Professional Documents

Culture Documents

BV351 Dismantling Joint

BV351 Dismantling Joint

Uploaded by

FAIYAZ AHMED0 ratings0% found this document useful (0 votes)

9 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesBV351 Dismantling Joint

BV351 Dismantling Joint

Uploaded by

FAIYAZ AHMEDCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

WE Dismantling Joints se

The Dismantling Joints are double flanged fittings that accommodate up to 50 mm longitudinal

adjustment, which allows for the simplified assembly and disassembly of valves between two fixed

trunking components. The sliding system allows for a simplified removal of the valve device.

They are an essential aid during the installation and removal of pipe sections and valves. The valve can be

fitted next to the dismantling joint and it can be set to the exact length required prior to being securely

connected to flanges.

‘he reverse sequence is used for dismantling, where readjustment of the length of the dismantling joint

creates enough space to loosen and remove the valve. In both cases, the dismantling joint guarantees fast

installation and removal, thus contributing to increased efficiency and reducing site operations and down

time.

The simplicity and versatility of the fittings make them suitable for many applications including HVAC,

pumping stations, water treatment works, sewage treatment works, plant rooms, meter chambers, power

generation equipment, gas distribution stations etc.

|

PB swoesnaoynco

:

belver’

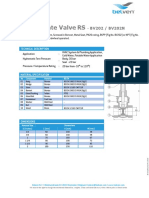

EEE Dismantling Joints series av 351

Dismantling Joint, PN 16 rated, Powder Epoxy coated body, Outer and inner telescopic flanges and center

flange connected by tie rods, EPDM rubber seal , Stainless steel studs and nuts, maximum lateral displace-

ment of 50 mm.

US ee Saat

Application Water Network, District Cooling

Hydrostatic Test Pressure Body: 24 bar

Pressure / Temperature Rating 16 bar from -10° to 110°C

Coating Internal and External coated with Fusion Bonded Epoxy paint RAL

5015 (Blue), Coating Thickness (DFT) - 200 microns

Standard Flange Drilling EN 1092 PN 16 or ASME B16.5 CL150

Pais

POM Carbon Stee! Galvanized

NBR. Stainless Steel

Castiron 16625 Epoxy coated

Ductile Iron 56640 Epoxy coated

*Other variations available on request

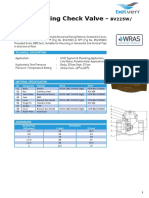

WH Dismantling Joint series av 351

DIMENSIONS:

omnes

PCIe ey}

sr

belver’

ON (mm)

65

80

4100

125

150

200

250

300

350)

400

450

500

600)

700

800)

900

1000

1100

1200

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

L (mm)

200

200

200

200

200

220

230

250

260

270

270.

200

300

300

320

320

340)

340

360.

350

350,

350

350,

350

380

380

410

410

450

450

450

430

430

500

500

550

550

590

on

oz

03

04

05

06

07

08

ae see

Component

Inner Flange

uter Flange

Centre Flange

Sealing

sue

Cap

Washer

Nut

Material

Ductile ron AS EN 1583 GJS-400-15

Duetile ron 8S EN 1563 GJS-400-15

Ductile ron BS EN 1563 GS-400-15

Rubber EPOM

Stainless steel SS 304

Pastic

Stainless steel SS 304

Stainless steel $304

e

:

26

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- DELMON ProfileDocument77 pagesDELMON ProfileFAIYAZ AHMEDNo ratings yet

- WINMENA - DPG Installation and Maintenance InstructionsDocument2 pagesWINMENA - DPG Installation and Maintenance InstructionsFAIYAZ AHMEDNo ratings yet

- Dellag La 3-36Document2 pagesDellag La 3-36FAIYAZ AHMEDNo ratings yet

- Delfix 8-10Document2 pagesDelfix 8-10FAIYAZ AHMEDNo ratings yet

- Delseal 3-17 HighlightedDocument2 pagesDelseal 3-17 HighlightedFAIYAZ AHMEDNo ratings yet

- Delseal 3-15Document2 pagesDelseal 3-15FAIYAZ AHMEDNo ratings yet

- Winmena - DPGDocument1 pageWinmena - DPGFAIYAZ AHMEDNo ratings yet

- Winmena - D90Document2 pagesWinmena - D90FAIYAZ AHMEDNo ratings yet

- PFQ PFQ-LFDocument10 pagesPFQ PFQ-LFFAIYAZ AHMEDNo ratings yet

- Winmena - D81Document2 pagesWinmena - D81FAIYAZ AHMEDNo ratings yet

- Winmena - D85Document2 pagesWinmena - D85FAIYAZ AHMEDNo ratings yet

- BV224VDocument1 pageBV224VFAIYAZ AHMEDNo ratings yet

- Belven Procesfolder BallV ENG LRDocument28 pagesBelven Procesfolder BallV ENG LRFAIYAZ AHMEDNo ratings yet

- Winmena - DTPGDocument2 pagesWinmena - DTPGFAIYAZ AHMEDNo ratings yet

- Bv231 Belven Y-StrainerDocument1 pageBv231 Belven Y-StrainerFAIYAZ AHMEDNo ratings yet

- Bv241w Belven Butterfly ValvesDocument4 pagesBv241w Belven Butterfly ValvesFAIYAZ AHMEDNo ratings yet

- BV 457 Solenoid Valve NCDocument1 pageBV 457 Solenoid Valve NCFAIYAZ AHMEDNo ratings yet

- BV232 - Y Strainer DN350Document1 pageBV232 - Y Strainer DN350FAIYAZ AHMEDNo ratings yet

- BV251 - Lug Butterfly ValveDocument2 pagesBV251 - Lug Butterfly ValveFAIYAZ AHMEDNo ratings yet

- BV202 Bronze RS Gate ValveDocument1 pageBV202 Bronze RS Gate ValveFAIYAZ AHMEDNo ratings yet

- BV261 - U Type Butterfly ValveDocument2 pagesBV261 - U Type Butterfly ValveFAIYAZ AHMEDNo ratings yet

- BV218 CI Globe ValveDocument1 pageBV218 CI Globe ValveFAIYAZ AHMEDNo ratings yet

- BV422 Pressure Reducing-Sustaining ValveDocument4 pagesBV422 Pressure Reducing-Sustaining ValveFAIYAZ AHMEDNo ratings yet

- BV217 Bronze Globe ValveDocument1 pageBV217 Bronze Globe ValveFAIYAZ AHMEDNo ratings yet

- BV233 - Basket StrainerDocument3 pagesBV233 - Basket StrainerFAIYAZ AHMEDNo ratings yet

- Bv251v Series Pn25Document1 pageBv251v Series Pn25FAIYAZ AHMEDNo ratings yet

- BV426 Pressure Relief Sustaining ValveDocument4 pagesBV426 Pressure Relief Sustaining ValveFAIYAZ AHMEDNo ratings yet

- Belven Bronze Swing Check ValveDocument1 pageBelven Bronze Swing Check ValveFAIYAZ AHMEDNo ratings yet

- BV204VDocument1 pageBV204VFAIYAZ AHMEDNo ratings yet

- Plumbing Specialty CatalogueDocument50 pagesPlumbing Specialty CatalogueFAIYAZ AHMEDNo ratings yet