Professional Documents

Culture Documents

Sen012en 00

Uploaded by

sayed atefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sen012en 00

Uploaded by

sayed atefCopyright:

Available Formats

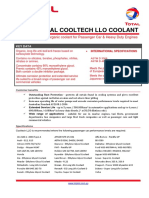

PREVENTIVE MAINTENANCE PRODUCTS AND SERVICES

™

Extended Life Coolant (ELC )

®

For Europe, Africa and Middle Eastern Countries

For all Caterpillar and most OEM and gasoline engines

Developed, tested, and approved by Caterpillar,

Cat® Extended Life Coolant lasts at least twice as Cat® ELC™ Characteristics*

long as conventional coolant in Cat machines and

commercial engines and three times as long in Cat

Appearance Strawberry Red

truck engines. It requires no supplemental coolant

additives (SCAs); instead, Cat ELC Extender is Specific gravity ASTM D1122 1.110

added once, at the time conventional coolants would pH (33% solution) ASTM D1287 8.3

otherwise be replaced. Reserve alkalinity ASTM D1121 5.5

Recommended use Ash content, % max. ASTM D1119 5.0

Boiling protection, 1 bar pressure cap

Cat ELC is the coolant used as factory fill

worldwide for all Caterpillar machines. It can be 50% (Cat ELC premixed) 129°C

used in all Cat and most OEM diesel and gasoline 60% (Cat ELC concentrate) 132°C

engines. It exceeds Caterpillar’s EC-1 coolant Freezing protection

performance specification (see page 2). It also

50% (Cat ELC premixed) -37°C

exceeds ASTM D4985 and ASTM D5345

standards for heavy duty, low silicate antifreeze/ 60% (Cat ELC concentrate) -54°C

coolants and ASTM D3306 and ASTM D4656 for Nitrites 550 ppm

automotive applications. Molybdates 950 ppm

Cat ELC Premixed contains 50% ELC and 50% Silicate, % 0

totally purified water. It is to be used for initial fill Phosphate, % 0

and for top-off. This formula ensures that water Amine, % 0

quality does not compromise engine coolant

Borate, % 0

performance and life. With Cat ELC there is no

concern about hard water scale or the correct Nitrates, % 0

mixture of water and concentrate. Freeze protection * The values shown are typical values and should not be used as quality control parameters

with Cat ELC is to -37° C. Cat ELC Concentrate either to accept or reject product. Specifications are subject to change without notice.

is available to further lower the freeze protection

point.

Cat ELC Extender should be added after 3,000 Full Compatibility

hours (500,000 km.) of operation, and the system

Your entire fleet can benefit from the protection of Cat ELC. It is fully compatible with

should be drained and flushed with clean water after

6,000 hours (1,000,000 km.). No cleaning agents all brands of diesel and gasoline engines. After nine years of extensive testing and

are needed. If Caterpillar’s S•O•S Coolant Analysis commercial experience, there have been no documented failures of cooling system

Program is used regularly, safe operation with Cat

components, gaskets, seals or hoses with proper use of Cat ELC.

ELC may extend beyond 6,000 hours.

With Cat ELC you can inventory one coolant for

your entire fleet. Contact your nearest Cat dealer

for further information concerning coolants and

lubricants. Bauer Doc-No.:

SEN012EN_00

Extended Life Coolant

Better protection for longer life

Bemco (the Caterpillar dealer in Botswana) compared engine Injector sleeves from the same Bemco engine showed similar

component life using Cat ELC vs. conventional coolant. The liner on success for Cat ELC vs. conventional coolant. Note the deposits and

the left – from a Cat 3406 HEUI engine – operated 5,300 hours at the severe pitting after 5,300 hours with conventional coolant (left)

Gaborone Mine with conventional coolant. It had pitting, which compared with the excellent condition of the injector sleeve with

penetrated the liner wall. The liner on the right from the same ELC after 10,013 hours of operation (right).

engine ran 10,013 hours with Cat ELC. The coolant side of the liner is

like new.

New chemical technology for long life Caterpillar EC-1 Specification

Cat Extended Life Coolant (ELC) incorporates an advanced formula The world’s most stringent standard for heavy duty coolant

technology with organic additive corrosion inhibitors. Instead of nitrates, performance is the Caterpillar EC-1 Specification.

silicates, phosphates, borates, and amines, Cat ELC contains mono- and This specification requires that the coolant pass extensive tests

dibasic organic acid salts for maximum protection of the six basic metal including:

alloys—copper, solder, brass, steel, cast iron, and aluminum—found in most • Physical and chemical testing

heat transfer systems. Some nitrites and molybdates are added to help protect • Compatibility characteristics with other coolants

the iron components in the cooling system, reducing steel corrosion and • Bench performance testing

pitting effects. • Field testing

Cat ELC contains no phosphates or silicates so hard water deposits are The EC-1 tests go far beyond the usual ASTM and other industry

practically eliminated. The low level of total dissolved solids and absence of standard tests. Unlike other coolant standards, EC-1 requires field

silicantes extends water pump seal life. testing. To qualify as EC-1, a coolant must be operated for a

Coolant life in heavy-duty diesel engines is limited by the depletion of minimum of 7,000 hours (450,000 km.) in at least six

corrosion inhibitors. In conventional coolants, supplemental coolant additives Caterpillar engines. Coolant samples are required every 500 hours

(SCAs) deplete, so you must add SCAs at every oil change. With Cat ELC, (40,000 km.). The sample results must conform to stringent limits

however, additives deplete very slowly—so you don’t need to add any SCAs. concerning pH, reserve alkalinity, metallic corrosion, contaminants

Coolant samples indicate that Cat ELC maintains its nitrite levels up to 20 and inhibitor concentration.

times better than conventional coolants. At the conclusion of the EC-1 testing, each engine is disassembled

The presence of ethylene glycol in Cat ELC protects cooling systems in cold and components must meet strict condition requirements. In

climates because it lowers the freezing point. It is also important in all particular, the EC-1 test requires no corrosion or pitting, scale or

climates because it raises the coolant boiling temperature. deposits on the cylinder liners, radiator core, water pump parts,

cylinder head water passages and thermostat housing.

PREVENTIVE MAINTENANCE PRODUCTS AND SERVICES

Proper use for optimum results

Mixing Cat ELC with other Using this kit confirms whether ELC low-silicate antifreeze/coolant, first clean

antifreeze/coolants inhibitors are within an acceptable limit for your system with Cat Cooling System

While Cat ELC is compatible with conven- continued use of the coolant. If the coolant Cleaner 6V4511 or 4C4611 or a similar

tional antifreeze/coolants, we recommend has had water or standard coolant added, commercial cleaner at the change interval.

you do not mix the two. Cat ELC is there may not be enough of the ELC After draining the cleaner, flush the system

ethylene-glycol based for anti-boil and additives present for adequate protection. thoroughly with water three times to

freeze protection, but its corrosion chemical We recommend testing annually for remove the cleaning agent. It is imperative

system is different than that of conventional freeze/anti-boil protection in case water to remove all the cleaning agent from

antifreeze/coolants. (rather than ELC) has been used for top off. the system.

If they are mixed, don’t add more than 10% Cleaning your cooling system Less old coolant for disposal

of the conventional coolant. If you exceed Used coolant disposal requirements have

When draining ELC from your cooling

10%, treat the system as if it contains become more stringent and costly in recent

system, just flush the system with clean

conventional coolant or drain and flush the years. Disposal of used coolants can be

water—no cleaning agents are required

system and refill with ELC. difficult and expensive and must be done in

when you drain Cat ELC for a new batch.

Using test kits for Cat ELC accordance with local or national laws. Cat

Converting to Cat ELC ELC reduces coolant disposal volume by

The Contamination Test Kit (172-8851) for

It’s easy to convert to Cat ELC. If you’ve 50% or more — cutting disposal costs.

Cat ELC provides a pass/fail result based on

been using a conventional heavy-duty,

inhibitors present in the coolant sample.

Cat Extender for maximum coolant life

• Exceeds Cat EC-1 performance require-

ments.

• Contains nitrites and molybdates to protect

against cylinder liner/block pitting and

cavitation erosion.

• Should be added at 500,000 km. for Cat on-

highway trucks and 3,000 hours for Cat

machines and commercial engines.

• Ensures Cat ELC performance to 1,000,000

km. or 6,000 hours.

Benefits of Cat ELC

Quantity of Extender Needed at Cat Extended Life Coolant Half-Life*

• Maximizes water pump seal life.

Approximate Amount at

Cooling System Capacity 500,000 km or 3000 Hours** • Eliminates gel formation.

Liters Quantity (Bottle: 119-5152) • Contains no silicates, phosphates,

or borates.

22-30 0.5

• Allows you to inventory one coolant for

30-49 1.0

entire mixed fleet (can be used in most

49-83 1.5

OEM diesel, gasoline, and natural gas

83-114 2.0 engines).

114-155 3.0 • Requires no SCAs (one maintenance

155-197 4.0 intervention required using Cat

197-243 5.0 Extender at coolant mid-life).

* Cat Extender is not required for initial fill or top-off since Cat ELC already contains the appropriate level of all inhibitors.

• Provides excellent protection

** A clear view strip on the side of the bottle makes measurement easier. for all cooling system metals,

including aluminum.

Cat ELC & Extender ordering information • Offers outstanding protection against

cylinder liner cavitation corrosion.

Part No. Package Size Description • Ensures quality make-up water

206-7831 Bulk (10,000 Liters) Premixed (50/50) (Premixed).

205-6614 1,000 Liter Container Premixed (50/50) • Ensures correct antifreeze-to-water mix

205-6613 210 Liter Drum Premixed (50/50) (Premixed).

205-6612 25 Liter Canister Premixed (50/50) • Eliminates hard water scale.

205-6611 5 Liter Jug Premixed (50/50) • Requires no coolant conditioner test

205-6615 5 Liter Jug Concentrate* kit to check nitrite level.

119-5152 Quart Bottle Coolant Extender** • Lets you adjust coolant freeze point

temperature.

*ELC Concentrate is used to adjust the coolant for temperatures below -37°C.

• Anti-boil properties reduce damage from

**ELC Extender is added at the half life of the coolant (500,000 km for truck engines and 3,000 hours for other engines).

steam in cooling system.

• Reduces disposal volume and

is recyclable.

• Reduces engine coolant and additives

costs from a minimum of 42% to as

S·O·S Coolant Analysis

SM

much as 80% over Cat DEAC.

• May be used as top-off with traditional

Protect your investment with S•O•S Coolant Analysis. Level 1 Analysis provides a close look at the coolants.

condition of your coolant, including nitrite level, pH, conductivity, visual and odor characteristics,

freeze protection and water hardness (if conventional coolant is used). • One coolant for your entire fleet.

Level 2 Analysis includes all level 1 tests plus spectrographic and electrophoresis analysis. It can

detect metal corrosion, build-up of impurities, scaling and other problems before they cause

downtime and major repairs. Level 2 Analysis is especially important if you are using conventional

coolants which offer less protection than Cat ELC. Ask your nearest Cat dealer about S•O•S coolant

services.

Proper use for health and safety

According to toxicology information, Cat Extended Life Coolant has little or no adverse effects if

handled and used properly. It contains an embittering agent to assume that it will not be swallowed

by humans or animal. No special precautions are suggested beyond attending to good personal

hygiene and avoiding prolonged, repeated skin contact. For more information, refer to the Material

Safety Data Sheet, located on the Caterpillar website at www.catmsds.com

PEHP9557 © 2001 Caterpillar Printed in U.S.A.

Cat ELC

® ™

Extended Life Coolant for Caterpillar and original equipment

50/50 Premix

manufacturer (OEM) diesel and gasoline engines.

Recommended Use Caterpillar. The difference counts.™

Cat ELC meets or exceeds the requirements of the following specifications:

• Cat EC-1 • TMC RP-329 • TMC RP-338

• ASTM D-3306 • ASTM D-6210 • SAE J1034 Cat Dealers define world-class

Cat ELC also meets the performance requirements of Cummins, Detroit Diesel, product support. We offer you the

International, Mack and Volvo. right parts and service solutions,

Discover the Difference when and where you need them.

Cat ELC is developed, tested and approved by Caterpillar to meet the same high

standards as Genuine Cat Parts. The Cat Dealer network of highly

Factory-Fill—Used as standard factory-fill for all Cat machine cooling systems. trained experts keeps your entire

Lower Maintenance Costs—Reduces engine coolant and additive costs by as fleet up and running to maximize

much as 500% compared to conventional coolants. It eliminates the need for

supplemental coolant additives, extends coolant change-out intervals and reduces your equipment investment.

disposal requirements.

Advanced Metal Protection—Incorporates an advanced formula technology

with organic acid additive corrosion inhibitors, such as a combination of mono

and dicarboxylates for maximum protection of copper, solder, brass, steel, cast

iron and aluminum.

Cat ELC

Cat ELC for Maximum Coolant Life Cat ELC Extender for Longer Life

Cat DEAC™ • Exceeds Cat EC-1 performance requirements

• Protects against cylinder liner/block pitting

3000 Hour Life or

and cavitation erosion

333,000 km (200,000 miles)

Cat Supplemental Coolant Additives Every 250 Hours • Should be added at 500,000 km (300,000 miles)

or 25,000 km (15,000 miles) for Cat powered on-highway trucks and 6,000

hours for commercial engines

Cat ELC (Machines and Commercial Engines) • Extender is only necessary once during the

life of the coolant

• Ensures Cat ELC performance to 1,000,000 km

(600,000 miles) or 12,000 hours

Cat Extender Every 6000 Hours 12,000 Hour Life or 6 Years*

(whichever comes first)

Available Pre-Mixed or in Concentrate

Cat ELC (Truck Engines) Cat ELC 50/50 Premix is provided in standard

English and metric container sizes. Cat ELC

Concentrate is only available in 1- and 55-gallon

Cat Extender Every 500,000 km (300,000 miles) 1,000,000 km (600,000 miles) or 6 Years* sizes for radiator top-off. Coolant Conditioner

(whichever comes first) and ELC Dilution Test kits are also available.

* These coolant change intervals are only possible with annual S•O•S Level 2 coolant sampling and analysis.

ELC Extender and Flush Intervals

Cat ELC Extender should be added after 6,000

hours or 300,000 miles (500,000 km) of operation,

and the system should be drained and flushed

with clean water after 12,000 hours or 600,000

miles (1,000,000 km). No cleaning agents are

needed. If S•O•SSM Services are used regularly,

safe operation with Cat ELC may extend beyond

12,000 hours.

Typical Characteristics* S•O•S Services for early problem detection

Protect your investment with Cat S•O•S

Color Strawberry Red Coolant Analysis, the ultimate detection and

Boiling protection with 15 psi (1 bar) radiator cap diagnostic tool for your engines. We

50% Cat ELC/50% water 129°C (265°F) recommend S•O•S Level 1 Coolant Analysis

60% Cat ELC/40% water (ELC concentrate added) 132°C (270°F) according to the engine‘s Operation and

Maintenance Manual, or Level 2 Coolant

Freezing protection Analysis annually for all your Cat equipment.

50% Cat ELC/50% water -37°C (-34°F)

60% Cat ELC/40% water (ELC concentrate added) -52°C (-62°F) Cat Filters: Complete protection for your machine

Nitrite (50% solution) 500 ppm Combine Cat Fluids with Cat Filters for the

Molybdate (50% solution) 530 ppm highest level of contamination control and

protection for your machine. We recommend

*The values shown are typical values and should not be used as quality control parameters to either Cat Filters for all Cat machine applications.

accept or reject product. Specifications are subject to change without notice.

Health and Safety

For information on proper use for health, safety, and environment, please refer to

the Material Safety Data Sheet (MSDS). Read and understand the MSDS before

using this product. Always observe good hygiene measures. For a copy of the

MSDS, contact us or visit the web at www.catmsds.com.

PEHJ0067-01 www.cat.com © 2005 Caterpillar All Rights Reserved Printed in USA

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- ELC Data Sheet PEHP9557Document4 pagesELC Data Sheet PEHP9557Суйунбай Солпуев100% (1)

- Extended LifeDocument4 pagesExtended LifePrzemek SankowskiNo ratings yet

- Cat ElcDocument4 pagesCat ElcDoru IonNo ratings yet

- Cat CoolantDocument4 pagesCat CoolantMaqsood Ahmad100% (1)

- ELC Data SheetDocument2 pagesELC Data SheetFabio Junior100% (1)

- Cat Deac: Prevents Freezing While Providing Superior Component ProtectionDocument2 pagesCat Deac: Prevents Freezing While Providing Superior Component ProtectionCarlos Indigoyen LimaymantaNo ratings yet

- PDSDetail PageDocument4 pagesPDSDetail Pagemgamal1080No ratings yet

- Caterpillar ELC Coolant Longest PerformanceDocument2 pagesCaterpillar ELC Coolant Longest PerformancePETROTECHMECONo ratings yet

- Coolant Flyer EAMEDocument1 pageCoolant Flyer EAMEHubertt Chacon AntonioNo ratings yet

- 339-3778 NGEC Heavy Duty Cooling System FluidDocument3 pages339-3778 NGEC Heavy Duty Cooling System Fluidchristian ivan castro canoNo ratings yet

- ES COMPLEAT™ AntifreezeCoolant - LT15548Document2 pagesES COMPLEAT™ AntifreezeCoolant - LT15548Cesar G.No ratings yet

- HD Phosphate FreeDocument2 pagesHD Phosphate FreeLankaster Flórez ChNo ratings yet

- Shell Rotella ELC Libre de Nitrito Prediluido 50-50Document3 pagesShell Rotella ELC Libre de Nitrito Prediluido 50-50Jorge Arrieta TorresNo ratings yet

- Lehe1612 04Document10 pagesLehe1612 04mvlNo ratings yet

- OEM Advanced 48 RTU Coolant-PI SheetDocument3 pagesOEM Advanced 48 RTU Coolant-PI SheetJ. Carlos Alvarez C.No ratings yet

- Cat Deac: Prevents Freezing While Providing Superior Component ProtectionDocument2 pagesCat Deac: Prevents Freezing While Providing Superior Component ProtectionEbied Yousif AlyNo ratings yet

- Shell IVeco 1811Document2 pagesShell IVeco 1811Jorge Arrieta TorresNo ratings yet

- Fluid Recommendations ###Document5 pagesFluid Recommendations ###benjir shuvoNo ratings yet

- C15 BrochureDocument9 pagesC15 Brochurehmdawu baslNo ratings yet

- 6btaa5 9-G7Document10 pages6btaa5 9-G7Jakir HossainNo ratings yet

- 9 Sinopec TULUX T500 Classic Diesel Engine Oil (CI-4SL)Document3 pages9 Sinopec TULUX T500 Classic Diesel Engine Oil (CI-4SL)Salman Ahmed PrinceNo ratings yet

- Diesel Generator 350-To-500-Kw-Specs-SheetDocument9 pagesDiesel Generator 350-To-500-Kw-Specs-SheetamrNo ratings yet

- Cat C15: Diesel Generator SetsDocument6 pagesCat C15: Diesel Generator SetsAung Min HtetNo ratings yet

- Cooltech LLO CoolantDocument2 pagesCooltech LLO CoolantahmedalgaloNo ratings yet

- Delo Extended Life Coolant Antifreeze 5050Document5 pagesDelo Extended Life Coolant Antifreeze 5050Ravi SekhonNo ratings yet

- CM20200727 78ead 369e2Document9 pagesCM20200727 78ead 369e2kNdash5No ratings yet

- Cat NGEC 50 - 50Document2 pagesCat NGEC 50 - 50shamsalihu2729No ratings yet

- Gpcdoc Gtds Shell Argina T 40 (2005) (En) TdsDocument2 pagesGpcdoc Gtds Shell Argina T 40 (2005) (En) Tdscesar_lub100% (1)

- Mack T13 Engine Lubricant TestDocument2 pagesMack T13 Engine Lubricant TestFrank FareNo ratings yet

- Shell Helix Ultra SP 0W-20 - Advanced Synthetic Motor Oil for High Performance EnginesDocument1 pageShell Helix Ultra SP 0W-20 - Advanced Synthetic Motor Oil for High Performance EnginesJAVIERNo ratings yet

- Cat NGEO EL350: (Natural Gas Engine Oil)Document2 pagesCat NGEO EL350: (Natural Gas Engine Oil)Alfonso Alberto ArguelloNo ratings yet

- Kohler Sdmo Kd2250-EDocument6 pagesKohler Sdmo Kd2250-EMartin KratkyNo ratings yet

- Peak Final Charge 50-50Document2 pagesPeak Final Charge 50-50andymoreNo ratings yet

- Cat DEO (Diesel Engine Oil) PEHJ0021 PDFDocument2 pagesCat DEO (Diesel Engine Oil) PEHJ0021 PDFfjaristizabalNo ratings yet

- Delo® XLC Antifreeze-CoolantDocument5 pagesDelo® XLC Antifreeze-CoolantAymanSayedElantableeNo ratings yet

- Hydraulic 150Document1 pageHydraulic 150Cleveston MoraisNo ratings yet

- Shell Helix Ultra Professional AF 5W-20: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix Ultra Professional AF 5W-20: Performance, Features & Benefits Main ApplicationsCristiBvNo ratings yet

- Gpcdoc Gtds Shell Argina T 30 (2005) (En) TdsDocument2 pagesGpcdoc Gtds Shell Argina T 30 (2005) (En) TdsEdgar Leonel CortésNo ratings yet

- Castrol Antifreeze NF Product Data SheetDocument5 pagesCastrol Antifreeze NF Product Data SheetJaya PranataNo ratings yet

- Shellzone AFC 50-50Document2 pagesShellzone AFC 50-50Jorge Arrieta TorresNo ratings yet

- 207 EN Conc Reco-Cool-Antifreeze-Coolant Technical-Data-Sheet 1Document2 pages207 EN Conc Reco-Cool-Antifreeze-Coolant Technical-Data-Sheet 1Jon HermanNo ratings yet

- LT15108 GBDocument8 pagesLT15108 GBvNo ratings yet

- Cat Deo 15W40 - Pehj0059-02 PDFDocument2 pagesCat Deo 15W40 - Pehj0059-02 PDFpaolo88No ratings yet

- Coolant For EngineDocument27 pagesCoolant For EnginemunhNo ratings yet

- Shell Rotella T5 NG 15W 40 DatasheetDocument3 pagesShell Rotella T5 NG 15W 40 DatasheetRonald BarriosNo ratings yet

- Freecorev - Micro - 10 - English ARtecoDocument5 pagesFreecorev - Micro - 10 - English ARtecoManh Nguyen TheNo ratings yet

- TITLE Technical Data Sheet for Shell Argina X 40Document2 pagesTITLE Technical Data Sheet for Shell Argina X 40HUM CIREBON DFLTS100% (1)

- Coolant OAT Bulletin LT32533Document2 pagesCoolant OAT Bulletin LT32533Castro RicardoNo ratings yet

- Mobil EAL Arctic Series Mobil EAL Arctic Series Mobil EAL Arctic Series Mobil EAL Arctic SeriesDocument3 pagesMobil EAL Arctic Series Mobil EAL Arctic Series Mobil EAL Arctic Series Mobil EAL Arctic SeriesAbdul SattarNo ratings yet

- Shell Helix Ultra 5W-30: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix Ultra 5W-30: Performance, Features & Benefits Main ApplicationsCristiBvNo ratings yet

- Reflo™ CFC R C O: Efrigeration Ompressor ILDocument2 pagesReflo™ CFC R C O: Efrigeration Ompressor ILRicardo Lucio ZuimNo ratings yet

- QST30-G3 Hci634hDocument10 pagesQST30-G3 Hci634hMiguel AngelNo ratings yet

- Cat Deo PDFDocument2 pagesCat Deo PDFBROCHIERNo ratings yet

- Astm D6210 10Document2 pagesAstm D6210 10Gabriel ChelloNo ratings yet

- Kta50 G9Document2 pagesKta50 G9Paul TriumfanteNo ratings yet

- Helix Ultra Ect C3 5W-30 PDFDocument2 pagesHelix Ultra Ect C3 5W-30 PDFCristiBvNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Astm F 781Document4 pagesAstm F 781DmitriyNo ratings yet

- SS - AIATS - 01 (Adv) - P - 1 - A - 2020-06-21 - 2020 - QDocument23 pagesSS - AIATS - 01 (Adv) - P - 1 - A - 2020-06-21 - 2020 - Qyash chawliyaNo ratings yet

- SolderDocument11 pagesSolderahmedNo ratings yet

- Psychrometry For Air ConditioningDocument59 pagesPsychrometry For Air ConditioningPraveenkumar KashyabNo ratings yet

- Science Lab ReportDocument8 pagesScience Lab Reportapi-452660914No ratings yet

- 29 Welded Joints Types and UsesDocument10 pages29 Welded Joints Types and UsesPRASAD326100% (1)

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationyazNo ratings yet

- 1993 - Diamond - Microstructure of Hardened Cement PasteDocument7 pages1993 - Diamond - Microstructure of Hardened Cement PasteTomás Venegas PardoNo ratings yet

- Nanotechnology: What Is Nano Technology?Document5 pagesNanotechnology: What Is Nano Technology?Francis PrasadNo ratings yet

- Bio-Vision - SSLC Chemistry SmileDocument19 pagesBio-Vision - SSLC Chemistry SmilemujeebNo ratings yet

- FUJIFILM Minilab Paper Processing ManualDocument36 pagesFUJIFILM Minilab Paper Processing Manualmdobrica100% (1)

- Kaise Kbl12550Document2 pagesKaise Kbl12550Seba LopezNo ratings yet

- Composite AssignmentDocument4 pagesComposite AssignmentAmna QureshiNo ratings yet

- Physical States & Types of Food DispersionsDocument13 pagesPhysical States & Types of Food DispersionsKhaled Abu-AlruzNo ratings yet

- Rubber Mixing SimulationDocument147 pagesRubber Mixing Simulationalperen52100% (2)

- ST Epan: Product BulletinDocument2 pagesST Epan: Product BulletinJulio Ramos GonzalezNo ratings yet

- Analysis of Marks of Questions (Subject-Wise) Appeared in GATE ExamDocument2 pagesAnalysis of Marks of Questions (Subject-Wise) Appeared in GATE ExamRakesh KumarNo ratings yet

- 59a. IS - 2041 - 2009Document9 pages59a. IS - 2041 - 2009hhr2412No ratings yet

- Sop of Aqu - ExtractionDocument5 pagesSop of Aqu - ExtractioneyobNo ratings yet

- Gear Beam and Wear StrengthDocument46 pagesGear Beam and Wear StrengthNisarg MistryNo ratings yet

- BioreactorsDocument0 pagesBioreactorsPaulo SouzaNo ratings yet

- Cycle-III Expt 9 ESR - Lande G FactorDocument6 pagesCycle-III Expt 9 ESR - Lande G FactorSwapnil BabeleNo ratings yet

- Chapter 3: Atomic and Ionic Arrangements: 3-1 SolutionDocument52 pagesChapter 3: Atomic and Ionic Arrangements: 3-1 SolutionMarcos Jose100% (1)

- Chemistry HistoryDocument8 pagesChemistry HistorykylianNo ratings yet

- Macgrid Asia BiDocument2 pagesMacgrid Asia Bisundra0No ratings yet

- Balancing Equations ModuleDocument3 pagesBalancing Equations ModuleRonie MalazzabNo ratings yet

- DIN 3015 Clamp Guide for Pipes & HosesDocument32 pagesDIN 3015 Clamp Guide for Pipes & Hosesxuanphuong2710No ratings yet

- r05310805 Chemical Reaction Engineering IDocument8 pagesr05310805 Chemical Reaction Engineering ISrinivasa Rao GNo ratings yet

- SS1 Chemistry First, Second, and Third Term NotesDocument225 pagesSS1 Chemistry First, Second, and Third Term NotesSochiNo ratings yet

- Csec Lab Manual 2017 PDFDocument36 pagesCsec Lab Manual 2017 PDFCamaya Rumble100% (3)