Professional Documents

Culture Documents

Automatic Synchronizer Technical Manual

Uploaded by

TESLA IngenieriaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Synchronizer Technical Manual

Uploaded by

TESLA IngenieriaCopyright:

Available Formats

MX3EG1A

Autom

Automati

aticc Sy

Synch

nchron

roniz

izer

er

TECHNICAL MANUAL MDE/A133 2295 001

ABCD

Downloaded from www.Manualslib.com manuals search engine

Appositely left blank

Downloaded from www.Manualslib.com manuals search engine

Appositely left blank

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

SUMMARY

1. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. GENERAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Parallel sequence start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Voltage regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.1 Max. deviation bar voltage/rated voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.2 Min. generator voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2.3 Max. voltage difference

difference.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Frequency regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3.1 Max. deviation rated frequency/ bar frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3.2 Max. deviation rated frequency/ generator frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3.3 Max. frequency difference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Load pulse and parallel command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Dead-bar mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.1 DB dead-bar mode OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.2 DB dead-bar mode ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.3 DB dead-bar mode ON-CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Main and spare settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. ADDITIONAL FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Output circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 LED signalling circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.6 Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.7 Measurement

Measurements s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.8 Test

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.9 Alphanumeric code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.10 Languag

Language e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.11 LCD

LCD settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.12 Inhibiting operation-deconfiguration from network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.13 Serial communication on LONWORKS (TM) (TM) bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.14 RS485 serial communication

communication on MODBUS protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.15 Oscillopertu

Oscilloperturbography

rbography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5. LOCAL INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

pag. 3

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

6. LCD MENU STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 MAIN READING MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1.1 Changing dialogue language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1.2 Changing date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.3 Displaying settings in use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.4 Displaying main settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1.5 Displaying spare settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.6 Displaying current measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.7 Displaying counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1.8 Displaying events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.9 Displaying output relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.10 Displaying digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1.11 Displaying leds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.12 Displaying relay data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1.13 Displaying diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 MAIN SETTING CHANGE MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.1 Selecting current setting group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2 Changing main settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.3 Changing spare settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.4 Setting output relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.5 Setting digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.6 Setting LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.7 Setting alphanumeric code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.8 LCD back-lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 TEST MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7. APPLICATION AND USE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8. INSTALLATION - TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.1 ESD electrostatic charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 Acceptance-storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Assembling and connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9. SETTING THE UNIT AT WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.1 Safety regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.2 Checking nameplate ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9.3 Final inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

APPENDIX A - Network data exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

pag. 4

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

possibility of selecting, for each LED, the monostable or

1. TECHNICAL DATA

bistable operating mode (stored)

The device belongs to the Modulex 3 line, and processes with a

optoinsulated digital inputs which can be programmed for

numerical technique two phase voltages to provide the automatic

control and reset functions. These can be indi vidually enabled

synchronization besides several additional functions.

by normal energizing or de-energizing, on front or o on level.

The user's interface is available locally through the presence of

They can also be used to control the continuity of the tripping

a display unit and remotely through a LONWORKS(TM)b bus with

circuit

a control and monitoring system.

partial and total counters for each kind of event

It is furthermore capable of dialoguing with a Personal Computer

through a special connector placed on the relay front and an

interface programme; this feature makes it easier and safer to MAIN SETTINGS

programme the setting and configure parameters and read the

Main parameters

set values, measurements and logged events; the programming

bar rated voltage: Ubn: 40 ÷ 130 V

can also be performed from previously created file s.

generator rated voltage: Ugn: 40 ÷ 130 V

by steps of 0.1 V

Control functions: measuring range: 0 ÷ 200 V

oper.frequency range for measurements for fn 50Hz: 10 ÷ 60 Hz

max. rated frequency/bar frequency deviation

oper.frequencyca range for measurements for fn 60Hz: 10 ÷ 72 Hz

max rated frequency/generator frequency deviation

permanent overloading: 200 V

max. rated voltage /bar voltage deviation overloading for 10 s: 250 V

min. generator voltage value burden with 100 V: ≤ 0.6 VA per phase

max frequency difference

max. frequency voltage difference Synchronization parameters

max. phase difference parallel sequence max. time ts: 1 ÷ 30 min

by steps of 1 min

max. time for parallel operation execution

max. number of parallel attempts Ns: 1 ÷ 10

max. no.of parallel attempts

by steps of 1

live bar/dead bar control closing command pulse time tc: 0.10 ÷ 9.99 s

possibility of two settings groups - spare and main settings closing delay tr: 0.02 ÷ 0.99 s

occurred-closing wait time twc: 0.10 ÷ 9.99 s

Measurements functions: by steps of 0.01 s

fb/fn max.deviation Dfb: (±) 1 ÷ 5 %

effect. Ub bar voltage value expressed in Ubn multiples

fg/fn max. deviation Dfg: (±) 1 ÷ 20 %

effect. Ug generator voltage value expressed in Ugn multiples

Ub/Ubn max. deviation DUb: (±) 1 ÷ 5 %

fb bar frequency value expressed in Hz Ug/Ugn min. generator voltage DUg: 70 ÷ 85 %

fg generator frequency value expresse d in Hz by steps of 1%

phase difference between bar voltage and Dp generator voltage stability time td: 0.1 ÷ 10.0 s

expressed in grades by steps of 0.1 s

max. frequency difference Df: (±) 0.02 ÷ 0.50 Hz

logging of the last eight events with storage of event type, date,

by steps of 0.01 Hz

time, valuesof Ub,Ug, fb, fg, Dp measurements, no. of parallel max. voltage difference DU: (±) 1 ÷ 30 %

attempts and parallel time by steps of 1%

oscilloperturbography: recording, for a total time equalling 2.5 max. phase difference Dp: (±) 1 ÷ 30 º

s, of the instant values (12 samples per period) of the inputs by steps of 1º

live bar, parallel mode LB: NORM

measurements (Ub,Ug) and of the 18 logical states among

SUBSYNC

which are digital inputs, end relays and leds

SUPERSYNC

RCE: recording of the last 32 state changes (with relati ve date dead bar DB: OFF

and time); they are only available through PC or network. ON

ON CHECK

Other functions: dead bar level Ud: 0.10 ÷ 0.30 Ubn

by steps of 0.01 Ubn

selection of rated frequency within 50Hz and 60Hz

selection of dialogue language (Italian, English, French and

Frequency regulator parameters

Spanish)

frequency regulating mode CPf: CONT-PULSE

self-monitoring with detailed indication of the fault and alarm frequency regulation pulse time tfpu: 0.10 ÷ 9.99 s

through LEDs and "normally energized" output relays (X6) frequency regulation min. pause time tfpa: 1.00 ÷ 9.99 s

possibility of serial communication both with a local PC and on fr equ ency re gulat io n max. p ause time tfpm: 10. 00 ÷ 99.9 9 s

LONWORKS (TM) bus by steps of 0.01 s

load pulse LP: ON-OFF

possibility of assigning one or more functions of the device to

load pulse time tlp: 0.10 ÷ 9.99 s

each output relay and each LED

by steps of 0.01 s

possibility of setting all the output relays to "normally energized"

or "normally de-energized"

pag. 5

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

Voltage regulator parameters Timing error variation

voltage regulation mode CPU: CONT-PULSE as frequency varies within ± 5% fn (for voltage values) ± 10Hz (for

voltage regulation pulse time tupu: 0.10 ÷ 9.99 s frequency values) and with distortion factor ≤ 5%

voltage regulation pause time tupa: 0.10 ÷ 9.99 s relative error on independent times: ≤ 1% or 10 ms

by steps of 0.01 s

as temperature and Uaux vary within the operation field

ADDITIONALSETTINGS relative error on independent times: ≤ 0.5% or 10 ms

bar TV primary rated voltage: 100 ÷ 1000000 V

generator TV primary rated voltage: 100 ÷ 1000000 V

Further characteristics

by steps of: 1V

rated frequency fn: 50 o 60 Hz Max.threshold drop-out ratio: > 0.95

Min. threshold drop-out ratio: < 1.03

Max.frequency drop-out thresholds: (threshold - 0.01) Hz

Auxiliary power supply Min.frequency drop-out thresholds: (threshold + 0.01) Hz

versions MX3EG1A.11, .61 and .71 drop-out time: ≤ 50 ms

Uaux: 19 ÷ 100 Vcc idle time (overshoot): ≤ 30 ms

Uaux: 19 ÷ 72 Vca

versions MX3EG1A.12, .62 and .72

Operating ranges

Uaux: 64 ÷ 300 Vcc

Uaux: 64 ÷ 275 Vca Operating temperature: -10 °C ÷ +60 °C

a.c. frequency for Uaux: 47 ÷ 63 Hz storage and transport temperature: -25 °C ÷ +80 °C

d.c.burden (min/max): 5 W / 10 W relative humidity: < 95% without formation of condensate

a.c.burden (min/max): 10VA / 20VA vibrations: IEC255-21-1; class 2; 0.075mm 10-60Hz; 1g 60-500Hz

Contacts features Weight

rated current: 5A Total: 2.5 Kg

breaking power (110 Vcc; L/R= 40 ms; 105 operations): 0.3 A

closing and capacity for 0.5 s: 30 A Protection class

mechanical life: 10 6 operations device: IP52

on request, front panel: IP66

Digital inputs terminal board with mounted covering: IP20

versions MX3EG1A.11, .61 and .71

Uaux IN DIG: 19 ÷ 100 Vcc Insulation

input resistance: 9 kohm To ground and between two independent circuits:

versions MX3EG1A.12, .62 and .72 2 kV, 50 Hz per minute

Uaux IN DIG: 64 ÷ 264 Vcc Pulse holding: 5 kV 1.2/50 µs

input resistance: 48 kohm

Electromagnetic compatibility

Errors of measuring equipment

89/336/ECC directive : EN50081-2 EN50082-2

Voltage thresholds For industrial environments

relative error: ≤ 2.5% on point + 0.02 V UNIPEDE NORM(SPEC)13 "Automation and control apparatus for

fidelity error: ≤ 0.02 V generating station and substation"

ENEL R_EMC_02 "Apparati di automazione e controllo per centrali e

Frequency thresholds stazioni elettriche".

relative error: ≤ 0.01 Hz Electromagnetic compatibility conditions:

fidelity error: ≤ 0.01 Hz IEC 1000-4-8 EN 61000-4-8 lev.5; 1000 A/m

IEC 1000-4-10 EN 61000-4-10 lev.5; 100 A/m

Phase thresholds

IEC 1000-4-3 ENV 50140 lev.3; 10 V/m

relative error: ≤ 1° 77B(Sec)1 ENV 50204 lev.3; 10 V/m

fidelity error: ≤ 1° IEC 1000-4-2 EN 61000-4-2 lev.4; 8kV contact;15kV in air

77A/120/CD lev.4 / 3; 300V / 10-1-1-10 V

IEC 1000-4-5 EN 61000-4-5 lev.4; 4kV 1.2/50 µ s

Error variations IEC 1000-4-12 EN 61000-4-12 lev.3; 2.5 kV

as frequency varies within ± 5% fn (for voltage values) ± 10Hz (for IEC 1000-4-4 EN 61000-4-4 lev.4; 4 kV

frequency values) and with distorsion factor ≤ 5% 77B/144/DIS ENV 50141 lev.3; 10 V

77A(Sec)99 lev.2; 10%

Voltage threshold IEC 1000-4-11 EN 61000-4-11 > 20 ms

relative error: ≤ 0.5% on point + 0.02 V IEC/CISPR 11 EN 55011 group 1 class A

as temperature and Uaux vary within the operation field

Reference standards

Voltage threshold

CEI 95-1 EN 60255-6 IEC 255

relative error: ≤ 0.25% on point + 0.01 V

Low voltage directive 73/23/ECC

for asymmetric quantities

relative error in the presence of unidirectional: ≤ 5%

Timing errors

relative error on independent times: ≤ 3% o 20 ms

fidelity error on independent times: ≤ 1% o 20 ms

pag. 6

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

2. GENERAL CHARACTERISTICS 3. OPERATION

The device features a mechanical casing that is 4 U in height and 3.1 Parallel sequence start

as wide as to allow up to 4 pieces to be accommodated in a 19"

Upon enabling the digital input associated with LB start (with

rack in addition to normal flush-mounting.

enabling characteristic on front) the stability timer td is started to

The casing is made of hot-galvanized PVC-coated plate frame

allow any external settings to be made; when the td time is over,

inside which the movable part that carries all the electronic

the device begins the parallel sequence.

circuits and the local interface slides on guides. The pull-out

The sequence can be stopped by enabling the digital input

action is facilitated by special 'handles', which, when the device

associated with STOP, An EXT 1 or An EXT 2 (respectively, for

is "plugged in", are also used to lock the two parts. The aluminium

manual sequence interruption or external failures).

frame of the moving part renders the latter excellentl y rigid.

In this case, the command relative to the synchronization

The device/system interface terminal blocks are located on the

sequence interrupted by STOP or an external event EXT1 or

rear side of the casing and, for each electrical connection, a

EXT2 as well as any signal correspond ing to the event are sent;

screw clamp is available to receive up to 2 cable terminals, 4mm2

i

the partial and total counter corresponding to the mentioned event

in size; using a special accessory that is included in the supply,

is incremented and the event logging is enabled.

the connection can also be made by means of Faston units.

Once the parallel has been performed, the sequence is interrupted

Special error-sensing codes avoid inserting relays other than

when the signal of "closed breaker" is received (enabling of the

those compatible with the housing.

digital input associated with CH52).

A cover lid classes the terminal block within the IP20 protection.

When the movable part is pulled out, the voltage and auxiliary

circuits are disconnected. 3.2 Voltage regulator

The device front bears two labels: 3.2.1 Max. deviation bar voltage/rated voltage

one plate listing the factory settings of the device, namely auxiliary

The device works by comparing the Ub bar voltage with the Ubn

voltage and frequency;

bar rated voltage.

the other plate, always in accordance with the factory settings,

When the deviation between the voltages exceeds the DUb set

provides a description of LED signals.

value, the 'START request failed' command - due to Ub out-of-

Both these plates can be easily replaced with new ones, showing

tolerance condition - as well as any signal corresponding to the

all the information as required by the client.

event are sent; the partial and total counter relative to the event

As far as the factory settings relevant to output relays, LEDs,

is incremented and the event logging is enabled.

digital inputs and relative sett ings are concerned, refer to tables

A, B and C.

3.2.2 Min. generator voltage

The device works by comparing the Ug generator voltage with the

Ugn generator rated voltage.

When the Ug voltage falls below the DUg set value, the 'START

request failed' command - due to Ug out-of-tolerance conditio n -

as well as any signal corresponding to the event are sent; the

partial and total counter relative to the mentioned event is

incremented and the event logging is enabled.

3.2.3 Max. voltage difference

The device works by comparing the Ub bar voltage with the Ug

generator voltage.

When the difference between the modules of the two voltages

modules expressed in Ubn and Ugn multiples, exceeds the DU

set value, the 'voltage increase' (if Ug<Ub) or 'voltage decrease'

(if Ug>Ub) command is sent.

The voltage increase/decrease commands can be of 'continuous'

or 'pulse' type depending on the regulation mode that has been

set, that is CPU CONT or PULSE.

If the PULSE mode has been set, the pulse time is de fined by the

tupu set parameter; the min. pulse interval is given by the tupa set

parameter.

The device makes it possible to obtain Ubn and Ugn values that

are different from each other. This allows the parallel to be

performed even with one TV installed upstream and the other

installed downstream a transformer with Yd group; this is made

by using, on one side, a phase-phase voltage and, on the other,

the corresponding neutral-phase voltage without the application

of any TV adapter.

pag. 7

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

3.3 Frequency regulator 3.4 Load pulse and parallel command

3.3.1Max. deviation rated frequency/ bar frequency When none of the following thresholds: DUb, DUg, DU, Dfb, Dfg,

Df, Dp is tripping, the protection sends a parallel command with

The device works by comparing the fb bar frequency with the fn

a pulse duration equal to tc; the command is sent with a n

rated frequency.

advance time equal to tr (breaker trip time) compared to the

When the deviation between the two frequencies exceeds theDfb

expected Dp=0 phase difference instant: this to allow the breaker

set value, the 'START request failed' command - due to fb out-

to be closed just when the voltages are in phase with each other.

of-tolerance condition - as well as any signal corresponding to the

If after the twc time the breaker is not closed (corresponding

event are sent; the partial and total counter relative to the

digital input enabling failed) and the parallel conditions are still

mentioned event is incremented and the event logging is enabled.

acceptable, a further closing comma nd is sent; the max. number

of commands is defined by the set Ns.

3.3.2Max. deviation rated frequency/ generator frequency If after the last attempt the breaker is not closed, the 'failed

The device works comparing the fg generator frequency with the synchronization sequence' command - once the max. number of

rated frequency. attempts has been reached - as well as any signal corresponding

When the deviation between the two frequencies exceeds the Dfg to the event will be sent; the partial and total counter relative to the

set value, the 'START request failed' command - due to fg out- event is incremented and the event logging is enabl ed.

of-tolerance condition - as well as any signal corresponding to the In the same way, if the sequence has not been terminated after

event, are sent; the partial and total counter relative to the event the max. time ts defined for the parallel sequence, the 'failed

is incremented and the event logging is enabled. synchronization sequence' command - following a timeout

condition - as well as any signal corresponding to the event will be

sent; the partial and total counter relative to the mentioned event

3.3.3 Max. frequency difference

is incremented and the event logging is enabled.

The device works by comparing the fb bar frequency with the fg

On receiving the 'breaker closed' signal, the 'correctly-performed

generator frequency.

synchronization sequence' command is sent, the event logging

When the difference between the two frequencies exceed the Df

is also enabled.

set value, the 'frequency increase' (if fg<fb) or 'frequency decrease'

Together with the 'breaker closing' command, in the event of LP

(if fg>fb) command is sent.

load pulse in ON mode, a frequency increase pulse is issued for

The frequency increase/decrease commands can be of

a time duration equal to tlp. This frequency increase pulse and,

'continuous' or 'pulse' type depending on the regulation mode that

therefore, the system speed are aimed at preventing energy

has been set, that is CPf CONT or PULSE.

returns from occurring.

If the PULSE mode has been set, the pulse time is defined by the

tfpu set parameter; the min. pulse interval is given by the tfpa set

parameter. 3.5 Dead-bar mode

If the phase difference between bar and generator constantly lies The device can even be used to feed an out-of-voltag e bar (dead

above the Dp set threshold, after a time interval equal to tfpm has bar): the generator parameter can be set before the breaker

expired since the last frequency increase/decrease command, closing.

the following types of desynchronization commands will be sent: The sequence start occurs upon enabling the digital input

'frequency increase' in the event of SUPERSYNC live bar parallel associated with a DB start (with enabling characteristic on front).

mode or 'frequency decrease' in the event of SUBSYNClive bar The dead-bar level is defined by the Ud set value; below the said

parallel mode; in case of NORM live bar parallel mode the value the bar is considered as not-fed.

'increase' command will be sent when the generator is in 'delay'

condition compared to the bar, whereas the 'decrease' command 3.5.1 DB dead-bar mode OFF

will be sent when the generator is in 'advance' condition.

Any request of dead-bar synchronization is ignored.

3.5.2 DB dead-bar mode ON

The device checks that the generator frequency and voltage lie

within the limits defined by Dfg and DUg, by controlling the parallel

breaker closing without carrying out any adjusting action.

pag. 8

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

3.5.3 DB dead-bar mode ON-CHECK 4. ADDITIONAL FUNCTIONS

The device checks that the generator frequency and voltage lie 4.1 Diagnostics

within the limits defined by Dfb and DUb: if these do not lie within

Diagnostic activities are envisaged which are automatically carried

the mentioned limits, the device carries out all the adjusting

out upon powering on the device as well as from time to time

operations necessary to make them lie within the range of values

during the running, and which allow the following actions to be

defined. The 'parallel breaker closing' command will be then sent.

performed:

- signalling fault or failure conditions. This signal de-energizes

3.6 Main and spare settings the diagnostic relay, turns off the green LED (running device)

The device can store two groups of settings, namely 'main' and and turns on the red LED ( faulty devi ce);

spare', which can be selected through keyboard, PC or network. - locking out the device in the event of faults that might entail ill-

The group of setting being used is shown on the display as timed operation (VITAL FAULTS)

'SETTINGS IN USE'. - displaying the code referring to the type of fault occurred.

Independently of the selection made, the device can be 'forced' The following faults are defined as NOT VITAL FAULTS:

to use the SPARE settings. This 'forcing' can be carried out from - output relay (X1 - X5) faulty

the network or by permanently enabling the digital input (IN DIG 1) - communication faulty

configured to such aim. This condition is signalled by the - internal clock faulty

characters <!> which appear near the group already selected; The following faults are defined as VITAL FAULTS:

when the input is disabled, the group of settings previously - feeder faulty

selected is restored and the characters <!> disappear (see - EEPROM faulty

paragraph 6.1.3). - internal or exteranl RAM faulty

- analog/digital converter faulty

In the event of vital faults the device automatically displays the

code relative to the kind of fault occ urred; if allowed by the device,

this condition can only be solved by enabling the 'settings change'

command.

In the event that, upon starting up the equipment, an EEPROM

failure makes it impossible to retrieve the information on the

selected dialogue language, the device will continue on working

using Italian as default language.

The device includes the 'Watch Dog'.

The diagnostic activity is also aimed at signalling any condition of

'inhibited equipment': the relevant code is displayed, the diagnostic

relay is de-energized and the red LED (faulty device) lights on.

This condition can only be solved by enabling the 'settings

change' command.

The diagnostic menu also indicates the date when last changes

were made to the equipment.

4.2 Output circuits

The output circuits are composed of six relays: each of them is

provided with two contacts (see block diagram).

The X6 relay, normally energized, is strictly assigned to the

diagnostic function.

Each remaining relay, if duly programmed from the keyboard, PC

or network, can be set to carry out one or more functions.

The operation of these six relays is of monostable type: that is,

it allows to immediate return to the quiescent position when the

cause that operated it is removed.

The output relays, except for the diagnostic relays, can all be

simultaneously set to 'normally energized' (NORMAL.ON=ON)

or to 'normally de-energized' (NORMAL.ON=OFF): the selection

occurs bymeans of the S1 jumper which is accessible when the

relay has been pulled out (see fig. 2a, 2b).

pag. 9

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

4.3 LED signalling circuits 4.6 Event log

The signalling circuits are made up of twelve LEDs (see fig. 3). When an event occurs, the following information is stored in

Four LEDs are strictly assigned to previously established signalling circulating memory:

functions: - day, month, year, time, minute, second and thousandth of a

- green LED (Uaux) ON in the presence of power supply and second concerning the tripping moment

correct feeder output voltage values - type of event

- green LED (RUN) ON with fixed light in normal conditions and - bar frequency

blinking light during setting change or test operations - generator frequency

- red LED (RUN) ON with fixed light when the diagnostics - bar voltage

detects a fault or the device is inhibited. - generator voltage

- green LED (Rx Tx) ON with fixed light when the device is - phase difference

correctly connected to the network; ON with blinking light when - total parallel time

the communication board is not enabled or configured; OFF - number of parallel attempts

when the device is provided with no communication board. All this information is called 'event'.

Each of the eight remaining LEDs, if duly programmed from the The circulating memory allows the last eight events to be stored,

keyboard, PC or network, can be: and when this number is exceeded, a new record replaces the

- assigned to one or more control outputs or, in the event of older: the last event is stored as EVENT 1.

failures or events, The stored events can be read from the front display unit or from

- pre-set for : a PC serially connected to the device.

- monostable operation; it immediately goes off when the Furthermore, the device can store the last 32 changes of state

cause that made it go on is removed (with relative date and time) and make them readable through PC

- bistable operation (MEMOR): the LED remains on until a or network only.

reset signal is sent from the front push-button, digital input or

serial connection. Any failure of auxiliary voltage entails the

4.7 Measurements

momentary loss of the luminous signals, which are reset as

The device can display the effective current values concerning

soon as the voltage is restored.

the bar voltage expressed in Ubn multiples, the generator voltage

A pocket is provided close to the LEDs, where explanatory la bels

expressed in Ugn multiples, the bar and generator frequency

can be placed.

expressed in Hz, and the phase difference expressed in grades.

It also displays the effective current primary values relative to the

4.4 Digital inputs bar and generator voltage expressed in V.

If duly programmed from the keyboard, PC or network, each of

the five optoinsulated inputs can be assigned to one or more of the

4.8 Test

following functions referring to the device.

Besides the normal diagnostics already dealt with, the device

- Start LB

also offers, in the TEST mode, the possibility of testing the leds,

- Start DB

the display and the output relays.

- Synchronism Stop

- The LED test turns on all the LEDs from L1 to L8 and the

- Ch52 parallel breaker closing

display unit (LCD) for two seconds.

- EXT1, EXT2 external failure

Once the test is over, the LEDs that were supposed to be ON

The factory settings envisage that the above mentioned functions

before the test remain ON and the display unit goes back to the

are assigned according to the block diagram (fig. 3).

previous information displayed; the test can be carried out

The input voltage can differ from the auxiliary voltage of the

during any running condition, without affecting the operation in

device.

progress.

The enabling of the digital inputs can be programmed by normally

- The relay test allows the output relays from X1 to X5 to be

energizing or de-energizing or on front or level.

sequentially selected and checked for correct operation. IN

WARNING: the digital inputs associated with the Start LB

this way, any external signalling or control circuit can be

and Start DB functions must be ON on front , whereas all the

tested.

other functions must be ON on level.

The tested relay remains energized for 150 and 200 ms.

If commands are already present, the test cannot be carried

4.5 Counters out and a message appears on the display unit.

Each type of tripping is associated with a partial or total counter The test on auxiliary relays does not affect counters, event

(see paragraph 6.1.7). logs and LEDs.

The counters work within the 0-9999 range; if 9999 is exceeded,

the counter is automatically set to zero and the counting restarts

from zero.

All the partial counters can be set to zero from the keyboard, from

PC or network.

pag. 10

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

4.9 Alphanumeric code 4.13 Serial communication on LONWORKS (TM) bus

The device can be identified in the system by an alphanumeric In the version including the bus board, the device can communicate

code, which can be set by the user directly on the equipment code with a central monitoring and control system at a speed of 1.2 5

or from a PC. With a network-linked device, the alphanumeric Mbaud. The connection to the field bus is made through terminals:

code can only be modified by operating through the network. 43 and 45.

The communication board, which can even be added afterwards,

4.10 Language is enabled only if the special jumper is provided in S6, and is

disabled when the mentioned jumper is placed vertically between

The device can display information in four languages: Italian,

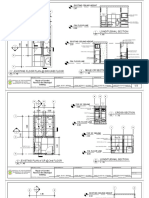

S5 and S6 (see fig.1).

English, French and Spanish. The language can be selected

The positioning of the jumper in S6 without the above mentioned

through the keyboard.

communication board, causes, just as a faulty board, a failure

message to be displayed in the diagnostics function.

4.11 LCD settings In the Appendix A all the data available for the network are shown.

The display can be set for fixed (OFF) or timed (ON) backlighting;

in the last case, the display lights up for 300s any time a key is

pressed.

4.12 Inhibiting operation-deconfiguration from network

Inhibiting the device is useful in already operating systems, to

avoid troubles when a protection is to be fed with voltage whose

settings are not known or meant to be changed . TOP

The inhibiting occurs by keeping the 'setting change' key pressed

for about 2s, and using auxiliary voltage simultaneously until the

following message is displayed:

[ BLOC ] RELAY

[ ] FRONT

When the said key is released, the condition of the inhibited

device is signalled with a message in the P fault diagnostics.

The operation reset is only made possible by selecting the setting

change function, which is however enabled; a momentary loss

of the auxiliary voltage does not change the device inhibition state.

If the device is equipped with a network board, from the BLOC

view A-A

condition, by furtherly keeping the setting change key pressed for

about 2s, the following message is displayed:

[ NET RESET ? ]

[_ NO YES _]

BOARD

If confirmed, the device can even leave its network configuration. NOT BOARD

The complete network de-configuration and inhibiting procedure ENABLED

ENABLED

is necessary every time the device must be replace d.

The reset of an inhibited and de-configured device entails the

view A-A view A-A

displaying of K fault messages until a new setting of the device

itself has not been made.

The operation reset is only made possible by selecting the setting

change function, which is however enabled.

fig. 1

I CAUTION

Hazardous voltages canremain in the unit even in the absence

of power supply or after it has been pulled out of its casing

(capacitor storage).

pag. 11

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

4.14 RS485 serial communication on MODBUS protocol These parameters can be modified in loco or from the network.

To this aim, the following extension of the 'RELAY DATA' has

Devices with 2.00 and higher software versi ons can feature three

been added :

different kinds of communication:

- no communication board

[MX3EG1A ] relay type

(version MX3EG1A .11 and .12); [Sw Vers 2.00/01] software version

- LonWorks(TM) communication board ñ ò

(version MX3EG1A .61 and .62); [PLANT IDENTIFIER]

- Modbus communication board [GenPan ] ðplant identifier

(version MX3EG1A .71 and .72); ñ ò

The type of communication board installed is automatically [SPEED 38400 Bb ] ðspeed setting

recognized. [PARITY NONE ] ðparity setting

In the event of device with LonWorks(TM) communication board it ñ ò

is necessary to carry out the connection as provided for and set [DATA BIT 8 ] ð data bit setting

all the connected devices. This is automatically possible by [STOP BIT 1 ] ð stop bit setting

connecting a PC equipped with PCLTA10 or SLTA10 board to a ñ ò

[ADDRESS 111 ] ð address setting

CORMOX2 programme.

[ ]

In the event of device with Modbus communication board, each

relay can be set through the front interface or through the IRMA2 Upon request, the message describing documents referrin g to the two

programme installed on PC connected to the front serial port. The different versions, LonWorks(TM) and Modbus, can be supplied.

configuration can be carried out even on relays which are still

connected to one another and can be pre-set on files together

4.15 Oscilloperturbography

with other information.

The device can record the course of the two input voltages - Ub

and Ug - and the logic states of the: 8 LEDs, 5 auxiliary relays and

5 digital inputs. The total recording time equals 2.5s, and can be

The configuration of the Modbus communication board requires

divided into variable time before start-up and variable time after

the following parameters:

start-up. The oscilloperturbography function can be started for:

remote control (from PC or network) of Start LB or Start DB,

PARAMETER VALUE remote control of Stop, synchronization sequence correctly

concluded, synchronization sequence failed, digital input enabling.

Speed 300 Baud The selection of the start parameters, the graphic display and the

600 Baud oscilloperturbography functio n reset can be made through PC or

1200 Baud network. The function reset can also be enabled by interrupting

2400 Baud the auxiliary voltage for a short time.

4800 Baud

9600 Baud

19200 Baud

38400 Baud

Parity NONE

EVEN

ODD

Data bits 7

8

Stop bits 1

2

Address 1 - 255 (0 broadcast)

pag. 12

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

5. LOCAL INTERFACE Key It allows the menu to be scrolled to the

left and the value to change to be

selected if the settings change function

is enabled. [ï ]

Key It allows the stored LEDs indications to

be reset if the cause has been removed,

or the partial counters to be reset if they

are in the 'display counters' menu.

It sets the end relays to quiescent state

when they are set to bistable operation.

Key If pressed for at least 2s, this key

allows the settings to be changed; when

the settings change function is enabled,

the green LED (RUN) lights up blinking.

If pressed once again for at least 2sec.,

the system goes back to normal running

conditions and, provided that a

confirmation is given, the new settings

become the current ones (the key can

only be reached by removing the cover

lid). During the settings-change

operations the device continues

working with the old settings. If the

changes made are confirmed in the

presence of a fault, the changes are

The local interface is made up of: not accepted until the event is over: the

- a LCD display unit organized on two lines of sixteen characters interrupt state is signalled for 3sec by a

each. message on the display unit, after which

Through a special keyboard-controlled scanning, the display

you are prompted to confirm the

unit enables the settings to be read and changed, the

changes made.

measurements, the counters, the logged events and the

diagnostic information to be read. If pressed when feeding the device with

- A keyboard made up of six keys, five of which can even be auxiliary voltage until a failure message

reached when the cover lid is fitted through a special link. appears on the display, this key inhibits

In addition to the above-mentioned scanning, the keyboard is the device from operating.

also used to change the settings, carry out tests that require

commands to be sent and stored indic ations to be set to zero; Keys If simultaneously pressed for at

the keys that can be reached when the cover lid is fitted only least 2sec, these keys allow the

allow for read-out and reset operations.

protection Test to be carried out. When

the testing activity is enabled, the green

Key It allows the menu to be scrolled

LED (RUN) lights up blinking.

upwards or the value to be increased if

If simultaneously pressed for 2 sec.

the settings change function is enabled.

during the TEST routing, these keys

[ñ]

enable you to leave the protection

testing mode.

Key It allows the menu to be scrolled

downwards or the value to be

decreased if the settings change

function is enabled. [ò]

Key It allows the menu to be scrolled to the

right or the value to change to be

selected if the settings change function

is enabled.[ð]

pag. 13

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

- Twelve LEDs, four of which are rigorously associated with 6. LCD MENU STRUCTURE

general functions.

- A four-pin connector in compliance with FCC 68. 6.1 MAIN READING MENU

By means of a special optoelectrical adapter, an optical fibre The device features a main menu that leads to several submenus

cable and RS232 optical convert er, it allows the device to be (tree-structure). All the displayed messages can be made

locally linked with a personal computer. permanently.

By means of a special interface programme, the PC enables

the settings to be read and changed, the measurements, the [Ug Ugn] Current value of generator voltage

[fg Hz ] Current value of generator frequency

counters, the logged events, the diagnostic information and

ñ ò

the oscilloperturbography to be read.

[MENU: ITALIAN ] Dialogue language

[ ] ð change dialogue language

ñ ò

[DATE ] current date and time

[TIME ] ð change date and time

ñ ò

[SETTINGS IN USE ] display settings in use

[ MAIN]

ñ ò

[SETTINGS READING] ð display main settings

[MAIN ]

ñ ò

[SETTINGS READING] ð display spare settings

[SPARE ]

ñ ò

[ MEASUREMENTS ] ð display/reset current and stored

[ ] values

ñ ò

[ COUNTERS ] ð display counters and reset

[P = RESETTABLE] partial counters

ñ ò

[ EVENTS ] ð display stored events

[EVENT 1=LAST ]

ñ ò

[OUTPUT RELAYS ] ð display output relay

[ ] configuration

ñ ò

[ DIGITAL ] ð display digital inputs

[ INPUTS ] configuration

ñ ò

[ LED ] ð display LED configuration

[ ]

ñ ò

[ RELAY DATA ] ð display model-software version

[ ] and alphanumeric code

ñ ò

[ DIAGNOSTICS ] ð display failures

[ ] last change date

All the following examples take their start form the main menu.

6.1.1 Changing dialogue language

The dialogue language is ITALIAN.

Here follows an example showing how to change the dialogue

language. Suppose we wish to set ENGLISH as the desired

language.

a) Press the key ò or ñ until the following message appears on

the display:

[MENU: ITALIAN ]

[ ]

b) By pressing the key ð the dialogue language function is

enabled and the following message appears on the display:

[MENU: ITALIAN ]

[ ]

pag. 14

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

c) By pressing the key ò or ñ the stored language menu is j) By pressing the key ò the date-change function is enabled and

scrolled. For the purpose of our example, we mus t stop when the the steps to be followed are the same as those described from c)

following message appears:

to i).

[MENU: ENGLISH ]

[ ] The device does not accept time or date settings that do not exist.

The time counting starts upon moving from the digits that make

d) By pressing the key ï the selected dialogue language is up the date to the wording TIME at the beginning of the line.

confirmed and you go back to the main menu. The following

message appears on the display:

k) By pressing the key ï the changes made are confirmed and

[MENU: ENGLISH ]

[ ] you go back to the main menu: the display will show:

[DATE 24/05/95]

6.1.2 Changing date and time [TIME 9:38:43]

Access to the 'change date/time' function is denied when the

protection is network-connected. If the network connection is 6.1.3 Displaying settings in use

made after entering the change function, the local changes are a) Press the key ò or ñ until the display shows:

not enabled. [SETTINGS IN USE]

Suppose we wish to change the starting date 10/06/93 into 24/05/ [ MAIN]

95.

The second line will display the group of settings the device is

a) Press the key ò or ñ until the display shows the following using.

message:

[DATE 10/06/93]

Any <!> possibly displayed, notwithstanding the contents of the

[TIME 9:38:43] second line, indicates the device is working with the SPARE

settings.

b) By pressing the key ð the change function is enabled and the [SETTINGS IN USE]

display shows as follows: [ <!> MAIN]

[DATE 10/06/93]

[TIME 9:38:43]

The device will continue on working with the SPARE settings as

c) By pressing the key ð the value to be changed is selected. long as the 'settings-change' command sent by the IN DIG1

Press the key ð six times to select the last digit that makes up digital input remains enabled. When <!> characters disappear,

the date, the display will show as follows: the device restarts working with the group of settings displayed.

[DATE 10/06/93]

[TIME 9:38:43]

6.1.4 Displaying main settings

d) By pressing the key ñ the value of the selected number is a) Press the key ò or ñ until the display shows:

increased. Hold the key pressed until the display shows: [SETTINGS READING]

[DATE 10/06/95] [MAIN ]

[TIME 9:38:43]

b) Press the key ð to enter the 'main setting display' submenu

e) By pressing the keyï , the fourth digit that makes up the date and the keys ò or ñ to scroll the submenu showing as follows:

is selected: the display will show:

[DATE 10/06/95] rated frequency fn

[TIME 9:38:43]

bar rated voltage Ubn

generator rated voltage Ugn

f) By pressing the keyò , the selected number is decreased until

the display shows: closing pulse time tc

[DATE 10/05/95] breaker closing time tr

[TIME 9:38:43] max. no.of parallel sequence attempts Ns

closing min. interval time twc

g) By pressing the keyï twice further, the second digit of the date max. time for parallel sequence ts

is selected and the display will show: stability time td

[DATE 10/06/95]

max. deviation rated frequency/bar frequency Dfb

[TIME 9:38:43]

max. deviation rated frequency/generator frequency Dfg

h) By pressing the key ñ the selected number is changed (on max. deviation bar voltage/rated voltage DUb

reaching the number 9, the tens will go up by one unit) until the min. voltage generator voltage/rated voltage DUg

display shows: live bar mode LB

[DATE 24/05/95] max. frequency difference Df

[TIME 9:38:43]

max. voltage difference DU

max. phase difference Dp

i) Press the keyï until you move to the beginning of the line. The

display will show: dead-bar mode DB

[DATE 24/05/95] dead-bar level Ud

[TIME 9:38:43]

pag. 15

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

frequency regulation mode CPf

6.1.6 Displaying current measurements

frequency regulation pulse time tfpu

frequency regulation min. pause time tfpa a) Press the key ò or ñ until the display shows:

frequency regulation max. pause time tfpm [ MEASUREMENTS ]

[ ]

load pulse mode LP

load pulse time tlp

voltage regulation mode CPU b) By pressing the key ð you enter the measurements display

voltage regulation pulse time tupu

submenu and by pressing the keysò or ñ the following submenu

voltage regulation min. pause time tupa

is scrolled:

bar primary rated voltage Ub TV

bar primary rated voltage Ub TV

effective current value of bar voltage in multiples of Ubn Ub

effective current value of generator voltage in multiples of Ugn Ug

c) By pressing the keyï anywhere in the submenu, you go back

current value of bar frequency in Hz fb

to the main reading menu:

current value of generator frequency in Hz fg

[SETTINGS READING]

[MAIN ] current value of phase difference expressed in grades Dp

effective current value of bar primary voltage in Volt Ub'

effective current value of generator primary voltage in Volt Ug'

6.1.5 Displaying spare settings

a) Press the key ò or ñ until the display shows: c) By pressing the ï anywhere in the submenu, you go back to

[SETTINGS READING] the main reading menu:

[SPARE ] [ MEASUREMENTS ]

[ ]

b) By pressing the key ð you enter the spare setting display

submenu , and by pressing the keys ò or ñ you scroll the sub- 6.1.7 Displaying counters

menus showing as follows:

a) Press the key ò or ñ until the display shows:

[ COUNTERS ]

bar rated voltage Ubn [P = RESETTABLE]

generator rated voltage Ugn

closing pulse time tc b) By pressing the key ð you enter the counter display submenu

breaker closing time tr and by pressing the keys ò or ñ the following submenu is

max. no. of parallel sequence attempts Ns scrolled:

closing min. interval time twc

max. time for parallel sequence ts total trips caused by START request on LB failed due to fb or fg

stability time td or Ub or Ug out-of-rated tolerance

max. deviation rated frequency/bar frequency Dfb LB fU Fail T

max. deviation rated frequency/generator frequency Dfg partial trips caused by START request on LB failed due to fb or

max. deviation rated voltage/bar voltage DUb fg or Ub or Ug out-of-rated tolerance

min. generator voltage/rated voltage DUg LB fU Fail P

live bar mode LB total trips caused by START request on DB failed due to fg or Ug

max. frequency difference Df out-of-rated tolerance or present Ub (not-dead bar)

max. voltage difference DU DB fU Fail T

max. phase difference Dp partial trips caused by START request on DB failed due to fg or

dead-bar mode DB Ug out-of-rated tolerance or present Ub(not-dead bar)

dead-bar level Ud DB fU Fail P

frequency regulation mode CPf totaltripscaused byLBsynchronizationsequencefaileddueto timeout

frequency regulation pulse time tfpu or on reaching the max. no. of parallel sequence attempts

frequency regulation min. pulse time tfpa LB Timeout T

frequency regulation max. pulse time tfpm partial trips caused by LB synchronization sequence failed due to

load pulse mode LP timeout or on reaching the max.no. of parallel attempts

load pulse time tlp LB Timeout P

voltage regulation mode CPU total trips caused by DB synchronization sequence (ON-CHECK)

voltage regulation pulse time tupu failed due to timeout or on reaching the max. no. of parallel

voltage regulation min. pause time tupa attempts

bar primary rated voltage Ub TV DB Timeout T

bar primary rated voltage Ub TV partial trips caused by DB synchronization sequence (ON-

CHECK) failed due to timeout or upon reaching the max. no. of

Those parameters that are not listed in the SPARE menu take the parallel attempts

same value as those listed in the MAIN settings menu. DB Timeout P

total trips caused by LB or DB synchronization sequence (ON-

c) By pressing the ï anywhere in the submenu, you go back to CHECK) interrupted by STOP command

the main reading menu: STOP T

[SETTINGS READING] partial trips caused by LB or DB synchronization sequence (ON-

[SPARE ] CHECK) interrupted by STOP command

STOP P

pag. 16

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

total trips caused by LB or DB synchronization sequence (ON- no. of parallel attempts at the time of the even t

CHECK) interrupted by external event EXT1 Ns_E

EXT1 T

(1)

partial trips caused by LB or DB synchronization sequence (ON- The causes that lead to an event are those listed in the previous

CHECK) interrupted by external event EXT1 paragraph on counters.

EXT1 P

d) By pressing the key ï anywhere in the submenu, you go back

total trips caused by LB or DB synchronization sequence (ON- to the event reading submenu; follow the steps described in c) to

CHECK) interrupted by external event EXT2

display other events.Press the key ï anywhere in the submenu

EXT2 T

to go back to the main reading menu:

partial trips caused by LB or DB synchronization sequence (ON- [ EVENTS ]

CHECK) interrupted by external event EXT2 [EVENT 1=LAST ]

EXT2 P

total trips caused by LB synchronization sequence correctly

carried out 6.1.9 Displaying output relays

SYNC LB OK T a) Press the key ò or ñ until the display shows:

partial trips caused by LB synchronization sequence correctly [OUTPUT RELAY ]

carried out [ ]

SYNC LB OK P

total trips caused by DB synchronization sequence correctly b) By pressing the key ð, you enter the submenu that displays

carried out the allocation of auxiliary output relays. The display will show:

[f+ ]

SYNC DB OK T

[REL X1....]

partial trips caused by DB synchronization sequence correctly

carried out

The first line displays the function that is associated with the relay

SYNC DB OK P

or relays shown in the second line.

c) By pressing RESET you can reset the partial counter displayed. Press the keys ò or ñ to scroll the submenu.

The functions the output relays are associated with are as

follows:

d) By pressing the keyï anywhere in the submenu, you go back

to the main reading menu:

frequency-increase command f+

[ COUNTERS ]

frequency-decrease command f-

[P = RESETTABLE]

voltage-increase command U+

voltage-decrease command U-

6.1.8 Displaying events 52 parallel breaker closing command X52

a) Press the key ò or ñ until the display shows:

[ EVENTS ] The variable NORMAL.ON. indicates whether all the output relays

[EVENT 1=LAST ] are pre-set to be normally energized or not.

b) By pressing the key ð you enter the submenu where the eight c) Press the key ï anywhere in the submenu to go back to the

events can be selected. The display will show: main reading menu:

[EVEN.1 GG/MM/AA ]

[ OUTPUT RELAY ]

[ hh:mm:ss.xxx ]

[ ]

The first line displays the event number, the day, month and year,

whereas the second line lists the time, minutes, seconds and 6.1.10 Displaying digital inputs

milliseconds concerning the event.

a) Press the key ò or ñ until the display shows:

[ DIGITAL ]

c) By pressing the key ò or ñ you select the event to be [ INPUTS ]

displayed. Once the selection has been completed, by pressing

the key ð , you will enter the event display submenu; by pressing b) By pressing the key ð you enter the submenu that displays the

the keys ò or ñ the following submenu is scrolled: allocation of the digital inputs.

The first displaying refers to the digital inputs to be enabled by

event type or cause (1)

normal energizing (↑) or de-energizing (↓); the display unit will

bar frequency value in Hz at the time of the event show:

fb_E [IN DIG 12345]

generator frequency value in Hz at the time of the event [ENABLED ↑↑↑↑↑]

fg_E

bar voltage value in multiples of Ubn at the time of the event Press the keys ò or ñ to scroll the submenu.

Ub_E The second displaying refers to the digital inputs to be enabled

generator voltage value in multiples of Ugn at the time of the event on front (F) or on level (L); the display unit will sh ow:

Ug_E [IN DIG 12345]

phase difference value in grades at the time of the event [FR/LEV LLLFL]

Dp_E

parallel sequence total time expressed in minutes and seconds

at the time of the event ts_E

pag. 17

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

By pressing the keysò or ñ you can scroll the submenu until the c) By pressing the keyï anywhere in the submenu, you go back

digital inputs are displayed which are associated with the different to the main reading menu:

functions. The display unit will show: [ LED ]

[Start LB ] [ ]

[IN DIG ...4.]

6.1.12 Displaying relay data

The first line displays the function the digital inputs shown in the

second line are associated with. a) Press the key ò or ñ until the display shows:

[ RELAY DATA ]

The functions that can be associated with the inputs are: [ ]

LB synchronization sequence start Start LB b) By pressing the key ð you enter the submenu and the display

DB synchronization sequence start Start DB shows the device model and the software version:

[MX3EG1A ]

synchronization sequence stop STOP

[Soft Vers 001.00]

52 parallel breaker closed CH 52

external failure 1 An EXT 1

c) By pressing the key ò once again, the second line displays

external failure 2 An EXT 2

switch to spare settings SETTING SWITCH the alphanumeric identification code the plant has given to the

device. For instance:

LED reset RESET LED

[PLANT IDENTIFIER]

[CELL NO. 17bis ]

c) By pressing the keyï anywhere in the submenu, you go back

to the main reading menu: d) By pressing the keyï anywhere in the submenu, you go back

[ DIGITAL ] to the main reading menu:

[ INPUTS ]

[ RELAY DATA ]

[ ]

6.1.11 Displaying leds

a) Press the key ò or ñ until the display shows: 6.1.13 Displaying diagnostics

[ LED ]

[ ] 1) Detecting faults

a) Press the key ò or ñ until the display shows:

b) By pressing the key ð you enter the submenu that displays the [ DIAGNOSTICS ]

allocation of the LEDs. The display will shows: [ ]

[f+ ]

[LED L1.......] In the event of VITAL FAULTS the device automatically displays

the window without any need to enter the diagnostics menu.

The first line displays the function the LEDs shown in the second

line are associated with.

b) By pressing the key ð you enter the submenu that displays the

Press the key ò or ñ to scroll the submenu.

relay running state. The display will show:

The functions the LEDs can be associated with are as follows: [Last mod. Imp.]

[GG/MM/AA hh:mm]

frequency-increase command f+

frequency-decrease command f- The second line shows the day, month, year, time relative to the

voltage-increase command U+ last parameter modification.

voltage-decrease command U-

52 parallel breaker closing command X52 c) By pressing the key ò once again, if the device has not

bar frequency out of tolerance >fb< detected any failure, the display will show the following message:

generator frequency out of tolerance >fg< [ RUNNING ]

bar voltage out of tolerance >Ub< [ ]

generator voltage out of tolerance >Ug<

LB start failed due to incorrect parameters f / U LB fU Fail In the event of NOT VITAL FAULTS, the display will show:

DB start failed due to incorrect parameters f / U DB fU Fail [FAULT ]

LB start failed due to Timeout LB Timeout [ABCDE.....KL ]

DB start failed due to Timeout DB Timeout

synchronization sequence interrupted by Stop Stop whereas in the event of VITAL FAULTS the characters <!> will be

synchronization sequence interrupted by Ext1 Ext1 displayed:

[FAULT <!>]

synchronization sequence interrupted by Ext2 Ext2

LB synchronization sequence correctly carried out Sync LB OK [.....FGHIJ... ]

DB synchronization sequence correctly carried out Sync DB OK

The second line shows one or more fault detecti ng codes.

It is furthermore possible to display the LEDs that are associated

with the following setting:

bistable operation MEMOR

pag. 18

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

The following table describes the correspondence between the The access priority for the setting change function among PC,

fault code and the fault nature: network and keyboard is of time-dependent.

C ode type of fault

A coil relay X1 interrupted or relative driver During the setting change operations the device continues on

B coil relay X2 interrupted or relative driver working using the old settings.

C coil relay X3 interrupted or relative driver

D coil relay X4 interrupted or relative driver All the displayed messages can be made permanently.

E coil relay X5 interrupted or relative driver

[SETTINGS IN USE] settings in use

F internal feeder faulty

[ MAIN] ð selection of current setting group

G EEPROM not running

H internal RAM not running

I external RAM not running ñ ò

J analog/digital converter [SETTINGS CHANGE ] ð change main setting values

K communication board faulty or board enabled [MAIN ]

but not pre-set

L internal clock not running ñ ò

[SETTINGS CHANGE ] ð change spare setting values

The placing of the communication-board enabling S6 jumper [SPARE ]

(see fig.1) without the said board, just as for any fault, causes the

K code to appear. ñ ò

[ OUTPUT RELAY ] ð output relay configuration

[ ]

d) In the event of NOT VITAL FAULTS, by pressing the key ï

anywhere in the submenu, you go back to the main reading menu:

ñ ò

[ DIAGNOSTICS ]

[ ] [ DIGITAL ] ð digital inputs configuration

[ INPUTS ]

whereas in the event of VITAL FAULTS you can only lea ve the

diagnostics submenu - if allowed by the device - by enabling the ñ ò

change menu. [ LED ] ð LED configuration

[ ]

2) Inhibited device

ñ ò

If the device is inhibited or not configured, the following window will [ RELAY DATA ] ð alphanumeric code setting

be displayed: [ ]

[FAULT <!>]

[.............P ]

ñ ò

[ LCD ] ð permanent display back-lighting

You can only leave this condition by enabling the 'settings [AUTOMATIC RETURN] (LCD) enabled

change' function (it is however necessary to confirm SAVE

CHANGES even if no device setting has been changed).

By pressing the key for at least two seconds anywhere

Caution: in the change menu, you go back to the main reading menu but

the set parameters must be displayed in the cha nge menu as the you are first prompted to confirm the changes made:

device can only be restarted by leaving this condition. [SAVE CHANGES]

If, upon inhibiting the device, this is also not configured, the return [< NO YES >]

to the running condition will lead to the displaying of the K fault

messages until a new configuration is carried out (see paragraph By pressing the key ï the changes made will be discarded,

4.12). whereas by pressing the key ð they are confirmed.

The green LED ( RUN) stops blinking and becomes fixed.

If, on confirming the changes, any start or trip is occurring, the

6.2 MAIN SETTING CHANGE MENU

settings are not accepted as long as the event persists (fault or

enabling). This state is signalled for 3 sec. by the following

By pressing the key anywhere in the reading menu for message:

at least two seconds, you enter the main change menu. Thence, [CHANGE SETTINGS ]

several submenus can be entered (tree-structure). When the [DELAYED ]

change function is enabled, the green LED (RUN) lights up and

blinks. You are then prompted to confirm the changes made again.

If the setting change function is already enabled in use through a

PC or the network, the local setting is inhibited and the following Note: the setting change function can even be enabled when the

message will be displayed: device is 'forced' to use the SPARE settings. In this case, the

[ S ET TIN G CH AN GE ] system only interrupts the selection of SETTINGS IN USE: MAIN

[ N OT AV AI LAB LE ] until the external forcing signal disappears.

pag. 19

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001

If a setting change is made when the system is 'forced' from the By pressing the keyñ or ò the selected number is increased or

outside, the following message will be displayed for a few seconds: decreased until the desired value is reached; in our example, by

[SPARE SETTINGS IN USE] pressing the key ò once, the display will show:

[FROM EXTERNAL CONTROL] [Dfb ± 1% ]

[Dfg ± 15% ]

All the following examples take their start from the main change

menu. Press the key ï the cursor goes back to the beginning of the line

and the system goes back to the main change menu:

[ SETTINGS CHANGE ]

6.2.1 Selecting current setting group [ MAIN ]

a) Press the key ò or ñ until the display shows:

[SETTING IN USE]

6.2.3 Changing spare settings

[ MAIN]

a) Press the key ò or ñ until the display shows:

[SETTINGS CHANGE ]

b) By pressing the key ð you current settings can start being [SPARE ]

changed. The display will show:

[SETTINGS IN USE] b) By pressing the key ð you enter the spare settings change

[ MAIN] submenu, containing the parameters already listed in paragraph

6.1.5.

c) By pressing the key ò or ñ the display will show:

[SETTINGS IN USE]

c) Press the keys ò or ñ t o scroll the submenu and the key ð

[ SPARE]

to start changing the selected parameter. The change can be

made by using the keys ò or ñ.

d) By pressing the keyï the new selection is confirmed and the The change procedure is similar to the one shown in the previous

system goes back to the main change menu.The display will example relative to main settings change.

show:

[SETTINGS IN USE]

d) By pressing the keyï anywhere in the submenu, you go back

to the main change menu:

[ SPARE]

[ SETTINGS CHANGE ]

[ S PA RE ]

6.2.2 Changing main settings

a) Press the key ò or ñ until the display shows: 6.2.4 Setting output relays

[ SETTINGS CHANGE ]

a) Press the key ò or ñ until the display shows:

[MAIN ]

[ OUTPUT RELAY ]

b) By pressing the key ð you enter the main setting submenu [ ]

containing the parameters already listed in paragraph 6.1.4.

b) By pressing the key ð you enter the output relay setting

c) Press the key ò or ñ to scroll the submenu and the key ð submenu, containing the parameters already listed in paragraph

to start changing the displayed parameter. The change can be 6.1.9, except for NORMAL.ON (whose setting is implemented as

made by using the keys ò or ñ. described in paragraph 4.2).

d) By continuing pressing the key ï anywhere in the submenu, c) Press the keys ò or ñ to scroll the submenu and the key ð

you go back to the main change menu: to start changing the selected parameter. The change can be

[SETTINGS CHANGE ] made by using the keys ò or ñ .

[MAIN ]

d) By pressing the key ï anywhere in the submenu you go back

Example of setting procedure to the main change menu:

Suppose we must enable and set the Dfb a ± 1% threshold [ OUTPUT RELAY ]

starting from the initial setting of ± 2%. [ ]

Follow the steps described in a) and b).

Example of allocation

Press the key ò or ñ until the display shows the selected

Suppose we must allocate the f+ frequency-increase command

threshold to be changed:

to the X2 output relay, by starting from the initial configuration f+

[Dfb ± 2% ]

allocated to X1.

[Dfg ± 15% ]

Follow the steps described in a) and b).

Press the key ò or ñ until the display shows:

Press the key ð to select the digit to be changed. [f+ ]

In our example, by pressing the key ð once, the display will show: [REL X1....]

[Dfb ± 2% ]

[Dfg ± 15% ]

pag. 20

Downloaded from www.Manualslib.com manuals search engine

MX3EG1A MDE/A133 2295 001