Professional Documents

Culture Documents

Crosby 198

Uploaded by

oscar_jfrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosby 198

Uploaded by

oscar_jfrCopyright:

Available Formats

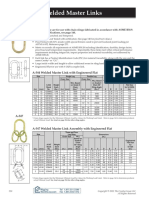

WIRE ROPE END FITTINGS

S-501

• Forged from special bar quality carbon steel, suitable for cold forming.

• Swage socket terminations have an efficiency rating of 100% based on

the catalog strength of wire rope.

• Hardness controlled by spheroidize annealing.

• Stamp for identification after swaging without concern for fractures (as

per directions in Wire Rope End Terminations User’s Manual).

• Swage sockets incorporate a reduced machined area of the shank

which is equivalent to the proper 'after swage' dimension. Before

swaging, this provides for an obvious visual difference in the shank

diameter. After swaging, a uniform shank diameter is created allowing

for a QUIC-CHECK® and permanent visual inspection opportunity.

• S-501 Swage Sockets are recommended for use with 6 x 19 or 6 x 37,

IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope.

• In accordance with ASME B30.9, all slings terminated with swage

sockets shall be proof loaded.*

S-501 Open Swage Sockets

S-501 and S-501B Open Socket Specifications Swager / Die Data

Rope Size Stock No. Side Load

Before Swage Dimensions Tolerance

(mm) +/- Max. 500

After 1000 1500

S-501 S-501B Wt. Ultimate Swage 1500 3000 1500 3000

Stock Stock Each Load** Dim. Die Ton Ton Ton Ton

No. No. † (in) (mm) (kg) (t) A B C D E F H L M N H (mm) Description 5x7 6 x 12 6 x 12 6 x 12

1039021 1054001 1/4 6 0.24 5.4 122 12.7 35.1 17.5 6.85 54.0 17.5 102 9.65 38.1 1.52 11.7 1/4 Socket 1192845 - - -

1039049 1054010 5/16 8 0.51 11.8 159 19.6 41.1 20.6 8.65 81.0 20.6 135 11.9 44.5 1.52 18.0 5/16-3/8 Socket 1192863 - - -

1039067 1054029 3/8 9-10 0.59 13.6 159 19.6 41.1 20.6 10.4 81.0 20.6 135 11.9 44.5 1.52 18.0 5/16-3/8 Socket 1192863 - - -

1039085 1054038 7/16 11-12 0.94 18.1 198 24.9 51.0 25.4 12.2 108 25.4 170 14.2 51.0 1.52 23.1 7/16-1/2 Socket 1192881 - - -

1039101 1054047 1/2 13 0.94 21.3 198 24.9 51.0 25.4 14.0 108 25.4 170 14.2 51.0 1.52 23.1 7/16-1/2 Socket 1192881 - - -

1039129 1054056 9/16 14 2.12 31.8 241 31.8 60.5 30.2 15.5 135 31.8 207 17.3 57.0 1.52 29.5 9/16-5/8 Socket 1192907 - - -

1039147 1054065 5/8 16 2.05 34.9 241 31.8 60.5 30.2 17.0 135 31.8 207 17.3 57.0 1.52 29.5 9/16-5/8 Socket 1192907 - - -

1039165 1054074 3/4 18-20 3.62 43.5 294 39.4 70.0 35.1 20.3 162 38.1 254 20.3 70.0 1.52 36.1 3/4 Socket 1192925 - - -

1039183 1054083 7/8 22 5.23 51.5 341 43.2 79.5 41.1 23.9 189 44.5 295 23.9 82.5 1.78 39.4 7/8 Socket 1192943 - - -

1039209 1054092 1 24-26 8.07 71.4 393 50.5 93.5 51.0 26.9 216 51.0 340 26.9 95.5 2.03 45.7 1 Socket 1192961 - - -

1039227 1054104 1-1/8 28 11.5 83.3 440 57.0 105 57.0 30.2 245 57.0 381 30.2 108 2.54 52.0 1-1/8 Socket 1192989 - - -

1039245 1054113 1-1/4 32 16.1 109 484 64.5 117 63.5 33.8 272 63.5 419 31.0 119 2.54 58.5 1-1/4 Socket 1193005 - - -

1039263 1054122 1-3/8 34-36 19.8 136 532 71.0 127 63.5 36.8 297 63.5 461 35.1 133 2.07 65.0 1-3/8 Socket 1193023 - - -

1039281 1054131 1-1/2 38-40 26.5 181 589 78.0 140 70.0 40.1 325 76.0 502 43.2 145 2.54 71.5 1-1/2 Socket 1193041 1191267 1195355 1195192

1039307 1054140 1-3/4 44 40.3 228 676 86.0 170 89.0 47.2 378 89.0 584 53.6 171 2.54 77.5 1-3/4 Socket 1193069 1191276 1195367 1195209

1042767 1054159 2 48-52 66 272 799 100 203 95.5 53.5 432 102 683 60.0 203 2.54 90.5 2 Socket 1193087 1191294 1195379 1195218

*Maximum Proof Load shall not exceed 50% of XXIP rope catalog breaking strength.** The Ultimate Loads of 3/4” through 1 1/4” sizes have been increased to meet the requirements

for 8 strand 2160 Grade pendants.† Assembly with bolt, nut and cotter pin. Note: Fittings designed only to be used on exact sizes listed.

NOTE: Before using any Crosby fitting with any other type lay, construction or grade of wire rope, it is recommended that the termination be destructive tested and documented to prove

the adequacy of the assembly to be manufactured.

198 thecrosbygroup.com Copyright © 2022 The Crosby Group LLC All Rights Reserved

You might also like

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- S409Document1 pageS409saddam4everNo ratings yet

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- T Series CouplingsDocument4 pagesT Series CouplingsiradocajNo ratings yet

- Angular Contact Bearing SwivelsDocument1 pageAngular Contact Bearing SwivelsmeromikhaNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- Care Lifting CatalougeDocument28 pagesCare Lifting CatalougeHari KrishnaNo ratings yet

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Crosby G416 MetricDocument1 pageCrosby G416 MetricRobby VillenaNo ratings yet

- Crosby Open Spelter SocketsDocument1 pageCrosby Open Spelter SocketsHenrique docinNo ratings yet

- Product CatalogueDocument44 pagesProduct CatalogueTo Van TinhNo ratings yet

- InertiaDynamics CBCouplings310 SpecsheetDocument2 pagesInertiaDynamics CBCouplings310 SpecsheetElectromateNo ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- PVC and XLPE Cable Current RatingDocument25 pagesPVC and XLPE Cable Current RatingMahamud MusaNo ratings yet

- PCV CableDocument12 pagesPCV CableMahamud MusaNo ratings yet

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocument2 pages3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNo ratings yet

- Obtegachi 1 PDFDocument4 pagesObtegachi 1 PDFSvetoslav SpasovNo ratings yet

- Brosure Kabel NA2XSYDocument5 pagesBrosure Kabel NA2XSYcandra handarsenNo ratings yet

- Branch v06Document4 pagesBranch v06Kerr AgotNo ratings yet

- WaboFlex 1013 DataSheetDocument4 pagesWaboFlex 1013 DataSheetSean BrownNo ratings yet

- Wabo Flex 0208Document4 pagesWabo Flex 0208walidNo ratings yet

- SCM Motoare Hidraulice SunfabDocument12 pagesSCM Motoare Hidraulice SunfabANTON NEAGUNo ratings yet

- Tuf Strand BrochureDocument4 pagesTuf Strand BrochureIllarick Balarezo SalgadoNo ratings yet

- Torch Setup: Instant-On Torches Plasma Arc Can Cause Injury and BurnsDocument17 pagesTorch Setup: Instant-On Torches Plasma Arc Can Cause Injury and Burnsabbas ahmedNo ratings yet

- Mohawk Riserlite Indoor Outdoor Fiber CableDocument2 pagesMohawk Riserlite Indoor Outdoor Fiber CablecolinyNo ratings yet

- Mooring Socket - CrosbyDocument1 pageMooring Socket - CrosbyPernando SagaNo ratings yet

- 44 CBL 21-09-2022Document15 pages44 CBL 21-09-2022Deelip ZopeNo ratings yet

- Crosby Grade 100 Chain FittingsDocument1 pageCrosby Grade 100 Chain FittingsKonstantinos SynodinosNo ratings yet

- InertiaDynamics ClutchCplng310s SpecsheetDocument2 pagesInertiaDynamics ClutchCplng310s SpecsheetElectromateNo ratings yet

- Crosby Hoisting RingDocument1 pageCrosby Hoisting RingI-SignNo ratings yet

- G-417 / S-417 Closed Spelter SocketsDocument1 pageG-417 / S-417 Closed Spelter SocketsHishamNo ratings yet

- DIEPA B cable lay types, properties, and technical specificationsDocument1 pageDIEPA B cable lay types, properties, and technical specificationsKonstantinos SynodinosNo ratings yet

- Terminales G-417 CrosbyDocument1 pageTerminales G-417 Crosbycorsini999No ratings yet

- SCM 012-130 SaeDocument12 pagesSCM 012-130 SaekazdanoNo ratings yet

- CatalogueDocument37 pagesCataloguekylegazeNo ratings yet

- TDG 19 CLT DiaphragmsDocument6 pagesTDG 19 CLT DiaphragmsCarsonBakerNo ratings yet

- N2XRY 3 X (1.5-300) MM 0.6/1 KVDocument1 pageN2XRY 3 X (1.5-300) MM 0.6/1 KVRyan FadhliNo ratings yet

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureMurli RamchandranNo ratings yet

- VSL - Multistrand Post TensioningDocument15 pagesVSL - Multistrand Post TensioningkmabdNo ratings yet

- Soow H07RN-F Aj 24.02.2022Document4 pagesSoow H07RN-F Aj 24.02.2022Tamara TrejosNo ratings yet

- GTOI Non-Capacitive Type Bushings, 12 - 36kV: Your Independent Bushing and Busbar SupplierDocument4 pagesGTOI Non-Capacitive Type Bushings, 12 - 36kV: Your Independent Bushing and Busbar SupplierKhalid AzmyNo ratings yet

- Brida Flexible VitaulicDocument3 pagesBrida Flexible VitaulicG Abigail MorenoNo ratings yet

- Assymetrical WedgeDocument1 pageAssymetrical WedgeNurettin IsikNo ratings yet

- MasterlinkDocument1 pageMasterlinkAndreyNo ratings yet

- Catálogo Accesorios para Cables NosermanDocument5 pagesCatálogo Accesorios para Cables NosermanSebastian AndreoliNo ratings yet

- TornilleriaDocument26 pagesTornilleriacorpSIG corpSIGNo ratings yet

- Series 1000 Hinged ClosureDocument3 pagesSeries 1000 Hinged ClosureKavan PatelNo ratings yet

- Dyadic Systems SCN6 40kgfDocument1 pageDyadic Systems SCN6 40kgfServo2GoNo ratings yet

- TL Series Low Clearance / Direct Fit Hydraulic Wrench: Wwwbolttechmanningscom WwwbolttechmanningscomDocument2 pagesTL Series Low Clearance / Direct Fit Hydraulic Wrench: Wwwbolttechmanningscom WwwbolttechmanningscomAlexsandro CordeiroNo ratings yet

- CATDocument149 pagesCATSuat YamanNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- InertiaDynamics FlangeMtBk310p SpecsheetDocument2 pagesInertiaDynamics FlangeMtBk310p SpecsheetElectromateNo ratings yet

- S-265 Weld On Pivot LinkDocument1 pageS-265 Weld On Pivot LinkSarfaraz KhanNo ratings yet

- (1C X 95mm) N2XSYDocument3 pages(1C X 95mm) N2XSYRahmawan fiberhomeNo ratings yet

- Calculation Sheet Mat - FDNDocument14 pagesCalculation Sheet Mat - FDNDavid Sinambela0% (1)

- For Horizontal Lift and Transfer With Pretension System: Iphnm10 IPH10Document1 pageFor Horizontal Lift and Transfer With Pretension System: Iphnm10 IPH10oscar_jfrNo ratings yet

- KINEXTEC MOVE SeriesDocument2 pagesKINEXTEC MOVE Seriesoscar_jfrNo ratings yet

- T Series: Compact Size, Large CapabilitiesDocument2 pagesT Series: Compact Size, Large Capabilitiesoscar_jfrNo ratings yet

- Brick and Pail: Compact Safety and Utmost ManoeuvrabilityDocument2 pagesBrick and Pail: Compact Safety and Utmost Manoeuvrabilityoscar_jfrNo ratings yet

- Requirements For The Emergency ManualDocument8 pagesRequirements For The Emergency Manualoscar_jfrNo ratings yet

- LPR®-1DHP-260: Product Data SheetDocument2 pagesLPR®-1DHP-260: Product Data Sheetoscar_jfrNo ratings yet

- LPR®-1DHP-280: Product Data SheetDocument2 pagesLPR®-1DHP-280: Product Data Sheetoscar_jfrNo ratings yet

- Tsubaki ZipchainDocument40 pagesTsubaki Zipchainoscar_jfrNo ratings yet

- Lift Systems: Linear Telescopic Lifting ColumnsDocument12 pagesLift Systems: Linear Telescopic Lifting Columnsoscar_jfrNo ratings yet

- FLENDER - 2LP3021-0BJ50-6ZA0-Z - B41+C00+C82+G30+G36+H00+H10+P0B+P14+P88+P95+Y01+Y02+Y20+Y21+Y23 - Datasheet - enDocument3 pagesFLENDER - 2LP3021-0BJ50-6ZA0-Z - B41+C00+C82+G30+G36+H00+H10+P0B+P14+P88+P95+Y01+Y02+Y20+Y21+Y23 - Datasheet - enoscar_jfrNo ratings yet

- Pares de Apriete PDFDocument1 pagePares de Apriete PDFalexletNo ratings yet

- Elastomeric Bridge BearingsDocument4 pagesElastomeric Bridge BearingsagvsienaNo ratings yet

- EM 1110-2-1610 Hydraulic Design of Lock Culvert ValvesDocument59 pagesEM 1110-2-1610 Hydraulic Design of Lock Culvert Valvesdyc123No ratings yet

- Prospect Lasto Block CH enDocument4 pagesProspect Lasto Block CH enoscar_jfrNo ratings yet

- Ev VRF MMC Ap 0157 0187 0247 0277 0367 0487 0567 HP e enDocument9 pagesEv VRF MMC Ap 0157 0187 0247 0277 0367 0487 0567 HP e endenis almeidaNo ratings yet

- Overcurrent Protection2Document11 pagesOvercurrent Protection2Asanka RodrigoNo ratings yet

- Magnecraft General Purpose Relays: CatalogDocument76 pagesMagnecraft General Purpose Relays: CatalogLuis DGNo ratings yet

- Cómo hacer un comunicador Bluetooth de Star TrekDocument40 pagesCómo hacer un comunicador Bluetooth de Star TrekeeindustrialNo ratings yet

- MF 7700 enDocument44 pagesMF 7700 enriad100% (1)

- NKT 12-42kv GB BsDocument54 pagesNKT 12-42kv GB BsvhgiaoNo ratings yet

- Komatsu PW95-1 Hydraulic Excavator Service Repair Manual SN 0000007 and Up PDFDocument26 pagesKomatsu PW95-1 Hydraulic Excavator Service Repair Manual SN 0000007 and Up PDFfhjsjkmekmd44% (9)

- SSD 9971Document4 pagesSSD 9971Popa GabrielNo ratings yet

- Kushal M BrochureDocument2 pagesKushal M BrochureKangkan Kishore DasNo ratings yet

- Simba S7 D - TechspecificDocument4 pagesSimba S7 D - Techspecificsukhoi200900No ratings yet

- Election Transmission Media SetupDocument66 pagesElection Transmission Media SetupCherry Quinanahan UchiNo ratings yet

- Pioneer VSX-D912 ReceiverDocument80 pagesPioneer VSX-D912 ReceiverTom100% (3)

- Audi Self Study ProgramDocument76 pagesAudi Self Study ProgramJorge Gonzalez Perez100% (1)

- Instruction-JDC1316 Battery Powered Plastic Strapping Tool - 1Document116 pagesInstruction-JDC1316 Battery Powered Plastic Strapping Tool - 1Eduardo LópezNo ratings yet

- THC AHa-L2 ManualDocument16 pagesTHC AHa-L2 ManualaresotaNo ratings yet

- Bently Nevada MmsDocument30 pagesBently Nevada MmsMohamed HamizicNo ratings yet

- Saw 4DDocument33 pagesSaw 4DSai Ganadhi100% (1)

- X200 Hardware Maintenance ManualDocument260 pagesX200 Hardware Maintenance ManualAndre PennNo ratings yet

- Lifting Equipment 04 11 2023Document22 pagesLifting Equipment 04 11 2023rome reyesNo ratings yet

- Commutation Torque Ripple Reduction in BLDC Motor Using Modified SEPIC Converter and ThreeDocument2 pagesCommutation Torque Ripple Reduction in BLDC Motor Using Modified SEPIC Converter and ThreestarboyNo ratings yet

- Electrical Layout Load Computations: Ground FloorDocument2 pagesElectrical Layout Load Computations: Ground FloorCharlamagne MirandaNo ratings yet

- Käyttöohje Generaattori Esab LHN 250 EngDocument34 pagesKäyttöohje Generaattori Esab LHN 250 EngmaciucapompaNo ratings yet

- Iraq Gates Fiber Optic Testing ReportDocument2 pagesIraq Gates Fiber Optic Testing ReportAhmedNo ratings yet

- ARM Lab QuestionsDocument2 pagesARM Lab QuestionsAravind VinasNo ratings yet

- BN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedDocument2 pagesBN - 3803 Hexalobular Socket Countersunk Flat Head Screws Fully ThreadedMSD ENGRNo ratings yet

- Hmi Murphy G306a000Document8 pagesHmi Murphy G306a000DAVIS VELASQUEZNo ratings yet

- Control Your Telescope Using Stellarium Arduino PDFDocument28 pagesControl Your Telescope Using Stellarium Arduino PDFEd BergsteigerNo ratings yet

- Intro To Computer AssignmentDocument5 pagesIntro To Computer AssignmentRizwan KhokharNo ratings yet

- Genset Transfer TimesDocument13 pagesGenset Transfer Timesjerico dizonNo ratings yet

- ArticleDocument7 pagesArticlengô quânNo ratings yet