Professional Documents

Culture Documents

Closed Swage Sockets National Swage Buttons

Uploaded by

hoiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Closed Swage Sockets National Swage Buttons

Uploaded by

hoiCopyright:

Available Formats

WIRE ROPE END FITTINGS Closed Swage Sockets

• Forged from special bar quality carbon steel, suitable for cold forming.

• Swage Socket terminations have an efficiency rating of 100% based on the

catalog strength of wire rope.

• Hardness controlled by spheroidize annealing.

• Stamp for identification after swaging without concern for fractures (as per

directions in Wire Rope End Terminations User’s Manual).

• Swage sockets incorporate a reduced machined area of the shank which is

equivalent to the proper “After Swage” dimension. Before swaging, this provides

for an obvious visual difference in the shank diameter. After swaging, a uniform

shank diameter is created allowing for a QUIC-CHECK® and permanent visual

inspection opportunity.

• Designed to quickly determine whether the socket has been through the

swaging operation and assist in field inspections, it does not liminate the

need to perform standard production inspections which include gauging for the

proper “After Swage” dimensions or proof loading.

S-502

Closed Swage

Sockets

NOTE: S-502 Swage Sockets are recommended for use with 6 x 19 or 6 x 37, IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope. Before

using any National Swage fitting with any other type la , construction or grade of wire rope, it is recommended that the termination be

destructive tested and documented to prove the adequacy of the assembly to be manufactured. In accordance with ASME B30.9, all slings

terminated with swage sockets shall be proof loaded.*

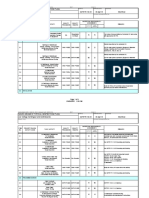

S-502 Closed Swage Sockets

S-502 Closed Socket Specifications Swager / Die Data

Rope Size Stock No. Side Load

Before Swage Dimensions

(in) Max. 500

After 1000 1500

S-502 Wt. Ultimate Swage 1500 3000 1500 3000

Stock Each Load** Dim. Die Ton Ton Ton Ton

No. (in) (mm) (lb) (t) A B C D E F H L (in) Description 5x7 6 x 12 6 x 12 6 x 12

1039325 1/4 6 .33 5.4 4.28 .50 1.38 .76 .27 2.19 .50 3.50 .46 1/4 Socket 1192845 - - -

1039343 5/16 8 .75 11.8 5.42 .77 1.62 .88 .34 3.25 .68 4.50 .71 5/16-3/8 Socket 1192863 - - -

1039361 3/8 9-10 .72 13.6 5.42 .78 1.62 .88 .41 3.25 .68 4.50 .71 5/16-3/8 Socket 1192863 - - -

1039389 7/16 11-12 1.42 18.1 6.88 1.01 2.00 1.07 .49 4.31 .87 5.75 .91 7/16-1/2 Socket 1192881 - - -

1039405 1/2 13 1.42 21.3 6.88 1.01 2.00 1.07 .55 4.31 .87 5.75 .91 7/16-1/2 Socket 1192881 - - -

1039423 9/16 14 2.92 31.8 8.59 1.27 2.38 1.28 .61 5.38 1.14 7.25 1.16 9/16-5/8 Socket 1192907 - - -

1039441 5/8 16 2.85 34.9 8.59 1.27 2.38 1.28 .68 5.38 1.14 7.25 1.16 9/16-5/8 Socket 1192907 - - -

1039469 3/4 18-20 5.00 43.5 10.25 1.56 2.88 1.49 .80 6.44 1.33 8.63 1.42 3/4 Socket 1192925 - - -

1039487 7/8 22 6.80 51.5 11.87 1.72 3.12 1.73 .94 7.50 1.53 10.09 1.55 7/8 Socket 1192943 - - -

1039502 1 24-26 10.40 71.4 13.56 2.00 3.62 2.11 1.07 8.63 1.78 11.50 1.80 1 Socket 1192961 - - -

1039520 1-1/8 28 14.82 83.3 15.03 2.25 4.00 2.37 1.19 9.75 2.03 12.75 2.05 1-1/8 Socket 1192989 - - -

1039548 1-1/4 32 21.57 109 16.94 2.53 4.50 2.62 1.34 10.81 2.25 14.38 2.30 1-1/4 Socket 1193005 - - -

1039566 1-3/8 34-36 28.54 136 18.59 2.81 5.00 2.62 1.46 11.88 2.29 15.75 2.56 1-3/8 Socket 1193023 - - -

1039584 1-1/2 38-40 38.06 181 20.13 3.08 5.38 2.87 1.59 12.81 2.56 17.00 2.81 1-1/2 Socket 1193041 1191267 1195355 1195192

1039600 1-3/4 44 51.00 228 23.56 3.40 6.25 3.63 1.87 15.06 3.08 20.00 3.06 1-3/4 Socket 1193069 1191276 1195367 1195209

1042589 2 48-52 89.25 272 27.13 3.94 7.25 3.88 2.12 17.06 3.31 23.00 3.56 2 Socket 1193087 1191294 1195379 1195218

* Maximum Proof Load shall not exceed 50% of XXIP rope catalog breaking strength. **The Ultimate Loads of 3/4” through 1 1/4” sizes have been increased to meet the requirements for 8 strand 2160

Grade pendants. Note: Fittings designed only to be used on exact sizes listed.

48 Copyright © 2019 The Crosby Group LLC All Rights Reserved

02_Wire_Rope_End_Fittings.indd 48 8/16/19 9:37 AM

You might also like

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Crosby 198Document1 pageCrosby 198oscar_jfrNo ratings yet

- T Series CouplingsDocument4 pagesT Series CouplingsiradocajNo ratings yet

- Wedge SoketDocument1 pageWedge SoketOscar Ortiz VazquezNo ratings yet

- Mps & Itt - Spiral SteelDocument23 pagesMps & Itt - Spiral SteelSiswo YuwonoNo ratings yet

- Branch v06Document4 pagesBranch v06Kerr AgotNo ratings yet

- VSL - Multistrand Post TensioningDocument15 pagesVSL - Multistrand Post TensioningkmabdNo ratings yet

- Brochure Corrugated Concrete Sheet Piles..Document8 pagesBrochure Corrugated Concrete Sheet Piles..Saraburi Construction Technology Company LimitedNo ratings yet

- Mercer Valve 9100 Relief Valve Flanged AEDocument16 pagesMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaNo ratings yet

- MultistrandPostTensioning PDFDocument15 pagesMultistrandPostTensioning PDFthowchinNo ratings yet

- Cable-Gard Static Discharge Reels 7P: ApplicationsDocument5 pagesCable-Gard Static Discharge Reels 7P: ApplicationscubarturNo ratings yet

- WaboFlex 1013 DataSheetDocument4 pagesWaboFlex 1013 DataSheetSean BrownNo ratings yet

- Catalogo - Cameron N Type Lockscrew (PDS0070)Document2 pagesCatalogo - Cameron N Type Lockscrew (PDS0070)Carlos Alberto Aguilera MendezNo ratings yet

- Wabo Flex 0208Document4 pagesWabo Flex 0208walidNo ratings yet

- Descarga 1er Paso Mercer 91-52j11t84u1Document16 pagesDescarga 1er Paso Mercer 91-52j11t84u1Alberto Esau Reyes CruzNo ratings yet

- Crosby Open Spelter SocketsDocument1 pageCrosby Open Spelter SocketsHenrique docinNo ratings yet

- TSeries CouplingDocument6 pagesTSeries Couplingcarlos sotoNo ratings yet

- Copperhead Bridge Plug M-957 Operating InstructionsDocument15 pagesCopperhead Bridge Plug M-957 Operating InstructionstonyNo ratings yet

- Schedule 40 PVC Rigid Nonmetallic ConduitsDocument3 pagesSchedule 40 PVC Rigid Nonmetallic ConduitsPRABHU SHANKAR MNo ratings yet

- Terminales G-417 CrosbyDocument1 pageTerminales G-417 Crosbycorsini999No ratings yet

- Crosby G416 MetricDocument1 pageCrosby G416 MetricRobby VillenaNo ratings yet

- Cilindro Hidraulico EnerpacDocument4 pagesCilindro Hidraulico EnerpacrrNo ratings yet

- SCM Motoare Hidraulice SunfabDocument12 pagesSCM Motoare Hidraulice SunfabANTON NEAGUNo ratings yet

- A Mefi MC001 E1Document16 pagesA Mefi MC001 E1aptureincNo ratings yet

- Filter Mounting Bank: For Particulate or Activated Carbon FiltersDocument6 pagesFilter Mounting Bank: For Particulate or Activated Carbon FilterskkkhattabbbNo ratings yet

- TS Spir Class-EnDocument2 pagesTS Spir Class-EnpdiconpNo ratings yet

- TSCS 0033Document8 pagesTSCS 0033Ranjan ShankarNo ratings yet

- Dextra Marine Tie Bars Interactive Brochure 2020Document7 pagesDextra Marine Tie Bars Interactive Brochure 2020Mohamed abou elnasrNo ratings yet

- Wire Line Set Retrievable Packer: Drilling & Down-Hole Completion ToolsDocument11 pagesWire Line Set Retrievable Packer: Drilling & Down-Hole Completion Toolsparag padoleNo ratings yet

- Travelling Block MC Kissick Serial 352Document1 pageTravelling Block MC Kissick Serial 352julioramcaNo ratings yet

- Mohawk Riserlite Indoor Outdoor Fiber CableDocument2 pagesMohawk Riserlite Indoor Outdoor Fiber CablecolinyNo ratings yet

- Fl4025 Cople DodgeDocument4 pagesFl4025 Cople DodgeGelasio VegaNo ratings yet

- AWC Series DatasheetDocument2 pagesAWC Series DatasheetHocine AminiNo ratings yet

- HAWKE GLAND-type OnlyDocument1 pageHAWKE GLAND-type OnlyJaaffer AliNo ratings yet

- Type 501-453-Universal PDFDocument1 pageType 501-453-Universal PDFwe202No ratings yet

- GNB Absoltye IIPDocument18 pagesGNB Absoltye IIPFederico Tellez QNo ratings yet

- Sikla Pipe Support Catalogue 07Document98 pagesSikla Pipe Support Catalogue 07ShubiNo ratings yet

- 501/453/universal Cable Gland Type: Flameproof and Increased SafetyDocument1 page501/453/universal Cable Gland Type: Flameproof and Increased SafetymahdimaziniNo ratings yet

- Ez Arc Brochure-14Document2 pagesEz Arc Brochure-14Shalom AvadovNo ratings yet

- wedge anchoring clamps Σελίδα 48 και 49Document1 pagewedge anchoring clamps Σελίδα 48 και 49Konstantinos SynodinosNo ratings yet

- Wilson Cables - FR.Document12 pagesWilson Cables - FR.ថុន មករាNo ratings yet

- 501,453 Classified GlandDocument1 page501,453 Classified GlandMuhammad RamzanNo ratings yet

- S-TSK TLKDocument6 pagesS-TSK TLKEdgarNo ratings yet

- N Lockscrew Assembly - PDS0070 - REVDocument2 pagesN Lockscrew Assembly - PDS0070 - REVvinayakbankarNo ratings yet

- WaboCreteStripSealPark 1216 DataSheetDocument5 pagesWaboCreteStripSealPark 1216 DataSheetSean BrownNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Flush Joint ConnectionDocument8 pagesFlush Joint Connectionhuyenhvtc252No ratings yet

- Asco Series 290 Angle Body Full CatalogDocument12 pagesAsco Series 290 Angle Body Full CatalogJuan Sebastián BustosNo ratings yet

- Heat Resistant Single Core PVC Insulated CablesDocument2 pagesHeat Resistant Single Core PVC Insulated CablesOgnjen BiočaninNo ratings yet

- Tuf Strand BrochureDocument4 pagesTuf Strand BrochureIllarick Balarezo SalgadoNo ratings yet

- Brida Flexible VitaulicDocument3 pagesBrida Flexible VitaulicG Abigail MorenoNo ratings yet

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNo ratings yet

- Marathon Crusher DutyDocument3 pagesMarathon Crusher DutyKamer YıldızNo ratings yet

- Category 6A UTP Indoor/Outdoor Cable - GlobalDocument3 pagesCategory 6A UTP Indoor/Outdoor Cable - GlobalValentina CardonaNo ratings yet

- Multi-Stage Cementing Collar: Specification GuideDocument2 pagesMulti-Stage Cementing Collar: Specification GuideOdesya SatyaNo ratings yet

- Fan Vanco CatalogueDocument24 pagesFan Vanco CatalogueYizhar Bechamel MestokoNo ratings yet

- VORTXcatpgDocument5 pagesVORTXcatpgJaime Arellano HuertaNo ratings yet

- VAM SFC 0511 SPDocument8 pagesVAM SFC 0511 SP11tkt11No ratings yet

- Gear Code BookDocument81 pagesGear Code BookhoiNo ratings yet

- ActuatorsDocument37 pagesActuatorshoiNo ratings yet

- A Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..Document74 pagesA Full Range of Hydraulic Parts Such As: Pumps, Hydraulic Valves, Hoses, Steering Pumps, Lift Cylinders, Cylinder Repair Kits, Fittings, ..hoiNo ratings yet

- 04 6750036 EL 180910 enDocument227 pages04 6750036 EL 180910 enhoiNo ratings yet

- 00a 6720169 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720169 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- BasicsDocument170 pagesBasicshoiNo ratings yet

- DanfossomrDocument30 pagesDanfossomrhoiNo ratings yet

- 01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)Document190 pages01b - 6720168-169 - CHAPTER1 - BA - 191130 - en (Us)hoiNo ratings yet

- Ols 120Document1 pageOls 120hoiNo ratings yet

- 00a 6720168 CONTENTS CHALLENGER280 PDFDocument1 page00a 6720168 CONTENTS CHALLENGER280 PDFhoiNo ratings yet

- Angebot 1042622 (81 - 8492 - 3h)Document2 pagesAngebot 1042622 (81 - 8492 - 3h)hoiNo ratings yet

- Angebot 1027718Document2 pagesAngebot 1027718hoi100% (1)

- ServiceInfo15-WT-05 Rev ADocument38 pagesServiceInfo15-WT-05 Rev AhoiNo ratings yet

- Angebot 1047857Document2 pagesAngebot 1047857hoiNo ratings yet

- 9 Hydraulic2006Document91 pages9 Hydraulic2006hoiNo ratings yet

- Angebot 1033668 PDFDocument2 pagesAngebot 1033668 PDFhoiNo ratings yet

- 00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)Document2 pages00b - 6720168-169 - VORSPANN - BA - 191130 - en (Us)hoiNo ratings yet

- 09 6720168-9 EK 200214 enDocument449 pages09 6720168-9 EK 200214 enhoiNo ratings yet

- 08 000 630 0263 Gearbox Dana Wa 041101 D3Document106 pages08 000 630 0263 Gearbox Dana Wa 041101 D3hoi100% (1)

- HMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationDocument44 pagesHMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationhoiNo ratings yet

- 01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)Document8 pages01a - 6720168-169 - BRIEFINSTRUCTIONS - 171108 - en (GB)hoiNo ratings yet

- PGP020™ Series: Pumps and MotorsDocument16 pagesPGP020™ Series: Pumps and MotorshoiNo ratings yet

- BSWR CatalogDocument16 pagesBSWR CataloghoiNo ratings yet

- 1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90Document2 pages1ce Series Overcentre Valve: Pilot Assisted Relief With Check 1CE90hoiNo ratings yet

- Olympian Plus Plug-In System: General Purpose FiltersDocument1 pageOlympian Plus Plug-In System: General Purpose FiltershoiNo ratings yet

- Accessories AH2342-CA Ȝ: SpecificationDocument1 pageAccessories AH2342-CA Ȝ: SpecificationhoiNo ratings yet

- Piston & Motors: PumpsDocument4 pagesPiston & Motors: PumpshoiNo ratings yet

- D101NLB - D102NLB Service GB - 10 - 2012Document124 pagesD101NLB - D102NLB Service GB - 10 - 2012hoiNo ratings yet

- With DC Motor: The Professional ChoiceDocument12 pagesWith DC Motor: The Professional ChoicehoiNo ratings yet

- APC200 Calibration X Operator-EDocument13 pagesAPC200 Calibration X Operator-EhoiNo ratings yet

- Quality Policy Enhanced UnderstandingDocument9 pagesQuality Policy Enhanced UnderstandingReginald MalibiranNo ratings yet

- Dry Coal ProcessingDocument16 pagesDry Coal ProcessingmosesmattekkNo ratings yet

- JQuery Set Content and AttributesDocument8 pagesJQuery Set Content and AttributesGodwin LarryNo ratings yet

- A Four Element Rectangular Dielectric Resonator Antenna Array For Wireless ApplicationsDocument4 pagesA Four Element Rectangular Dielectric Resonator Antenna Array For Wireless ApplicationsSubhanjali MyneniNo ratings yet

- Design of Telemonitoring Medical Record of Cardiac Arrhythmia Patients Based On RFID and WEBDocument4 pagesDesign of Telemonitoring Medical Record of Cardiac Arrhythmia Patients Based On RFID and WEBRahul SharmaNo ratings yet

- Gs Autoclave Mediano SP PDFDocument8 pagesGs Autoclave Mediano SP PDFagh8garciaNo ratings yet

- Tajima Librarian by PulseDocument12 pagesTajima Librarian by PulseArnold PereaNo ratings yet

- Beck, Ulrich & Lau, Christoph - Second Modernity As A Research Agenda (2005)Document33 pagesBeck, Ulrich & Lau, Christoph - Second Modernity As A Research Agenda (2005)Germán GiupponiNo ratings yet

- Trigger Sprayer Dynamic Systems ModelDocument5 pagesTrigger Sprayer Dynamic Systems ModelLTE002No ratings yet

- Bonneville T100 (MY16) BrochureDocument9 pagesBonneville T100 (MY16) Brochurehardworking_studentNo ratings yet

- Swagelok Tubular FittingsDocument8 pagesSwagelok Tubular FittingstotcsabNo ratings yet

- Tutorial 3 - DMCF 2223 (Manometer)Document4 pagesTutorial 3 - DMCF 2223 (Manometer)zul hilmiNo ratings yet

- Managerial CommunicationDocument17 pagesManagerial Communicationbadree456No ratings yet

- Basic MathsDocument12 pagesBasic Mathsgud2cupiyushNo ratings yet

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocument2 pagesRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakNo ratings yet

- Echnical News: Power Factor, What Is It?Document6 pagesEchnical News: Power Factor, What Is It?Fuji Electric SMBENo ratings yet

- Nabl 400 PDFDocument582 pagesNabl 400 PDFBullzeye StrategyNo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- CNC Milling: Technical DescriptionDocument15 pagesCNC Milling: Technical Descriptiongia1985No ratings yet

- History of The MicroscopeDocument19 pagesHistory of The MicroscopeShafici CqadirNo ratings yet

- HRD536C Hrd536cki HRD536C2Document82 pagesHRD536C Hrd536cki HRD536C2David ThijsNo ratings yet

- Xiaoming Zhu China's Technology Innovators Selected Cases On Creating and Staying Ahead of Business TrendsDocument193 pagesXiaoming Zhu China's Technology Innovators Selected Cases On Creating and Staying Ahead of Business TrendsrezasattariNo ratings yet

- LEXE0047-02 Data SheetDocument4 pagesLEXE0047-02 Data Sheetsklm123No ratings yet

- Fuji-Electric Fujitsu Rs9lb Rs12lbDocument16 pagesFuji-Electric Fujitsu Rs9lb Rs12lbAlain ClementeNo ratings yet

- Edtech 2 ExamDocument3 pagesEdtech 2 ExamShairon palma100% (4)

- Wpa Supplicant Devel 04Document620 pagesWpa Supplicant Devel 04renzoefraNo ratings yet

- 03-Datalink, Cabin CANDocument20 pages03-Datalink, Cabin CANEbied Yousif AlyNo ratings yet

- CT 110 - Window Detail58Document2 pagesCT 110 - Window Detail58cantika lestarieNo ratings yet

- Lowara PumpDocument68 pagesLowara Pumpa safaieNo ratings yet

- Predicting Remaining Life by Fusing The Physics of Failure Modeling With Diagnostics PDFDocument7 pagesPredicting Remaining Life by Fusing The Physics of Failure Modeling With Diagnostics PDFPradeep KunduNo ratings yet