Professional Documents

Culture Documents

VRF Specs

Uploaded by

Ashar HassanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VRF Specs

Uploaded by

Ashar HassanCopyright:

Available Formats

Y.H.

ASSOCIATES DIVISION 23 00 00

CONSULTING ENGINEERS HVAC SYSTEM

PAGE 1 OF 6

SECTION 23 81 56 VARIABLE REFRIGERANT FLOW (VRF) SYSTEM

1.0 GENERAL

1.1 CODE & COMPLIANCE

All materials and workmanship described herein shall be in accordance with the latest

editions and addenda of the codes and standards listed below and all State, and local codes,

and/or specifications, the more stringent shall be govern.

ASHRAE American Society of Heating, Refrigeration and Air-Conditioning

Engineers

ARI Air-conditioning & Refrigeration Institute

1.2 QUALITY ASSURANCE

All materials and equipment to be used for this contract shall be standard products of a

reputable manufacturer regularly engaged in the production of same. Where more than one

unit of an item is required, all shall be provided by the same manufacturer using identical

components. The manufacturer’s nameplate shall include model number, serial number and

performance data and shall be permanently affixed to all equipment furnished under this

contract.

Any work or materials found to be defective or which do not meet the requirements of this

specifications, shall be replaced by the Vendor at his own expense.

All materials shall be new, unused and free of defects and imperfections.

1.3 COORDINATION

In selecting the units, the tenderer shall carefully check and confirm that the units can be

installed and conveniently serviced and maintained within the respective spaces indicated on

the drawings for unit installation.

1.4 DELIVERY, STORAGE & HANDLING

Unit shall be delivered factory assembled with protective crating and covering and their

delivery coordinated in sufficient time to allow movement into building.

Preparation for shipment shall be in accordance with Vendor’s standards. Vendor shall be

solely responsible for the adequacy of the preparation for shipment provisions with respect to

materials and applications.

Adequate protection shall be provided against mechanical damage and atmospheric corrosion

in transit and for a 6 month period of outdoor storage at job site prior to installation. Control

panel shall be protected from moisture penetration.

Miscellaneous parts shall be tagged or marked with the equipment item number for which

they are intended.

SECTION 23 00 00 –HVAC SYSTEM SPECIFICATIONS

Y.H.ASSOCIATES DIVISION 23 00 00

CONSULTING ENGINEERS HVAC SYSTEM

PAGE 2 OF 6

1.5 WARRANTY

Vendor shall guarantee and provide a written statement as proof that the unit shall perform as

specified on the Data Sheets.

i. All equipment shall be guaranteed for satisfactory performance and shall be warranted

against faulty design, defective or improper materials.

ii. The Material and Workmanship Guarantees shall be extended for a period of eighteen

months from the date of shipment or one year from the date the equipment is placed in

service whichever occurs first.

1.5 FACTORY INSPECTION AND TESTING

Each unit shall be assembled at the factory, inspected and determined to be in compliance

with the specifications. Any deviations found shall be corrected.

2.0 PRODUCT

2.1 GENERAL

All equipment shall be of such overall dimensions, operating weights service area

requirements and configuration that it can be located where shown on the plans without any

adverse effect on its performance and clearance requirements. Any change in other trades

work, anticipated by offering alternate equipment shall be estimated by the Contractor and its

cost shall be included in the quoted price for HVAC works.

All equipment supplied under this section shall be brand-new, factory manufactured and

factory assembled and complete in all respects. The type, characteristics, capacity rating,

component sections of all equipment shall be as scheduled in the drawings.

All equipment furnished by the Contractor shall include vibration isolation mounting, pads,

anchors bolts frames or any other mounting or supporting accessories.

All power driven equipment shall include motor drives, and motor foundation bases and

accessories.

2.2 VARIABLE REFRIGERANT FLOW (VRF) SYSTEM

2.2.1 GENERAL

The Variable Refrigerant Flow (VRF) System shall be R410A refrigerant based Multi Split

Unit System with high C.O.P. The systems shall comprise of one or a number of outdoor units

connected via interconnecting refrigeration pipe work to multiple indoor units using simple Y,

T or Header type branch pipe connectors. Y Connectors (as per drawings/manufacturer’s

recommendations) shall be supplied with A/C units. The systems shall be complete with all

the necessary electronic controls board and control wiring to maintain the design room

conditions without external controller.

SECTION 23 00 00 –HVAC SYSTEM SPECIFICATIONS

Y.H.ASSOCIATES DIVISION 23 00 00

CONSULTING ENGINEERS HVAC SYSTEM

PAGE 3 OF 6

2.2.2 OUTDOOR UNITS

The units shall be air-cooled type incorporating heat exchanger coils manufactured from

copper tubes and aluminum fins, factory treated to reduce the effect of atmospheric corrosion.

The unit casing shall be manufactured from (70µ) polyester powder coated baked enamel

finish sheet steel in order to have a high corrosion resistance and to protect against salt laden

environment close to where the units may be installed. The color shall be manufacturer’s

standard. The air outlet grilles shall have plastic coated guards.

All outdoor units are to be permanently marked with an identification number. The removable

access panels are also to be marked with the same number.

The outdoor units are to be Variable Refrigerant Flow (VRF) inverter based centralized

combination of Multiple Outdoor Units of capacities given in schedules.

The outdoor units shall have inverter driven compressors electronically controlled and

capable of changing speed linearly to follow the variation in cooling and heating

requirements.

The capacity control of the outdoor units will be inverter controlled and shall be determined

electronically by sensing operational temperatures, pressures and ambient temperature and

monitoring requirements for the indoor units.

The units shall be complete with electronic expansion valve(s), oil separator(s), high pressure

switches, fan motor safety devices, over current relay, inverter overload protection, fuses,

necessary solenoid valves, refrigerant shutoff valves, re-cycling guard timer and all necessary

sensors for a safe and trouble free operation.

The access to the internal components for maintenance purposes shall be by removable

panels.

It shall be possible to connect up to 64 indoor units, capacity permitting, to one modular

outdoor unit.

The outdoor unit shall have full capacity control to meet the load fluctuation up to 130% and

indoor unit individual control.

The fan will be capable of overcoming a minimum of 58 Pascal of external static pressure.

The control PCB, the power and control wiring terminals shall be provided in an electrical

box attached to the front of the unit.

2.2.3 CONTROLS FOR OUTDOOR UNITS

The units shall be equipped with Auto Restart function, which allows the unit to start in the

same mode prior to the power failure.

Digital thermostat: Units shall be controlled with user friendly ,wall mounted microprocessor

based LCD, wired remote controller. The wired remote controller shall be slim having atleast

following features.

SECTION 23 00 00 –HVAC SYSTEM SPECIFICATIONS

Y.H.ASSOCIATES DIVISION 23 00 00

CONSULTING ENGINEERS HVAC SYSTEM

PAGE 4 OF 6

24 hour ON / OFF timer in 1 hour interval.

Test run mode.

Self-diagnosis function.

Operation indication.

Room temperature display.

Weekly programming.

Child lock function.

3 speed fan control.

Linear control of E.S.P/Airflow.

Computerized control shall be used to maintain a correct room temperature either at the fan

coil or from a sensor in the remote controller. The system shall be equipped with a self-

diagnostic feature for easy service and maintenance. The LCD remote controller shall be able

to control up to 16 indoor units as a group. It shall also be possible to select cooling, heating,

fan only or automatic change over mode for heat recovery systems.

PC Based Central Controller

A multi functional centralized Controller shall be supplied if mentioned in BOQ.

It will provide the following features:

Start/stop operation, set point control, cool/heat mode selection, air volume setting, air flow

direction setting and enabling/disabling operation of the remote.

Monitoring of operation status of the indoor units and error code of the group or the zone.

Comprehensive timer function to start/stop the air conditioning systems. This can be set for

year, month, day of week, hour and minute. This will enable normal day-to-day time clock

functions as well as yearly holiday set up.

The controller shall be installed on single PC and shall compatible with bac-net or remote

control through internet and can be wired by a non-polar 2-wire transmission cable to a

distance of 200m away from the outdoor with capability to control units up to group of max.

16 Outdoor and 4200 indoor.

2.3 INDOOR UNITS

The following type of indoor units can be used for this type of system;

2.3.1 Concealed Ducted Unit

The unit casing shall be manufactured from galvanized steel plate and shall be fully insulated.

Facility shall be provided for duct connection for introduction of the fresh air in the unit and

branch ductwork from the unit. The return air to the unit shall be through the bottom/back of

the unit as per manufacturer’s standard.

The heat exchanger coils will be manufactured from copper tubes and aluminum fins. It shall

have electronic expansion valve to control refrigerant flow rate in response to the load

SECTION 23 00 00 –HVAC SYSTEM SPECIFICATIONS

Y.H.ASSOCIATES DIVISION 23 00 00

CONSULTING ENGINEERS HVAC SYSTEM

PAGE 5 OF 6

variation in the conditioned space. The expansion valve shall be controlled by an integral

computerized control system to maintain correct room temperature.

The condensate shall be drained from the unit using thermally insulated copper tube and run

directly to the foul water drain as indicated.

When using the bottom return air configuration the air filters shall be incorporated within the

unit and shall be mould resistant washable resin net type.

When using the rear return air configuration a separate filter frame with 25 mm glass fibre

throwaway type filter shall be provided for on site installation. A blanking plate shall be

provided for the bottom opening. This blanking plate must be removable for access to the

internal components of the unit.

2.3.2 Concealed Ducted Fresh Air Handling Unit

The unit casing shall be manufactured from galvanized steel plate and shall be fully insulated.

Facility shall be provided for duct connection for introduction of the fresh air in the unit and

branch ductwork from the unit.

The heat exchanger coils will be manufactured from copper tubes and aluminum fins. It shall

have electronic expansion valve to control refrigerant flow rate in response to the load

variation in the conditioned space. The expansion valve shall be controlled by an integral

computerized control system to maintain correct room temperature.

The condensate shall be drained from the unit using thermally insulated copper tube and run

directly to the foul water drain as indicated.

When using the bottom return air configuration the air filters shall be incorporated within the

unit and shall be mould resistant washable resin net type.

When using the rear return air configuration a separate filter frame with 25 mm glass fibre

throwaway type filter shall be provided for on site installation. A blanking plate shall be

provided for the bottom opening. This blanking plate must be removable for access to the

internal components of the unit.

2.3.3 Controls For Indoor Units

Digital thermostat: Units shall be controlled with user friendly, wall mounted microprocessor

based LCD, wired remote controller. The wired remote controller shall be slim having the

following features;

24 hour ON / OFF timer in 1 hour interval.

Test run mode.

Self-diagnosis function.

Operation indication.

Room temperature display.

Weekly programming.

Child lock function.

speed fan control.

SECTION 23 00 00 –HVAC SYSTEM SPECIFICATIONS

Y.H.ASSOCIATES DIVISION 23 00 00

CONSULTING ENGINEERS HVAC SYSTEM

PAGE 6 OF 6

Linear control of E.S.P/Airflow.

Auto swing

Clean filter indication

3.0 COMMISSIONING AND PERFORMANCE TESTS

The air-conditioning system described in this specification and shown on the

drawings shall be commissioned. A program for the commissioning, and any

specified tests, shall be prepared and this shall be incorporated in the contract

program following approval by the Engineer.

Commissioning shall mean, the advancement of all the building services system, from

the state of static completion to full working order, adjusted to the design

requirements, which are given.

The cost of providing all instruments and associated equipment whether of a

temporary and/or permanent nature, attendance of any specialists, and for the

provision of test points required for; the commissioning; and testing, shall be included

in the tender. A recent calibration certificate for each instrument shall be available for

inspection.

3.0 EXECUTION

The Contractor shall make shop drawings of equipment and systems on the basis of

manufacturer certified dimensions and manufacturer recommendation for installation Shop

drawings and other details shall be submitted to the Consultant for approval before

installation.

Exact dimensions and locations of equipment and allied connections shall be submitted to the

Consultant for approval, otherwise any changes directed after installation shall be made by

the Contractor without any additional cost to the Employer.

SECTION 23 00 00 –HVAC SYSTEM SPECIFICATIONS

You might also like

- Control Valves For Ahu Chilled WaterDocument4 pagesControl Valves For Ahu Chilled WaterHussein Akil100% (1)

- Dedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity ControlDocument39 pagesDedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity Controlhtanh100% (1)

- Saiver AHUDocument12 pagesSaiver AHUNorsyafiqah RoziNo ratings yet

- Chiller Vs VRF PDFDocument26 pagesChiller Vs VRF PDFHenry San PedroNo ratings yet

- Technical Overview On AHUDocument12 pagesTechnical Overview On AHUJahidul IslamNo ratings yet

- Control Sequences For Chilled Water Systems - Consulting-Specifying EngineerDocument5 pagesControl Sequences For Chilled Water Systems - Consulting-Specifying EngineerNeal JohnsonNo ratings yet

- Chiller Ahu and Fcu SystemsDocument67 pagesChiller Ahu and Fcu Systemsrawand adnanNo ratings yet

- Chiller System BMS PDFDocument42 pagesChiller System BMS PDFYahya SalemNo ratings yet

- Optimizing HVAC Water Pumping SystemsDocument49 pagesOptimizing HVAC Water Pumping SystemsVasanth KumarNo ratings yet

- Energy Sav HVAC SystemDocument16 pagesEnergy Sav HVAC SystemrapidSHVNo ratings yet

- Daikin VRVDocument53 pagesDaikin VRVBazeeth AhamedNo ratings yet

- Ahu BoqDocument2 pagesAhu BoqRajesh BMNo ratings yet

- AHU ChecklistDocument11 pagesAHU Checklistmohammad hamdanNo ratings yet

- Chilled Water System Sequence of OperationDocument3 pagesChilled Water System Sequence of OperationdimasNo ratings yet

- HVAC ReportDocument5 pagesHVAC ReportrazahNo ratings yet

- Variable Refrigerant Flow Systems Efficient at Part LoadsDocument5 pagesVariable Refrigerant Flow Systems Efficient at Part LoadsF. A AhmedNo ratings yet

- Proper Engine Room VentilationDocument2 pagesProper Engine Room VentilationAsok AyyappanNo ratings yet

- Comparison of ASHRAE 52.1 and 52.2 PDFDocument5 pagesComparison of ASHRAE 52.1 and 52.2 PDFChi Kit PhoonNo ratings yet

- BTU MeterDocument13 pagesBTU MeterMahesh Sadasivan NairNo ratings yet

- ICP Cleanroom Level 1Document4 pagesICP Cleanroom Level 1Asok AyyappanNo ratings yet

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlNo ratings yet

- Prinston Smart Engineers InternshipDocument33 pagesPrinston Smart Engineers InternshipCalvin bNo ratings yet

- Ashrae Ashraejournal JHGVDFDocument69 pagesAshrae Ashraejournal JHGVDFArcgireiNo ratings yet

- PRICE - Air Distribution GuideDocument5 pagesPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- HVAC Calculation for Dr.Reddy's - Generics CP- 2 GOWNING AHU 1Document4 pagesHVAC Calculation for Dr.Reddy's - Generics CP- 2 GOWNING AHU 1Sudhir KumarNo ratings yet

- Water Heater Sizing GuidelinesDocument8 pagesWater Heater Sizing GuidelinesMac ShaikNo ratings yet

- District Cooling Guide Second Edition - Unlocked-2Document2 pagesDistrict Cooling Guide Second Edition - Unlocked-2Ahmed LabibNo ratings yet

- Introduction to Clean Room WebinarDocument91 pagesIntroduction to Clean Room WebinarPriyawan SukisnoNo ratings yet

- Treated Fresh Air Guidelines by BryairDocument13 pagesTreated Fresh Air Guidelines by BryairRajanNo ratings yet

- Selecting the Right AHUDocument24 pagesSelecting the Right AHUrahulNo ratings yet

- System Design Manual-DPCVDocument29 pagesSystem Design Manual-DPCVrama_easNo ratings yet

- York Chillers SOW Chiller 2019 1Document22 pagesYork Chillers SOW Chiller 2019 1Pratikno SajaNo ratings yet

- Section 15900 - Building Management System and Hvac EquipmentDocument18 pagesSection 15900 - Building Management System and Hvac EquipmentBudi MarelanNo ratings yet

- 2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1Document29 pages2012 VAV Boxes Energy Efficiency, Air Leakage and ASHRAE 90.1din_thorpe3248No ratings yet

- Hvac OtDocument4 pagesHvac OtshreyaNo ratings yet

- DDC Basics HogerDocument37 pagesDDC Basics HogerharimadhavNo ratings yet

- Chiller Performance Calculation SheetDocument4 pagesChiller Performance Calculation SheetYasser FathiNo ratings yet

- Hap Space SheetDocument3 pagesHap Space Sheetcalvin.bloodaxe4478No ratings yet

- VRV SystemDocument152 pagesVRV SystemKHA120096 StudentNo ratings yet

- Shubharambh Banquets HL - All Halls 26-5-2017Document5 pagesShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478No ratings yet

- Air vs Water Chiller DifferencesDocument7 pagesAir vs Water Chiller DifferencesKrishna Chaitanya KalagaNo ratings yet

- PCU0610A - Chiller (Small)Document16 pagesPCU0610A - Chiller (Small)jeromeduytscheNo ratings yet

- Ducts and Diffusers Design PDFDocument106 pagesDucts and Diffusers Design PDFsiroliver39No ratings yet

- MepDocument3 pagesMepGiftson ImmanuelNo ratings yet

- Ahu & Chiller OkDocument40 pagesAhu & Chiller OkAndy DwiNo ratings yet

- Materaial For Question 3. - Cooling Load CLTD Example Ashrae PDFDocument5 pagesMateraial For Question 3. - Cooling Load CLTD Example Ashrae PDFkumarNo ratings yet

- HVAC Design in Animal Facilities: by Christopher K. Wilkins, P.E., Member ASHRAE, and Brian A. WatersDocument6 pagesHVAC Design in Animal Facilities: by Christopher K. Wilkins, P.E., Member ASHRAE, and Brian A. WaterssuhasNo ratings yet

- Fcu PipingDocument20 pagesFcu PipingRamadan RashadNo ratings yet

- FI NotesDocument1,069 pagesFI NotesparadoxendazzlingNo ratings yet

- Design Standards and Guidelines at 60Document5 pagesDesign Standards and Guidelines at 60bgmladicNo ratings yet

- Ahu ControlDocument13 pagesAhu ControleslamNo ratings yet

- HVAC Control Solution PDFDocument16 pagesHVAC Control Solution PDFlinus77No ratings yet

- AHU Catalogue enDocument68 pagesAHU Catalogue enTRISTIANDINDA PERMATANo ratings yet

- Data Entry: 3.5 Sq. Meter Room CFM CalculationDocument38 pagesData Entry: 3.5 Sq. Meter Room CFM Calculationehtesham314No ratings yet

- Cooling Load Rule of Thumb PDFDocument36 pagesCooling Load Rule of Thumb PDFmaungNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- Technical Specification - ACDocument7 pagesTechnical Specification - ACRabin ShresthaNo ratings yet

- BMS SpecificationsDocument55 pagesBMS SpecificationseyadNo ratings yet

- HVAC Drawings ListDocument1 pageHVAC Drawings ListAshar HassanNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- Sprinkler ObstructionsDocument10 pagesSprinkler ObstructionsAshar HassanNo ratings yet

- V2-SA-P1 Scope of Work (Grp2 Final) - S24 FINAL 191212 Rev1Document96 pagesV2-SA-P1 Scope of Work (Grp2 Final) - S24 FINAL 191212 Rev1Ashar HassanNo ratings yet

- Top PageDocument1 pageTop PageAshar HassanNo ratings yet

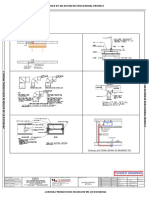

- Description S.NO.: Produced by An Autodesk Educational ProductDocument1 pageDescription S.NO.: Produced by An Autodesk Educational ProductAshar HassanNo ratings yet

- Section-Aa: PharmacyDocument1 pageSection-Aa: PharmacyAshar HassanNo ratings yet

- Produced by An Autodesk Educational Product: Tender DrawingDocument1 pageProduced by An Autodesk Educational Product: Tender DrawingAshar HassanNo ratings yet

- Fire Rating of Construction MaterialDocument2 pagesFire Rating of Construction MaterialAshar HassanNo ratings yet

- Produced by An Autodesk Educational Product: Design ConditionsDocument1 pageProduced by An Autodesk Educational Product: Design ConditionsAshar HassanNo ratings yet

- Overhead CraneDocument1 pageOverhead CraneAshar HassanNo ratings yet

- Produced by An Autodesk Educational Product: Tender DrawingDocument1 pageProduced by An Autodesk Educational Product: Tender DrawingAshar HassanNo ratings yet

- HVAC-Indoor AC-LG-Cassette 4 Way 2x2Document4 pagesHVAC-Indoor AC-LG-Cassette 4 Way 2x2Ashar HassanNo ratings yet

- Job Description and Eligibility Criteria of StaffDocument15 pagesJob Description and Eligibility Criteria of StaffAshar HassanNo ratings yet

- Electricity Bill: Units ConsumedDocument2 pagesElectricity Bill: Units ConsumedAshar HassanNo ratings yet

- Excel Uses 2Document1 pageExcel Uses 2Ashar HassanNo ratings yet

- 35CMTPDocument1 page35CMTPAshar HassanNo ratings yet

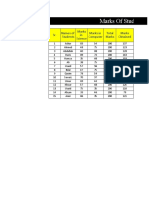

- Marks of Students: Sr. Names of Students Marks in Science Marks in Computer Total Marks Marks ObtainedDocument2 pagesMarks of Students: Sr. Names of Students Marks in Science Marks in Computer Total Marks Marks ObtainedAshar HassanNo ratings yet

- Specification of Split and Floor StandingDocument39 pagesSpecification of Split and Floor StandingAshar HassanNo ratings yet

- Financial Proposal For Conducting Feasibilty For Solar ProjectDocument4 pagesFinancial Proposal For Conducting Feasibilty For Solar ProjectAshar HassanNo ratings yet

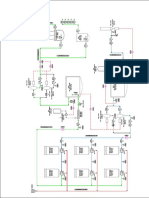

- Daikin WM Inverter VZ Panel 1Document6 pagesDaikin WM Inverter VZ Panel 1Ashar HassanNo ratings yet

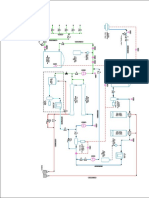

- 1000LPH RO PlantDocument1 page1000LPH RO PlantAshar HassanNo ratings yet

- 1.3.1. LEHE1448-02r - G3512HDocument7 pages1.3.1. LEHE1448-02r - G3512HJuan Valdivieso100% (2)

- PF SectionDocument1 pagePF SectionAshar HassanNo ratings yet

- Total Daily Water DemandDocument3 pagesTotal Daily Water DemandAshar HassanNo ratings yet

- Flow Velocity m3/h M/s 11.33 0.00277778 11.33333: Dia MM 1201Document3 pagesFlow Velocity m3/h M/s 11.33 0.00277778 11.33333: Dia MM 1201Ashar HassanNo ratings yet

- Fire Hydrant DrawingDocument3 pagesFire Hydrant DrawingAshar HassanNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationEnsan MasryNo ratings yet

- Sample Quality ManualDocument49 pagesSample Quality ManualNigel Lim100% (1)

- Cos Modul 7 Clutch RepairDocument12 pagesCos Modul 7 Clutch Repaireizz88No ratings yet

- EMS-APT V3.1 Performance Management Guide PDFDocument293 pagesEMS-APT V3.1 Performance Management Guide PDFapelei956350% (2)

- What Is The Music OntologyDocument5 pagesWhat Is The Music OntologyNegruta DumitruNo ratings yet

- Qcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFDocument5 pagesQcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFbryanpastor106No ratings yet

- Archives ManagementDocument17 pagesArchives Managementfelix miritiNo ratings yet

- Industrial Heat-Tracing: Installation and Maintenance Manual For Self-Regulating and Power-Limiting Heating Cable SystemsDocument52 pagesIndustrial Heat-Tracing: Installation and Maintenance Manual For Self-Regulating and Power-Limiting Heating Cable SystemsaybNo ratings yet

- Acti9 iCV40 - A9DE3740Document3 pagesActi9 iCV40 - A9DE3740Victor Marcel Leon PachecoNo ratings yet

- Project ManagementDocument9 pagesProject ManagementkrrisakashNo ratings yet

- 04 - Writing Letters, Memoranda, and E-Mail (Ch4)Document23 pages04 - Writing Letters, Memoranda, and E-Mail (Ch4)Ahmad ShdifatNo ratings yet

- 7785 A5Document13 pages7785 A5hmltdt9221100% (1)

- pmp-2051 000v001Document4 pagespmp-2051 000v001Jorge D. PardoNo ratings yet

- Viscosity CupDocument2 pagesViscosity Cupmshabanero2359No ratings yet

- 181012-180505-Multi Component Distillation (Department Elective-II)Document2 pages181012-180505-Multi Component Distillation (Department Elective-II)Nagwa MansyNo ratings yet

- Retro Briefcase Turntable Instruction ManualDocument20 pagesRetro Briefcase Turntable Instruction ManualMuhammad TauseefNo ratings yet

- Lube Oil PumpsDocument60 pagesLube Oil PumpsReza AgustianNo ratings yet

- Littelfuse Ground Fault Protection Charging Current NGR Selection MonitoringDocument75 pagesLittelfuse Ground Fault Protection Charging Current NGR Selection MonitoringAlmir GarciaNo ratings yet

- Stinger MRT-36A DSL Access Concentrator: Applications BenefitsDocument2 pagesStinger MRT-36A DSL Access Concentrator: Applications BenefitsJuanNo ratings yet

- 5359 - LOADER COMANDER 15i PDFDocument2 pages5359 - LOADER COMANDER 15i PDFDEIFY LORENA GONZALEZ VARGAS100% (2)

- KW DTV Release NotesDocument13 pagesKW DTV Release NotesMauricio AguilarNo ratings yet

- Ev Buses For HRTCDocument21 pagesEv Buses For HRTCS.KAMBANNo ratings yet

- Io Magellan9400i 9300iDocument520 pagesIo Magellan9400i 9300iiulianNo ratings yet

- Structured COBOL Programming: Nancy Stern Hofstra University Robert A. SternDocument65 pagesStructured COBOL Programming: Nancy Stern Hofstra University Robert A. SternVinod MallaNo ratings yet

- RAN17Document9 pagesRAN17agoyiNo ratings yet

- SSA0G Formation Ibm Xiv Technical Training PDFDocument1 pageSSA0G Formation Ibm Xiv Technical Training PDFCertyouFormationNo ratings yet

- SOW2021BUILDUPCANOPYFORPARKINGMOTORCYCLEANDFABRICATEHOTBARRIER NfrefDocument26 pagesSOW2021BUILDUPCANOPYFORPARKINGMOTORCYCLEANDFABRICATEHOTBARRIER NfrefXII-2 MOH FAWAIDNo ratings yet

- Internet of Things: Applications, Protocols, and Best PracticesDocument39 pagesInternet of Things: Applications, Protocols, and Best PracticesAfrinNusratNo ratings yet

- Astm b0117Document10 pagesAstm b0117Anjali AnjuNo ratings yet

- Lesson: Embedded Communications Wireless CommunicationDocument8 pagesLesson: Embedded Communications Wireless CommunicationPuspala ManojkumarNo ratings yet

- BS en 10203-1991 (1999)Document32 pagesBS en 10203-1991 (1999)Sainath AmudaNo ratings yet