Professional Documents

Culture Documents

Inspection Certificate 3.1 - ,: According EN 10204: 2005

Uploaded by

B.M Industrial WorksOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Certificate 3.1 - ,: According EN 10204: 2005

Uploaded by

B.M Industrial WorksCopyright:

Available Formats

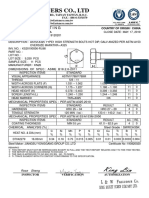

L~ E;s~ !!

R,,gd. Offlce&Worb: Pa No.. 235. Snhlja.-,N,H. No. U., Wtagu Sar~ T,_,... S.....IIJ,

Dlll . Nwnedlblo-392220. Gl4a~IIW

T: 02717 -11108D0t 100ht ). I F : 017H , 610S24

M IS0 9001 . 201S~Con1)11'1y E.~ .aJffl l W · - -~ .mr,i

Inspection Certificate 3.1 According To EN 10204 : 2005

CONSIGNEE Sancfwl Steel & Alloys TestCertffkateNo. 177542

27/29, Nakoda Bhavan, Ground Floor Date of Issue 09.09.2022

---------------,

_Si _l_la_ne~• - - - - - - - - - - - - - - < P.O. No.& Date

_n_dh

Mumbai • 400004 Invoice No. & Date

5tampof

""""

Suppty Process

Product Grade Tolerance Welsht(Mt,)

Condition Route IMeterl En ineer

Round Bars

1.4401/ 1.4404

316/316L

Solution

Annealed

EIF•AOD ·

CCM

~ -,

....

CHEMICAL COMPOSITION (%)

C Si s p C, Mo

Heat No.

22l1444 0.022

Mn

1.63 0.34 0.011 0.039 16.90

NI

10.13

N

0.0680 2.01 105mm '"

3

22L1517 0.021 1.84 0.37 0.011 0.041 17.00 10.07 0.0510 2.03 90mm 4

22L1587 0.023 1.59 0.30 0.008 0.040 16.67 10.05 0.0634 2.03 95mm 3

MECHANICAL TEST RESULT

. ,.

Tensile lmPKt,Jo11let

Chatpy-2mmVNotc:h,

Proof Stren,th, Strenath, Hardness

Elonptlon Reduction Direction• Loncit.,dlnal

Parameter N/MM' ASTM ENISO

of Area" Test M.mod :• EN ISO 141-1,

0.2% IRD 0.21 N/MM 2

" 6506-1 HBW Test Temoeni tur e- 20" C

I I II I Ill I Avera e

22l1444/10Smm 265 637 57.00 73.02 165-167 210 I 266 I 262 I 266

22l1517/90mm 260 620 55.12 72.02 170-172 250 I 254 I 250 I 251.33

22l1587/95mm 272 646 55 .32 75.00 169-171 260 I 252 I 260 I 257.33

Remarks:

Material is uhrasonkally tested as per ASTM A388 & found satlsfact<>fV.

The material Is free from Radioactive conumlnatlons.

l eadhasno!adde-dduri ngmanufacturing.

IGC Ies1 as per ASTM A.262 Practic e E & no cracks & f issures observed on bend portion al 20X & 2SOX found satisfactory.

Material confirms 1he requirements as per NACE MR 017S-201S & NACE MR 0103-201S.

Material confirms the requirements as per ASTM A276, ASTM A.479, ASME SA.479.

Visual & Dimensional inspection: OK • Micro & Macro test • SatisfactOf'{.

Solution annealed at lOSO"C, so aking for lhrs/lnch -Water Quenched.

Reduction ratio = Size -105 mm (6:1), 90 mm(6:1), 9S mm(6:1)

Material is as per AO 2000-MERKBLATT WO CERTIFICATE NO. 07/203/1409/WP/1414/22 & PED 2014/68/EU CERT! NO

07/ 202/1409/WZ/1414/ 22

We here by certify that above material described herein has been

manufactured and tested with satisfactory results in accordance with

the Specification & requirements

You might also like

- Heat C090 SK3RQ1.5X1Document1 pageHeat C090 SK3RQ1.5X1Keshia Murillo PinnockNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- BOHLER E71T-1C - 1M 1.2mm F71TA08173Document1 pageBOHLER E71T-1C - 1M 1.2mm F71TA08173ALexander HuancahuireNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- Sarma Tub Inox Certificat PDFDocument1 pageSarma Tub Inox Certificat PDFJacob HarrisNo ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- 14mm Gr60Document1 page14mm Gr60alshaya steelNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- Test Ce Tificate: C EMI AL OM OS On PercentDocument2 pagesTest Ce Tificate: C EMI AL OM OS On PercentPravin HonmuteNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- 1 4501 Super Duplex TubesDocument3 pages1 4501 Super Duplex TubesAlma JakirovićNo ratings yet

- Material Product Data SheetDocument4 pagesMaterial Product Data SheethungNo ratings yet

- Perno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Document1 pagePerno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Alexander Ortiz CarrionNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- 20-2572-MTC - 2 PDFDocument1 page20-2572-MTC - 2 PDFQualityNo ratings yet

- 60 MM SA 516 GR 70 MTCDocument21 pages60 MM SA 516 GR 70 MTCgeoanburajaNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- voestalpine Bohler Welding inspection certificate for FLUXCORED WIREDocument1 pagevoestalpine Bohler Welding inspection certificate for FLUXCORED WIREAhmad KamilNo ratings yet

- Welding Wire 25.10.4.LDocument2 pagesWelding Wire 25.10.4.LisupmanNo ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- TC - ASTM 517 GR FDocument1 pageTC - ASTM 517 GR FPremnath YadavNo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

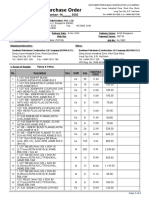

- Purchase Order: Number: 14 - SOODocument4 pagesPurchase Order: Number: 14 - SOOLê Đức ThiệnNo ratings yet

- Product Information: Inspection Certificate No. 161723Document1 pageProduct Information: Inspection Certificate No. 161723nwoforNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- Vendor ListDocument2 pagesVendor ListfarjadulhaqNo ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- Test Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)Document1 pageTest Certificate: T T T T %elon H.No. A B H.No. Size (MM) Hardness (BHN) Yield Strength UTS (Kg/mm2)yskushwah16No ratings yet

- CERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETDocument1 pageCERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETCarlos RomeroNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- AnexerDocument52 pagesAnexernagarajhebbarNo ratings yet

- Test Certificate AnalysisDocument1 pageTest Certificate AnalysisSagar KumarNo ratings yet

- ArfDocument60 pagesArftechbhaskarNo ratings yet

- N.R. Engineering: Chemical AnalysisDocument4 pagesN.R. Engineering: Chemical Analysisrajesh reddyNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Vedanta Limited Integrated Field Plan Inspection ReportsDocument23 pagesVedanta Limited Integrated Field Plan Inspection ReportsPRAKASH PANDEYNo ratings yet

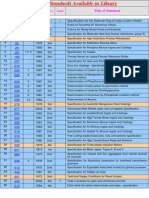

- Scanned Indian Standards ListDocument30 pagesScanned Indian Standards ListJignesh TrivediNo ratings yet

- Prime Fastener M20 Nut - MTCDocument1 pagePrime Fastener M20 Nut - MTCCyril J PadiyathNo ratings yet

- PWHT Procedure for Berri Increment ProjectDocument36 pagesPWHT Procedure for Berri Increment ProjectRizwan.descon DesconNo ratings yet

- MTC TubeDocument1 pageMTC TubeLUIZ CALROSNo ratings yet

- QM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)Document20 pagesQM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)hemantmech099200No ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- List of Approved Venders For Rggvy Work in Puvvnl: S.No Material Name Vendor Name 1 2 3Document6 pagesList of Approved Venders For Rggvy Work in Puvvnl: S.No Material Name Vendor Name 1 2 3Karthick MahadevanNo ratings yet

- Chemical and Mechanical PropertiesDocument5 pagesChemical and Mechanical PropertiesAristotle MedinaNo ratings yet

- Is 1570 1Document17 pagesIs 1570 1Raj K Sharma100% (1)

- SS SAW Welding Flux Sample MTCDocument1 pageSS SAW Welding Flux Sample MTCKunal AjgaonkarNo ratings yet

- Data Sheet Material 2.4819Document3 pagesData Sheet Material 2.4819BoberNo ratings yet

- Metal matrix composites: Processing and InterfacesFrom EverandMetal matrix composites: Processing and InterfacesR EverettNo ratings yet

- SI Engine CombustionDocument1 pageSI Engine CombustionPerumal GovindanNo ratings yet

- Presentation PDFDocument14 pagesPresentation PDFHaroon RahimNo ratings yet

- 3-Admixtures For ConcreteDocument35 pages3-Admixtures For ConcreteMa ThiNo ratings yet

- 8 3 Types of Reactions 4th EdDocument21 pages8 3 Types of Reactions 4th EdDaffa FachrurNo ratings yet

- BaS separation process countercurrent column designDocument1 pageBaS separation process countercurrent column designDylan Navarro LNo ratings yet

- ENERGY FROM BIOMASS: ANCIENT FUEL FOR MODERN TIMESDocument100 pagesENERGY FROM BIOMASS: ANCIENT FUEL FOR MODERN TIMESC Venkataramana ReddyNo ratings yet

- List of References in The Food & Beverage Industry Christ Holland B.VDocument3 pagesList of References in The Food & Beverage Industry Christ Holland B.VariefmailNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- Inhibitor for Hydrochloric Acid Descaling SolutionDocument7 pagesInhibitor for Hydrochloric Acid Descaling SolutionRezaNo ratings yet

- 6 2 1 2 Liquid-Preparations-For-Oral-Use PDFDocument4 pages6 2 1 2 Liquid-Preparations-For-Oral-Use PDFSunil BudhkarNo ratings yet

- Electroplating PowerpointDocument18 pagesElectroplating PowerpointAkhlis Rahman Sari NurhidayatNo ratings yet

- RX Marine International: Electrosol PlusDocument1 pageRX Marine International: Electrosol PlusSuresh RamanujaluNo ratings yet

- SCH 300 COMPARATIVE STUDY OF S - P - BLOCK ELEMENTS 2003Document70 pagesSCH 300 COMPARATIVE STUDY OF S - P - BLOCK ELEMENTS 2003wafula kennedyNo ratings yet

- Periodic Table TrendsDocument37 pagesPeriodic Table Trendsahmad yasinNo ratings yet

- Nutrien Fact Book 2018 - 1 PDFDocument52 pagesNutrien Fact Book 2018 - 1 PDFRoopen Fearky100% (1)

- Prevention of Enzymatic Browning in Fruit and Vegetables: Irina Ioannou Mohamed GhoulDocument32 pagesPrevention of Enzymatic Browning in Fruit and Vegetables: Irina Ioannou Mohamed GhoulMyka ZoldyckNo ratings yet

- Discontinued ASTM MethodsDocument3 pagesDiscontinued ASTM MethodsNoorshalehahNo ratings yet

- 2 Soap and Detergent Cleaansing ActivityDocument7 pages2 Soap and Detergent Cleaansing ActivityFebian HenryNo ratings yet

- A575Document2 pagesA575Demetrio Rodriguez100% (1)

- Functional Biopolymers: Mohammad Abu Jafar Mazumder Heather Sheardown Amir Al-Ahmed EditorsDocument586 pagesFunctional Biopolymers: Mohammad Abu Jafar Mazumder Heather Sheardown Amir Al-Ahmed EditorsMonique BarretoNo ratings yet

- PJSIR Series A: Physical Sciences Vol. 56, No. 1, January-February, 2013Document15 pagesPJSIR Series A: Physical Sciences Vol. 56, No. 1, January-February, 2013Syed Umair AnwerNo ratings yet

- Section 6 - Fracturing Fluids and MaterialsDocument40 pagesSection 6 - Fracturing Fluids and Materialsmahimoh18100% (3)

- Well Test Standards WTS 3.8 Coflexip Hoses: Global ManualDocument9 pagesWell Test Standards WTS 3.8 Coflexip Hoses: Global ManualEmmanuel100% (1)

- 2016 Book Glass-Ionomersindentistry PDFDocument161 pages2016 Book Glass-Ionomersindentistry PDFFernando AguirreNo ratings yet

- Catalytic Steam Gasification of Biomass Surrogates - A ThermodynamDocument266 pagesCatalytic Steam Gasification of Biomass Surrogates - A ThermodynamMandeepSharmaNo ratings yet

- Intermolecular ForcesDocument28 pagesIntermolecular ForceskarjackerNo ratings yet

- Transition Metal Ion Metal Aqua Ion With OH With Excess OHDocument1 pageTransition Metal Ion Metal Aqua Ion With OH With Excess OHsammam mahdi samiNo ratings yet

- The Periodic Table: Grade 10 (ICSE)Document31 pagesThe Periodic Table: Grade 10 (ICSE)Kirthika SNo ratings yet

- FV520BDocument232 pagesFV520BPacoNo ratings yet

- Advantages and Disadvantages of Different ChemicalDocument2 pagesAdvantages and Disadvantages of Different ChemicalSteph Phanie G. Gomez100% (3)

- Hormuud University: Faculty of Engineering Department of Civil EngineeringDocument22 pagesHormuud University: Faculty of Engineering Department of Civil EngineeringAbdi Aziz Mohamed BuleNo ratings yet