Professional Documents

Culture Documents

UPVC Pipes

UPVC Pipes

Uploaded by

Ashar Hassan0 ratings0% found this document useful (0 votes)

16 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views4 pagesUPVC Pipes

UPVC Pipes

Uploaded by

Ashar HassanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

NON-CONDUCTIVE NON-CORROSIVE LIGHT WEIGHT

JOINTING:

‘A wide range of UPVC Pipes & Fittings are available, They are economical, durable, leak proof, easy & quick forthe connections.

These Fittings include Coupling Sockets, Flbows, Tees, end Caps Flanges, (45 & 90) and reducers, UPVC Pipes & Fittings are

available in various sizes for different pressure classes of Pipes. Confirming to BS, PS, ASTM & other international Standards.

POPULAR UPVC PRESSURE JOINTING SYSTEM

The following jointing systems are available,

«+ Solvent Cement Joint

++ ZJointiRubber Ring Joint

SOLVENT CEMENT JOINTING SYSTEM

PROCEDURE FOR SOLVENT JOINT INSTALLATION:

> Chamfer the Pipe and at a angle of 15 or 20 to an extent for 0.5mm length

> Apply solvent cement thoroughly & evenky over spigot endl and inside of socket

> Ensure that both spigot & socket are thoroughly clean

> Inset the pipe quickly into the socket

> Hold for a while say 4-5 minutes

> Wipe all excessive solvent cement with a cloth

> Leave for 24 hours before pressure testing

THINGS TO REMEMBER

Krife or ha round coarse fle, natural bristle, primer, aplication cane solvent cement & tools tray ate required for solvent cement

jointing, cALLMe

Z" JOINTING SYSTEM

PROCEDURE FOR INSTALLATION:

> Ensure that the mating areas of spigot and socket are thoroughly clean. This is extremely important for the correct positioning ofthe

rubber ring during assembly.

> Sel the rubber ring into the grove, pushing it firmly in as far as it goes all the way round, The opening in the rubber ring must face

backwards.

> Assess the full socket depth by simply measurement & mark spigot accordingly.

> Accurate axial alignment ofthe spigot & socket prior t jointing is important, hand feed spigot into rubber joint until resistance from

the inner seating section i felt

> Stop atthe entry mark (13-25mm) from the end of the socket to cater for potential expansion & contraction

> Make sure thatthe pipes to be jointed are aligned correctly against each other.

MATERIAL

U-Plasticised Potyiny! Chiorige (U-PVO).

UPVC Preaoure Piping Sysiem are in Gray & White Color

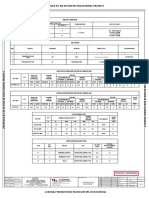

STANDARD & SPECIFICATIONS AS PER BS-3505 EQUIVALENT TO PS-3051/91

vernal) gE WALL THCOESS

mee | Sure, Gans om) Bases O60 cane G2 Gene oe

lveraged altar —Javoregea] altos averaged aha —Javrgea] aa

= [ae Ga-[se[ ae [sass ae 7a [ a 3008

MAXIMUM SUSTAINED WORKING & FIELD TEST PRESSURE

ease an nator? we casa aan Karen rsd

STANDARD ASTM D-1785 SCHEDULE 80

‘HOUINAL SE [WEAN OUTER OIG) [WALL THICKNESS (@) | NOMINAL WIGHT | PRESGURE RATING BAR

wer io mn max a Tereed ber | Ustiveed bar

«| 256r sa a om 8 476

STANDARD ASTM D-1785 SCHEDULE 40

Nownat size | wean oureR Dwyo) | war THICKNESS (5) | now. weiGHT| PRESSURE RATING BAR

INCH em) MIN MA ‘gm ‘An

ADVANTAGES

> Corrosion Resistance

> Resistance to Biological

> Growth

> Flexibility

> Coefficient of Friction

> Thermal insulation

> Environmental Benefit

> Strength to Weight Ratio

> Chemical Resistance

> Long Term Tensile Strength

> Impact Strength

> Longer Lengths

> Flame Resistance

> Favorable Cost

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- VRF SpecsDocument6 pagesVRF SpecsAshar HassanNo ratings yet

- Template Wet Riser CalculationDocument2 pagesTemplate Wet Riser CalculationAshar HassanNo ratings yet

- Sprinkler ObstructionsDocument10 pagesSprinkler ObstructionsAshar HassanNo ratings yet

- Produced by An Autodesk Educational Product: Design ConditionsDocument1 pageProduced by An Autodesk Educational Product: Design ConditionsAshar HassanNo ratings yet

- Fire Rating of Construction MaterialDocument2 pagesFire Rating of Construction MaterialAshar HassanNo ratings yet

- Description S.NO.: Produced by An Autodesk Educational ProductDocument1 pageDescription S.NO.: Produced by An Autodesk Educational ProductAshar HassanNo ratings yet

- Produced by An Autodesk Educational Product: Tender DrawingDocument1 pageProduced by An Autodesk Educational Product: Tender DrawingAshar HassanNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- List of DrawingDocument1 pageList of DrawingAshar HassanNo ratings yet

- Top PageDocument1 pageTop PageAshar HassanNo ratings yet

- Job Description and Eligibility Criteria of StaffDocument15 pagesJob Description and Eligibility Criteria of StaffAshar HassanNo ratings yet

- Durapipe PVC UserGuide-v1Document4 pagesDurapipe PVC UserGuide-v1Ashar HassanNo ratings yet

- Section-Aa: PharmacyDocument1 pageSection-Aa: PharmacyAshar HassanNo ratings yet

- Daikin WM Inverter VZ Panel 1Document6 pagesDaikin WM Inverter VZ Panel 1Ashar HassanNo ratings yet

- Produced by An Autodesk Educational Product: Tender DrawingDocument1 pageProduced by An Autodesk Educational Product: Tender DrawingAshar HassanNo ratings yet

- HVAC-Indoor AC-LG-Cassette 4 Way 2x2Document4 pagesHVAC-Indoor AC-LG-Cassette 4 Way 2x2Ashar HassanNo ratings yet

- Pressure at Hydrant 1Document2 pagesPressure at Hydrant 1Ashar HassanNo ratings yet

- Specification of Split and Floor StandingDocument39 pagesSpecification of Split and Floor StandingAshar HassanNo ratings yet

- Fire Hydrant DrawingDocument3 pagesFire Hydrant DrawingAshar HassanNo ratings yet

- Total Daily Water DemandDocument3 pagesTotal Daily Water DemandAshar HassanNo ratings yet

- P.O. BOX 030040 Fort Lauderdale, FL, 33303: 1/4" Thick & Heavier Classed As PlatesDocument2 pagesP.O. BOX 030040 Fort Lauderdale, FL, 33303: 1/4" Thick & Heavier Classed As PlatesAshar HassanNo ratings yet

- NFPA Reference Pump Requirement For Combined SystemDocument6 pagesNFPA Reference Pump Requirement For Combined SystemAshar HassanNo ratings yet

- Pressure at Hydrant 2Document2 pagesPressure at Hydrant 2Ashar HassanNo ratings yet

- HDPE Pipe SizesDocument6 pagesHDPE Pipe SizesAshar HassanNo ratings yet

- Backwash and Flow Rates of Filter Media - Pure Water Products, LLCDocument6 pagesBackwash and Flow Rates of Filter Media - Pure Water Products, LLCAshar HassanNo ratings yet