Professional Documents

Culture Documents

Raw Materials For Making Jingdezhen Porcelain From The Five Dynasties To The Qing Dynasty

Uploaded by

FURY FURIONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raw Materials For Making Jingdezhen Porcelain From The Five Dynasties To The Qing Dynasty

Uploaded by

FURY FURIONCopyright:

Available Formats

Raw Materials for Making Jingdezhen Porcelain from the

Five Dynasties to the Qing Dynasty

C. T. YAP* and Y O U N A N H U A

Department of Physics, National University of Singapore, Singapore 0511

This is a study of 66 pieces of Jingdezhen porcelain bodies and their J I N G D E Z H E N P O R C E L A I N S A N D RAW

relation to 13 raw materials, three of which are kaolin and the rest MATERIALS

porcelain stones from Jingdezhen. For Jingdezhen porcelains, the results

show that the alumina content increases and silica content decreases as Jingdezhen is in south China in the Jiangxi province.

a function of time, except during the Yuan and Ming Dynasties, when It has been the most famous porcelain production center

this trend was reversed. For raw materials, although kaolin could never in China as well as in the world. Most of the world's fine

be used alone for porcelain production, four of the porcelain stones could porcelains of imperial quality in museums and in private

be used alone for this purpose during the Five Dynasties and part of the collections come from Jingdezhen. Recent excavations

Song Dynasty. However, all porcelains made thereafter have varying show that white porcelains were produced as early as the

amounts of kaolin added to the porcelain stone. Except for a reversal

during the Yuan and Ming Dynasties, we found that the amount of kaolin

Five Dynasties. By the Ming Dynasty, very high quality

added was a function of time, reaching as high as about 60% during the pieces were produced, with a fine-grained body and thick

Qing Dynasty. glaze giving rise to small ripples called "orange peel."

Index Headings: Principal component analysis; Chinese porcelain; Raw In this paper, we use principal component analysis to

materials. study the relationship between the porcelain bodies of

66 Jingdezhen pieces and 13 different Jingdezhen raw

INTRODUCTION materials for porcelain making. Table I gives the chem-

ical compositions of the seven major and minor chemical

There have been many scientific studies of Chinese constituents ( S i 0 2 , A1203, Fe203, K20, Na20, CaO, and

porcelains in recent years, both by destructive chemical MgO) for the 66 pieces of Jingdezhen porcelain bodies

analysis of major and minor chemical constituents ~ and from the Five Dynasties to the Qing Dynasty. 21 Table II

by nondestructive trace element analysis. 7-18This paper gives the mean concentration of each chemical constit-

looks at the possible raw materials for making Jingde- uent in each dynasty for the Jingdezhen porcelains given

zhen porcelain bodies during the Five Dynasties (907- in Table I.

960), Song Dynasty (960-1280), Yuan Dynasty (1280- Table III gives the chemical composition (Si02, A1203,

1368), Ming Dynasty (1368-1644), and Qing Dynasty Fe203, TiO2, CaO, MgO, K 2 0 , N a 2 0 , and MnO) of 13

(1644-1911). Jingdezhen raw materials: R1-R9, ~R10 (see Ref. 6, which

Raw material for porcelain making has been the de- also contains R1-R4 and R7), and R l l - R 1 3 . 2 For pur-

termining factor in the development of Chinese porce- poses of porcelain production, R10 has to be normalized

lain, as evidenced by the production of the characteristic to 100 % without ignition loss, and for purposes of com-

highly siliceous southern Chinese wares and the equally parison, for R l l - R 1 3 the values of FeO have been con-

characteristic aluminous northern Chinese wares. Recent verted to Fe203. The raw materials listed are of two types:

studies show that, in contrast to the feldspathic materials kaolin (R1-R3) and porcelain stone (R4-R13).

used in Western porcelains, ancient Chinese porcelains In general, kaolin contains too much alumina ( ~ 4 0 % )

in general do not contain feldspar-rich materials except and too little flux and therefore will not vitrify at tem-

for certain wares such as those from the Gongxian in peratures below 1400°C. As such high temperatures were

Henan province. 19 Therefore, the word "feldspathic," difficult to attain, pure kaolin alone could not be used

whether applied to the body or glaze, should not be used to produce porcelain. However, Chinese porcelain stone

in general for Chinese ceramics. is suitable for making porcelain because it is plastic like

Our previous study 2° of the body material of 66 pieces kaolin and contains enough fusible materials, mainly in

of Jingdezhen porcelains shows that porcelains made the form of potassium mica known as sericite.

during the Five Dynasties, Yuan Dynasty (or Ming Dy-

nasty), and Qing Dynasty can be segregated completely,

without any overlap between them. Results also show P R I N C I P A L C O M P O N E N T ANALYSIS

that the percentage of silica in the porcelain body de- The objective of principal component analysis is to

creases and that of alumina increases as a function of take multiple variables (in this case, the concentrations

time, with the exception of the porcelain of the Yuan of the oxides of seven major and minor elements: SiO2,

and Ming Dynasties, when this trend was reversed. All A1203, Fe203, CaO, MgO, K20, and Na20) and find linear

these results indicate the use of different raw materials combinations, with principal component 1 having the

in different periods. largest variance, principal component 2 the second larg-

est variance and so on. Therefore, if the data are highly

correlated positively or negatively, we can reduce the

Received 22 May 1992. number of dimensions drastically from 7 to 2 or 3, de-

* Author to whom correspondence should be sent. pending on the data, since in general there is a good deal

1488 Volume 46, Number 10, 1992 0003-7028/92/4610-i48852.0o/0 APPLIED SPECTROSCOPY

© 1992 Society for Applied Spectroscopy

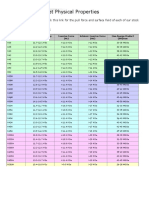

TABLE I. Chemical composition of Chinese porcelains from the Five Dynasties to the Qing Dynasty for Jingdezhen porcelain bodies (wt %).

Code in the Type of Chinese

No. Code original porcelain bodies Dynasties Si02 AI20a Fe~03 K20 Na20 CaO MgO

1 F1 150 Celadon body Five Dynasties 75.16 16.92 2.19 2.37 0.14 0.40 0.64

2 F2 T2-1 White Glaze body Five Dynasties 77.48 16.93 0.77 2.63 0.35 0.80 0.51

3 F3 T2°2 White Glaze body Five Dynasties 76.96 18.04 0.81 2.97 0.25 0.57 0.35

4 F4 TS3-1 White Glaze body Five Dynasties 74.58 19.24 1.12 2.35 0.56 1.27 0.20

5 F5 TS3-2 White Glaze body Five Dynasties 75.84 18.33 1.00 2.44 0.40 0.73 0.76

6 S1 JHYQ-1 Yingqing body Song 75.48 18.37 0.86 2.63 1.34 0.57 0.03

7 $2 JHYQ-2 Yingqing body Song 74.71 18.40 0.84 2.92 1.00 0.63 0.18

8 $3 JHYQ-4 Yingqing body Song 75.91 17.24 0.83 2.47 2.15 0.55 0.13

9 $4 JHYQ-5 Yingqing body Song 77.32 16.54 0.65 2.87 0.39 0.87 0.54

10 $5 JHYQ-7 Yingqing body Song 74.86 18.14 0.93 2.37 1.83 0.62 0.62

11 $6 JHYQ-8 Yingqing body Song 75.60 16.31 1.12 2.62 2.68 0.59 0.43

12 $7 S10-1 Yingqing body Song 75.41 18.15 0.81 2.95 0.46 0.96 0.63

13 $8 S10-2 White Glaze body Song 76.52 18.80 0.70 2.71 0.29 0.35 0.11

14 $9 S10-5 White Glaze body Song 75.92 18.53 0.71 2.99 0.49 0.76 0.30

15 S10 S10-6 White Glaze body Song 77.39 17.54 0.63 2.85 0.21 0.54 0.35

16 Sll $9-1 Yingqing body Song 76.24 17.56 0.58 2.76 1.02 1.36 0.10

17 S12 $9-2 Yingqing body Song 74.70 18.65 0.96 2.79 1.49 1.01 0.50

18 S13 $9-5 Yingqing body Song 77.79 16.16 0.59 3.25 1.14 0.40 0.16

19 Y1 Q4 Blue-and-White body Yuan 72.75 20.24 0.93 2.87 1.78 0.24 0.15

20 Y2 Q5 Blue-and-White body Yuan 72.64 21.08 0.97 2.69 1.52 0.20 0.18

21 Y3 $9-4 Yingqing body Yuan 72.94 19.86 0.88 2.11 2.78 0.56 0.30

22 Y4 SHUFU-2 Shufu body Yuan 73.75 19.52 1.40 3.18 2.03 0.18 0.21

23 Y5 SHUFU-3 Shufu body Yuan 72.73 20.70 1.16 2.74 2.39 0.14 0.17

24 Y6 SHUFU-4 Shufu body Yuan 72.15 21.59 1.19 2.81 2.12 0.06 0.18

25 Y7 SHUFU-5 Shufu body Yuan 73.06 20.89 1.17 2.84 1.96 0.10 0.25

26 Y8 SHUFU-6 Shufu body Yuan 72.71 21.43 1.25 3.07 1.57 0.18 0.20

27 Y9 Y-11 Blue-and-White body Yuan 74.58 19.53 0.81 2.72 2.34 0.04 0.17

28 Y10 Y-8 Blue-and-White body Yuan 74.91 19.47 0.16 3.03 2.39 0.90 0.08

29 Yll Y-2 White Glaze body Yuan 72.28 21.83 0.91 3.25 0.78 0.93 0.28

30 Y12 Y-5 Blue-and-White body Yuan 71.95 20.75 0.84 2.73 2.76 0.15 0.16

31 M1 MJVR1 Coloured Glaze body Ming 74.93 18.03 0.70 3.21 1.66 0.12 0.19

32 M2 SM10-1 Blue-and-White body Ming 73.35 20.76 1.25 3.26 0.42 0.60 0.21

33 M3 MM-1 Blue-and-White body Ming 75.31 18.20 0.73 4.28 1.75 0.65 0.16

34 M4 MM-2 Blue-and-White body Ming 74.39 20.49 0.87 3.52 0.63 0.41 0.18

35 M5 MM-4 Blue-and-White body Ming 76.03 19.17 1.04 3.26 0.14 0.53 0.26

36 M6 M-I' Blue-and-White body Ming 72.84 19.03 0.60 3.11 3.54 0.75 0.30

37 M7 M1 White Glaze body Ming 73.58 20.05 0.90 2.87 2.01 0.53 0.14

38 M8 Q12 Blue-and-White body Ming 74.05 19.97 0.79 3.13 1.16 0.13 0.16

39 M9 M-1 Blue-and-White body Ming 73.66 21.24 0.59 3.12 0.60 0.12 0.15

40 M10 MM-6 Blue-and-White body Ming 72.80 20.64 1.66 4.08 0.14 0.54 0.31

41 Mll MM-7 Blue-and-White body Ming 74.63 18.83 1.25 3.18 1.15 1.02 0.26

42 M12 MM-8 Blue-and-White body Ming 74.35 18.33 1.27 3.81 1.09 1.31 0.28

43 M13 M10 White Glaze body Ming 74.53 19.97 0.84 3.18 0.60 0.45 0.15

44 M14 M-4 Blue-and-White body Ming 73.38 18.49 1.24 3.30 1.00 1.21 0.18

45 M15 M-7 Blue-and-White body Ming 74.29 19.41 0.88 3.80 1.42 0.27 0.20

46 M16 M5 Blue-and-White body Ming 73.99 18.90 1.08 3.05 1.69 1.19 0.27

47 M17 MM-10 Blue-and-White body Ming 74.75 18.53 0.77 4.02 1.89 0.66 0.23

48 M18 MM-9 Blue-and-White body Ming 75.33 18.99 0.76 3.36 1.60 0.39 0.22

49 M19 MM-11 Blue-and-White body Ming 73.48 20.20 1.02 3.79 1.86 0.42 0.20

50 M20 M-8 Blue-and-White body Ming 73.59 19.61 0.87 3.46 1.95 0.46 0.17

51 M21 M-9 Blue-and-White body Ming 75.62 19.12 0.99 3.55 0.86 0.24 0.18

52 M22 M3 Blue-and-White body Ming 71.69 20.69 1.26 3.37 1.55 1.01 0.28

53 M23 MM-13 Blue-and-White body Ming 72.42 21.69 0.74 3.51 0.95 1.02 0.18

54 Q~ C-1 Blue-and-White body Qing 68.07 25.82 0.83 3.04 1.54 0.36 0.11

55 Q2 C-2 Blue-and-White body Qing 65.76 28.57 0.84 3.22 0.83 0.50 0.12

56 Q3 Cll Five Colours body Qing 66.33 26.33 1.37 2.91 2.44 0.65 0.09

57 Q4 C12 Blue-and-White body Qing 68.59 24.08 1.15 3.13 2.35 0.71 0.30

58 Q~ C14 Five Colours body Qing 66.67 26.25 0.91 2.56 2.15 1.25 0.33

59 Q8 C17 Doucai body Qing 65.09 26.72 1.06 3.11 2.57 1.62 0.13

60 Q7 C4 Blue-and-White body Qing 70.22 22.97 0.81 3.49 1.18 0.68 0.11

61 Qs C13 Famille-rose body Qing 67.78 26.25 0.84 3.28 1.12 0.71 0.16

62 Q9 C15 Famille-rose body Qing 66.27 27.42 0.77 3.07 1.29 1.36 0.13

63 Q~o C22 Blue-and-White body Qing 65.81 30.51 1.07 1.81 0.26 0.22 0.15

64 Q~I C5 Blue-and-White body Qing 70.38 24.10 0.82 3.33 0.69 0.66 0.15

65 Q12 C20 White Glaze body Qing 67.28 27.20 0.67 3.41 0.95 0.63 0.18

66 Q13 C21 Blue-and-White body Qing 68.93 24.25 0.84 2.38 1.87 0.74 0.20

of redundancy in the original variables, as most of them p l e s f r o m f i v e p e r i o d s ( F i v e D y n a s t i e s = 5, S o n g = 13,

are measuring similar things. Y u a n = 12, M i n g = 23, a n d Q i n g = 13) f o r m a d a t a m a t r i x

For porcelain bodies, the concentrations of the oxides X~N×M) w h e r e X,m is t h e v a l u e o f t h e c o n c e n t r a t i o n of

of seven major and minor elements measured on 66 sam- c o m p o u n d m m e a s u r e d o n s a m p l e n. T h e m e a n 2m a n d

APPLIED SPECTROSCOPY 1489

TABLE II. The mean concentration of each chemical constituent in on the principal components, we auto-scaled the d a t a to

each dynasty for Jingdezhen porcelains (wt %). have zero m e a n and unit variance:

Num-

b e r of

Xnm - - Xm

z,m (3)

sam- 8m

Dynasties ples SiO2 A1203 Fe203 K20 Na20 CaO MgO

T h e principal c o m p o n e n t s P are calculated 22 as linear

Five Dynasties 5 76.00 17.89 1.18 2.55 0.34 0.75 0.49 combinations of the original variables (concentrations of

Song Dynasty 13 75.99 17.72 0.79 2.78 1.12 0.71 0.31

Yuan Dynasty 12 73.04 20.57 0.97 2.84 2.04 0.31 0.19 c o m p o u n d s ) so t h a t the first principal c o m p o n e n t has

Ming Dynasty 23 74.04 19.58 0.96 3.44 1.29 0.61 0.21 the largest variance, the second principal c o m p o n e n t has

Qing Dynasty 13 67.44 26.19 0.92 2.98 1.48 0.78 0.17 the second largest variance and is orthogonal to the first,

and so on. This calculation is expressed as

M

s t a n d a r d deviation sm of the concentration of each com- P.k = ~_~ ZnrnVrnk (4)

p o u n d are given by: m=l

where Pnh is the value of the k t h principal c o m p o n e n t

• m = ~f x.m (1) for sample n, a n d vmh the ruth t e r m of the k t h eigenvector

n=l

of the (M x M ) correlation matrix.

1 N

s~ - ~ (x,m - ~m)2. (2)

N- ln= 1 RESULTS AND DISCUSSION

For each raw material, N = 67 since principal c o m p o n e n t One R a w M a t e r i a l for P o r c e l a i n B o d i e s . Figure 1 shows

analysis is p e r f o r m e d on the 66 pieces plus I raw material, a plot of principal c o m p o n e n t s 1 and 2 for the 66 pieces

b u t m is still 7, as explained later. T o avoid the concen- of J i n g d e z h e n porcelains (Table I) a n d the 13 raw ma-

tration of any c o m p o u n d from having too m u c h influence terials (Table III) using the seven chemical constituents

£,,4/

Z 4

g

/ i FIVE DYNASTIES

°

R1 R3° o R2 2-------~QING

o

a_'~-2 / /

/I

n

~ MING

.,.~[~*~,..~,,~ ~,.z~ PRINCIPAL COMPONENT 1

" 4

X~l?

YUAN ~ " :-~,~,? V,"-/ AR9

• FIVE DYNASTIES --2~/ ~/SONG

• SONG

• YUAN

× MING A R10

• QING ~ R6

o RAW MATERIALS (KAOLIN)

"--4

" RAW MATERIALS (PORCELAIN STONE) A R13

"-5 ~ R5

FIG. 1. Plot of principal components 1 and 2 for 66 pieces of Jingdezhen porcelains and 13 different raw materials using the concentrations of

seven chemical constituents (SiO2, A12Q, Fe203, CaO, MgO, K20, and Na20).

1490 Volume 46, Number 10, 1992

z 4

W

Z

O

12_ FIVE DYNASTIES

O

li

(D

QING __1

< .i I

-,

------/2-"'.,

o'eJgO °/~" ~ ~_50/o ~:

/ j

6oo/ ,. -,o " - <

½.....? " \ XI.. PRINCIPAL COMPONENT 1

>

-6 4

40% ~ \\'-----'-~.~/ { :'~ ~0"- /" ,~0,''- ..

",, RB

•

• SONG

• YUAN

FIVE DYNA',,STIES 30/o

o'0,\

,,, Y U A N

\ ~,x

;",,i',

~ \ "- ./.,

\/X~ SONG

"

\ \Q

-2 2

× MING

10O/o'- \

• QING \

o RAW MATERIALS (KAOLIN) \" R10

,, RAW MATERIALS (PORCELAIN STONE)

MIXED RAW MATERIALS --4

(KAOLIN + PORCELAIN STONE)

FIG. 2. P l o t of principal c o m p o n e n t s 1 a n d 2 for 66 pieces of Jingdezhen porcelain and various mixtures of two types of raw materials: kaolin

(R3) and porcelain stones (R8, R9, a n d RI0) u s i n g t h e c o n c e n t r a t i o n s of seven chemical c o n s t i t u e n t s (SiO2, A1203, Fe203, CaO, MgO, KzO, and

Na20).

(SiO2, A1203, Fe203, CaO, MgO, K20, and Na20). Each Five Dynasties and the Song Dynasty indicates the use

point for the raw material was obtained by applying prin- of similar raw materials. The complete segregation, as

cipal component analysis to the 66 Jingdezhen porcelains between Qing porcelains and Yuan porcelains or between

plus that raw material. In other words, to plot the 13 Yuan porcelains and Song porcelains, indicates that rath-

points for the raw materials in Fig. 1, we performed prin- er different compositions of raw materials were used. As

cipal component analysis 13 times. discussed previously, 2° in Fig. 1 from right to left the

The appreciable overlap between porcelains from the percentage of silica in the porcelain body decreases and

TABLE III. Chemical composition of raw materials used in Jingdezhen porcelain bodies (wt %).

Code in

No. original ~ Name Si02 A1203 Fe~03 TiO2 CaO MgO K20 Na20 MnO Total

R1 R1 Xingzi kaolin (refined clay) 54.60 41.30 1.46 -.. 0.15 0.22 2.01 0.19 0.16 100.09

R2 R2 Mingsha kaolin 55.62 37.89 1.27 0.06 0.37 0.26 3.02 1.15 0.37 100.01

R3 R3 Mingsha kaolin (refined clay) 53.60 40.47 1.11 0.05 0.50 0.28 2.82 1.07 0.16 100.06

R4 R4 Qimen porcelain stone 76.20 16.30 0.58 0.09 1.90 0.36 3.92 0.61 0.02 99.98

R5 R5 Qimen porcelain stone 73.00 18.45 0.69 0.07 2.20 0.42 4.82 0.56 0.01 100.06

(refined clay)

R6 R6 S a n b a o p e n g porcelain stone 71.70 18.10 0.70 -.- 0.55 0.09 4.10 4.77 ... 100.01

R7 R7 N a n k a n g porcelain stone 78.74 15.50 0.79 ... 1.50 ..- 2.87 0.44 0.06 100.00

R8 R8 Yaolidongshi porcelain stone 80.50 14.45 0.85 0.07 0.38 0.46 3.54 0.19 ..- 100.44

R9 R9 Shoxiwu porcelain stone 77.70 16.20 1.18 0.13 0.03 0.24 3.97 0.56 0.04 100.05

R10 a S a n b a o p e n g porcelain stone 74.78 15.56 0.71 ... 0.71 0.16 4.19 3.85 0.04 100.00

Rll b N a n k a n g porcelain stone 77.50 16.60 0.67 ... 0.80 0.40 3.20 0.90 .-. 100.07

R12 b Porcelain s t o n e (Vogt, 1900) 76.10 18.00 1.11 -.. 0.20 0.20 4.10 0.40 ... 100.11

R13 b S a n b a o p e n g porcelain stone 77.80 14.50 0.44 -.. 0.20 0.10 2.10 4.60 P20~ 100.04

0.30

"Note: (a) Data have been normalized to 100% w i t h o u t ignition loss. (b) FeO values have been converted into Fe203 values.

APPLIED SPECTROSCOPY 1491

C'q

t-- 4

Z

I,I

Z

O

n / FIVE DYNASTIES

R3 8

-" ":# --"-~r. - _ 60°/o ~

- #oo/o

-2

M'NG / ¢ m /

//I

I I I ". / AA

,V / PRINCIPAL COMPONENT 1

"~ I &

x

2~/ "~

QING

o RAW MATERIALS (KAOLIN)

A RAW MATERIALS (PORCELAIN STONE)

® MIXED RAW MATERIALS

(KAOLIN.PORCELAIN STONE) --4

FIG. 3. Plot of principal components 1 and 2 for 66 pieces of Jingdezhen porcelains and various mixtures of two types of raw materials: kaolin

(R3) and porcelain stones (R4, R l l , and R12) using the concentrations of seven chemical constituents (SiO2, A1203, Fe~O3, CaO, MgO, K20 and

Na20).

that of alumina increases as a function of time from the Vogt porcelain stone (R12) as a one-material porcelain

Five Dynasties to the Qing Dynasty, with the exception stone during the Song Dynasty. Furthermore, it seems

of the Yuan and Ming Dynasties, when this trend was likely that Yaolidongshi porcelain stone (R8) and San-

reversed. baopeng porcelain stone (R6, R10, and R13) could not

The raw material kaolin comes from the high ridge be used alone for the production of Jingdezhen porcelains

known as Kaolin, which is about 28 miles from north- unless they were mixed with kaolin. It is interesting to

north-east Jingdezhen. As kaolin has a high alumina note that the refined Qimen porcelain stone (R5, refined)

( ~ 4 0 % ) and low silica (~55%) content, the kaolin raw is located at the extreme bottom whereas the unrefined

materials R1-R3 appear clustered on the left of Fig. 1. Qimen porcelain stone (R4) is located near the Song

Obviously, these points on the graph are far away from pieces, indicating that the Qimen porcelain stone used

any of the points for Jingdezhen porcelains, and there- in Song porcelain production was not washed and refined.

fore could never have been used for one-material por- Mixed Raw Materials for Porcelain Bodies. From Fig.

celain production. Therefore, Xingzi kaolin (R1) or 1, it is evident that from the time of the Yuan Dynasty

Mingsha kaolin (R2 and R3) must be mixed with por- (and later part of the Song Dynasty) porcelains made in

celain stone for the production of Qing, Ming, Yuan, and Jingdezhen were composed of a mixture of porcelain stone

certain Song porcelains. and kaolin. In order to study quantitatively the propor-

Similar raw materials were used during the Five Dy- tion of kaolin added to the porcelain stone, we first looked

nasties and part of the Song Dynasties because of the at the possible candidates for kaolin and porcelain stone,

appreciable overlap of porcelains during these periods. selecting appropriate ones for further investigation.

The most likely candidate would be the Nankang por- With regard to kaolin, Xingzi kaolin (R1) was not used

celain stone (R7 and R l l ) . Thus, during these periods, until the late nineteenth century 1 and therefore will be

Jingdezhen porcelain bodies were made of porcelain stone left out of our discussion. The most typical kaolin used

only. In the figure, the Five Dynasties piece at the top in Jingdezhen is Mingsha kaolin from Fuliangdong xiang,

is F1 and is not typical, as it has an extremely high iron 28 miles away. We used the refined Mingsha kaolin (R3)

content (> 2 % ). instead of Mingsha kaolin (R2) in its natural state, since

Figure 1 also indicates the possible use of Qimen por- it is R3 that was used in porcelain production.

celain stone (R4), Shoxiwu porcelain stone (R9), and As for porcelain stones, the following six were chosen:

1492 Volume 46, Number 10, 1 9 9 2

kaolin (wt°/o) kaolin (wt °/o) TABLE IV. Estimate of the percentage of kaolin used in Jingdezhen

I porcelain bodies during the various dynasties (wt %).

R4 (Qimen) 60 R10 (Sanbaopeng)

60 Estimate of percentage of

Name of some

typical porcelain kaolin used in porcelain bodies

stone used in Five Dy-

,o No. Jingdezhen nasties" Song" Yuan Ming Qing

R4 Qimen 0 4-10 15-25 10-20 30-55

R8 Yaolidongshi a a 25-35 20-30 40-65

R9 Shoxiwu 0 3-10 20-30 15-25 35-60

R10 Sanbaopeng a a 10-20 5-15 30-60

Rll Nankang 0 0-8 18-25 10-20 35-60

D R12 Porcelain stone a 0-5 10-22 5-18 25-55

F S Y M O F S Y M Q (Vogt, 1900)

"Note: (a) Porcelain stone not used during the period under consid-

eration.

R8 (Yootidongshi) Rll (Nankang)

60 60

T a b l e IV gives the e s t i m a t e of the p e r c e n t a g e of kaolin

used in J i n g d e z h e n porcelain bodies during the various

40 40 dynasties, a n d these are p l o t t e d in Fig. 4. F r o m Fig. 2,

if Yaolidongshi porcelain stone (R8) were used during

the Five D y n a s t i e s a n d early Song, the p e r c e n t a g e of

20 20 kaolin a d d e d would be a r o u n d 15%, which is m o s t un-

likely. Hence, we conclude t h a t it was n o t used a t t h a t

time. Irrespective of the porcelain stone used, Fig. 4 shows

t h a t the a m o u n t of kaolin a d d e d increases as a function

F S Y M Q F S Y M Q of time, except for a reversal during Y u a n a n d Ming

Dynasties. In addition, an unusually large p r o p o r t i o n of

kaolin was used during the Qing D y n a s t y , reaching as

R9 (Shoxiwu) R12 (Vogt) high as a b o u t 60%. Such large additions of kaolin in-

60 6O crease the t e m p e r a t u r e a n d the range of firing t e m p e r -

40

20

D ,o

atures, which in t u r n enhance the quality a n d s t r e n g t h

of the b o d y a n d glaze of J i n g d e z h e n porcelains. T h e re-

m a r k a b l e quality a n d s t r e n g t h of high-kaolin J i n g d e z h e n

porcelains could be seen f r o m the excellent condition of

the N a n k i n g cargo 17 of over 100,000 pieces of Qianlong

blue-and-white, salvaged in 1985 f r o m a ship t h a t s a n k

in a b o u t 1750.

F S Y M Q F S Y M Q ACKNOWLEDGMENTS

FIG. 4. Plot of the percentage of kaolin added to porcelain stones as We wish to thank Miss Ng Soo Ngo for drawing the diagrams. Younan

a function of time, where F = Five Dynasties, S = Song, Y = Yuan, M Hua wishes to acknowledge with thanks the hospitality of the De-

= Ming, and Q = Qing. partment of Physics of National University of Singapore.

1. Li Jiazhi and Guo Yanyi, "Famous White Porcelain of the Various

R4 (Qimen), R8 (Yaolidongshi), R9 (Shoxiwu), R10 (San- Dynasties in the North and South of China," in Scientific and

baopeng), R l l (Nankang), a n d R12 (Vogt). T h e others Technical Achievements in Ancient Chinese Pottery and Porce-

are o m i t t e d since R7 ( N a n k a n g ) is similar to R l l , b o t h lain, Li Jiazhi, Chen Xianqui, Zhang Fukang, Guo Yanyi, and Chen

Shiping, Eds. (Shanghai Scientific and Technical Publishers,

R6 a n d R13 (Sanbaopeng) are similar to R10, a n d R5 Shanghai, 1984).

was not used in Jingdezhen, as discussed above. 2. M. S. Tite, I. C. Freestone, and M. Bimson, Archaeometry 26, 139

T h e chosen M i n g s h a kaolin (R3) was t h e n m i x e d with (1984).

individual porcelain stones (R4, R8, R9, R10, R l l , or 3. Li Guozhen and Guo Yanyi, Technological Bases o[ Famous Chi-

R12) in varying p r o p o r t i o n s f r o m 10% to 60% kaolin. nese Porcelain (Shanghai Scientific and Technical Publishers,

Shanghai, 1985).

P r i n c i p a l c o m p o n e n t analysis was t h e n p e r f o r m e d on the 4. A. M. Polland and E. T. Hall, "Provenance Studies of Oriental

66 pieces of porcelain b o d y f r o m J i n g d e z h e n together Porcelain by Chemical Analysis," in Scientific and Technological

with one of these points, as shown in Figs. 2 a n d 3 for Insights on Ancient Chinese Pottery and Porcelain (Science

principal c o m p o n e n t s 1 a n d 2. Actually, Figs. 2 a n d 3 Beijing, China, 1986).

could be p l o t t e d as one figure a n d are s e p a r a t e l y p l o t t e d 5. N. Wood, Transact. Orient. Ceram. Soc. 50, 37 (1986).

6. Guo Yanyi, Archaeometry 29, 3 (1987).

for clarity. 7. C. T. Yap, National Palace Museum (Taipei) Bulletin 19(3), 1

Figure 2 shows that, with the exception of those of the (1984).

Five D y n a s t i e s a n d p a r t of Song D y n a s t y , practically all 8. C. T. Yap, Oriental Art 32, 48 (1986).

J i n g d e z h e n porcelains are b o u n d e d within the triangle 9. C. T. Yap, Archaeometry 28, 197 (1986).

10. C. T. Yap, Appl. Spectrosc. 40, 839 (1986).

f o r m e d b y R3 (Mingsha kaolin), R8 (Yaolidongshi por- 11. C. T. Yap, X-Ray Spectrom. 16, 55 (1987).

celain stone), a n d R10 ( S a n b a o p e n g porcelain stone). 12. C. T. Yap, Appl. Spectrosc. 41, 1446 (1987).

APPLIED SPECTROSCOPY 1493

13. C. T. Yap, X-Ray Spectrom. 16, 229 (1987). nese Porcelains from the Five Dynasties to the Qing Dynasty,"

14. C. T. Yap, Zeitschrift fur Naturforschung 42A, 1253 (1987). submitted for publication (1992).

15. C. T. Yap, J. Archaeol. Sci. 16, 173 (1988). 21. Chen Shiping and Chen Xiangqiu, "The Comprehensive Summary

16. C. T. Yap, X-Ray Spectrom. 18, 31 (1989). of the Chemical Composition of Various Ancient Chinese Porce-

17. C. T. Yap, Appl. Spectrosc. 45, 584 (1991). lains," in Scientific and Technical Achievements in Ancient Chi-

18. C. T. Yap, Appl. Spectrosc. 46, 843 (1992). nese Pottery and Porcelain, Li Jiazhi, Chen Xianqui, Zhang Fu-

19. C. T. Yap and Y. N. Hua, "A Study of Chinese Porcelain Raw kang, Guo Yanyi, and Chen Shiping, Eds. (Shanghai Scientific and

Materials for Ding, Xing, Gongxian, and Dehua Wares," submitted Technical Publishers, Shanghai, 1984).

for publication (1992). 22. W. W. Cooley and P. R. Lohnes, Data Analysis (John Wiley, New

20. C. T. Yap and Y. N. Hua, "Principal Component Analysis of Chi- York, 1971), pp. 96-108.

1494 Volume 46, Number 10, 1992

You might also like

- Analysis of Raw Glass From Carthage HIMTDocument2 pagesAnalysis of Raw Glass From Carthage HIMTr monpeanNo ratings yet

- Micro Analysis Crystals 1Document15 pagesMicro Analysis Crystals 1nikrouNo ratings yet

- Xie Rehren 2009 Lead Silver Slag China BUMA VIDocument9 pagesXie Rehren 2009 Lead Silver Slag China BUMA VIth_rehrenNo ratings yet

- J Ceramint 2021 05 303Document6 pagesJ Ceramint 2021 05 303FURY FURIONNo ratings yet

- Two Glass Beads From Wisad Pools in TheDocument5 pagesTwo Glass Beads From Wisad Pools in TheEmre TaştemürNo ratings yet

- Petrographic and Chemical Characterisation of Fine Ware From Three Archaic and Hellenistic Kilns in Gela, SicilyDocument6 pagesPetrographic and Chemical Characterisation of Fine Ware From Three Archaic and Hellenistic Kilns in Gela, SicilyIS AANo ratings yet

- Cone 5 - 6 Crystalline GlazesDocument105 pagesCone 5 - 6 Crystalline GlazesVasiliy DyominNo ratings yet

- NASTSDocument25 pagesNASTSManuel AlejandroNo ratings yet

- Elemental Characterization by Edxrf of Imperial Longquan Celadon Porcelain Excavated From Fengdongyan Kiln, Dayao CountyDocument11 pagesElemental Characterization by Edxrf of Imperial Longquan Celadon Porcelain Excavated From Fengdongyan Kiln, Dayao CountyAlexander Robert JennerNo ratings yet

- The Geochemistry of Rare Earth Elements (REE) in Acid Mine Drainage From The Sitai Coal Mine, Shanxi Province, North ChinaDocument9 pagesThe Geochemistry of Rare Earth Elements (REE) in Acid Mine Drainage From The Sitai Coal Mine, Shanxi Province, North ChinaAbie BadhurahmanNo ratings yet

- Kokubo, 1990, Apatite Coating On Ceramics, Metals and Polymers Utilizing A Biological ProcessDocument6 pagesKokubo, 1990, Apatite Coating On Ceramics, Metals and Polymers Utilizing A Biological ProcessEvaldo FilhoNo ratings yet

- CimentDocument8 pagesCimentwissalNo ratings yet

- Catalogue,: ON Meteoric Iron From Four Corners, San Juan County, New GzorgsDocument7 pagesCatalogue,: ON Meteoric Iron From Four Corners, San Juan County, New Gzorgsbuhl66No ratings yet

- 59 - Isijint 2018 613Document8 pages59 - Isijint 2018 613Satadal GhoraiNo ratings yet

- Alloys of Japanese Patinated Metalwork: ISIJ International June 2014Document7 pagesAlloys of Japanese Patinated Metalwork: ISIJ International June 2014Abdul RehmanNo ratings yet

- Ceramic Raw Materials: Institute of Ceramics Textbook SeriesFrom EverandCeramic Raw Materials: Institute of Ceramics Textbook SeriesRating: 3.5 out of 5 stars3.5/5 (3)

- Mineral Composition of The Average ShaleDocument6 pagesMineral Composition of The Average ShaleCAMILO ANDRES BOHORQUEZ ESPARZANo ratings yet

- Low-Cost Purification of Silicon by Dissolution in Sodium SolventDocument5 pagesLow-Cost Purification of Silicon by Dissolution in Sodium Solventسید حسین عارفیNo ratings yet

- Silver Coins Mining in Shan StateDocument6 pagesSilver Coins Mining in Shan StateAung Htun LinnNo ratings yet

- Analysis of Ancient Metals: International Series of Monographs on Analytical ChemistryFrom EverandAnalysis of Ancient Metals: International Series of Monographs on Analytical ChemistryNo ratings yet

- Faience: An Investigation of The Microstructures Associated With The Different Methods of GlazingDocument12 pagesFaience: An Investigation of The Microstructures Associated With The Different Methods of GlazingAlyaa GamalNo ratings yet

- Experimental Study of Historical Processing of Cobalt Arsenide Ore For Colouring Glazes (15-16th Century Europe)Document10 pagesExperimental Study of Historical Processing of Cobalt Arsenide Ore For Colouring Glazes (15-16th Century Europe)jmoleraNo ratings yet

- Dry Grinding of KaolinDocument16 pagesDry Grinding of Kaolinscata1117No ratings yet

- The Effect of Grog Sizing On The Performance of Ire Ekiti Fire Clay Refractory BricksDocument8 pagesThe Effect of Grog Sizing On The Performance of Ire Ekiti Fire Clay Refractory BricksAdvanced Research PublicationsNo ratings yet

- Report PDFDocument24 pagesReport PDFDiego SaenzNo ratings yet

- 2007 Bullentin Rel. 2 WearMechanism-DataDocument4 pages2007 Bullentin Rel. 2 WearMechanism-Data1977julNo ratings yet

- April, 1943: Pamphlet 63Document10 pagesApril, 1943: Pamphlet 63Russell HartillNo ratings yet

- Journal of Non-Crystalline Solids: Zhong-Jie Wang, Wen Ni, Yan Jia, Li-Ping Zhu, Xiao-Yan HuangDocument5 pagesJournal of Non-Crystalline Solids: Zhong-Jie Wang, Wen Ni, Yan Jia, Li-Ping Zhu, Xiao-Yan HuangBayu MuhammadNo ratings yet

- Crystallization Behaviour of Fluorphlogopite Glass Ceramics: Received February 7, 2000 Accepted February 20, 2001Document8 pagesCrystallization Behaviour of Fluorphlogopite Glass Ceramics: Received February 7, 2000 Accepted February 20, 2001Ali AddieNo ratings yet

- TEKTITE OR OBSIDIAN-CALI GLASSDocument2 pagesTEKTITE OR OBSIDIAN-CALI GLASSLaura Daniela Jimenez PradaNo ratings yet

- ICCF-9metallic Transmutations by Acetic AcidDocument7 pagesICCF-9metallic Transmutations by Acetic Acidsaint saul100% (2)

- Discover the origins of lead crystal glassDocument6 pagesDiscover the origins of lead crystal glassAnas SiddNo ratings yet

- Dissolution Rates of Plagioclase Minerals at Low pHDocument7 pagesDissolution Rates of Plagioclase Minerals at Low pHAna Emily PrentissNo ratings yet

- Recovery of Silver and Indium from Zinc Industry ResiduesDocument9 pagesRecovery of Silver and Indium from Zinc Industry ResiduesBlanca GonzalezNo ratings yet

- Mineralogy and Crystal Chemistry of A Low Grade Nickel Laterite OreDocument10 pagesMineralogy and Crystal Chemistry of A Low Grade Nickel Laterite Orejeha kunramadiNo ratings yet

- Electrolytic lead refining process in Sardinia optimizes costsDocument9 pagesElectrolytic lead refining process in Sardinia optimizes costsGeorgettaNo ratings yet

- Isijinternational 45 551Document9 pagesIsijinternational 45 551sahib mohammadNo ratings yet

- Native AI and Si Formation: Scientific CorrespondenceDocument1 pageNative AI and Si Formation: Scientific CorrespondenceAdrian Dacosta LazeraNo ratings yet

- Chemistry Qbank PDFDocument106 pagesChemistry Qbank PDFgowrimanohar1975No ratings yet

- (Sici) 1097 4539 (199611) 25:6 281::aid xrs174 3.0.co 2 7Document5 pages(Sici) 1097 4539 (199611) 25:6 281::aid xrs174 3.0.co 2 7FURY FURIONNo ratings yet

- 10 1002@14356007 A27049Document34 pages10 1002@14356007 A27049Adam Septiyono ArlanNo ratings yet

- A Mineralogical Study of Nodulated Copper Cathodes - 1999Document21 pagesA Mineralogical Study of Nodulated Copper Cathodes - 1999Ela CJNo ratings yet

- Ancient Lead Glaze ReviewDocument20 pagesAncient Lead Glaze ReviewRafael Marques GarciaNo ratings yet

- A Review of Slag Chemistry in Lead RecyclingDocument10 pagesA Review of Slag Chemistry in Lead Recyclingjessy eghNo ratings yet

- relacion defloculanteDocument13 pagesrelacion defloculantejsteven0211No ratings yet

- Flux Growth of Hexagonal Bipyramidal Ruby Crystals.Document4 pagesFlux Growth of Hexagonal Bipyramidal Ruby Crystals.GisbellAcostaVillasmilNo ratings yet

- Whittington Ve Muir, 2000Document74 pagesWhittington Ve Muir, 2000laguna028No ratings yet

- 02 Chapter 2Document23 pages02 Chapter 2pinkan25No ratings yet

- Eldspar Elspar:) - Albite andDocument8 pagesEldspar Elspar:) - Albite andnur anisa panusuNo ratings yet

- In Situ SAXS Studies of The Structural Changes of Sepiolite Clay and Sepiolite-Carbon Composites With TemperatureDocument4 pagesIn Situ SAXS Studies of The Structural Changes of Sepiolite Clay and Sepiolite-Carbon Composites With TemperatureLaysFitaroniNo ratings yet

- Tin Tin Alloys, and Tin CompoundsDocument35 pagesTin Tin Alloys, and Tin Compoundsapi-3801291100% (6)

- Photoluminescence Emissions of Ceramics: A Marker of Production TechnologyDocument4 pagesPhotoluminescence Emissions of Ceramics: A Marker of Production TechnologyRupeshRaoNo ratings yet

- Lead Smelting and Refining, With Some Notes on Lead MiningFrom EverandLead Smelting and Refining, With Some Notes on Lead MiningNo ratings yet

- The Taupo Obsidian Source Central North Island New ZealandDocument12 pagesThe Taupo Obsidian Source Central North Island New ZealandRobNo ratings yet

- Ceramics by The Solution-Sol-Gel RouteDocument6 pagesCeramics by The Solution-Sol-Gel Route王玏No ratings yet

- Chapter 2REVIEW OF RELATED LITERATUREDocument8 pagesChapter 2REVIEW OF RELATED LITERATUREmolecule atomNo ratings yet

- Two-Stage Agitation Leaching of Old Flotation TailingsDocument5 pagesTwo-Stage Agitation Leaching of Old Flotation TailingsMaria José FuturoNo ratings yet

- Grossmanite Yatsenko - Abstract - Semenenko - 2021Document5 pagesGrossmanite Yatsenko - Abstract - Semenenko - 2021Eduardo ZappettiniNo ratings yet

- Akira Mikuni Et - Al 2007, Dissolution Properties of Some Fly Ash Fillers Applying To Geopolymeric Materials in Alkali SolutionDocument5 pagesAkira Mikuni Et - Al 2007, Dissolution Properties of Some Fly Ash Fillers Applying To Geopolymeric Materials in Alkali SolutionSatya ChaitanyaNo ratings yet

- Group IV A CompleteDocument64 pagesGroup IV A Completeshazi5250No ratings yet

- Characterising black Fe-based ceramic coatingsDocument15 pagesCharacterising black Fe-based ceramic coatingsFURY FURIONNo ratings yet

- 2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainDocument8 pages2013 - Dolomite, Wollastonite and Calcite As Different CaO Sources in Anorthite-Based PorcelainFURY FURIONNo ratings yet

- 2013 - Preliminary Archaeometric Study of The Neolithic PotteryDocument9 pages2013 - Preliminary Archaeometric Study of The Neolithic PotteryFURY FURIONNo ratings yet

- Avian Pale On Tolo 89 SociDocument356 pagesAvian Pale On Tolo 89 SociFURY FURIONNo ratings yet

- 2018 - Feldspathic Fluxes For CeramicsDocument15 pages2018 - Feldspathic Fluxes For CeramicsFURY FURIONNo ratings yet

- 2020 - How To Recognize Them and Locate The Supply Basins - ChemistryDocument17 pages2020 - How To Recognize Them and Locate The Supply Basins - ChemistryFURY FURIONNo ratings yet

- 2001 - New Porcelainized Stoneware Materials Obtained by Recycling of MSW Incinerator Fly Ashes and Granite Sawing ResiduesDocument8 pages2001 - New Porcelainized Stoneware Materials Obtained by Recycling of MSW Incinerator Fly Ashes and Granite Sawing ResiduesFURY FURIONNo ratings yet

- 2020 - Trends and Growth in Ceramics IndustryDocument14 pages2020 - Trends and Growth in Ceramics IndustryFURY FURIONNo ratings yet

- 2004 - The Influence of Microstructure On The Performance of White Porcelain StonewareDocument11 pages2004 - The Influence of Microstructure On The Performance of White Porcelain StonewareFURY FURIONNo ratings yet

- 2020 - Resource Efficiency Versus Market Trends in The Ceramic Tile IndustryDocument12 pages2020 - Resource Efficiency Versus Market Trends in The Ceramic Tile IndustryFURY FURIONNo ratings yet

- Ceramic IndustryDocument65 pagesCeramic IndustryMarybeth HopeNo ratings yet

- 2020 - How To Recognize Them and Locate The Supply Basins - Mineralogy Et PetrologyDocument19 pages2020 - How To Recognize Them and Locate The Supply Basins - Mineralogy Et PetrologyFURY FURIONNo ratings yet

- Prosperity and Decline: A Comparison of The Fate of Jingdezhen, Zhuxianzhen, Foshan and Hankou in Modern TimesDocument34 pagesProsperity and Decline: A Comparison of The Fate of Jingdezhen, Zhuxianzhen, Foshan and Hankou in Modern TimesFURY FURIONNo ratings yet

- 1990 - A Mathematical Model For The Calculation of Ceramic Batch FormulasDocument8 pages1990 - A Mathematical Model For The Calculation of Ceramic Batch FormulasFURY FURIONNo ratings yet

- JWH 2012 0028Document33 pagesJWH 2012 0028FURY FURIONNo ratings yet

- Wu 2000Document6 pagesWu 2000FURY FURIONNo ratings yet

- Cij.2.3.305 7Document9 pagesCij.2.3.305 7FURY FURIONNo ratings yet

- Alves 2021Document15 pagesAlves 2021FURY FURIONNo ratings yet

- amr 503-504 23Document5 pagesamr 503-504 23FURY FURIONNo ratings yet

- J Cities 2019 102569Document9 pagesJ Cities 2019 102569FURY FURIONNo ratings yet

- Journal of The Royal Asiatic SocietyDocument26 pagesJournal of The Royal Asiatic SocietyFURY FURIONNo ratings yet

- Blue and White Porcelain Study Using XAFS SpectroscopyDocument6 pagesBlue and White Porcelain Study Using XAFS SpectroscopyFURY FURIONNo ratings yet

- RAW MATERIALS FOR MAKING PORCELAINDocument17 pagesRAW MATERIALS FOR MAKING PORCELAINFURY FURIONNo ratings yet

- Gselements 10 3 177Document6 pagesGselements 10 3 177FURY FURIONNo ratings yet

- (Sici) 1097 4539 (199611) 25:6 281::aid xrs174 3.0.co 2 7Document5 pages(Sici) 1097 4539 (199611) 25:6 281::aid xrs174 3.0.co 2 7FURY FURIONNo ratings yet

- Arcm 12539Document13 pagesArcm 12539FURY FURIONNo ratings yet

- Fragments of A Global Past: Ceramics Manufacture in Song-Yuan-Ming JingdezhenDocument37 pagesFragments of A Global Past: Ceramics Manufacture in Song-Yuan-Ming JingdezhenFURY FURIONNo ratings yet

- Awr 12028Document15 pagesAwr 12028FURY FURIONNo ratings yet

- SDS - Chemrock 958aDocument1 pageSDS - Chemrock 958amangengueyNo ratings yet

- EE 322 TransformersDocument73 pagesEE 322 TransformersCedric BernardNo ratings yet

- Glossaries Construction BG-ENDocument13 pagesGlossaries Construction BG-ENVania AngelovaNo ratings yet

- Reinforced concrete service and lift core designDocument4 pagesReinforced concrete service and lift core designOmer AkifNo ratings yet

- 02 Quote CIF GBM Remote Control GrabDocument7 pages02 Quote CIF GBM Remote Control GrabPanggi Eko PrasetiyoNo ratings yet

- SEEMSAN Product RangeDocument12 pagesSEEMSAN Product RangeSPE PROCESS PUMPSNo ratings yet

- K&J Magnetics - SpecificationsDocument5 pagesK&J Magnetics - SpecificationsMilad TilaNo ratings yet

- FINITE ELEMENT 18ME73 ASSIGNMENTSDocument10 pagesFINITE ELEMENT 18ME73 ASSIGNMENTSFOODIE USNo ratings yet

- Journal Bearing LubricationDocument5 pagesJournal Bearing LubricationkulilistrikNo ratings yet

- To Study The Presence of Insecticides and Pesticides in Various Fruits and VegetablesDocument9 pagesTo Study The Presence of Insecticides and Pesticides in Various Fruits and VegetablesReetul PriyaNo ratings yet

- Jotashield Alkali Resistant Primer Technical Data SheetDocument3 pagesJotashield Alkali Resistant Primer Technical Data Sheetomda4wadyNo ratings yet

- Homework stresses and strains analyzed with KENPAVE softwareDocument17 pagesHomework stresses and strains analyzed with KENPAVE softwareRobel TeweldeNo ratings yet

- Chapter 3Document23 pagesChapter 3PreethaSureshNo ratings yet

- Plasticity in Structural Engineering Fundamentals and ApplicationsDocument10 pagesPlasticity in Structural Engineering Fundamentals and Applicationstemp ovaryNo ratings yet

- Chi Trans or Mat Ion System USADocument20 pagesChi Trans or Mat Ion System USAMaria MantuanoNo ratings yet

- Experiment 9Document6 pagesExperiment 9clairedemotica100% (1)

- Steel PipesDocument16 pagesSteel PipesAdam GordonNo ratings yet

- PDF ST PROLITE Vertrieb en 3 2020.en - UndefinedDocument6 pagesPDF ST PROLITE Vertrieb en 3 2020.en - UndefinedArgenis Emmanuel Rodriguez MarianoNo ratings yet

- Quench Sensitivity of AlMgSi Alloys Containing Mn or CrDocument6 pagesQuench Sensitivity of AlMgSi Alloys Containing Mn or CrzhaomingbaoNo ratings yet

- Biomass Characterization - Part 1Document56 pagesBiomass Characterization - Part 1Giovani de MoraisNo ratings yet

- Steel SectionsDocument33 pagesSteel Sectionssam_antony2005No ratings yet

- Permanent FormworkDocument13 pagesPermanent FormworkjimmydomingojrNo ratings yet

- Gsi, Q, RMRDocument8 pagesGsi, Q, RMRDeepthi AcharNo ratings yet

- Dissolution Apparatus - USPDocument6 pagesDissolution Apparatus - USPkakak zeaNo ratings yet

- Et ChantsDocument5 pagesEt ChantsVenkatakrishna.ANo ratings yet

- Jfe SteelDocument44 pagesJfe SteelTuấn Phạm AnhNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetBiju_PottayilNo ratings yet

- Exergy: A Measure of Work Potential Study Guide in PowerpointDocument27 pagesExergy: A Measure of Work Potential Study Guide in PowerpointKent_RichieanNo ratings yet

- Marine Grease SeparatorsDocument2 pagesMarine Grease SeparatorsMuzami ThahirNo ratings yet

- Koyo Ceramic Catb1013exDocument17 pagesKoyo Ceramic Catb1013exJose DonaireNo ratings yet