Professional Documents

Culture Documents

Performance of Recycled Aggregate Concrete - Formatted Paper

Uploaded by

litacoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance of Recycled Aggregate Concrete - Formatted Paper

Uploaded by

litacoCopyright:

Available Formats

Journal of Building Construction

Volume 3 Issue 2

Performance of Recycled Aggregate Concrete in Bangladesh

Context: A Review

Raisul Islam Shuvo1*, Razesh Kanti Sarkar2, Md. Mehrab Mostak3,

Dr Sharmin Reza Chowdhury4

1,2,3

Student, 4Professor

Department of Civil Engineering, Ahsanullah University of Science and Technology, Dhaka,

Bangladesh.

*Corresponding Author

E-mail Id:-160203095@aust.edu

ABSTRACT

Bangladesh is experiencing faster urbanization. Multi-storied building technology has

become popular in urban areas due to fulfill urban housing demand in Bangladesh. The

Government, manufacturers and stakeholders should explore proper approaches to reuse the

building /construction wastes without aggravation to climate. The main objective of this study

is to review the physical and mechanical properties of recycled coarse aggregate (RCA) and

to compare these properties with that of natural aggregates. This review also focuses on the

influence of RCA on Recycled Aggregate Concrete (RAC). It is found from this review study

that RCA can be used in non structural member efficiently by replacing 25 to 30% natural

course aggregate. For using RAC in structural member, still some improvements of flexural

properties of RCA are required. It is also shown that recovery of construction and demolition

waste is higher in developed countries.

Keywords:-Recycled coarse aggregate, physical and mechanical properties, demolition

waste.

INTRODUCTION bound together with cement and water.

Bangladesh is a developing country where Worldwide over 12 billion tons of concrete

city urbanization started in 1991s. Due to are being used each year. Around 1.5

industrialization, Bangladesh's billion tons of cement, 9.3 billion tons of

urbanization rate is very high. aggregates, and 1.2 billion tons of water

Bangladesh's GDP is growing at an annual are used to produce this massive volume of

rate of 8.2% (2018/2019 e) [1]. For concrete [3]. For this huge production,

achieving GDP rate, it is necessary to build maximum portion of the aggregates come

various industrial structures using from natural assets which is limited.

concrete. Cutting rocks, crushing river gravels, and

other methods are often used to extract

Since we spend 90% of our time in natural aggregates.

building or other infrastructures such as

roads, highways, and bridges, so concrete But in Bangladesh the sources of crushed

materials are extremely momentous in our stones are limited. For this reason, baked

lives. The word concrete comes from the clay brick chips are used which is

Latin word “Concretus” (meaning destructive for our current circumstance.

condensed) [2]. Concrete is a close-knit From climate perspective, for production

mixture of fine and coarse aggregates of natural aggregate, large amount of

HBRP Publication Page 1-13 2021. All Rights Reserved Page 1

Journal of Building Construction

Volume 3 Issue 2

carbon releases. In future, when natural generates about 3340 tons of solid waste

resources will finish what we do? So, it is every day, of which 668 tons are recycled,

urgent to provide alternative materials 1236 tons are illegally dumped, and 1436

which could be used to replace natural tons are disposed of in landfills (AIT-

aggregates in concrete. UNEP RRC.AP, 2005) [6]. Construction

and demolition waste accounts for around

On the other hand, Construction and (15 to 20 percent) of their waste.

demolition (C&D) industries in Asia and

many other developing countries around The tremendous measure of waste is

the world manufacture and dump huge treated for our current circumstance. We

amounts of waste. Among the materials need preserve the assets and relief from

found in (C&D) waste, significant portions this huge amount of construction waste.

of total weight of waste are represented by We have to use “3R” principle (i.e.,

concrete. Debris from the demolition of reduce, reuse and recycle) which has been

homes, highways, bridges, and other investigated from long time [7].

infrastructure is referred to as demolition

waste. The primary causes of the rise in On an environmental standpoint, the

demolition concrete waste are as follows: production of 1 ton of natural aggregate

• Destruction of buildings & structures emits 0.0046 million tons of carbon, while

due to cataclysmic event the production of 1 ton of recycle

(Earthquakes, Storms, Landslide aggregate emits 0.0024 tons of carbon. By

etc.)& wars. recycling building and demolished

• Rearrangement of a city. concrete, more than 30% of natural

• Many old houses and other structures aggregate can be saved [8].

have reached the end of their useful

life and must be demolished. Use of recycle aggregate is not a new

• In Bangladesh, low rise building thing. In past, many investigations have

owners started to construct high rise been done by various researchers. Reusing

building replacing their old houses. of crushed concrete was first recorded in

1860 in Germany. At the end of World

Every day, at least 3.5 million tons of solid War II, many countries started to use

waste are generated around the world (In recycled aggregate for the excessive

18 may,2018) [4]. In September 2018, demolition of building and roads. It

According to the World Bank, global became popular in the United States in

waste generation is expected to increase by 1970’s.

70% by 2050 unless people take

immediate action (Sesonseo Global Waste People may encourage for using recycled

Index 2019) [5]. According to statistic in concrete aggregate (RCA) due to benefits

2010, Dhaka, Bangladesh's capital, as shown below:

HBRP Publication Page 1-13 2021. All Rights Reserved Page 2

Journal of Building Construction

Volume 3 Issue 2

Use as a

landfills

material which

saves land

spaces

RCA reduce

the need for provides

gravel mining

Benefits economic

and also save

benefits

money of RCA

use

Less emission

Creates

of carbon, this

business is good for our

opportunities environment

Demolished Concrete Blocks Recycled Coarse Aggregate [9]

(Collected from demolished building sites) (After Crushing Concrete blocks)

Fig.1:-Demolished Concrete Block and Recycled Aggregates

Demolished concrete blocks were sites and cut into pieces as aggregate for

extracted from demolished construction the investigation, as seen in Figure 01.

STATUS OF RECOVERY OF JAPAN: In early 1970, some Japanese

CONSTRUCTION AND researcher had been investigated about

DEMOLITION WASTE IN recycling of concrete. In Japan, the

DIFFERENT COUNTRIES majority of recycling and demolition waste

The current state of construction and is based on earthquake-resistant materials

demolition waste recovery in a few foreign and prefabrication [10].

countries is described in this section.

Fig.2:-Construction and Demolition waste of Japan [10]

HBRP Publication Page 1-13 2021. All Rights Reserved Page 3

Journal of Building Construction

Volume 3 Issue 2

Figure 2 shows the construction and concrete. Construction waste reuse has

demolition waste situation in Japan in the become a hot topic in China recently and

year 2000. deserves deep researches [14]. China

produces approximately 300 million tons

In Japan, approximately 77 million tons of of construction and demolition waste per

construction and demolition waste are year and recovered around 120 million

produced each year and around 80.50% tons. Approximately 40% construction &

construction & demolition waste has been demolition waste has been recovered per

recovered per year [11]. year in china [11].

INDIA: Rapid infrastructural growth in HONG KONG: For regulating NOx in

India, such as airports, highways, and the surrounding air, concrete bricks and

housing, as well as the demand for paving blocks were successfully

construction materials, has resulted in impregnated with photograph impetus. The

scarcity and an increase in the cost of public authority generally supports the

construction materials. The majority of the reusing of C&D materials taken from

buildings that have been destroyed are development work and overseeing

used as landfill materials. As a result, there development squander. The amount of

is a scarcity of land for disposal in urban construction and demolition waste

areas. So, it is essential to begin reusing generated each year approximately 24.3

demolition concrete waste [12]. In India, million tons in Hong Kong and recovered

approximately 150 million tons of around 6.8million tons. Approximately

construction and demolition waste are 28% construction & demolition waste has

produced each year. However, the official been recovered per year [11].

recycling capacity is just 6,500 tons per

day (TPD), which is less than 1% of total TAIWAN: The amount of construction

capacity [13]. and demolition waste generated each year

approximately 63 million tons in Taiwan

CHINA: In China, with the fast and recovered around 58 million tons.

improvement of development industry Approximately 92% construction

which depends on the expense of &demolition waste has been recovered per

unnecessary common asset utilization and year in Taiwan [11].

the disintegration of the climate, the

logical inconsistency between the practical THAILAND: The amount of construction

advancement of the development business and demolition waste generated each year

and the deficiency of assets will turn out to approximately 10 million tons in Thailand

be more also more genuine. At the same and recovered around 3.2 million tons.

time, the interaction of the development of Approximately 32% construction &

new structures and destruction of old demolition waste has been recovered per

structures is produced a large amount of year in Thailand [11].

solid waste in every year. Natural disasters

in China, such as the 2008 Wenchuan The recovery of construction and

earthquake, the 2010 Yushu earthquake, demolition waste described in the above is

and the 2011 Yunnan earthquake, have summarized in Table

resulted in a large amount of waste

HBRP Publication Page 1-13 2021. All Rights Reserved Page 4

Journal of Building Construction

Volume 3 Issue 2

Table 1:-Recovery of construction & demolition waste [11]

Total C&D waste

Countries Total C&D Recovery(million tons)

(million tons)

Australia 19.30 12.00

China 300.00 120.00

Hong Kong 24.30 6.80

Japan 77.00 62.00

Taiwan 63.00 58.00

Thailand 10.00 3.20

Belgium 40.20 34.57

Denmark 21.70 20.40

Finland 20.80 5.40

France 342.60 212.40

Germany 192.30 165.40

Ireland 16.60 13.30

Netherland 25.80 25.28

Norway 1.30 0.87

Portugal 11.40 5.52

Spain 38.50 5.39

Switzerland 7.00 2.00

United Kingdom 114.20 74.23

Brazil 101.00 6.20

Canada 0.66 0.20

USA 534.00 256.30

South Africa 4.70 0.76

600.00

500.00

Total C & D

(Million Tons)

400.00

waste

300.00

200.00

100.00 Total C & D

waste recovery

0.00

United…

Australia

USA

Hong Kong

Portugal

South Africa

China

Finlang

Brazil

Canada

Belgium

Taiwan

Denmark

France

Spain

Switzerland

Japan

Thailand

Germany

Ireland

Norway

Netherland

Countries

Fig.3:-Comparison of C&D Waste VS C&D Waste Recovery

The recovery status of the different Concrete mix design and various

countries which is shown in tabular form is properties of concrete are getting impacted

again shown in pictorial view at Figure 3. by the physical properties of recycled

concrete aggregate. Due to the existence of

AGGREGATE PROPERTIES OF remaining cement mortar in recycled

RECYCLED CONCRETE aggregates, the essential qualities of RCA

AGGREGATE (RCA) such as Shape and Texture, Specific

Physical Properties gravity, Bulk density, Water absorption

HBRP Publication Page 1-13 2021. All Rights Reserved Page 5

Journal of Building Construction

Volume 3 Issue 2

Capacity are worse than NCA's. Table 2 of NCA and RCA, which are briefly

shows the fundamental physical properties discussed later.

Table 2:-Fundamental physical properties of NCA and RCA [15]

Physical properties Natural Concrete Recycled Concrete Recycled Concrete

Aggregate(NAC) Aggregate(RCA) Aggregate(RCA)

(For stone) (For Brick) [16]

Shape and texture Well rounded, smooth Angular with rough Almost Angular with

(gravels) to surface rough surface

angular and rough (crushed

rock)

Specific gravity (saturated surface- 2.4-2.9 2.1-2.5 2.02

dry based)

Bulk density(Kg/m3) 1450-1750 1200-1425 1096-1245

Water absorption (wt. %) 0.5-4 3-12 14

Pore Volume (vol. %) 0.5-2 5-16.5 40

Particle Shape and Texture NCA. The bulk density of NCA was found

The aggregate particle form and texture in range between (1450-1750)

have a significant impact on the concrete's kg/m3whereas the bulk density of NCA

workability. RCA will in general be was found in range between (1200-1425)

exceptionally precise and harsh due to the kg/m3 (for stone) [15] and (1096-

pulverization of old concrete and the 1245)kg/m3 (for brick) [16] from Table 2.

inclusion of hardened cement mortar This is due to the RCA's higher porosity in

adhered to the surfaces of recycled coarse the presence of ascribed cement paste to

aggregate. The shape of NCA is almost the surfaces of recycled coarse aggregate.

well rounded whereas the shape of RCA Because of the lower Bulk Density, the

(for stone) is almost angular. In context of concrete mix gets influenced.

Bangladesh, here brick chips are used in

concrete for casting slabs. Particle shapes Water Absorption Capacity

are almost same in both cases of RCA as As seen in Table 2, the water absorption

can be seen from Table 02. capacity of RCA is noticeably greater than

that of NCA. The ability of aggregate to

Specific Gravity absorb water has a major impact on the

As can be seen from Table 2, RCA has a concrete mix design. The water absorption

lower specific gravity than NCA. The capacity of NCA was found within the

specific gravity of recycled concrete range of (0.5-4) % which is less than the

aggregate (for stone) was determined to be water absorption capacity of RCA (for

between 2.1 and 2.5 in saturated surface both stone & brick) [15]. The bulk density

dry conditions, which is lower than NCA's of RCA (for stone) was observed to be

specific gravity [15].In case of RCA(for 9.8% lower than that of NCA in Yong and

brick), specific gravity is about 2.02 which Teo (2009)'s experiments [17]. Because of

is very disappointing [16]. The reason of the higher porosity of RCA in the

lower specific gravity of RCA is the appearance of added cement paste, this

adherence of remaining old cement paste occurs.

on recycled aggregate, which renders it

less dense than natural aggregate. Pore Volume

Table 2 shows that the pore volume of

Bulk Density RCA is slightly greater than that of NCA.

As seen in Table 2, the bulk density of The pore volume of RCA (for brick) was

RCA is appreciably smaller than that of found 40 % which is higher among NCA

HBRP Publication Page 1-13 2021. All Rights Reserved Page 6

Journal of Building Construction

Volume 3 Issue 2

and RCA (for stone) [16]. The porous affection. The aggregate impact value

nature of remaining mortar with old brick (AIV) is a measure of resistance to abrupt

aggregates does this. In comparison to impact, as opposed to incremental

NCA, RCA has a higher pore volume, compression load. The AIV of RCA (20–

making it frail and less dense. 25%) is more prominent than that of NCA

(15–20%), according to previous

Mechanical Properties investigations (Table 03) [15]. RCA is

Concrete's mechanical properties are weakened by the mortar and cement paste

dependent on aggregate mechanical that has been incorporated with it. The

properties. Mechanical properties are used lower the AIV, the stronger is the

to help classify and identify material. The aggregate.

choice of aggregates for construction work Aggregate Crushing Value

is primarily determined by its physical and The strength of aggregates is determined

mechanical properties. Table 3 contains by their crushing value. The aggregate

the major mechanical properties of NCA crushing value (ACV) is a measurement of

and RCA, which will be discussed briefly aggregate's resistance to pulverization

later. continuously applied compressive load.

The Aggregate crushing value of recycled

Table 3:-Major mechanical properties of concrete aggregate (for stone) was found

NCA and RCA [15] from (20-30) %which is more than NCA’s

Mechanical property (wt. %) NAC RCA(for Stone) aggregate crushing value [15].The higher

Aggregate abrasion value 15-30 20-45

Aggregate impact value 15-20 20-25

the aggregate crushing value, the weaker is

Aggregate crushing value 14-22 20-30 the aggregate. Lower crushing value is

recommended for roads and pavements

Aggregate Abrasion Value construction due to the indication of long

The aggregate abrasion value (AAV) is a service life.

measurement of aggregate wear resistance.

When material loss due to wear becomes ADVERSE EFFECTS OF RECYCLED

larger, a higher AAV is obtained. Abrasion AGGREGATE ON CONCRETE

test provides the result that helps the user The use of recycled aggregate has a

to compare the materials and helps to detrimental impact on the strength of

judge the service life of the material. The concrete because it is made from

aggregate abrasion value of recycled demolition building waste. How recycled

concrete aggregate (for stone) was found aggregate influences the various strength

from (20-40) %which is more than NCA’s of concrete is discussed in this portion.

aggregate abrasion value [15].In case of The effects of RCA on various concrete

RCA (for brick), exact data was not found.

properties are discussed one by one.

It may predict that the aggregate abrasion

value of RCA (for brick) may higher than

the RCA (for stone). Compressive Strength of Concrete

Usually the compressive strength of

Aggregate Impact Value Recycled aggregate concrete is lower

The aggregates must be sufficiently tough when it is compared with Natural

to withstand impact disintegration. The aggregate concrete as demonstrated in

impact value test is used to measure this Figure 04.

HBRP Publication Page 1-13 2021. All Rights Reserved Page 7

Journal of Building Construction

Volume 3 Issue 2

Compressive Strength (Mpa) 18

17 100% Fresh

16 Concrete

15

14

13 50%

50%

12 Replacement

replacement by

11 RAC

by RCA (for

10 brick)

9

8

0 5 10 15 20 25 30

Days

Fig.4:-Effect of RCA(by brick)on the compressive strength of concrete [18]

The compressive strength of natural strength that is about two-thirds that of

aggregate concrete is higher compared to natural aggregate concrete. The reasons for

recycled aggregate concrete for both 7 & the decrease in compressive strength are

28 days which are clear from figure 04. listed below [18]

Recycled concrete has a compressive

The water

requirements of

recycled aggregate

concrete are greater

than those of natural

aggregate concrete

Approximate

causes of

compressive

strength

reduction

The bond

As compared to

between the new

natural aggregate,

and old mortar

recycled aggregate

adhering to the

has a lower

recycled concrete

mechanical

aggregate is

resistance

poorer

12 14

% reduction of Comressive strength than

11%

% reduction of Comressive strength than

W/C=0.35

12%

10 9.6% W/C=0.5 12

5

10%

% reduction 10 9.4% 9.6%

% reduction

8 7.2

6.8 of 8% of Comressive

%

% Comressive 8 strength than

NCA

NCA

6 5.6% strength than NCA(28 days)

4.4 NCA(28 days) 6 5.9%

%

4 3.7%

4 % reduction

2 % reduction 2.6% 3%

2 % of of Comressive

2 strength than

Comressive

strength than NCA(56 days)

0 NCA(56 days)

0

25 50 75 100 25 50 75 100

% replacement by RCA % replacement by RCA

Fig.5(a): % reduction of compressive strength of concrete Fig.5(b): % reduction of compressive strength of concrete

for 28 & 56 days with various replacement by RCA (for for 28 & 56 days with various replacement by RCA (for

stone) considering W/C = 0.55 [19] stone) considering W/C = 0.35 [19]

HBRP Publication Page 1-13 2021. All Rights Reserved Page 8

Journal of Building Construction

Volume 3 Issue 2

It is found from both figure 05 (a and b) compressive strength is comparatively

that mixing 50 % to 100 % recycled increased with the decrease of water

concrete aggregate (for stone) with natural cement ratio (W/C) from 0.55 to 0.35 [19].

aggregate reduces the compressive

strength of concrete by around 5% to 15%. Flexural Strength of Concrete

Flexural strength is commonly used to

However, the use of (25-30) % of recycled design structural components such as

aggregate with (75-70) % natural beams, columns etc. It aids in determining

aggregate almost doesn’t show any vital the consistency of building structures. It is

effect on compressive strength. Figure 05 a parameter that aids in the prediction of

(a and b) shows that the % reduction of object resistance and durability.

7

6

Flexural strength (MPa)

5.818 5.637 5.436 5.334

5 4.69 4.57 4.48 4.396 Flexural strength

4 (MPa)(7 days)

3

2

Flexural strength

1 (MPa)(28 days)

0

0 10 20 30

% Replacement by RCA(for stone)

Fig.6:-Effect of RCA (for stone)on the flexural strength of high strength concrete [8]

The flexural strength of concrete is Recycled concrete aggregate [8].

marginally affected by recycled aggregate. However, the use of (25-30) % of recycled

As compared to natural aggregate aggregate with (75-70) % natural

concrete, the flexural strength of recycled aggregate almost doesn’t show any

aggregate concrete is smaller, as seen in adverse effect on flexural strength due to

figure 06. It's also been discovered that the its negligible reduction. The reduction of

flexural strength of concrete decreases Flexural strength is limited to 10%.

very slowly with increasing the amount of

Shear Strength of Concrete

25

% reduction of Shear strength than NCA

21.7%

20.3%

20

15

10.6%

10

0

25 50 100

% replacement by RCA

Fig.7:-% Reduction of flexural strength of concrete with various % replacements by RCA (for

stone) [20]

HBRP Publication Page 1-13 2021. All Rights Reserved Page 9

Journal of Building Construction

Volume 3 Issue 2

The reduction of shear strength is limited aggregate concrete was found 41943.7

to 10% for (25 to 30) % replacement by MPa where as 20% RCA mix gave

RCA instead of NCA. It is found from maximum value of 38908.2 MPa with

figure 07 that 25% to 100% use of 5.01% reduction compared to natural

recycled concrete aggregate (for stone) aggregate concrete [22]. Therefore 20%

with natural aggregate decrease the shear RCA mix shows optimum potential for

strength of concrete by approximately 10% both normal & high strength concrete.

to 20% [20]. This is because of the recycle

aggregate has weaker spots formed while Shrinkage & Creep

demolition of concrete is done. Recycled Aggregate Concrete has a higher

rate of shrinkage and creep deformation

Durability of Recycled Aggregate than Natural Aggregate Concrete. That is

Several factors affect the durability of usually 25% to 35% higher. However, this

recycled aggregate concrete, including:- behavior can be controlled by altering the

• Ratio of aggregate replacement mix design & water cement ratio.

• Age of concrete

• Water cement ratio(W/C) and Workability of Concrete

• Moisture content. Higher water content is necessary in

recycle aggregate concrete to achieve the

Because of the high porosity of recycled same workability as natural aggregate

aggregate, the concrete is less durable. The concrete. This is due to recycled

reason for this decrease is due to the lower aggregate's higher water absorption

resistance of concrete to Carbonation, capacity, as well as the lower specific

Chloride penetration & Reinforcement gravity and bulk density of recycled

Corrosion. However, uses of aggregate.

supplementary cementing materials like fly

ashes, slag cement & silica fume etc. OVERALL STRUCTURERAL

improves the durability & strength of the PERFORMANCE OF RECYCLED

concrete. CONCRETE AGGREGATE (RCA)

Limited literature is available concerning

Modulus of Elasticity about the structural performance of

The volume fraction of aggregates as well Recycle Aggregate Concrete. Etxeberria,

as the elastic modulus of the aggregate has A. R. Mari, E. Vázquez 2007 announced

an effect on the modulus of elasticity of that the impact of the utilization of

concrete. The modulus of elasticity of recycled aggregate on the beam's shear

brick chip concrete is almost identical to strength relies upon the percentage of

that of stone chip concrete. [21]. As coarse aggregate substituted, specially for

compared to Natural Aggregate Concrete, beams without transverse reinforcement

the Modulus of Elasticity of Recycled [23]. For low percentage of replacement

Aggregate Concrete is observed to be (under 25%) it tends to be said that this

marginally lower. For normal strength, 28 impact is basically negligible [23].

day’s modulus of elasticity of Natural From a source university of Notre dame

aggregate concrete was found 32264.4 Australia [24], The variability and

MPa whereas 20% RCA mix gave uncertainty in the consistency and

maximum value of 31126.6 MPa with properties of recycled concrete, as well as

3.52% reduction compared to Natural how this variability influences the

aggregate concrete. For high strength, 28 strength, stiffness, and longevity of

days modulus of elasticity of natural reinforced concrete buildings, has been the

HBRP Publication Page 1-13 2021. All Rights Reserved Page 10

Journal of Building Construction

Volume 3 Issue 2

greatest obstruction to utilizing recycled with satisfactory properties and

concrete. durability is advantageous. The

heterogeneity and uncertainty in the

Based on service load deflection, between consistency and properties of recycled

conventional concrete beams and RCA concrete aggregate, particularly when

reinforced concrete beams, the it is obtained through demolition of

conventional concrete beams are old concrete structures, has been the

performed well. According to Fathifazl et most significant barrier to its usage.

al. (2009), the midspan deflection for RCA • In the vast majority of cases, RCA is

beams was greater than for Natural utilized without any form of treatment,

Aggregate beams under a load of 40% of such as washing, acetic acid treatment,

failure load [25]. Maruyama et al. (2004) one layer cement treatment etc. If one

and Sato et al. (2007) have found that can utilize recycled aggregates by

RCA produces higher midspan deflections providing proper treatment then the

in beams than Natural Aggregate-based water absorption capacity, bulk

concrete. [25]. density and specific gravity will

additionally boost.

CONCLUSIONS • This can be seen that the trend of

Bangladesh is experiencing rapid replacement of recycled concrete

urbanization. High rise building concept aggregate is almost same in brick and

became popular in urban areas due to stone aggregates.

fulfill urban housing demand in

Bangladesh. The Government, • It may conclude based on various

manufacturers and stakeholders should researchers that around 25% to 30% of

discover proper approaches to reuse the natural coarse aggregate can be

building /construction wastes without supplemented with recycled coarse

genuine aggravation to climate. This is a aggregate without adversely altering

work to encourage people for using the properties of concrete.

recycled aggregate in construction works • It is conducted that the strength such

as coarse aggregate. The following are the as compressive strength, flexural

findings of this research: strength and shear strength of the

• Demolition and recovery data for recycled aggregate concrete, is

almost all countries is recorded. But in considered to be weaker than natural

Bangladesh no specific data is found. aggregate due to RCA's high

Nowadays, Bangladesh has started aggregate abrasion, impact, and

research and activities over recycling crushing values.

but has not started large scale like • It's also been discovered that the use

other countries which has to start as of recycled concrete aggregate in

soon as possible for a sustainable structural member is not that much

development. popular because the quality is not

• The principal disadvantage of recycled ensured like natural concrete

concrete aggregate is the adhered aggregate and also due to the greater

mortar layer. If it could be removed as midspan deflection.

much as possible then the properties • Further research is required to get

of concrete would have improved clear picture about RCA, specially

significantly. experiments on RCA is strongly

• The use of RCA as a replacement for recommended.

NCA in the manufacture of concrete

HBRP Publication Page 1-13 2021. All Rights Reserved Page 11

Journal of Building Construction

Volume 3 Issue 2

REFERENCES 10. T.NAWA. [Online].

1. Byron, R. K., & Rahman, M. F. 11. Tam, V. W., Soomro, M., &

(2020). Bangladesh to post highest Evangelista, A. C. J. (2018). A review

GDP growth in Asia this fiscal of recycled aggregate in concrete

year. The Daily Star. applications (2000–

2. Pavan, P. S., Rani, B., Girish, D., 2017). Construction and Building

Raghavendra, K., Vinod, P. N., Materials, 172, 272-292.

Dushyant, V., & Numani, S. (2018). A 12. Singh, S. K., & Sharma, P. C. (2007).

study on recycled concrete Use of recycled aggregates in

aggregates. International Journal of concrete—A paradigm shift. Journal

Pure and Applied of New Building Materials and

Mathematics, 118(18), 3239-3263. Construction World, 13, 173-183.

3. Uddin, M. T., Khan, M. F. A., Kabir, 13. Nair, S. "Centre for secience and

M. R., Awal, M. A., Al Mahbub, A., environment.," [Online].

Hamada, H., & Khatib, J. M. (2010, 14. Ma, Z., Tang, Q., Yang, D., & Ba, G.

December). Recycling of Concrete (2019). Durability studies on the

Made with Brick Aggregate. In 2nd recycled aggregate concrete in China

International Conference on over the past decade: a

Sustainable Construction Materials review. Advances in Civil

and Technologies (pp. 949-959). Engineering, 2019.

4. S. Leahy, nationalgeographic, 2018. 15. Safiuddin, M., Alengaram, U. J.,

5. "Global Waste Index 2019.," Rahman, M. M., Salam, M. A., &

https://sensoneo.com/sensoneo- Jumaat, M. Z. (2013). Use of recycled

global-waste-index-2019/,, 2019. concrete aggregate in concrete: a

6. Afroz, R., Hanaki, K., & Tudin, R. review. Journal of Civil Engineering

(2011). Factors affecting waste and Management, 19(6), 796-810.

generation: a study in a waste 16. Islam, M., & Siddique, M. A. A.

management program in Dhaka City, (2017). Behavior of low grade steel

Bangladesh. Environmental fiber reinforced concrete made with

monitoring and assessment, 179(1), fresh and recycled brick

509-519. aggregates. Advances in Civil

7. Tiwari, P. K., & Nateriya, R. (2007). Engineering, 2017.

Replacement of recycled coarse 17. Yong, P. C., & Teo, D. C. L. (2009).

aggregates with natural coarse Utilisation of recycled aggregate as

aggregates in concrete. Cement and coarse aggregate in concrete. Journal

Concrete Research, 37, 735-72. of Civil Engineering, Science and

8. Sonawane, T. R., & Pimplikar, S. S. Technology, 1(1), 1-6.

(2013). Use of recycled aggregate 18. Keya, N. A. To investigate the effect

concrete. IOSR Journal of Mechanical of using recycled concrete as partial

and Civil Engineering, 52, 59. replacement of coarse aggregate in

9. Mohammed, T. U., Hasnat, A., Awal, concrete strength. Dhaka, 2018.

M. A., & Shamim, Z. B. (2013). 19. Zheng, C., Lou, C., Du, G., Li, X.,

Recycling of Brick Aggregate Liu, Z., & Li, L. (2018). Mechanical

Concrete: Physical and Mechanical properties of recycled concrete with

Properties. In Proceedings of the demolished waste concrete aggregate

Third International Conference on and clay brick aggregate. Results in

Sustainable Construction Materials Physics, 9, 1317-1322.

and Technologies (SCMT3) (pp. 18- 20. Etxeberria, M., Marí, A. R., &

21). Vázquez, E. (2007). Recycled

HBRP Publication Page 1-13 2021. All Rights Reserved Page 12

Journal of Building Construction

Volume 3 Issue 2

aggregate concrete as structural 23. Etxeberria, M., Marí, A. R., &

material. Materials and Vázquez, E. (2007). Recycled

structures, 40(5), 529-541. aggregate concrete as structural

21. Rahman, S. (2017). Comparison of material. Materials and

concrete properties made from structures, 40(5), 529-541.

recycled brick, virgin brick, and 24. Gilroy, W.G.(2016).Why not recycled

natural stone as coarse aggregates. concrete?. University of Notre Dame,

22. Hamad, B. S., & Dawi, A. H. (2017). 2016.

Sustainable normal and high strength 25. McNeil, K., & Kang, T. H. K. (2013).

recycled aggregate concretes using Recycled concrete aggregates: A

crushed tested cylinders as coarse review. International journal of

aggregates. Case Studies in concrete structures and

Construction Materials, 7, 228-239. materials, 7(1), 61-69.

HBRP Publication Page 1-13 2021. All Rights Reserved Page 13

You might also like

- Is 1893 2016Document48 pagesIs 1893 2016navanit patel100% (2)

- Method Statement - FA Silo-12.69m LVLDocument5 pagesMethod Statement - FA Silo-12.69m LVLArunkumarNo ratings yet

- Handrail DesignDocument5 pagesHandrail DesignMuhamadGustiMuharamaNo ratings yet

- Concrete Mix Design C 25 For KamoaDocument9 pagesConcrete Mix Design C 25 For KamoaMitendra Kumar ChauhanNo ratings yet

- Going Green Construction: An Insider's Look at the Trend in Green ConstructionFrom EverandGoing Green Construction: An Insider's Look at the Trend in Green ConstructionNo ratings yet

- Hyd - Ref - Sol - 6 - 23 Sept 2023Document10 pagesHyd - Ref - Sol - 6 - 23 Sept 2023mike reyesNo ratings yet

- Base Plate DesignDocument8 pagesBase Plate DesignHiep Truong Tuan100% (1)

- Recycled Concrete Aggregate General ReviewDocument14 pagesRecycled Concrete Aggregate General ReviewMohammad AkheelNo ratings yet

- Ijce V3i5p125Document6 pagesIjce V3i5p125FE3056 NAGARAJ.SNo ratings yet

- Construction and Building Materials: N. Kisku, H. Joshi, M. Ansari, S.K. Panda, Sanket Nayak, Sekhar Chandra DuttaDocument20 pagesConstruction and Building Materials: N. Kisku, H. Joshi, M. Ansari, S.K. Panda, Sanket Nayak, Sekhar Chandra DuttaGebremeskel TigabuNo ratings yet

- A Critical Review and Assessment For Usage of Recycled Aggregate As Sustainable Construction MaterialDocument21 pagesA Critical Review and Assessment For Usage of Recycled Aggregate As Sustainable Construction MaterialHERIBERT NELSON GIANCARLOS ROJAS ROMERONo ratings yet

- 2020aplicación de Materiales de Desecho Domésticos e Industriales en El Hormigón Una RevisiónDocument6 pages2020aplicación de Materiales de Desecho Domésticos e Industriales en El Hormigón Una RevisiónYudy Alejandra Buitrago MuñozNo ratings yet

- Vijju Updated NewDocument36 pagesVijju Updated NewKiran Rathod RitesNo ratings yet

- Use of SCC and Rca For Sustainable ConstructionDocument5 pagesUse of SCC and Rca For Sustainable ConstructionInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Innovative Study On Reusing Demolished WasteDocument3 pagesInnovative Study On Reusing Demolished Wastehasnath kpNo ratings yet

- Article 1 Jers Volume II Issue I January - March 2011Document9 pagesArticle 1 Jers Volume II Issue I January - March 2011Khan FaisalNo ratings yet

- Paper 6Document7 pagesPaper 6Tyler WhiteNo ratings yet

- Chapter 1Document6 pagesChapter 114C151 SWATHI B.No ratings yet

- Características de Compactación de La Arcilla de Bangkok Estabilizada Con Cenizas de Cáscara de Arroz, Cenizas de Fondo y CalDocument8 pagesCaracterísticas de Compactación de La Arcilla de Bangkok Estabilizada Con Cenizas de Cáscara de Arroz, Cenizas de Fondo y CalHeiner Requejo RamosNo ratings yet

- Demolition WasteDocument10 pagesDemolition WasteMilena EscalanteNo ratings yet

- Study of Recycled Concrete AggregatesDocument3 pagesStudy of Recycled Concrete AggregatesIsabela KotelakNo ratings yet

- 72 80 3857 Krissana Aug 2023 108 z1Document9 pages72 80 3857 Krissana Aug 2023 108 z1Muhammad EnricoNo ratings yet

- Sjeat 811 267-273Document7 pagesSjeat 811 267-273OksNo ratings yet

- Chap 1Document3 pagesChap 1emmanuelezekulie2No ratings yet

- Application of Recycled Aggregate in Concrete: A ReviewDocument5 pagesApplication of Recycled Aggregate in Concrete: A Reviewmohamed alyozbakiNo ratings yet

- Materials 16 05842Document13 pagesMaterials 16 05842Farjallah Al-AssãadNo ratings yet

- Human SettlementDocument6 pagesHuman SettlementMd Mhafuzur RahmanNo ratings yet

- Use of Recycled and Waste Materials in Concrete A Serbian PerspectiveDocument8 pagesUse of Recycled and Waste Materials in Concrete A Serbian PerspectiveMhel LaurelNo ratings yet

- A Review On Green Concrete: November 2014Document4 pagesA Review On Green Concrete: November 2014Abdul RahmanNo ratings yet

- Construction and Building Materials: Farid Debieb, Luc Courard, Said Kenai, Robert DegeimbreDocument6 pagesConstruction and Building Materials: Farid Debieb, Luc Courard, Said Kenai, Robert DegeimbreDaniela Vega AraujoNo ratings yet

- 20 Ce 137 PDFDocument6 pages20 Ce 137 PDFPtpgStucNo ratings yet

- Self Compaction High Performance Green Concrete For Sustainable DevelopmentDocument7 pagesSelf Compaction High Performance Green Concrete For Sustainable DevelopmentSOMNo ratings yet

- 123 Research On RecyledDocument5 pages123 Research On RecyledDEEPAK SHARMANo ratings yet

- 10 1016@j Conbuildmat 2011 12 020 PDFDocument8 pages10 1016@j Conbuildmat 2011 12 020 PDFFadhilatul rohmaNo ratings yet

- 2011-Effectiveness of Using Coarse Recycled Concrete Aggregate in Concrete PDFDocument7 pages2011-Effectiveness of Using Coarse Recycled Concrete Aggregate in Concrete PDF8790922772No ratings yet

- Recycled Construction AggregatesDocument4 pagesRecycled Construction AggregatesPiyush BhandariNo ratings yet

- Construction and Building MaterialsDocument13 pagesConstruction and Building MaterialsIsadora CresteNo ratings yet

- Role of Laws To Control Brick Manufacturing and KiDocument14 pagesRole of Laws To Control Brick Manufacturing and Kihossenriday41No ratings yet

- 100034014Document11 pages100034014Ar Vishul SaxenaNo ratings yet

- Hansen1986 Article RecycledAggregatesAndRecycledA PDFDocument46 pagesHansen1986 Article RecycledAggregatesAndRecycledA PDFAmeya KulkarniNo ratings yet

- Recycled ConcreteDocument7 pagesRecycled Concreteali najatNo ratings yet

- Use of SCC and Rca For Sustainable ConstructionDocument5 pagesUse of SCC and Rca For Sustainable ConstructionesatjournalsNo ratings yet

- 2Document7 pages2Ar Vishul SaxenaNo ratings yet

- Research Paper (Recycled Concrete)Document9 pagesResearch Paper (Recycled Concrete)Abhimanyu KumarNo ratings yet

- Evaluation of Characteristics of Concrete Mixed With Bamboo Leaf AshDocument14 pagesEvaluation of Characteristics of Concrete Mixed With Bamboo Leaf AshYasndra AbeygunewardhaneNo ratings yet

- FullPaperJCI2011 MiaWimalaSoejoso16Document7 pagesFullPaperJCI2011 MiaWimalaSoejoso16MD. MUSHFIQUE -US-SALEHEEN, 180051234No ratings yet

- An Experimental Study On Utilization of Demolished Concrete Waste For New ConstructionDocument6 pagesAn Experimental Study On Utilization of Demolished Concrete Waste For New ConstructionVennela ReddyNo ratings yet

- Green Concrete - Report For IBCDocument8 pagesGreen Concrete - Report For IBCAbhinav Srivastava67% (3)

- Experimental Investigational Study On The Physical Properties of A New Concrete Mixture Prepared With Recycled AggregateDocument12 pagesExperimental Investigational Study On The Physical Properties of A New Concrete Mixture Prepared With Recycled AggregateEditor IJTSRDNo ratings yet

- SCC Coconut Shell 3Document4 pagesSCC Coconut Shell 3NikhilNo ratings yet

- D Brick AggregateDocument40 pagesD Brick AggregateHekato AssumiNo ratings yet

- Brick 2Document13 pagesBrick 2GABRIEL MARTIN GUILLEN TORRESNo ratings yet

- Closed-Loop Recycling of Recycled Concrete Aggregates: Cite This PaperDocument7 pagesClosed-Loop Recycling of Recycled Concrete Aggregates: Cite This PaperJayro MendozaNo ratings yet

- M 14 PDFDocument30 pagesM 14 PDFadidas100% (1)

- Impact of Recycled Aggregate On The Mechanical-Andrea PiccinaliDocument19 pagesImpact of Recycled Aggregate On The Mechanical-Andrea PiccinaliRohit UbnareNo ratings yet

- Behavior of Concrete Utilizing Recycled Aggregate - A ReviewDocument10 pagesBehavior of Concrete Utilizing Recycled Aggregate - A ReviewShivaji DhoneNo ratings yet

- REplacement of Natural Sand With Efficient Alternatives PDFDocument8 pagesREplacement of Natural Sand With Efficient Alternatives PDFjerald bordenNo ratings yet

- 1 s2.0 S095965261830742X MainDocument20 pages1 s2.0 S095965261830742X MainHassan juttNo ratings yet

- Study of The Application of Glass Waste in Concrete ProductionDocument11 pagesStudy of The Application of Glass Waste in Concrete ProductionIJAERS JOURNAL100% (1)

- Cement ProductionDocument17 pagesCement Productionmuhammad wahid romadhoniNo ratings yet

- Utilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsDocument11 pagesUtilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsApoorva AgarwalNo ratings yet

- 118Document9 pages118Suhail KhanNo ratings yet

- The Use of Scrap Tires in The Construction Sector: January 2019Document5 pagesThe Use of Scrap Tires in The Construction Sector: January 2019Olivier GouveiaNo ratings yet

- Reddy Et Al, Physical Chemical and Geo Characterization of Fly Ash Bottom Ash and Municipal Solid Waste in IndiaDocument23 pagesReddy Et Al, Physical Chemical and Geo Characterization of Fly Ash Bottom Ash and Municipal Solid Waste in IndiaAnandro AmellonadoNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Solar Powered Irrigation Would Accelerate Indias Energy Transition June 2021Document13 pagesSolar Powered Irrigation Would Accelerate Indias Energy Transition June 2021litacoNo ratings yet

- An Approach For The Economical EvaluatioDocument6 pagesAn Approach For The Economical EvaluatiolitacoNo ratings yet

- Research On Comparative Advantages of SPV PumpingDocument7 pagesResearch On Comparative Advantages of SPV PumpinglitacoNo ratings yet

- NEPAL SITUATION ANALYSIS REPORT - Final Version 3Document52 pagesNEPAL SITUATION ANALYSIS REPORT - Final Version 3litacoNo ratings yet

- INDIA SITUATION ANALYSIS REPORT - Final Version 3Document41 pagesINDIA SITUATION ANALYSIS REPORT - Final Version 3litacoNo ratings yet

- 02 Rapid Assess 2 AEPC Final 15052020Document45 pages02 Rapid Assess 2 AEPC Final 15052020litacoNo ratings yet

- BANGLADESH SITUATION ANALYSIS REPORT - Final Version 2Document47 pagesBANGLADESH SITUATION ANALYSIS REPORT - Final Version 2litacoNo ratings yet

- IRENA RE Jobs 2021Document98 pagesIRENA RE Jobs 2021litacoNo ratings yet

- 2019 - Powerpoint - Sustainable & EE Brick Production in Bangladesh 2019-2030Document25 pages2019 - Powerpoint - Sustainable & EE Brick Production in Bangladesh 2019-2030litacoNo ratings yet

- Fluid Dynamics: Continuity Equation. The Continuity Equation States That The Flow PassingDocument3 pagesFluid Dynamics: Continuity Equation. The Continuity Equation States That The Flow PassingCiero John MarkNo ratings yet

- AY1516 Cuthbert's Reflections On LTA C923Document14 pagesAY1516 Cuthbert's Reflections On LTA C923bloodicewineNo ratings yet

- Falling Ball Viscometer: Abhishek Suman Department of Energy Science and Engineering IIT BombayDocument12 pagesFalling Ball Viscometer: Abhishek Suman Department of Energy Science and Engineering IIT BombayPratham sehgalNo ratings yet

- Shaft Failure Journal PDFDocument7 pagesShaft Failure Journal PDFBahim BahimanNo ratings yet

- Original Three ChapterDocument45 pagesOriginal Three ChapterNiyobuhungiro DominiqueNo ratings yet

- Installation Mantainance ManualFan CoilYEKN YGKNDocument19 pagesInstallation Mantainance ManualFan CoilYEKN YGKNJavier SosaNo ratings yet

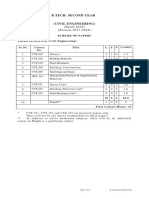

- B.Tech (Civil Engineering) Part-II (Sem III & IV) Batch 2016 PDFDocument27 pagesB.Tech (Civil Engineering) Part-II (Sem III & IV) Batch 2016 PDFHoe BhajiNo ratings yet

- Drawings Hanson Park H19!25!0010 Part4Document40 pagesDrawings Hanson Park H19!25!0010 Part4DhanyaNo ratings yet

- Ae Lab1Document4 pagesAe Lab1Ali SagırNo ratings yet

- Agard Ag 207Document186 pagesAgard Ag 207Arockia FenilNo ratings yet

- Khaleeq PaperDocument125 pagesKhaleeq Papervikas chawlaNo ratings yet

- MCT - Cement PaintsDocument13 pagesMCT - Cement PaintsIshika AgarwalNo ratings yet

- Hardinge Bridge To Padma BridgeDocument23 pagesHardinge Bridge To Padma BridgeBridge WingNo ratings yet

- Wing Wall DesignDocument3 pagesWing Wall DesignDhaivatNo ratings yet

- CE 2203 Construction Techniques, Equipment & Practices ABBREVIATIONS # Expansion Unit 1Document11 pagesCE 2203 Construction Techniques, Equipment & Practices ABBREVIATIONS # Expansion Unit 1Rajha RajeswaranNo ratings yet

- CEE 110 Lecture 1Document29 pagesCEE 110 Lecture 1Tousif RahmanNo ratings yet

- Jiroga Weir SchemeDocument10 pagesJiroga Weir SchemeShashi PrakashNo ratings yet

- Flare Boom Engineering - Failure - DrillSafeDocument11 pagesFlare Boom Engineering - Failure - DrillSafeAndrey RogozhaNo ratings yet

- ENGR 244 Final Lab (Final)Document22 pagesENGR 244 Final Lab (Final)snakeNo ratings yet

- DRG 02Document1 pageDRG 02Palak BhatiaNo ratings yet

- Screw Jack OptimizationDocument3 pagesScrew Jack OptimizationEsmael Adem0% (1)

- RCCDocument46 pagesRCCNareshNo ratings yet

- RCD ExcelDocument17 pagesRCD ExceljunNo ratings yet

- Combined & Separate Sewer SystemsDocument9 pagesCombined & Separate Sewer SystemsKhairylle JuanNo ratings yet