnthend.to buy & new union... :

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E2E05 Pos-Drives 01Document18 pagesE2E05 Pos-Drives 01Juan CaceresNo ratings yet

- E2E06 ControlSystemsSafetyConcept 01Document24 pagesE2E06 ControlSystemsSafetyConcept 01Juan CaceresNo ratings yet

- E2E04 ControlSystemsMachineControl 02Document28 pagesE2E04 ControlSystemsMachineControl 02Juan CaceresNo ratings yet

- Mi-0173 Operation Manual Uc-0140 2011 HP (En)Document31 pagesMi-0173 Operation Manual Uc-0140 2011 HP (En)Juan CaceresNo ratings yet

- E2E02 - 02 - Putting-Into-Operation S217 - 99CA111Document106 pagesE2E02 - 02 - Putting-Into-Operation S217 - 99CA111Juan Caceres100% (1)

- Modulo UV - BLP 59-S - E ManualDocument21 pagesModulo UV - BLP 59-S - E ManualJuan CaceresNo ratings yet

- Icoat30000 Stacker HP Ver0 Rev2Document43 pagesIcoat30000 Stacker HP Ver0 Rev2Juan CaceresNo ratings yet

- RefroidisseurDocument40 pagesRefroidisseurJuan CaceresNo ratings yet

- SIEMENS RI45III eDocument68 pagesSIEMENS RI45III eJuan CaceresNo ratings yet

- Vianord EVO 2 Technical Manual V1.1Document37 pagesVianord EVO 2 Technical Manual V1.1Juan CaceresNo ratings yet

- Lista de Fallos UNISET - AcronymsDocument4 pagesLista de Fallos UNISET - AcronymsJuan CaceresNo ratings yet

- Magpower B25 B50 BrakesDocument4 pagesMagpower B25 B50 BrakesJuan CaceresNo ratings yet

- Instruction Manual - DFC-90 Tension ControlDocument10 pagesInstruction Manual - DFC-90 Tension ControlJuan CaceresNo ratings yet

- Magpower Clutch Model CDocument4 pagesMagpower Clutch Model CJuan CaceresNo ratings yet

- Change Encoder Value ZennaCADDocument5 pagesChange Encoder Value ZennaCADJuan CaceresNo ratings yet

- LincolnDocument4 pagesLincolnJuan CaceresNo ratings yet

- Cygnus Setup Instruction-4Document6 pagesCygnus Setup Instruction-4Juan CaceresNo ratings yet

- Hub City Beveal Gear DrivesDocument5 pagesHub City Beveal Gear DrivesJuan CaceresNo ratings yet

- Dayton GearmotorsDocument7 pagesDayton GearmotorsJuan CaceresNo ratings yet

- Ea6 14 200 31 GB-2Document19 pagesEa6 14 200 31 GB-2Juan CaceresNo ratings yet