Professional Documents

Culture Documents

BS 2989 HDG-Steel - PDF - TOAZ

BS 2989 HDG-Steel - PDF - TOAZ

Uploaded by

dinesh0 ratings0% found this document useful (0 votes)

12 views17 pagesBS 2989 HDG-

Original Title

BS 2989 HDG-Steel.PDF _ TOAZ

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBS 2989 HDG-

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views17 pagesBS 2989 HDG-Steel - PDF - TOAZ

BS 2989 HDG-Steel - PDF - TOAZ

Uploaded by

dineshBS 2989 HDG-

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

BRITISH STANDARD

Specification for

Continuously hot-dip

zinc coated and iron-zinc

alloy coated steel of

structural qualities:

wide strip, sheet/plate

and slit wide strip

BS 2989 : 1991

BST BS*2989 9) MM 1624669 0234529 T

BS 2989 : 1991

———————

Committees responsible for this

British Standard

‘The preparation of this British Standard was entrusted by the Iron and Stee!

Standards Policy Committee (ISM/-) to Technical Committee ISM/10, upon

which the following bodies were represented:

British Railways Board

British Steel Industry

Cold Rolled Sections Association

Institution of Production Engineers

Society of Motor Manufacturers and ‘Traders Limited

‘The following bodies were also represented in the drafting of the standard,

through subcommittees and panels:

British Welded Steel Tube Association

Coated Metals Limited

Department of the Environment (Property Services Agency)

Intornational Tin Research Institute

Metal Roof Deck Association

National Association of Steel Stockholders

Paintmakers Association of Great. Britain Ltd.

Zinc Development Association

‘Tals Beeh Standard, having

‘heen prepa

“ivecton af the Seandarda Policy

Committee, was published under

tho uthenity ofthe Standarts

[oard sind comea inte effet on

Bt duly 1001

©nst 1991

Amendments issued since publication

‘Amd, No. [Date “Text affected

inet publised May 1958

Second edition Docemer 1967

‘Third ediuon Maren 107

tele tothe morc

Standa

Comite reference 154/10

Spec annoutcement —

BSLNews Aug 1001

ISBN 0 580 195767 ft

BSI 8S*2989 9) MM LG24669 0234530 & mm

BS 2989 : 1991

Contents

Page

Committees responsible Inside front cover

Foreword

Specification

1 Scope

General information

Definitions

Designation

Steelmaking process

Surface finish

2.5 Strain ageing

2.6 Surface protection

2.7 Application

2.8 Infomation to be supplied by the purchaser 5

3 Requirements 5

3.1 Chemical composition 5

8.2. Mechanical properties 5

3,3 Coating mass 5

3.4 Test methods 7

8.5 Dimensional tolerances and geometrical deviations 7

83,6 Inspection and acceptance u

3.7. Marking 11

3.8 Packaging _ LL

Appendix

A Determination az

‘Tables —

1 Availability of grades, coating types and surface finishes 4

2 — Chemical composition 5

8 Tensile properties 6

4 Goating types and bend tests 6

5 Coating mass 7

6 Thickness tolerance (including coating on both sides) 8

7 Tolerance on length 8

8 —Tbleranee on width, 9

9 — Maximum permissible deviation from flatness for plate and sheet in

Tengths up to and including 6 m 9

10 Out-of-squareness for resheared material 10

Figures

1 Flatness of sheet/plate 9

2 Out-of-squareness 10

8 __ Edge camber of sheet 10

BST BS*2969 9) MM Lbe4bb9 O23453) 6 mw

BS 2989 : 1991.

Foreword

‘This British Standard has been prepared under the direction of the Iron and steel

Standards Policy Committee and is technically identical to BS 2989 : 1982 except

for the deletion of the forraing qualities together with any references to ther In

text,

‘This standard, together with BS EN 10142 supersedes BS 2989 ; 1982, which is,

withdrawn,

‘The Huropean equivalents of the forming qualities are specified in BS EN 10142

whieh is the English language version of EN 10142 and is published

simultaneously with this standard, There are no equivalents to qualities Z1 and

7A in EN 10142 and they are consequently deleted.

Work is going on in Europe to prepare standards covering the structural grades of

BS 2089 and the dimensional tolerances

As these projects achieve European Standard status the English language

versions will be published as BS Ns and the necessary changes made to this

British Standard,

Compliance with a British Standard does not of itself confer immunity from

legal obligations,

BSI BS*2989 9) MM LG24G69 0234592 T i

1. Scope

‘This British Standard species requirements for ho- 3 mm.

2.1.1.5 product thickness. The thicknoss of the finlzhed

product aftor coating.

2.4.1.6 zine coating (G). A hot-dip zine coating producnd

fon hot rolled and descaled strip or on cold rolled strip.

NOTE. This term is somotines raterred to a3 ‘avanized.

2.4.4.7 Wron-zine alloy coating (IZ). A costing composed

of iron-zine alloy, produced by the thermal processing of

zine coated strip after the hot-dipping operation.

2.4.1.8 coating mass. The total mass of coating por unit

area Including both surfaces of the product.

NOTE. Coating mass Is exprossd In len,

2:42 Coating finih definitions

2.4.2.1. normal spangle (N). A zine coating finish, having @

metalic lustre, that Is the result of unrestricted growth of

‘tho zing erystals during normal solidification.

NOTE, Normal spangl ls the type normally supplied for @ wide

varlaty of applications,

BS 2089 : 1991

2.4.2.2 minimized spangle (M). A zine coating finish,

normally supplied with zine coatings in the range G'100

‘0 G3E0, that is obtained by restricting the normal zine

crystal formation.

2.4.2.3 rogular finish (R). The normal iron-zine slloy

coating finish; I is grey matt in appearance and shows

no spangle.

2.1.2.4 smooth finish (S). A finith euitable for decorative

ppalnting that is available for zine coatings up to G50 and

lron-zine alley coatings.

2.1.26 extra smooth finish (XS). A coating finish,

produced by rolling processes aftor coating and available

or zine coatings up ta G276 and for iron-zine alloy

coatings, suitable for appliestions where a high gloss

palnted finish is required,

2.2 Designation. The designation consists of the following

items in the order given:

{a) the number of this British Standard, i

{b) the word ‘plato, ‘shoot’ or ‘strip’;

(6) tho lotter 2" and a number denoting the structural

quality grade (see tabulated data as follows):

- BS 2980)

Grade Name of grade

222 220 N/mm? Structural

225 260 N/mm? | minimum | quality steels

228 280 Nim? | yield, with specified

235 360 N/mm? | strength | minimur

255 850 N/mm? vlold strengths

NOTE. 12 non-luting quality for eylindreal forming erequtad

‘this should be stated on the order (eo8 2-0).

{a) one or two letters indicating the type of coating:

sc tes zine coating

IZ indicates iron-zine alloy coating

(6) a pumbor denoting the mass of coating,

‘29. 200 denotes 200 g/m? including both sides;

{f) ono or two letters denoting the surface finish of

the coating (s00 2.1.2):

N_ denotes normal spangie

M_ donotos minimized spangle

denotes regular iron-zine alloy coating

S denotes smooth costing

XS denotes extra smooth costing

Examples of the designations ara:

BS 2089 shoot 222 G275M

[BS 2989 strip 225 1Z100R

BST BS*2969 51 MM Lbe4bb5 02

BS 2989 : 1991

2.8 Steolmaking process. The processes used in the

Steelmaking and manufacture of the product aro loft to

tho diserotion of the manufacturer.

2.4 Surface finish, The availability of the various surface

finishes is shown in table 1

2.5 Strain ageing. Products that have beon subjected to

rolling processes after coating tend to strain age and this

‘may load to the following:

{a) surface markings from stretcher strain (

‘or fluting when tho steal is form:

(b) deterioration in ductility.

Bocauso of theso factors itis essential that the period

betwaen final processing at the mill and fabrication Is kept

10 a minimum, Rotation of stock, by using the oldest

product first i important.

hon-proteoted products, the manufacturer Is not responsible

for the formation of any storage stains.

NOTE 1. Chemical passivation may cous slight dacolrstion of the

surface thot isnot datmental to the guneral purformance ofthe

Drodiuct soe alto 2.7.3),

NOTE 2. XS quality i not nonmelly avilable inthe pasate stato,

2.7 Application

2.7.1 Forming. The product may be formed satisfactorily

within the limitations of the quality provided that the

following procedures are followed.

‘The diameter of bending should be as generous as possible

and not smaller than the mandrel diameters specified in

table 4, The bond tost requiramants specified in 3.2.2 are for

test pieoos, but fabrication conditions do not alwoys

‘correspond to laboratory testing. Care should be taken to

avoid using sharp-edged bending tools.

Table 1. Availability of grades, coating types and surface finishes

se” | Staoaton ‘Sroctarat wel padoe

™ [= Je [s ps

wo |x |x x | 222,226,228, 206, 255°

200 |x |x x | 222,226,228, 296, 205"

ows |x |x x _ | 222,226, 228, 296, 255"

oso |x [x 00 _ | 222,225,228, 236, 265"

G450 : x 222, 226, 228, Z36, Z65

ooo |x B 222, 228, 228, 236

1z100 x |x |x |z22,z26,228, 236

2180 x [x [x [222,225,220 295

"Smooth and extra smooth fi

X Indleates avait

(00 indicates eval

1 BY special errongement.

2.6 Surface protection. All types of coating normally

rocoive a surface protection at the producer's plant.

This may consist of

‘chemical passivation; or

ing: or

‘chemical passivation and oiling.

‘Tho purchaser should state on his order the treatment

required (see 2.8(4))

Chomical passivation and/or oiling protects the surface

‘against humidity and reduces the risk of formation of wot,

storage stains (so-called ‘white rust’). However, the

protection afforded is limited. Ifthe purchaser specifies

thes for 258 may bo available by agroament a th time of ordering.

2.7.2 Welding. Tho product is sultable for welding if

Proper methods and procedures are used, Special attention

‘may be required for heavy coatings. The iron-zine coating

Is more suitable for resistance welding than the conventional

zine ooating.

NOTE. f eppropeate walding conditions ae sslctad, the etuctural

‘grades are eltabl for rexstance wolding os well s fusion wolding.

However, os the carbon plus phosphorus content Ineraases above

(0.10 3 In those grades, rosstance voting boeame increasingly

slice (S20 table 2)

‘Reduction of the coating mess the vicinity of welds will rues

corrosion protaction.

‘Tho hast of wolding may heve a sonificant affect n lowering the

ith of Grade 268.

2.7.8 Painting, Clean zino coated stool ie « sultable bao for

palnt, but the first treatment may be different from thoso

luted on uncoated stool, Chamieal conversion coatings

(chromate, phosphate or oxide types, see 2.6) and primers

have been specially formulated for first troatmont of

zine coated stool.

‘Specially formulated paints for direct application to

Zine coated surfacos aro also available.

{In drawing up a painting schedulo, It should be considered

whother the product should be ordored with or without

‘chemical passivation. Surfacos with cortain passivation

treatments

For some applications, ron-zine alloy coating may be

sultable for immediate painting without further

pretreatment except normal cleaning.

2.8 Information to be supplied by the purchasor. To ossist

‘the manufacturor In supplying tho correct form, quality,

‘te. of materials, the following information should be given

{in the inquiry and order:

{2} the complete product designation as given in 2.2,

(1) the number of this British Standard, i.e. BS 2989;

(2) whether plate, sheet or strip Is requl

(8) tho grade of the stool baso;

(4) the coating type, ie. G or 12;

(6) the coating mass:

(6) the coating finis

(0) the dimensions (see 3.5) of the material and any

special requirements for reshearad matarial (see tables 7,

@ and 10) or flattoned matarial (soe 3.6.4) and for

thickness tolerances (see 3.6.1) and notes of tabla 6) or

flatness tolerances (see 3.5.4 and notes 1 to 3 of table 9);

{c} whether & nonefluting quality for eylindrieal forming

is required;

{a} tho surface protection (sve 2.6), e.g, passivated, oiled;

{6} the application of the material (Le. product, part

‘purpose or use for which the material is required),

resistance welding (see 2.7.2) and for particular

‘mechanical properties

(A whether test certificate is required (see 3.1 and

34.3);

(6) whethor the material is to be inspected by the

urchasor at the works of the manufecturer (see 3.6.1);

{(h) whether both surfaces of the material are to be

Inspected (see 3.6.2):

(i) whether branding or marking is not required (see 3.

(0) whather strip welds are acceptable (see also 3.5.1);

(ke) the packaging data and instructions (seo 3.8), 0.

mass and inside and outside diameter of coils.

9. for

3. Requirements

3.1. Chemical compositior

shall be as given in table 2,

[NOTE 1. Tho specified ranges of chemical eompesition ar based on

“The chemical compositions

Prolonged storage of product of srades 222, 226, 228 and Z36 ma

lending toa reduction In ormebilty.

BSI BS*2989 9] MM bb24b69 0234534 3 mm

chromated) are not suitable for phosphating.

BS 2989 : 1991

Any subsequent analytical checks shall take into consider=

ation the normal heterogeneity of the steel and shall not be

Used as the basis for rejection unless the supply of an

correct grade is clearly indicated. If specified on the order,

the manufacturer shall state on a tost certificate (eoa 2.8(F))

the cast analysis of the material supplied,

Table 2. Chemical composi

do _| Chemtet composition (est analy

ee

% % “

016/60 | 0.040

016 |oso | 0.040

020/00 | 0.040

028 [180 [0.040

016 [oso | 0.040

NOTE 1. Strengthening aloment other than carbon anor

‘mangance may be edded to achleve the speoliog mechanlest

NOTE 2, As he carbon plus phosphorus content Inareses

‘bots 0.10 %, esntance welding Bacomesineessingly ficult

teeo 272).

INOTE 3. A specified copper content range may be opreed betwoan

the menutacturer end the purchaser.

3.2 Mechanical properties

13.2.1 Tensile properties*. The tenslle properties shall be

“determined in accordance with 3.4,

‘Tho tensile properties shall be as given in table 3.

3.2.2 Bend characteristics", The bend charactaristics shall

be determined in accordance with 3.

‘The bend characteristics shall be as given in table 4,

After bonding, the tost pleco shall not show any flaking of

‘the zine coating at a distance greater than 6 mm from each

edge of the specimen. Crazing or roughening of the zine

coating, or dusting of the iron-zine alloy coating, shall not

be cause for rejection.

Irrespective of the coating type, the steel base shall not

show, after bending, any flaw oF crack visible to the

raked eye.

‘3.8 Coating mass. The coating mass shal be determined by

the single and/or triple spot tests alven in 3.4.1.2 and.

3.4.2.4 and shall comply with the values given in table 6.

NOTE 1. Tho cooting mess ie the total minimum amount of zine por

[nit ares inluding both surfeca, im gh”

NOTE 2. A maximum coating mass may be eqroad botwoen

‘manufecturer and purchesr et tha tine of ordering.

For products greater than or equal to 600 mm wide, both

‘the triple spot and single spot tests shall be carried out.

For routine control purposes, the coating mass may be

determined by other methods, but the single and/or triple

spot tosts shall be the referee methods.

1 result in ome chang In tho mechanical properties

5

BSI BS*29695 9) MH Lb24bb9 02394535 S mm

BS 2989 : 1991

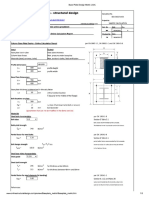

‘Table 3. Tensile properties

Grado | miniewum | mtnimum | Morera thickness

vite tonite

faronots, | stronats, | < 0.7 mm

Minimune 2 stongation

wr

Ea

ew [imn

N/mm? N/mm? % % % %

za fo eso an fizz |

zs [20 Jom fo fe fan ft

ze [ro fiom = fro fo fam |

zs [oso Jas as |’) fe fit

zo [so fom | |

NOTE 1. Grade 256 isn the unannealed condition and therefor

[NOTE 2, Figuras in brackets are non‘mandetory and are for Information oni.

NOTE 8. For determination of viol strenath 0 24.22.

ited duct

Table 4. Coating types and bend tests"

Coating type | Mando dlamotor (180° bond) for grade and a material thickness of:

za 225 228 238

2mm 3mm

6100, 6200,

6275, 6350,

12100, 12180 | ta 20 10 20 20 3 20 30

caso te 2 to 20 20 3 20

G600 2» 3 20 a 20 30 20 3a

“For essosmant ofthe bond toe, se 3.2.2.

{1285 In tho unannealed condition and terafore hes Henites ductity Ion zine alley costings ae not evalabie

{or grade 285.

NOTE. «athe thickness ofthe ben! txt pcs, in mm.

Table 5. Coating mass

‘Couting designation | Minimum costing mane

(inctuaing both ses).

Tripte | single

spottest | spot tort

cfm? | g/m?

Zine coatings (8)

Gi00 100 a5,

@200 200 170

e275 278 236

6380 360 300

6450 450 385

600 600 510

tronzinc alloy coatings (12)

12100 100 95

1z180 180 180

NOTE 1. The mass of zin Ie not always evenly divided botweon

the two surfaces ofthe sheet. Howaver, it can normally bo

‘hpaoted thet not eta than 4S ofthe spac minima

{onting moss detemlnod by the single spot test, wl be Found

‘on eooh surface

[NOTE 2. For sian purposes the nominal thickness

‘coating may be ealutated from tha following

tng mass oF 100 g/m? Including Both st

bo usd for guidance purperes only.

3.4 Test methods

3.4.1 Sampling and preparation of test pieces

3.4.1.4 Tensile and bond tasts, Ove sample shall be takon

‘or each tost, either parallel or at right angles to the

irection of rolling. The samples shall be taken at least

‘60 mm from the edges of the prociuct, excopt that in the

case of products having widths too narrow to permit this

‘the sampling requirements shall be agreed between

‘manufacturor and purchaser.

NOTE. For narrow product lt ewey from wide strip, tho purchaser

‘ay permit the samples tobe takan fromm the ide stip priors

setnae

3.4.1.2 Coating mass tests, Three circular or rectangular

samples shall be taken, one from the mid-width position

and one from each side at loast 60 mm from the side edger.

‘Tho minimum specimen arva shall be 6000 mm? each side.

For slit strip less than 600 mm wide, only one sample shi

be taken.

NOTE, Sampling i normaliyearied out by stamping ou a known

area of product,

3.4.2 Procedure

3.4.2.1. General. The mechanical property and costing

‘mass tests shal be carried out at ambient temperature,

3.4.2.2 Tansile rest, The tensile tos shall be carried out in

accordance with 8S EN 10002-1 and measured to the

nearest 10 N/mm. The tensile strength and yield strength

‘here specified shall be caloulated using the cross-sectional

‘area of the stool base.

BSI BS*2969 92 MM Lb24GE9 0234534 7 mm

BS 2989 : 1991

Tho yield strength, Ae, shall be determined elther os the

lower yield stress, RL, oF as the 0.6 % proof stress (total

slongation), Re, 0.5-

3.4.2.3 Bond toet. The test shal be carried out in

‘secordance with BS 1639 through an angle of 180° using

‘a mandrel diameter in accordance with table 4.

Care shall be taken in flattoning the bend that tho coating

isnot damaged.

3.4.2.4 Coating mess

3.4.2.8.1 Triple spot test. The triple spot test result shall

bbe determined as the average coating mass found on the

‘Urea specimens takon as described in 3.4.1.2.

The coating mass shall be calculated from the loss in mass

aftor removing the zine n a sultably inhibited acld.

‘A recommended method is given in appendix A and shall

bo the referee method.

3.4,2.4.2 Single spot test, The single spot teet result shall

tbo dotermined as the lowest of the coating massos found on.

the three specimens used for the triple spot test, or on the

single specimen, if only one specimen was available for

ling (see 9.4.1.2).

3.4.3 Number of taste. The manufacturer shall make’such

‘ests and measurements that aro considared necessary to

‘ensure that the product complies with the requirements of

this standard. When specified in the order the manufacturer

shall state tho results of the tensile test, bend test and

‘coating mass test at the rate of one test series per lot.

INOTE-4. Ifthe purchacer decides to tert the product on delivery,

he shoul oo a tho eo rate ae tho monutacte

A lot shall consist of 20 t (tonnes) oF a fraction of 20 t of

‘he same quality, rolled to the same thickness and surfaco

condition,

NOTE 2. Exampie. A consignment of 65 tie three late, 0 of 20

tach and the third of 8

3.4.4 Retests. Ifa test does not give the required result,

and the test piece is not otherwise faulty, two more tests

‘hall be taken at random from the same fot, Both these

‘ests shall meot tho specified requirements otherwiso the fot

shall be deemed not to comply with the requirements of

this standard. The manufacturer shall have the option to

carry out rectification processing or sorting, and resubmit

‘the product for inspection and testing. Ifthe test piace is

faulty the test shall be repested. In the case of oils, the

further samples shall be taken at a distance of at least one

lap and @ maximum of 20 m from one ond.

8.5 Dimensional tolerances and geometrical deviations

3.5.1 Thickness. The thickness including costing shal bs

‘measured at any point loceted more than 40 mm from the

‘edgos and the tolerance on the thickness shall be as given in

rable 6.

For strip or silt strip, the tolerance values given in table 6

refer to the whole length, except in the region of strip welds

‘where the valves shall be doubled over a length to be agrocd

between the manufacturer and purchaser.

In the case of st strip and cut langths having e width

of 80 mm or less, the position of measurement shall be

agreed at the time of ordering.

BSI BS*2989 92 MM 1624665 0234537 5 mm

BS 2989 : 1991

{3.8.2 Length. The length shall be measured along one of 3.6.4 Flatnass. The doviation from flatness shall be

the longer sides of the shoot or cut length and the tolerance measured as the maximum distance betwoon tho product

fon the length shall be as given in tablo 7. (shoot or plato) andl the flat horizontal surfaco on which It

3.5.3 Width. The width shall be measured at right angles to 18 Placed (see figure 1). Except for coating types G450

the longitudinal axis of the product and the tolerance on and GOO, the maximum deviation from flatness shal! be

the width shall be as given in table 8 as given in table 8,

NOTE. For cooting typos G480 and GB0O, the maximum deviation

{arn fiainass should be agro between manufactur ana puree.

‘Table 6. Thickness tolerance (including coating on both sides)

Nominal thickness | Norm tolerance for coating typo and « nominal width oft

(Coating types G100, 6200, 6275, 6350, 12100, 12180 | Costing types G450 and Ge00

< 120mm | > 120mm to < 1500 mm 1200 mm | > 1200 mm to < 1600 mm

>o35t0<040 | +005 +008 $0.07 +008

So40r<0.60 | +006 £007 0.08 0.09

>o60%<080 | 10.07 £0.08 0.09 £0.10

Soact<100 | +0.08 £0.09 £0.10 40.11

S100%<120 [+010 2041 £0.12 +013

S12006160 | +0.12 £0.13 £0.14 +018

S1.60%0<2.00 |+0.14 £0.15 20.16 #017

>2.00%0<250 | #0.16 £0.17 20.18 +019

S250%0<300 [+010 £0.20 £0.21 £0.22

>300<400 | +020 £025 £0.28 20.27

>4.0010<5.00 | 20.24 £0.26 £0.26 £0.28

NOTE 1. Products with elosertoleraneds may be supplied by agreement betwen manufseture and purchosu.

NOTE 2. 1f thle [specified a8 2 minimum th tolerances al + the permissbo varition is equal tothe total tolerance

Fr example,» spectied minimum thickness of 2.60 rm permits ~0,#0.88 rm {for meteral 1200 mw wick) and the nora!

‘thicknoss would bo 2.78 mm. However, hore, ox a ort, tho omindlthieknoss then falls within the next hsher rane for

‘homine! thicknesses, the tolerances for the Night ange spply sp. a minimum thickness of 2.0 sen Is ordered, she tolerance

‘aniga would Bo 0, #048 mm or maceral <1200 mm wide) and the nominal thickness would be 3.13 mm.

Table 7. Tolerance on length

‘Nominal ength Normal tolerance Reshoared tolerance

< 1600 0, +6 mm 0,43 mm

> 1800 to< 3000 0, +8 mm 0,44 mm

> 3000 0, 40.3 % of actual length 0, 40.16 % of actual length

BSI BS¥2969 9] MM Ub24bb9 0234538 0 mm

Bs 2989 : 1991

Table 8. Tolerance on

‘Nominal wieth ‘Resheared tolerance for atenath of

am

mm mm mm rm

<1200 0.46 0,42 ae

> 1200 to < 1600 0,47 Cer} ”

Table 9. Maximum permissible deviation from flatness for plate and sheet in lengths

up to and including 5 m

Nominal with ‘Maximum permisibledevietion

(s00 note 1)

070 | >120 |>2.00 |>300 | <0.70 | >0.70 |>1.20 |>200 |>3.00

2120 | 22.00 | 2a.00 | Sr20 22.00 | 23.00

<1200 2 | | 8 |i 1 5 a [3s [5 |e

>ro0te 1200 3

< 1500

> 3000 <1500 a

3.8.6 Edge camber. The odgo camber shall bo mossured as

the lateral departure of the edge of the material from a

straight line, forming a chord. The edge eambor shall be

‘measured on the concave edge (see figure 3}.

‘The moasuring base shall bea distance of 2 m, taken

anywhere along the edgo but if the shoet or cut length Is

less than 2 m long, the measuring base shall be its length.

Unless replaced by the requirement of 3.6.7, the edge

Figure 2. Outof squareness ‘eambor shall

(2) not exceed 6 mm, for lengths of 2 m and greator;

(b) be less than 0.3 % of the actual length, for lengths

less than 2 m.

WY Is the wieth of sheet

Lie the length of shoot

Is the odgo camber

Figure 3. Edge camber of shoot

BSI BS*2969 9) MM Lbz4e

3.8.7 Superimposenont of dimensions. By agreement at

‘the time of ordering, the limits on out-of-squarenoss

(soe 3.6.6) and edge camber (se 3.6.6) shall be replaced by

‘@ requirement that @ perfect rectangle formed by the

‘ordered width and length dimensions ean be sheared from

‘the shoots delivered.

‘3.6 Inspection and acceptance

3.6.1 General, Tho purchaser or his reprasentative shel

hhave reasonable access to the works of the manufacturer

for the purpose of inspection. If such inspection isto be

‘earried out this hall bo stated when placing the ordor

(ee 2.8(g)). The inspector shall have all reasonable

facilitios to determine that the product is being supplied

in eceordanee with this standard,

NOTE. In continuous hot-dipcouting practio all orders ara subjo

to. datelled symm of inspection ane esting. es desirable that

‘xtornal nepestor Uses the avaliable manufacturer's ecards

‘sherever possi

If tho purchaser elects to test and inspect the product after

olivery, any specimen thst does not appear to comply with

the requiroments of this standard shall be set aside, properly

land correctly Identified and adequately protected. The

‘manufacturer shall be informed so that he may investiga

3.8.2 Surface inspection, Unless otherwise agreed between:

‘manufacturer and purchaser at the time of ordering, only

fone surface shall bo inspected (seo 2.8(h)). If requested by

‘tho purchaser, the manufacturor shal indicate which

surfece has been inspected.

‘ering 8S 2089 00 or In relation to » product ropresent 8 manutectrorsdeclration ot conformity,

‘menufeoturr thatthe product mests the requirements of te standard

person making the ela, Such a decloration isnot to be confusad with

"

b 0234540 9 a

BS 2989 : 1991

NOTE. The normal spange, minimized spangle

Imoy exhibit small pts, varatione In spangte a2

‘done spots, sigh seratche, stripe marks and light pessvation stare

‘her strip is supplied, thre is cenoally grater risk of surfoco

ofects than In shoot ahd eut lengths because of the imposablty of

femovig the defect within cols This should be taken into account

by tho purchasor In his aneramane of the product. The maximum

‘amount and typo of detest that are porratted may be agreed

Between menufecturer and purchesor atthe time of ordering

3.7 Marking. Unisss otherwise stated (soo 2.8(1)), the

‘minimum requirements for identifying the stool shall be

the following:

(a) the manufacturer's name or identifying mark

(0) the complete product designation (soe 2.2)*;

(6) the manufacturer's order number;

(4) the ordered dimensions;

(c) the fot numbe

(8 the mass;

all written on @ label attached to each coil or bund

If the surfaco of the product Is required not brands

‘tis shall be stated on the order.

3.8 Packaging, The packaging conditions shall be agreed

when the order is placed (s00 2.8)

claim by or on tshalf ofthe

“Tho seauraey of the slain i thorefore soley the respaniy of th

thie party cortifteation of conformity, which may seo be Geib

BSI BS*2989 91 MM 1624669 0234541 0

BS 2989 : 1991

Appendix A

Determination of coating mass

‘AA Principle. Using a sample with a costed area of

15000 mm? on wach surface (total area af coated

surface 10 000 mm?) the loss of mass in grams when the

‘ating Is dissolved, multiplied by 260, will represent the

ne mass in grams per square metre of sheet, Including

both surfaces,

A2 Stripping solution. Dissolve approximately 3.2 9 of

antimony chloride (SbCIs) or 29 of antimony oxide

(8b;03) In 500 mi of eoncentrated hydrochloric acd

{0 © 1.19 g/ml) and make up to 1000 ml with distilled

water.

A Test procedure. When necessary, degrease the specimen

an organic solvent that will not attack the zinc and

then dry the specimen,

Beforo stripping, determine tho mass of the specimon with

‘an accuracy of better than 1 % of the presumed coating

‘Completely immerse the specimen in at least 600 mi of the

stripping solution at ambient temperature and leave until

the coating is completely dissolved. The dissolving process

is finished when no more hrydrogen is given off, Rinse tho

specimen in running water; brush, If necessary, to remove

any residues adhoring to the surface; immerse in aleoh

‘dry rapidly and determine the mass of the specimen a

‘as before.

ening Smal amounts of polzonous ge stbine (SHH) may ba

‘volved during the coating cisolution. Ie eonta to prowdo

{tdequate vetation conditions suing the reaction and for

fraquane tors a fume extrsetion hood should be used

‘BST BS*2989 91 MM LL24b_9 0234Su2 2

BS 2989 : 1991

————— eee

Publication(s) referred to

BS 1639 Methods for bend testing of metals

BS EN 10002-1 ‘Tensile testing of metallic materials

Part 1 Method of test at ambient temperature

BS EN 101429 Specification for continuous hot-dip zinc coated low carbon steel sheet and strip for

cold forming : technical delivery conditions,

" Rofeered to inthe foreword only

BS 2989 : 1991

BSI

2 Park Street

London

WIA 288

BSI

Linford Wood

Milton Keynes

MKKLA 6LE

BSI BS*e969 51 MM bbedybbS Oeshsh3s 4

BSI — British Standards Institution

BSI is the independent national body responsible for preparing British

Standards, It presents the UK view on standards in Europe and at the

international level. IL is Incorporated by Royal Charter.

Contract requirements

‘A British Standard does not purport: to include all the necessary provisions of a

contract, Users of British Standards are responsible for thelr correct.

application.

Revisions

British Standards are updated by amendment or revision. Users of British

Standards should make sure that they possess the latest amendments or

editions,

Any person who finds an inaccuracy or ambiguity while using this British

Standard should notify BSI without delay so that the matter may be

investigated swiftly.

BSI offers members an individual updating service called PLUS which ensures

that subscribers automatically receive the latest editions of standards.

Buying British Standards

Orders for all British Standard publications should be addressed to the Sales

Department at Milton Keynes,

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library, the Standardline Database, the BSI

Information Technology Service (BITS) and its Technical Help to Exporters

Service. Contact Customer Information at Milton Keynes: ‘el: 0908 221166.

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For

details of these and other benefits contact the Manager, Membership

Development at Milton Keynes: Tel: 0908 220022,

Copyright

Copyright subsists in all BSI publications. No part of this publication may be

reproduced in any form without the prior permission in writing of ISI. This

does not preclude the free use, in the course of implementing the standard, of

details such as symbols and size, type or grade designations. Enquiries about

copyright should be made to the Copyright Manager, Marketing at Milton

Keynes,

107-6 1.2e—-B

1sM/30

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UNit Transformer GA DrawingDocument3 pagesUNit Transformer GA DrawingdineshNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Calculation of Seismic Protective Qualities of Dampefer and AbsorterDocument4 pagesCalculation of Seismic Protective Qualities of Dampefer and AbsorterdineshNo ratings yet

- Seismic Risk Mapping For UzbekistanDocument20 pagesSeismic Risk Mapping For UzbekistandineshNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Difference Between GFRP & Steel RebarDocument10 pagesDifference Between GFRP & Steel RebardineshNo ratings yet

- DWC Pipe HDPE Double Wall Corrugated PiDocument7 pagesDWC Pipe HDPE Double Wall Corrugated PidineshNo ratings yet

- HDPEDocument4 pagesHDPEdineshNo ratings yet

- On The Correlation of Seismic Intensity Scale WithDocument25 pagesOn The Correlation of Seismic Intensity Scale WithdineshNo ratings yet

- Edoc - Pub - Transformer Foundation DesignDocument26 pagesEdoc - Pub - Transformer Foundation DesigndineshNo ratings yet

- Time and Materials (T&M) Contracts - How They Work and Free Template - NetSuiteDocument7 pagesTime and Materials (T&M) Contracts - How They Work and Free Template - NetSuitedineshNo ratings yet

- Design of Foundation For 220 KV ElectricalDocument7 pagesDesign of Foundation For 220 KV ElectricaldineshNo ratings yet

- Requirements For An Ideal Rail SectionDocument10 pagesRequirements For An Ideal Rail SectiondineshNo ratings yet

- Medvedev-Sponheuer-Karnik Scale - WikipediaDocument2 pagesMedvedev-Sponheuer-Karnik Scale - WikipediadineshNo ratings yet

- Seismic Risk Assessment of Built Environment in PakistanDocument10 pagesSeismic Risk Assessment of Built Environment in PakistandineshNo ratings yet

- Tube Structural System - Types & Features - The ConstructorDocument11 pagesTube Structural System - Types & Features - The ConstructordineshNo ratings yet

- Schedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PriceDocument10 pagesSchedule 80 Mild Steel Pipe Sizes - Dimensions - Weight and PricedineshNo ratings yet

- Monorail SupportingDocument1 pageMonorail SupportingdineshNo ratings yet

- Aisc Asd Parameters KX, Ky, KZ, LX, LyDocument12 pagesAisc Asd Parameters KX, Ky, KZ, LX, LydineshNo ratings yet

- RAM Connection Standalone CE Report - 11Document2 pagesRAM Connection Standalone CE Report - 11dineshNo ratings yet

- Probabilistic Seismic Hazard Analysis For YemenDocument16 pagesProbabilistic Seismic Hazard Analysis For YemendineshNo ratings yet

- Comparative Study of Diagrid Structures With and Without Corner ColumnsDocument6 pagesComparative Study of Diagrid Structures With and Without Corner ColumnsdineshNo ratings yet

- MSP 2018-2023 Final AdoptedDocument28 pagesMSP 2018-2023 Final AdopteddineshNo ratings yet

- Annexure-6 FOSROC - Lokfix & Nitobond Technical DataDocument10 pagesAnnexure-6 FOSROC - Lokfix & Nitobond Technical DatadineshNo ratings yet

- Base Plate Design Metric UnitsDocument3 pagesBase Plate Design Metric UnitsdineshNo ratings yet

- Steel Design Parameter - EuroDocument11 pagesSteel Design Parameter - EurodineshNo ratings yet

- Aisc Asd ParametersDocument9 pagesAisc Asd ParametersdineshNo ratings yet

- Seismic Code Developments For Steel & Composite StructuresDocument23 pagesSeismic Code Developments For Steel & Composite StructuresdineshNo ratings yet

- Cross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3Document12 pagesCross-Sectional Optimization of Cold-Formed Steel Channels To Eurocode 3dineshNo ratings yet

- Nuclear CodesDocument4 pagesNuclear CodesdineshNo ratings yet

- Bored CIP Piles - Capacity Calculation - International Practice - Updated-1Document13 pagesBored CIP Piles - Capacity Calculation - International Practice - Updated-1dineshNo ratings yet

- SS en 10268 2006 A1 2013 en PDFDocument11 pagesSS en 10268 2006 A1 2013 en PDFdineshNo ratings yet