Professional Documents

Culture Documents

APL5930 3A, Ultra Low Dropout (0.23V Typical) Linear Regulator

APL5930 3A, Ultra Low Dropout (0.23V Typical) Linear Regulator

Uploaded by

jose jesus arteaga gomezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APL5930 3A, Ultra Low Dropout (0.23V Typical) Linear Regulator

APL5930 3A, Ultra Low Dropout (0.23V Typical) Linear Regulator

Uploaded by

jose jesus arteaga gomezCopyright:

Available Formats

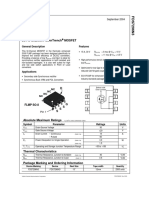

APL5930

3A, Ultra Low Dropout (0.23V Typical) Linear Regulator

Features General Description

• Compatible with APL5913 The APL5930 is a 3A ultra low dropout linear regulator.

• Ultra Low Dropout The IC needs two supply voltages, one is a control voltage

- 0.23V(typical) at 3A Output Current (VCNTL) for the control circuitry, the other is a main supply

• Low ESR Output Capacitor (Multi-layer

voltage (VIN) for power conversion, to reduce power dissi-

pation and provide extremely low dropout voltage.

Chip Capacitors (MLCC)) Applicable

The APL5930 integrates many functions. A Power-On-

• 0.8V Reference Voltage

Reset (POR) circuit monitors both supply voltages on

• High Output Accuracy VCNTL and VIN pins to prevent erroneous operations.

- ±1.5% over Line, Load, and Temperature Range The functions of thermal shutdown and current-limit pro-

• Fast Transient Response tect the device against thermal and current over-loads. A

• Adjustable Output Voltage POK indicates the output voltage status with a delay time

• Power-On-Reset Monitoring on Both VCNTL and set internally. It can control other converter for power

VIN Pins sequence. The APL5930 can be enabled by other power

• Internal Soft-Start

systems. Pulling and holding the EN voltage below 0.4V

shuts off the output.

• Current-Limit and Short Current-Limit Protections

The APL5930 is available in a SOP-8P package which

• Thermal Shutdown with Hysteresis

features small size as SOP-8 and an Exposed Pad to

• Open-Drain VOUT Voltage Indicator (POK) reduce the junction-to-case resistance to extend power

• Low Shutdown Quiescent Current (<30 µA) range of applications.

• Shutdown/Enable Control Function

• Simple SOP-8P Package with Exposed Pad Applications

• Lead Free and Green Devices Available • Front Side Bus VTT (1.2V/3A)

(RoHS Compliant) • Note Book PC Applications

• Motherboard Applications

Pin Configuration Simplified Application Circuit

VCNTL

GND 1 8 EN

FB 2 7 POK

VOUT 3 6 VCNTL VIN

VOUT 4 5 VIN VCNTL

POK POK VIN

SOP-8P (Top View) VOUT VOUT

APL5930

= Exposed Pad EN EN FB

(connected to VIN plane for better heat dissipation) Enable GND

Optional

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp. 1 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Ordering and Marking Information

Package Code

APL5930

KA : SOP-8P

Operating Ambient Temperature Range

Assembly Material

I : -40 to 85 oC

Handling Code Handling Code

Temperature Range TR : Tape & Reel

Package Code Assembly Material

G : Halogen and Lead Free Device

APL5930

APL5930 KA : XXXXX - Date Code

XXXXX

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020D for

MSL classification at lead-free peak reflow temperature. ANPEC defines “Green” to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

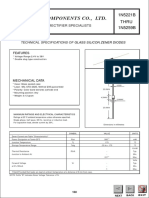

Absolute Maximum Ratings (Note 1)

Symbol Parameter Rating Unit

VIN VIN Supply Voltage (VIN to GND) -0.3 ~ 4.0 V

VCNTL VCNTL Supply Voltage (VCNTL to GND) -0.3 ~ 7 V

VOUT VOUT to GND Voltage -0.3 ~ VIN +0.3 V

POK to GND Voltage -0.3 ~ 7 V

EN, FB to GND Voltage -0.3 ~ VCNTL +0.3 V

PD Power Dissipation 3 W

o

TJ Maximum Junction Temperature 150 C

o

TSTG Storage Temperature -65 ~ 150 C

o

TSDR Maximum Lead Soldering Temperature, 10 Seconds 260 C

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Thermal Characteristics

Symbol Parameter Typical Value Unit

Junction-to-Ambient Resistance in Free Air (Note 2)

θJA

o

42 C/W

SOP-8P

Junction-to-Case Resistance in Free Air (Note 3)

θJC

o

18 C/W

SOP-8P

Note 2: θJA is measured with the component mounted on a high effective thermal conductivity test board in free air. The exposed pad

of SOP-8P is soldered directly on the PCB.

Note 3: The “Thermal Pad Temperature” is measured on the PCB copper area connected to the thermal pad of package.

1 8

2 7

VIN

3 6

4 5

Measured Point

PCB Copper

Copyright ANPEC Electronics Corp. 2 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Recommended Operating Conditions

Symbol Parameter Range Unit

VCNTL VCNTL Supply Voltage 3.0 ~ 5.5 V

VIN VIN Supply Voltage 1.2 ~ 3.65 V

VOUT VOUT Output Voltage (when VCNTL-VOUT>1.9V) 0.8 ~ VIN – VDROP V

Continuous Current 0~3

IOUT VOUT Output Current A

Peak Current 0~4

IOUT = 3A at 25% nominal VOUT 8 ~ 1100

COUT VOUT Output Capacitance IOUT = 2A at 25% nominal VOUT 8 ~ 1700 µF

IOUT = 1A at 25% nominal VOUT 8 ~ 2400

ESRCOUT ESR of VOUT Output Capacitor 0 ~ 200 mΩ

o

TA Ambient Temperature -40 ~ 85 C

o

TJ Junction Temperature -40 ~ 125 C

Electrical Characteristics

Unless otherwise specified, these specifications apply over VCNTL=5V, VIN=1.8V, VOUT= 1.2V and TA= -40 ~ 85 oC. Typical values

are at T A=25oC.

APL5930

Symbol Parameter Test Conditions Unit

Min. Typ. Max.

SUPPLY CURRENT

IVCNTL VCNTL Supply Current EN = VCNTL, IOUT=0A - 1.0 1.5 mA

ISD VCNTL Supply Current at Shutdown EN = GND - 15 30 µA

VIN Supply Current at Shutdown EN = GND, VIN=3.65V - - 1 µA

POWER-ON-RESET (POR)

Rising VCNTL POR Threshold 2.5 2.7 2.9 V

VCNTL POR Hysteresis - 0.4 - V

Rising VIN POR Threshold 0.8 0.9 1.0 V

VIN POR Hysteresis - 0.5 - V

OUTPUT VOLTAGE

VREF Reference Voltage FB=VOUT - 0.8 - V

VCNTL=3.0 ~ 5.5V, IOUT= 0~3A,

Output Voltage Accuracy -1.5 - +1.5 %

TJ= -40~125oC

Load Regulation IOUT=0A ~3A - 0.06 0.25 %

Line Regulation IOUT=10mA, VCNTL= 3.0 ~ 5.5V - 0.15 - + 0.15 %/V

VOUT Pull-low Resistance VCNTL=3.3V, VEN=0V, VOUT<0.8V - 85 - Ω

FB Input Current VFB=0.8V -100 - 100 nA

DROPOUT VOLTAGE

TJ=25oC - 0.26 0.31

VOUT=2.5V

TJ=-40~125oC - - 0.42

TJ=25oC - 0.24 0.29

VDROP VIN-to-VOUT Dropout Voltage VCNTL=5.0V VOUT=1.8V V

, IOUT=3A TJ=-40~125oC - - 0.40

TJ=25oC - 0.23 0.28

VOUT=1.2V

TJ=-40~125oC - - 0.38

Copyright ANPEC Electronics Corp. 3 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Electrical Characteristics (Cont.)

Unless otherwise specified, these specifications apply over VCNTL=5V, VIN=1.8V, VOUT= 1.2V and TA= -40 ~ 85 oC. Typical values

are at T A=25oC.

APL5930

Symbol Parameter Test Conditions Unit

Min. Typ. Max.

DROPOUT VOLTAGE (CONT.)

TJ=25oC 4.7 5.7 6.7

ILIM Current-Limit Level o

A

TJ= -40 ~ 125 C 4.2 - -

PROTECTIONS

ISHORT Short Current-Limit Level VFB<0.2V - 1.1 - A

Short Current-Limit Blanking

From beginning of soft-start 0.6 1.5 - ms

Time

o

TSD Thermal Shutdown Temperature TJ rising - 170 - C

o

Thermal Shutdown Hysteresis - 50 - C

ENABLE AND SOFT-START

EN Logic High Threshold

VEN rising 0.5 0.8 1.1 V

Voltage

EN Hysteresis - 0.1 - V

EN Pull-High Current EN=GND - 5 - µA

TSS Soft-Start Interval 0.3 0.6 1.2 ms

Turn On Delay From being enabled to VOUT rising 10% 60 120 180 µs

POWER-OK AND DELAY

VTHPOK Rising POK Threshold Voltage VFB rising 90 92 94 %

POK Threshold Hysteresis - 8 - %

POK Pull-low Voltage POK sinks 5mA - 0.25 0.4 V

POK Debounce Interval VFB<falling POK voltage threshold - 10 - µs

POK Delay Time From VFB =VTHPOK to rising edge of the VPOK 1 2 4 ms

Copyright ANPEC Electronics Corp. 4 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Typical Operating Characteristics

Current-Limit vs. Junction Short Current-Limit vs. Junction

Temperature Temperature

6.5 1.20

VOUT = 1.2V

1.18

Short Current-Limit, ISHORT (mA)

6.0 VCNTL = 5V

1.16

Current-Limit, ILIM (A)

1.14

5.5 VCNTL = 5V

1.12

5.0 1.10

VCNTL = 3.3V

1.08

4.5

1.06 VCNTL = 3.3V

1.04

4.0

1.02

3.5 1.00

-50 -25 0 25 50 75 100 125 -50 -25 0 25 50 75 100 125

Junction Temperature (oC) Junction Temperature (oC)

Dropout Voltage vs. Output Current Droput Voltage vs. Output Current

450 450

VCNTL = 5V VCNTL = 3.3V

400 VOUT = 1.2V 400 VOUT = 1.2V

Dropout Voltage, VDROP (mV)

Dropout Voltage, VDROP (mV)

350 350

TJ = 125°

C TJ = 125°

C

300 TJ = 75°

C 300 TJ = 75°

C

250 TJ = 25°

C 250 TJ = 25°

C

200 200

150 150

100 100

TJ = 0°

C TJ = 0°

C

50 TJ = - 40°

C 50 TJ = - 40°

C

0 0

0 0.5 1 1.5 2 2.5 3 0 0.5 1 1.5 2 2.5 3

Output Current, IOUT (A) Output Current, IOUT (A)

Dropout Voltage vs. Output Current Dropout Voltage vs. Output Current

400 400

VCNTL = 5V VCNTL = 5V

350 VOUT = 1.5V 350

Dropout Voltage, VDROP (mV)

Dropout Voltage, VDROP (mV)

VOUT = 1.8V

TJ = 125°

C

TJ = 125°

C

300 300

TJ = 75°

C TJ = 75°

C

250 250

TJ = 25°

C TJ = 25°

C

200 200

150 150

100 100 TJ = 0°

C

TJ = 0°

C

50 50 TJ = - 40°

C

TJ = - 40°

C

0 0

0 0.5 1 1.5 2 2.5 3 0 0.5 1 1.5 2 2.5 3

Output Current, IOUT (A) Output Current, IOUT (A)

Copyright ANPEC Electronics Corp. 5 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Typical Operating Characteristics (Cont.)

Reference Voltage vs. Junction

Dropout Voltage vs. Output Current

Temperature

450 0.808

VCNTL = 5V

400 0.806

VOUT = 2.5V

Dropout Voltage, VDROP (mV)

Reference Voltage, VREF (V)

350 TJ = 125°

C

0.804

300 TJ = 75°

C

0.802

250 TJ = 25°

C

0.800

200

0.798

150

100 0.796

TJ = 0°

C

50 0.794

TJ = - 40°

C

0 0.792

0 0.5 1 1.5 2 2.5 3 -50 -25 0 25 50 75 100 125

Output Current, IOUT (A) Junction Temperature ( C) o

VIN Power Supply Rejection Ratio VCNTL Power Supply Rejection Ratio

(PSRR) (PSRR)

0 0

VCNTL=5V

Power Supply Rejection Ratio (dB)

VCNTL=4.6~5.4V

Power Supply Rejection Ratio (dB)

VIN=1.8V

-10 VINPK-PK=100mV -10 VIN=1.8V

VOUT=1.2V VOUT=1.2V

IOUT=3A IOUT=3A

-20

-20 CIN=10µF CIN=COUT=10µF

COUT=10µF

-30

-30

-40

-40

-50

-50

-60

-60 -70

1000 10000 100000 1000000 1000 10000 100000 1000000

Frequency (Hz) Frequency (Hz)

Copyright ANPEC Electronics Corp. 6 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Operating Waveforms

Refer to the typical application circuit. The test condition is VIN=1.8V, VCNTL=5V, VOUT=1.2V, TA= 25oC

unless otherwise specified.

Power On Power Off

VCNTL

VCNTL

1 1

VIN

VIN

2 2

VOUT VOUT

3 3

VPOK VPOK

4 4

COUT=10µF, CIN=10µF, RL=0.4Ω COUT=10µF, CIN=10µF, RL=0.4Ω

CH1: VCNTL, 5V/Div, DC CH1: VCNTL, 5V/Div, DC

CH2: VIN, 1V/Div, DC CH2: VIN, 1V/Div, DC

CH3: VOUT, 1V/Div, DC CH3: VOUT, 1V/Div, DC

CH4: VPOK, 5V/Div, DC CH4: VPOK, 5V/Div, DC

TIME: 2ms/Div TIME: 2ms/Div

Load Transient Response Over Current Protection

VOUT

VOUT

1

IOUT

IOUT

2 4

IOUT=10mA to 3A to 10mA (rise / fall time = 1µs) COUT=10µF, CIN=10µF, IOUT= 2A to 5.6A

COUT=10µF, CIN=10µF CH1: VOUT, 0.5V/Div, DC

CH1: VOUT, 50mV/Div, AC CH4: IOUT, 2A/Div, DC

CH2: IOUT, 1A/Div, DC TIME: 0.2ms/Div

TIME: 50µs/Div

Copyright ANPEC Electronics Corp. 7 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Operating Waveforms (Cont.)

Refer to the typical application circuit. The test condition is VIN=1.8V, VCNTL=5V, VOUT=1.2V, TA= 25oC

unless otherwise specified.

Shutdown Enable

VEN VEN

1 1

VOUT

VOUT

2 2 VPOK

VPOK

3 3

IOUT

IOUT

4 4

COUT=10µF, CIN=10µF, RL=0.4Ω COUT=10µF, CIN=10µF, RL=0.4Ω

CH1: VEN, 5V/Div, DC CH1: VEN, 5V/Div, DC

CH2: VOUT, 1V/Div, DC CH2: VOUT, 0.5V/Div, DC

CH3: VPOK, 5V/Div, DC CH3: VPOK, 5V/Div, DC

CH4: IOUT, 2A/Div, DC CH4: IOUT, 2A/Div, DC

TIME: 2µs/Div TIME: 0.5ms/Div

Pin Description

PIN

FUNCTION

NO. NAME

1 GND Ground pin of the circuitry. All voltage levels are measured with respect to this pin.

Voltage Feedback Pin. Connecting this pin to an external resistor divider receives the feedback voltage

2 FB

of the regulator.

Output pin of the regulator. Connecting this pin to load and output capacitors (10µF at least) is required

3,4 for stability and improving transient response. The output voltage is programmed by the resistor-divider

VOUT

connected to FB pin. The VOUT can provide 3A (max.) load current to loads. During shutdown, the

output voltage is quickly discharged by an internal pull-low MOSFET.

Main supply input pin for voltage conversions. A decoupling capacitor (≥10µF recommended) is usually

5 VIN connected near this pin to filter the voltage noise and improve transient response. The voltage on this

pin is monitored for Power-On-Reset purpose.

Bias voltage input pin for internal control circuitry. Connect this pin to a voltage source (+5V

6 VCNTL recommended). A decoupling capacitor (1µF typical) is usually connected near this pin to filter the

voltage noise. The voltage at this pin is monitored for Power-On-Reset purpose.

Power-OK signal output pin. This pin is an open-drain output used to indicate the status of output

7 POK voltage by sensing FB voltage. This pin is pulled low when output voltage is not within the Power-OK

voltage window.

Active-high enable control pin. Applying and holding the voltage on this pin below the enable voltage

threshold shuts down the output. When re-enabled, the IC undergoes a new soft-start process. When

8 EN

leave this pin open, an internal pull-up current (5µA typical) pulls the EN voltage and enables the

regulator.

Exposed

- Connect this pad to system VIN plane for good thermal conductivity.

Pad

Copyright ANPEC Electronics Corp. 8 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Block Diagram

VCNTL

Power-

Thermal POR

On-Reset

VCNTL Shutdown

(POR)

5µA

Control Logic

EN Enable

and

Soft-Start

0.8V

Soft-Start

Enable

VIN

POK

POR

VREF

PWOK

0.8V VOUT

Error Amplifier

ISEN

Delay Current-Limit

and

90% Short Current- GND

VREF Limit

FB

Typical Application Circuit

VCNTL

(+5V is preferred)

CCNTL

1µF

VIN

+1.8V

6

R3 CIN

5.1kΩ VCNTL 10µF

7 VIN 5

POK POK

3,4

VOUT VOUT

+1.2V / 3A

COUT

APL5930 10µF

8 2

EN EN FB (X5R/X7R Recommended)

Enable GND R1

R2 12kΩ

1

24kΩ

C1

Optional

(X5R/X7R Recommended)

10µF: GRM31MR60J106KE19 Murata

Copyright ANPEC Electronics Corp. 9 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Function Description

Power-On-Reset Thermal Shutdown

A Power-On-Reset (POR) circuit monitors both of supply A thermal shutdown circuit limits the junction tempera-

voltages on VCNTL and VIN pins to prevent wrong logic ture of APL5930. When the junction temperature exceeds

controls. The POR function initiates a soft-start process +170oC, a thermal sensor turns off the output NMOS, al-

after both of the supply voltages exceed their rising POR lowing the device to cool down. The regulator regulates

voltage thresholds during powering on. The POR func- the output again through initiation of a new soft-start pro-

tion also pulls low the POK voltage regardless the output cess after the junction temperature cools by 50oC, result-

status when one of the supply voltages falls below its ing in a pulsed output during continuous thermal over-

falling POR voltage threshold. load conditions. The thermal shutdown is designed with

a 50oC hysteresis to lower the average junction tempera-

Internal Soft-Start

ture during continuous thermal overload conditions, ex-

An internal soft-start function controls rise rate of the out- tending lifetime of the device.

put voltage to limit the current surge during start-up. The For normal operation, the device power dissipation should

typical soft-start interval is about 0.6 ms. be externally limited so that junction temperatures will

not exceed +125oC.

Output Voltage Regulation

Enable Control

An error amplifier works with a temperature-com-

pensated 0.8V reference and an output NMOS regulates The APL5930 has a dedicated enable pin (EN). A logic

output to the preset voltage. The error amplifier is de- low signal applied to this pin shuts down the output. Fol-

signed with high bandwidth and DC gain provides very lowing a shutdown, a logic high signal re-enables the

fast transient response and less load regulation. It com- output through initiation of a new soft-start cycle. When

pares the reference with the feedback voltage and ampli- left open, this pin is pulled up by an internal current source

fies the difference to drive the output NMOS which pro- (5µA typical) to enable normal operation. It’s not neces-

vides load current from VIN to VOUT. sary to use an external transistor to save cost.

Current-Limit Protection Power-OK and Delay

The APL5930 monitors the current flowing through the The APL5930 indicates the status of the output voltage by

output NMOS and limits the maximum current to prevent monitoring the feedback voltage (VFB) on FB pin. As the

load and APL5930 from damages during current over- VFB rises and reaches the rising Power-OK voltage thresh-

old (VTHPOK), an internal delay function starts to work. At

load conditions.

the end of the delay time, the IC turns off the internal

Short Current-Limit Protection NMOS of the POK to indicate that the output is ok. As the

V FB falls and reaches the falling Power-OK voltage

The short current-limit function reduces the current-limit

threshold, the IC turns on the NMOS of the POK (after a

level down to 1.1A (typical) when the voltage on FB pin

debounce time of 10µs typical).

falls below 0.2V (typical) during current overload or short-

circuit conditions.

The short current-limit function is disabled for success-

ful start-up during soft-start interval.

Copyright ANPEC Electronics Corp. 10 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Application Information

Power Sequencing Ultra-low-ESR capacitors (such as ceramic chip capaci-

tors) and low-ESR bulk capacitors (such as solid

The power sequencing of VIN and VCNTL is not neces-

tantalum, POSCap, and Aluminum electrolytic capacitors)

sary to be concerned. However, do not apply a voltage to

can all be used as an input capacitor of VIN. For most

VOUT for a long time when the main voltage applied at

applications, the recommended input capacitance of VIN

VIN is not present. The reason is the internal parasitic

is 10µF at least. However, if the drop of the input voltage

diode from VOUT to VIN conducts and dissipates power

is not cared, the input capacitance can be less than 10µF.

without protections due to the forward-voltage.

More capacitance reduces the variations of the supply

Output Capacitor voltage on VIN pin.

The APL5930 requires a proper output capacitor to main-

Setting Output Voltage

tain stability and improve transient response. The output

capacitor selection is dependent upon ESR (equivalent The output voltage is programmed by the resistor divider

series resistance) and capacitance of the output capaci- connected to FB pin. The preset output voltage is calcu-

tor over the operating temperature. lated by the following equation :

Ultra-low-ESR capacitors (such as ceramic chip R1

VOUT = 0.8 ⋅ 1 + ........... (V)

capacitors) and low-ESR bulk capacitors (such as solid R2

tantalum, POSCap, and Aluminum electrolytic capacitors)

Where R1 is the resistor connected from VOUT to FB with

can all be used as output capacitors.

Kelvin sensing connection and R2 is the resistor con-

During load transients, the output capacitors, depending

nected from FB to GND. A bypass capacitor(C1) may be

on the stepping amplitude and slew rate of load current,

connected with R1 in parallel to improve load transient

are used to reduce the slew rate of the current seen by

response and stability.

the APL5930 and help the device to minimize the varia-

tions of output voltage for good transient response. For

the applications with large stepping load current, the low-

ESR bulk capacitors are normally recommended.

Decoupling ceramic capacitors must be placed at the

load and ground pins as close as possible and the im-

pedance of the layout must be minimized.

Input Capacitor

The APL5930 requires proper input capacitors to supply

current surge during stepping load transients to prevent

the input voltage rail from dropping. Because the para-

sitic inductor from the voltage sources or other bulk ca-

pacitors to the VIN pin limit the slew rate of the surge

currents, more parasitic inductance needs more input

capacitance.

Copyright ANPEC Electronics Corp. 11 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Layout Consideration

1. Please solder the Exposed Pad on the VIN pad on Thermal Consideration

the top-layer of PCBs. The VIN pad must have wide

Refer to the figure 2, the SOP-8P is a cost-effective pack-

size to conduct heat into the ambient air through the age featuring a small size like a standard SOP-8 and a

VIN plane and PCB as a heat sink.

bottom exposed pad to minimize the thermal resistance

2. Please place the input capacitors for VIN and VCNTL of the package, being applicable to high current applica-

pins near the pins as close as possible for

tions. The exposed pad must be soldered to the top-layer

decoupling high-frequency ripples. VIN plane. The copper of the VIN plane on the Top layer

3. Ceramic decoupling capacitors for load must be

conducts heat into the PCB and ambient air. Please en-

placed near the load as close as possible for large the area of the top-layer pad and the VIN plane to

decoupling high-frequency ripples.

reduce the case-to-ambient resistance (θCA).

4. To place APL5930 and output capacitors near the

load reduces parasitic resistance and inductance 102 mil

for excellent load transient response.

5. The negative pins of the input and output capacitors 1 8

and the GND pin must be connected to the ground 2 7

plane of the load. 118 mil SOP-8P

3 6

6. Large current paths, shown by bold lines on the fig- 4 5

ure 1, must have wide tracks.

7. Place the R1, R2, and C1 near the APL5930 as close

as possible to avoid noise coupling. Top Exposed

VOUT Die Pad Top

8. Connect the ground of the R2 to the GND pin by us- plane VIN

ing a dedicated track. plane

9. Connect the one pin of the R1 to the load for Kelvin Ambient

Air

sensing. PCB

10. Connect one pin of the C1 to the VOUT pin for reli-

able feedback compensation. Figure 2

Recommended Minimum Footprint

VCNTL 0.024

CCNTL

8 7 6 5

0.072

CIN

VCNTL

VIN VIN

APL5930

VOUT

VOUT 0.138

0.212

0.118

COUT

C1

FB

Load

GND R1

R2

1 2 3 4

Figure 1 0.050 Unit : Inch

Copyright ANPEC Electronics Corp. 12 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Package Information

SOP-8P

D

SEE VIEW A

D1

E2

THERMAL E1

E

PAD

h X 45o

e b c

A2

0.25

A1

GAUGE PLANE

SEATING PLANE

L

θ

VIEW A

S SOP-8P

Y

M MILLIMETERS INCHES

B

O

L MIN. MAX. MIN. MAX.

A 1.60 0.063

A1 0.00 0.15 0.000 0.006

A2 1.25 0.049

b 0.31 0.51 0.012 0.020

c 0.17 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

D1 2.50 3.50 0.098 0.138

E 5.80 6.20 0.228 0.244

E1 3.80 4.00 0.150 0.157

E2 2.00 3.00 0.079 0.118

e 1.27 BSC 0.050 BSC

h 0.25 0.50 0.010 0.020

L 0.40 1.27 0.016 0.050

o o o

0 0C 8C 0C 8oC

Note : 1. Followed from JEDEC MS-012 BA.

2. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion or gate burrs shall not exceed 6 mil per side .

3. Dimension "E" does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 10 mil per side.

Copyright ANPEC Electronics Corp. 13 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Carrier Tape & Reel Dimensions

OD0 P0 P2 P1 A

E1

F

W

B0

K0 A0 OD1 A

B B

SECTION A-A

T

SECTION B-B

d

H

A

T1

Application A H T1 C d D W E1 F

12.4+2.00 13.0+0.50

330.0±2.00 50 MIN. 1.5 MIN. 20.2 MIN. 12.0±0.30 1.75±0.10 5.5±0.05

-0.00 -0.20

SOP-8P P0 P1 P2 D0 D1 T A0 B0 K0

1.5+0.10 0.6+0.00

4.0±0.10 8.0±0.10 2.0±0.05 1.5 MIN. 6.40±0.20 5.20±0.20 2.10±0.20

-0.00 -0.40

(mm)

Devices Per Unit

Package Type Unit Quantity

SOP- 8P Tape & Reel 2500

Copyright ANPEC Electronics Corp. 14 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Taping Direction Information

SOP-8P

USER DIRECTION OF FEED

Classification Profile

Copyright ANPEC Electronics Corp. 15 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Classification Reflow Profiles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Preheat & Soak

100 °C 150 °C

Temperature min (Tsmin)

150 °C 200 °C

Temperature max (Tsmax)

60-120 seconds 60-120 seconds

Time (Tsmin to Tsmax) (ts)

Average ramp-up rate

3 °C/second max. 3°C/second max.

(Tsmax to TP)

Liquidous temperature (TL) 183 °C 217 °C

Time at liquidous (tL) 60-150 seconds 60-150 seconds

Peak package body Temperature

See Classification Temp in table 1 See Classification Temp in table 2

(Tp)*

Time (tP)** within 5°C of the specified

20** seconds 30** seconds

classification temperature (Tc)

Average ramp-down rate (Tp to Tsmax) 6 °C/second max. 6 °C/second max.

Time 25°C to peak temperature 6 minutes max. 8 minutes max.

* Tolerance for peak profile Temperature (Tp) is defined as a supplier minimum and a user maximum.

** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum.

Table 1. SnPb Eutectic Process – Classification Temperatures (Tc)

3 3

Package Volume mm Volume mm

Thickness <350 ≥350

<2.5 mm 235 °C 220 °C

≥2.5 mm 220 °C 220 °C

Table 2. Pb-free Process – Classification Temperatures (Tc)

3 3 3

Package Volume mm Volume mm Volume mm

Thickness <350 350-2000 >2000

<1.6 mm 260 °C 260 °C 260 °C

1.6 mm – 2.5 mm 260 °C 250 °C 245 °C

≥2.5 mm 250 °C 245 °C 245 °C

Reliability Test Program

Test item Method Description

SOLDERABILITY JESD-22, B102 5 Sec, 245°C

HOLT JESD-22, A108 1000 Hrs, Bias @ 125°C

PCT JESD-22, A102 168 Hrs, 100%RH, 2atm, 121°C

TCT JESD-22, A104 500 Cycles, -65°C~150°C

HBM MIL-STD-883-3015.7 VHBM≧2KV

MM JESD-22, A115 VMM≧200V

Latch-Up JESD 78 10ms, 1tr≧100mA

Copyright ANPEC Electronics Corp. 16 www.anpec.com.tw

Rev. A.4 - Sep., 2009

APL5930

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics Corp. 17 www.anpec.com.tw

Rev. A.4 - Sep., 2009

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Dewatering Pump ChecklistDocument1 pageDewatering Pump ChecklistMD Abdullah100% (1)

- Silergy Corp SY8213FCC - C178246Document9 pagesSilergy Corp SY8213FCC - C178246Thai LamNo ratings yet

- IEEE Recommended Settings For Generator ProtectionDocument7 pagesIEEE Recommended Settings For Generator ProtectionBruno SamosNo ratings yet

- Manual GE 752 UPDocument84 pagesManual GE 752 UPDaniel RincónNo ratings yet

- Easy 800 ManualDocument351 pagesEasy 800 ManualDaniel Enea100% (1)

- Apl5930 PDFDocument20 pagesApl5930 PDFanthony loboNo ratings yet

- Apl 5920Document18 pagesApl 5920Las Dus100% (1)

- Anels00779 1Document20 pagesAnels00779 1Momo MendozaNo ratings yet

- Apl5916 AnpecDocument20 pagesApl5916 Anpecايهاب فوزيNo ratings yet

- Features General Description: 3A, Ultra Low Dropout (0.23V Typical) Linear RegulatorDocument24 pagesFeatures General Description: 3A, Ultra Low Dropout (0.23V Typical) Linear RegulatorOdyem SadamNo ratings yet

- Apw 7165 CDocument20 pagesApw 7165 Cterry panNo ratings yet

- Features General Description: High Input Voltage, Low Quiescent Current, 150ma LDO RegulatorDocument20 pagesFeatures General Description: High Input Voltage, Low Quiescent Current, 150ma LDO RegulatorRoxanaDelcampoNo ratings yet

- Anpec Elec APW7301KAI TRG - C115136Document20 pagesAnpec Elec APW7301KAI TRG - C115136Bawantha Prasad MihirangaNo ratings yet

- Features General Description: Low Dropout 600ma Linear Regulator For DC Fan ControlDocument13 pagesFeatures General Description: Low Dropout 600ma Linear Regulator For DC Fan ControlTimuçin İLTERNo ratings yet

- DATASHEET Up1542rDocument17 pagesDATASHEET Up1542rjoao doisssNo ratings yet

- 1581 DatasheetDocument17 pages1581 Datasheettekchan2002No ratings yet

- Features General Description: 3A, 12V, Synchronous-Rectified Buck ConverterDocument21 pagesFeatures General Description: 3A, 12V, Synchronous-Rectified Buck ConverterVeronica GonzalezNo ratings yet

- APL5606/A: Features General DescriptionDocument16 pagesAPL5606/A: Features General Descriptionlordycarlos8588No ratings yet

- Features General Description: Source and Sink, 2A, Fast Transient Response Linear RegulatorDocument18 pagesFeatures General Description: Source and Sink, 2A, Fast Transient Response Linear RegulatorEnriqueNo ratings yet

- APW8720BDocument22 pagesAPW8720BAlbertNo ratings yet

- AOZ3015AIDocument14 pagesAOZ3015AIIcomNo ratings yet

- 3A Ultra Low Dropout Linear Regulator With Enable: GND FB V EN PG V V 8 7 6 5 1 2 3 4 VDocument14 pages3A Ultra Low Dropout Linear Regulator With Enable: GND FB V EN PG V V 8 7 6 5 1 2 3 4 VNuriyanto 3No ratings yet

- APL5932A/B/C/D: Features General DescriptionDocument21 pagesAPL5932A/B/C/D: Features General DescriptionAku KudupiknikNo ratings yet

- 3A, 40V, 200Khz Step-Down Converter: Description FeaturesDocument10 pages3A, 40V, 200Khz Step-Down Converter: Description FeaturesWhatsapp de jyroNo ratings yet

- APW7068Document23 pagesAPW7068Fərid SirafilzadəNo ratings yet

- Datasheet APW7142Document22 pagesDatasheet APW7142José Aparecido BarbosaNo ratings yet

- APW7142Document22 pagesAPW7142gsmaster4141No ratings yet

- Up 11541Document14 pagesUp 11541techgamebr85No ratings yet

- 5V/12V Synchronous-Rectified Buck Controller With Reference InputDocument19 pages5V/12V Synchronous-Rectified Buck Controller With Reference InputIgor LabutinNo ratings yet

- uPI Confidential: 3A Ultra Low Dropout Linear RegulatorDocument13 pagesuPI Confidential: 3A Ultra Low Dropout Linear RegulatorLEONNo ratings yet

- Features General Description: Synchronous Buck PWM ControllerDocument19 pagesFeatures General Description: Synchronous Buck PWM Controllergarcia5No ratings yet

- Ap3106 Ap3106mtr-G1Document12 pagesAp3106 Ap3106mtr-G1J Fernando GarciaNo ratings yet

- APW7073A: Features General DescriptionDocument20 pagesAPW7073A: Features General DescriptionyanjunNo ratings yet

- Up7706 DatasheetDocument12 pagesUp7706 DatasheetFernando DupuyNo ratings yet

- APL5607A - 600ma Linear Regulator For DC Fan Speed ControlDocument16 pagesAPL5607A - 600ma Linear Regulator For DC Fan Speed ControlLangllyNo ratings yet

- uPI Semiconductor Up1735 Synchronous-Rectified Buck Converter DatasheetDocument13 pagesuPI Semiconductor Up1735 Synchronous-Rectified Buck Converter DatasheetSultan SinghNo ratings yet

- APW8715A: Features General DescriptionDocument26 pagesAPW8715A: Features General Descriptionmben osbiNo ratings yet

- AOZ3013PI: General Description FeaturesDocument14 pagesAOZ3013PI: General Description FeaturesJohn KleinNo ratings yet

- Features General Description: High Input Voltage 6A PWM Converter With Adj. Soft StartDocument20 pagesFeatures General Description: High Input Voltage 6A PWM Converter With Adj. Soft StartLeonardo DiegoNo ratings yet

- Datasheet AP7175Document14 pagesDatasheet AP7175Edwin SorianoNo ratings yet

- Features General Description: Stereo 2.7-W Audio Power Amplifier (With DC - Volume Control)Document25 pagesFeatures General Description: Stereo 2.7-W Audio Power Amplifier (With DC - Volume Control)iuri63No ratings yet

- Step-Down Converter: 3A, 30V, 340Khz SynchronousDocument11 pagesStep-Down Converter: 3A, 30V, 340Khz SynchronouschaghoufNo ratings yet

- NCP1002Document14 pagesNCP1002Ailton De JesusNo ratings yet

- 28V, 6.5A, Low Iq, Synchronous Buck Converter With 2-Bit VIDDocument24 pages28V, 6.5A, Low Iq, Synchronous Buck Converter With 2-Bit VIDElla Wijaya ChandraNo ratings yet

- Apl 5336Document20 pagesApl 5336FlavianoSilvaNo ratings yet

- AP8836Document15 pagesAP8836SamerNo ratings yet

- Ap64350 2Document26 pagesAp64350 2Nishanth MNo ratings yet

- APW7159ADocument23 pagesAPW7159AVoicu AdrianNo ratings yet

- Datasheet PDFDocument21 pagesDatasheet PDFHamad FathiNo ratings yet

- AP22815 / AP22615: Single Channel Power Distribution Switch With Output OvpDocument17 pagesAP22815 / AP22615: Single Channel Power Distribution Switch With Output Ovpbong bernalbongNo ratings yet

- AP22815 / AP22615: Single Channel Power Distribution Switch With Output OvpDocument17 pagesAP22815 / AP22615: Single Channel Power Distribution Switch With Output Ovpbong bernalbongNo ratings yet

- A4950 DatasheetDocument9 pagesA4950 DatasheetIndra KurniawanNo ratings yet

- Eup3484dir1 C47740Document11 pagesEup3484dir1 C47740AndreskoiraNo ratings yet

- AT2003Document7 pagesAT2003williamsarenas75No ratings yet

- Anpec APL 1085Document11 pagesAnpec APL 1085mark7f2001No ratings yet

- TPS40170 4.5 V To 60 V, Wide-Input Synchronous PWM Buck ControllerDocument49 pagesTPS40170 4.5 V To 60 V, Wide-Input Synchronous PWM Buck ControllermachineintelNo ratings yet

- SY8201Document10 pagesSY8201relmasNo ratings yet

- EUP3482 EutechMicroelectronics PDFDocument11 pagesEUP3482 EutechMicroelectronics PDFMarco MachadoNo ratings yet

- 3A, 40V, 200Khz Step-Down Converter: Description FeaturesDocument10 pages3A, 40V, 200Khz Step-Down Converter: Description FeaturesEduardo Jose Fernandez PedrozaNo ratings yet

- BM1513 EtcDocument7 pagesBM1513 EtcDimas BarretoNo ratings yet

- Kbu8j - 600v, 8a Bridg RectifierDocument2 pagesKbu8j - 600v, 8a Bridg RectifierLangllyNo ratings yet

- IRFS630A - N CH, Power MOSFET 200V, 6.5A 25ºC, 4.1A 100ºC, 4v Vgs (TH)Document8 pagesIRFS630A - N CH, Power MOSFET 200V, 6.5A 25ºC, 4.1A 100ºC, 4v Vgs (TH)LangllyNo ratings yet

- GBK25M - 1000V, 25a Bridge RectifierDocument2 pagesGBK25M - 1000V, 25a Bridge RectifierLangllyNo ratings yet

- KB6206 - Compatible Positive Voltage RegulatorsDocument6 pagesKB6206 - Compatible Positive Voltage RegulatorsLangllyNo ratings yet

- GC08 CC2500 Wireless ModuleDocument6 pagesGC08 CC2500 Wireless ModuleLangllyNo ratings yet

- FDS7296N3 - 30V N-Channel PowerTrench MOSFETDocument7 pagesFDS7296N3 - 30V N-Channel PowerTrench MOSFETLangllyNo ratings yet

- D1933 - Silicon NPN Power TransistorsDocument3 pagesD1933 - Silicon NPN Power TransistorsLangllyNo ratings yet

- KSD1589 - NPN Silicon Darlington Transistor, Low Frequency Power AmplifierDocument5 pagesKSD1589 - NPN Silicon Darlington Transistor, Low Frequency Power AmplifierLangllyNo ratings yet

- CZT5551 - NPN Medium Power Transistor, 160v 600ma, 6v BaseDocument2 pagesCZT5551 - NPN Medium Power Transistor, 160v 600ma, 6v BaseLangllyNo ratings yet

- C1567 - NPN Transistor, 100v, 500ma, 5v Base, For Low-Frequency High Power DriverDocument4 pagesC1567 - NPN Transistor, 100v, 500ma, 5v Base, For Low-Frequency High Power DriverLangllyNo ratings yet

- FDS7066ASN3 30V N - Channel PowerTrench® SyncFET™Document8 pagesFDS7066ASN3 30V N - Channel PowerTrench® SyncFET™LangllyNo ratings yet

- C3691 - NEC, NPN Transistor, 100v, 7v Base, 5A, High Switching SpeedDocument3 pagesC3691 - NEC, NPN Transistor, 100v, 7v Base, 5A, High Switching SpeedLangllyNo ratings yet

- CYT8 (TX8) - ASK RF Transmitter ModuleDocument4 pagesCYT8 (TX8) - ASK RF Transmitter ModuleLangllyNo ratings yet

- D1589 - NPN Silicon Power Transistors, 100v 5A 7v Base, Low Speed SwitchingDocument3 pagesD1589 - NPN Silicon Power Transistors, 100v 5A 7v Base, Low Speed SwitchingLangllyNo ratings yet

- Dtc144wka - NPN Pre-Biased Small Signal Surface Mount TransistorDocument5 pagesDtc144wka - NPN Pre-Biased Small Signal Surface Mount TransistorLangllyNo ratings yet

- AON6710 - N-Channel Enhancement Mode Field Effect TransistorDocument5 pagesAON6710 - N-Channel Enhancement Mode Field Effect TransistorLangllyNo ratings yet

- CC2500 - Wireless Chip of GC08 Wireles ModuleDocument76 pagesCC2500 - Wireless Chip of GC08 Wireles ModuleLangllyNo ratings yet

- BD16A01 - 100 Base-T Single Port Through Hole MagneticsDocument1 pageBD16A01 - 100 Base-T Single Port Through Hole MagneticsLangllyNo ratings yet

- c5856 - 700v, DC 14a, Pulse 28a, Transistor Silicon NPN Triple Diffused Mesa TypeDocument6 pagesc5856 - 700v, DC 14a, Pulse 28a, Transistor Silicon NPN Triple Diffused Mesa TypeLangllyNo ratings yet

- B1568 - PNP Power Transistor ( 80V, 4A) (D1933 NPN)Document4 pagesB1568 - PNP Power Transistor ( 80V, 4A) (D1933 NPN)LangllyNo ratings yet

- AME431B-2.5V Adjustable PrecisionShunt RegulatorDocument23 pagesAME431B-2.5V Adjustable PrecisionShunt RegulatorLangllyNo ratings yet

- 40N03GP - N Channel Pwer MOSFET, 30v 40A, Vgs (TH) 3v, Vgs 20vDocument4 pages40N03GP - N Channel Pwer MOSFET, 30v 40A, Vgs (TH) 3v, Vgs 20vLangllyNo ratings yet

- APL5607A - 600ma Linear Regulator For DC Fan Speed ControlDocument16 pagesAPL5607A - 600ma Linear Regulator For DC Fan Speed ControlLangllyNo ratings yet

- B1009 - 32v 2A PNP Power TransistorsDocument3 pagesB1009 - 32v 2A PNP Power TransistorsLangllyNo ratings yet

- 2N60 - N Channel Power Mosfet 600V 2A, Vgs (TH) 2 4vDocument6 pages2N60 - N Channel Power Mosfet 600V 2A, Vgs (TH) 2 4vLangllyNo ratings yet

- QM3016P - N-CH 30V, 110A Fast Switching MOSFETsDocument4 pagesQM3016P - N-CH 30V, 110A Fast Switching MOSFETsLangllyNo ratings yet

- 1N5230B - 1N Zener Diode Table CodeDocument3 pages1N5230B - 1N Zener Diode Table CodeLangllyNo ratings yet

- PHE13007 - NPN Transistor, High Frequenci, 700v, 8A, 9v BaseDocument8 pagesPHE13007 - NPN Transistor, High Frequenci, 700v, 8A, 9v BaseLangllyNo ratings yet

- NDS9959 - Dual N-Channel Enhanement Mode Fild Efect TransistorDocument10 pagesNDS9959 - Dual N-Channel Enhanement Mode Fild Efect TransistorLangllyNo ratings yet

- Adl2 5Document2 pagesAdl2 5Daxesh ManiyarNo ratings yet

- Nigatu Gurmessa ThesisDocument47 pagesNigatu Gurmessa ThesisNigatu GurmessaNo ratings yet

- Awy14lsaz Aoy14lsawc PDFDocument24 pagesAwy14lsaz Aoy14lsawc PDFferber107eNo ratings yet

- Tpa3122d2 PDFDocument21 pagesTpa3122d2 PDFalbertNo ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Lap ReportDocument8 pagesLap ReportMohammed AlharbiNo ratings yet

- Experiment 5Document25 pagesExperiment 5abhi100% (3)

- F08941C-D02-01 - 0 Design Criteriafor Electrical Engineering of Power PlantDocument28 pagesF08941C-D02-01 - 0 Design Criteriafor Electrical Engineering of Power PlantAnindya ananda putriNo ratings yet

- GP2D12/GP2D15: General Purpose Type Distance Measuring SensorsDocument4 pagesGP2D12/GP2D15: General Purpose Type Distance Measuring SensorsKrlos D KnightNo ratings yet

- First Field Experience of On-Line Partial Discharge Monitoring of MV CableDocument4 pagesFirst Field Experience of On-Line Partial Discharge Monitoring of MV CableAmany HamdyNo ratings yet

- Sxg-Series Brochure-A - 1Document2 pagesSxg-Series Brochure-A - 1Phạm Nhật MinhNo ratings yet

- STB18NM80, STF18NM80, STP18NM80, STW18NM80Document21 pagesSTB18NM80, STF18NM80, STP18NM80, STW18NM80Gilvana Cristina FerreiraNo ratings yet

- Jameco Manmual NTC P92Document1 pageJameco Manmual NTC P92pecarriNo ratings yet

- Brochure Altanova 1Document11 pagesBrochure Altanova 1IAMATMANo ratings yet

- Comet Datasheet H3431Document2 pagesComet Datasheet H3431Karthikeyan NagarajanNo ratings yet

- Neo - 2016-32-64-128 - Manual de Referinta2015227134502767189 PDFDocument130 pagesNeo - 2016-32-64-128 - Manual de Referinta2015227134502767189 PDFglevikeNo ratings yet

- Intelli SW 250 TransferenciaDocument32 pagesIntelli SW 250 Transferenciajuanka209No ratings yet

- Research On PMN-PT Single CrystalDocument4 pagesResearch On PMN-PT Single CrystalING. DURANTENo ratings yet

- DatasheetDocument8 pagesDatasheetMaizatul Hanisah RoziNo ratings yet

- ROBICON Perfect Harmony: Application ConsiderationsDocument112 pagesROBICON Perfect Harmony: Application ConsiderationsRaul quispe quispeNo ratings yet

- Formula Sheet-Final ExamDocument3 pagesFormula Sheet-Final ExamKevin IbanezNo ratings yet

- MUltivibratorsDocument15 pagesMUltivibratorsTēmptēd Êģŏişitiç ßērrýx ÐxNo ratings yet

- Development of Microcontroller Based SolDocument76 pagesDevelopment of Microcontroller Based SolAlfie LariosaNo ratings yet

- Audio Amplifier 18W.Document3 pagesAudio Amplifier 18W.Yugo PrasetyoNo ratings yet

- Steady-State Analysis of An Interleaved Boost Converter With Coupled InductorsDocument9 pagesSteady-State Analysis of An Interleaved Boost Converter With Coupled InductorsNanda AzizahNo ratings yet

- 29M03 PDFDocument24 pages29M03 PDFAdam Liviu0% (1)