Professional Documents

Culture Documents

Oil Type Pre Commissioning Report

Uploaded by

Atluri Naga Sai Saran Kumar100%(1)100% found this document useful (1 vote)

69 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

69 views3 pagesOil Type Pre Commissioning Report

Uploaded by

Atluri Naga Sai Saran KumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

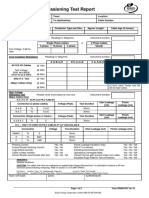

Checklist for Pre-commissioning of FORM NO: TF-QAD-402

Oil Type Transformer

Sr. No :- Customer :- Rating:- Rev -02 02.04.14

Vector Group: Type of Cooling:

Sr. No. Particulars Type of check Instrument used Observation

A. Transformer Receipt Checks

1. Date of receipt of transformer at site NA NA

2. Was Transformer received at site with oil filled Yes/No NA

3. If oil filled, level of oil in tank Measure Tape scale

Whether any short / wrong shipment or transit

4. If Yes, please attach a separate sheet with Yes/No NA

details

5. Foundation of skid base Visual NA

6. Flood level of area NA NA

7. Is height of Plinth above flood level of area Measure Tape Scale

8. Check plinth level for all corners Visual Spirit Level

9. Check proper tightening of gaskets Visual NA

Check Proper mounting of all accessories on

10. Visual NA

transformer as per drawings

I.R. values of condenser bushings measured

with 2.5 / 5 kV Insulation Tester (Megger)

11. Electrical Megger

between line terminal and capacitance tap in

ohm

12. RADIATOR

12.1 No. of radiators mounted Visual NA

12.2 Tie Bar /Bracing Strap Provided Visual NA

12.3 Checking of oil leakage Visual NA

13. LV CABLE BOX

13.1 Mounting of cable box as per drawing Visual NA

13.2 Oil leakage check on bushings Visual NA

13.3 Tightness check Visual NA

13.4 LV cable box connections as per drawings Visual NA

Check the direction of Buchholz Relay / Oil

14. Surge Relay towards conservator and check Visual NA

test / service position

Check the diaphragm of explosion vent

15. Visual NA

installed properly

Check the MOG before oil filling in the

16. Electric Electrical contacts

conservator / air cell commissioning

Colour of silica gel in Dehydrating Breather

17. Visual NA

shoul be Blue

18. BDV of oil before filling it in transformer Electric BDV Tester

Ensure proper tightening of all the accessories

i.e. inspection window, pipeline, radiators,

19. Visual NA

conservator, OLTC parts & other spare of

transformer before oil filling

20. Date of oil filling in main tank & OLTC Visual NA

Is filling oil in conservator as per the

21. Yes/ No NA

instruction in O & M manual

Check all Butterfly Valve caps for proper

22. Visual NA

tightening & leakage.

23. Value of resistance of the s/s earthing grid Electrical Earth Tester

All the cable clamps and connectors tightened

24. Visual NA

properly

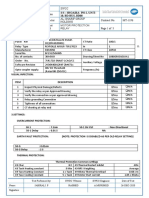

Sr. No. Particulars Type of check Instrument used Observation

B. Pre-Commissioning checks

1. OIL LEVEL & AIR RELEASE CHECKS

1.1 Main tank conservator Visual NA

1.2 OLTC conservator Visual NA

1.3 WTI / OTI thermometer pocket on Transformer Visual NA

Oil level in breather cup should not be more

1.4 Visual NA

than 5mm above the air slot

1.5 HV bushing air release plugs Physical NA

1.6 LV bushing air vent screws Physical NA

From all air release plugs on main tank, OLTC

head, inspection Covers, headers, PRV neck,

1.7 Physical NA

Buchholz Relay, Oil Surge Relay, and

Radiators.

2. OLTC / DM & RTCC

2.1 Make Visual NA

2.2 Type Visual NA

2.3 Serial No. Visual NA

Check OLTC Surge Relay in direction () of

2.4 Visual NA

conservator

2.5 Check relay Trip Wire Connected Visual NA

2.6 Set relay in Service condition Perform NA

Check all the inter connections of RTCC, DM &

2.7 Perform Multimeter

MB for continuity

Check interconnection of TPI & OLTC in RTCC

2.8 and RTCC wiring cable is not placed along with Perform Multimeter

high tension cables

2.9 Check for Annunciations on RTCC panel Visual NA

3. MAGNETIC OIL GAUGE

3.1 Make Visual NA

3.2 Serial No. Visual NA

3.3 Oil Level Visual NA

3.4 Test - Alarm : High / Low Perform NA

4. BUCHHOLZ RELAY

4.1 Make Visual NA

4.2 Type Visual NA

4.3 Serial No. Visual NA

Relay Trip & Alarm wire connections as per

4.4 Visual NA

drawings

4.5 Check Test / Service Perform NA

4.5 Set relay in Service condition Perform NA

5. PRESSURE RELIEF VALVE

5.1 Make Visual NA

5.2 Serial No. Visual NA

5.3 Mechanical Flag Operation Perform NA

5.4 Electrical Operation Test (Breaker Trip) Perform NA

5.5 Check Test / Reset Perform NA

6. PRV OF OLTC

6.1 Make Visual NA

6.2 Serial No. Visual NA

6.3 Mechanical Flag Operation Perform NA

Sr. No. Particulars Type of check Instrument used Observation

6.4 Electrical Operation Test (Breaker Trip) Perform NA

6.5 Check Test / Reset Perform NA

7. TEMPERATURE INDICATORS

7.1 WINDING TEMPERATURE INDICATOR

7.1.1 Make Visual NA

7.1.2 Serial No. Visual NA

7.1.3 Alarm Setting & Test Perform NA

7.1.4 Breaker Trip Setting & Test Perform NA

7.2 OIL TEMPERATURE INDICATOR

7.2.1 Make Visual NA

7.2.2 Serial No. Visual NA

7.2.3 Alarm Setting & Test Perform NA

7.2.4 Breaker Trip Setting & Test Perform NA

Check interconnection of MOG, CT & Fans in

8. Perform Multimeter

Marshalling Box

C. Checks to be performed

1. CHECK ALARM & TRIPS CIRCUIT CONNECTIONS OF THE FOLLOWING EQUIPMENT.

1.1 Buchholz Relay Alarm Perform Multimeter

1.2 Buchholz Relay Trip Perform Multimeter

1.3 Winding Temp. Indicator Alarm Perform Multimeter

1.4 Winding Temp. Indicator Trip Perform Multimeter

1.5 Oil Temp. Indicator Alarm Perform Multimeter

1.6 Oil Temp. Indicator Trip Perform Multimeter

1.7 Pressure Relief Valve Trip Perform Multimeter

1.8 Magnetic Oil Level Gauge Alarm Perform Multimeter

1.9 Oil Surge Relay Trip Perform Multimeter

Are tripping of HV & LV circuit breakers

2. checked through all the above protection Yes/No NA

devices

3. CHECKS ON OLTC OPERATIONS IN THE FOLLOWING MODES

3.1 Local manual Perform Handle

Local electrical (Min.10 operation from

3.2 maximum tap position to minimum position Perform NA

and minimum to maximum)

3.3 Remote electrical Perform NA

Auto by AVRR (AVR to be connected on the

3.4 Perform NA

secondary PT)

3.5 Mechanical / Electrical interlock Perform NA

Is TPI on RTCC matching with Tap Position

4. inside OLTC D.M.Box and diverter chamber Visual NA

OLTC ( If Provided )

Raychem RPG Representative

Date:

You might also like

- GS-F34 - Generator Set System (Off Load Test)Document2 pagesGS-F34 - Generator Set System (Off Load Test)Mohamed Firdaus Bin ZakariaNo ratings yet

- LCC Bus Coupler - Functional TestDocument7 pagesLCC Bus Coupler - Functional TestAmr ElkadyNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser MahamidNo ratings yet

- HT Breaker ChecklistDocument1 pageHT Breaker ChecklistElectrial DeptNo ratings yet

- HV Switch GearDocument46 pagesHV Switch GearSayuti SidikNo ratings yet

- AC Motor Inspection/Testing & Commissioning Check ListDocument9 pagesAC Motor Inspection/Testing & Commissioning Check ListAdnan AhmadNo ratings yet

- Erection Procedure For Control Battery - LatestDocument12 pagesErection Procedure For Control Battery - LatestAnmohieyNo ratings yet

- VFD Commissioning FormatDocument2 pagesVFD Commissioning FormatJun Lumayno100% (2)

- Insulation Resistance Test (Primary To Earth 500 Volt, Secondary To Earth 500 Volt, Primary To Secondary 500 Volt)Document2 pagesInsulation Resistance Test (Primary To Earth 500 Volt, Secondary To Earth 500 Volt, Primary To Secondary 500 Volt)MD JAHANGEER0% (1)

- Bet VT Test ReportDocument2 pagesBet VT Test ReportSathi Reddy ThondapuNo ratings yet

- Adr141c PDFDocument11 pagesAdr141c PDFNamrata Shetti100% (1)

- Electrical Loto ProcedureDocument2 pagesElectrical Loto ProcedureRitesh Dev MaityNo ratings yet

- Chloride FP 40r Ds en GL 0616 Rev6Document2 pagesChloride FP 40r Ds en GL 0616 Rev6Tanveer Ahmed100% (1)

- Method Statement For Cable Laying, Glanding and TerminationDocument12 pagesMethod Statement For Cable Laying, Glanding and TerminationSajid Raza100% (1)

- ZLAC8015Document9 pagesZLAC8015THANAWATNo ratings yet

- OCP - 05 Trans FormerDocument16 pagesOCP - 05 Trans FormerNaveedNo ratings yet

- SP0407C01 HV Cable Commissioning Test ReportDocument2 pagesSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNo ratings yet

- Commissioning Report For RectifierDocument29 pagesCommissioning Report For RectifierAnujGarg100% (1)

- Pre Commissioning Oil Type TransformerDocument4 pagesPre Commissioning Oil Type TransformerKanagaraj Ravi0% (1)

- HT Panel ChecklistDocument1 pageHT Panel ChecklistMahfuza MansuraNo ratings yet

- CCM 2.5MVATX QASCO CommissioningTest Report.Document13 pagesCCM 2.5MVATX QASCO CommissioningTest Report.Ginger TurnerNo ratings yet

- Function Checks Is Not Applicable For This Panel: Switchgear Functional TestDocument3 pagesFunction Checks Is Not Applicable For This Panel: Switchgear Functional Testeswaran005No ratings yet

- 01 - 4 Test Report For Power Transformer 1Document7 pages01 - 4 Test Report For Power Transformer 1PUSHPARAJ MAURYANo ratings yet

- TR001 Control Cable CFA901-Continuity TestDocument4 pagesTR001 Control Cable CFA901-Continuity TestCharlie MendozaNo ratings yet

- L86-051 Test ReportDocument6 pagesL86-051 Test ReportAMIT BISWASNo ratings yet

- Method of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorDocument9 pagesMethod of Statement For Current Transformer: Owner/Client Owner'S Engineer ContractorPandrayar MaruthuNo ratings yet

- Dry Type Transformer Test Report: Page 1 of 2Document2 pagesDry Type Transformer Test Report: Page 1 of 2erwin5sambas5aryanaNo ratings yet

- Appendix-2 (POWER PANEL Test Report)Document2 pagesAppendix-2 (POWER PANEL Test Report)hafed baccoucheNo ratings yet

- Prok DVs - ACCL - CatalougeDocument3 pagesProk DVs - ACCL - CatalougekapilNo ratings yet

- Etara Test Report R1Document15 pagesEtara Test Report R1Kholis JaimonNo ratings yet

- 007 LV & Control Cable Pre-CommissioningDocument6 pages007 LV & Control Cable Pre-CommissioningMohamed KasemNo ratings yet

- Erection Procedure For 415 V LCC, LDBS, LPS, SPDocument40 pagesErection Procedure For 415 V LCC, LDBS, LPS, SPAnmohieyNo ratings yet

- Earth Switch Contact Resistance TestDocument1 pageEarth Switch Contact Resistance TestGajendran SriramNo ratings yet

- Test Report of Sarfaraz Textile MillsDocument5 pagesTest Report of Sarfaraz Textile MillsSyed WaheedNo ratings yet

- Ocef Relay TestingDocument6 pagesOcef Relay TestingPandrayar MaruthuNo ratings yet

- WI-NG-6460-002-085 Work Instruction For Relay & Control Panel Scheme and Function Test Rev00Document15 pagesWI-NG-6460-002-085 Work Instruction For Relay & Control Panel Scheme and Function Test Rev00Mohamed NasrNo ratings yet

- Sf6 Gas Circuit Breaker Test Report: CharacteristicsDocument1 pageSf6 Gas Circuit Breaker Test Report: CharacteristicsIlir R. DalipiNo ratings yet

- CB Test ReportDocument2 pagesCB Test ReportLingga SuhadhaNo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- Procedure of Maintenance of 415V BUSDocument2 pagesProcedure of Maintenance of 415V BUSVatsavai Appala Narasimha Raju100% (1)

- HT Motor PrecommissioningDocument6 pagesHT Motor PrecommissioningJarrett Mathews100% (1)

- Test Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureDocument5 pagesTest Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureAnonymous dH3DIEtzNo ratings yet

- Site Testing Pre Commissioning PDFDocument2 pagesSite Testing Pre Commissioning PDFadi nugrohoNo ratings yet

- Old LT Panel 400 AmpDocument5 pagesOld LT Panel 400 AmpAbhinav TewariNo ratings yet

- 4 Ammeter Test ReportDocument1 page4 Ammeter Test ReportJayaprakash M PNo ratings yet

- Genset - Electrical ChecklistDocument1 pageGenset - Electrical ChecklistKarl Jared MasanqueNo ratings yet

- Maint - Check List - Oil Filled TransforsDocument2 pagesMaint - Check List - Oil Filled TransforsramNo ratings yet

- Precommissioning Procedures of Testing Commissioning PDFDocument96 pagesPrecommissioning Procedures of Testing Commissioning PDFRatheesh Kumar100% (1)

- HT Switch Gear & Breakers ManualDocument73 pagesHT Switch Gear & Breakers Manualwilliam lobo100% (9)

- 132 Testing - Power TransformerDocument3 pages132 Testing - Power TransformerSantosh GairheNo ratings yet

- Grouding System Field Test ProcedureDocument9 pagesGrouding System Field Test Proceduremilton1987No ratings yet

- LT Panel PDI SOPDocument4 pagesLT Panel PDI SOPShrikanth Sola100% (2)

- Circuit Breaker TestingDocument6 pagesCircuit Breaker TestingPandrayar MaruthuNo ratings yet

- Transformer WorkshopDocument44 pagesTransformer Workshopniyaz100% (3)

- Method Statement For Testing & Commissioning of Central Battery SystemDocument6 pagesMethod Statement For Testing & Commissioning of Central Battery SystemBabuNo ratings yet

- Pre Commissioningchecklist 211027021204 - 2Document150 pagesPre Commissioningchecklist 211027021204 - 2nassarkiNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- Pre-Commissioning Test of Transformer at SiteDocument2 pagesPre-Commissioning Test of Transformer at SiteMohammad Husain86% (7)

- Wap-7 PLW / Izn / NerDocument49 pagesWap-7 PLW / Izn / NerShrish ShankhdharNo ratings yet

- DCDB - Function TestDocument5 pagesDCDB - Function TestAmr ElkadyNo ratings yet

- CRN6829424563Document3 pagesCRN6829424563Atluri Naga Sai Saran KumarNo ratings yet

- CRN6828775028Document3 pagesCRN6828775028Atluri Naga Sai Saran KumarNo ratings yet

- CRN6819834915Document3 pagesCRN6819834915Atluri Naga Sai Saran KumarNo ratings yet

- CRN6828048139Document3 pagesCRN6828048139Atluri Naga Sai Saran KumarNo ratings yet

- CRN6819148666Document3 pagesCRN6819148666Atluri Naga Sai Saran KumarNo ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel WorksheetAtluri Naga Sai Saran KumarNo ratings yet

- Esa BurnerDocument34 pagesEsa BurnerMelesse SisayNo ratings yet

- MiCOM C264iAVR - NRJED115661EN - 190218Document4 pagesMiCOM C264iAVR - NRJED115661EN - 190218nguyễn văn thịnhNo ratings yet

- SE Electrical Engg. 2019 PattDocument47 pagesSE Electrical Engg. 2019 PattPrathameshNo ratings yet

- LL PSKDocument19 pagesLL PSKSuresh RamanujaluNo ratings yet

- Load Break SwitchDocument16 pagesLoad Break SwitchAditya Pratama VTNo ratings yet

- Multi-Winding TransformerDocument10 pagesMulti-Winding TransformerTariq SharabatiNo ratings yet

- ZS-648R & ZS-658R: Ceiling Mount SpeakersDocument2 pagesZS-648R & ZS-658R: Ceiling Mount SpeakersAtgProyek AvilaNo ratings yet

- Improvement of The Test Method For Insulating OilsDocument4 pagesImprovement of The Test Method For Insulating OilsJuan Manuel Ríos FrancoNo ratings yet

- Transformer - GA PDFDocument12 pagesTransformer - GA PDFepe civilNo ratings yet

- Transformer Bushings, Type GOB: Technical GuideDocument24 pagesTransformer Bushings, Type GOB: Technical GuideGerardo VillanuevaNo ratings yet

- RectifierDocument37 pagesRectifierMahendra Mandalapu MNo ratings yet

- IMEE-6 Maintenance PDFDocument8 pagesIMEE-6 Maintenance PDFHirakNo ratings yet

- Transmission and Distribution LossesDocument4 pagesTransmission and Distribution LossesJaiveerNo ratings yet

- Report For 25MVA-110-33KV PR - TR.TNR SSDocument7 pagesReport For 25MVA-110-33KV PR - TR.TNR SSPrasanth KumarNo ratings yet

- TEFELEN Technical Product CatalogueDocument16 pagesTEFELEN Technical Product CatalogueDiego MantillaNo ratings yet

- Protection & Coordination by - Dr. Hamid JaffariDocument83 pagesProtection & Coordination by - Dr. Hamid JaffariMuhammad HusnainNo ratings yet

- Rashid Ali: 2. IT Park Block-3 at Shastri Park, New Delhi. (DMRC Client) (Commercial Building With G+7 Floor)Document4 pagesRashid Ali: 2. IT Park Block-3 at Shastri Park, New Delhi. (DMRC Client) (Commercial Building With G+7 Floor)vikrant sharmaNo ratings yet

- Cable Schedule 2019 R2Document79 pagesCable Schedule 2019 R2ASHUTOSH RANJAN SINGHNo ratings yet

- UNIT-II - Electrical MachinesDocument16 pagesUNIT-II - Electrical MachinesArun VijayNo ratings yet

- KPTCL SR - 28 - 5 - 2019 PDFDocument224 pagesKPTCL SR - 28 - 5 - 2019 PDFpvaman100% (1)

- 700 Series Amplifiers A-706, A-712, A-724: Operating InstructionsDocument12 pages700 Series Amplifiers A-706, A-712, A-724: Operating InstructionsAngelo Rodríguez CondorNo ratings yet

- Iec Standards PDFDocument2 pagesIec Standards PDFNestrami100% (1)

- Projects: Dfid Hyderabad Integrated SCADA Project APCPDCL in The Reform ModeDocument7 pagesProjects: Dfid Hyderabad Integrated SCADA Project APCPDCL in The Reform ModeToroomNo ratings yet

- NCT Instruction ManualDocument1 pageNCT Instruction Manualvideo irfanNo ratings yet

- K-Sec 030Document12 pagesK-Sec 030Austin WadeNo ratings yet

- Vol IIIDocument30 pagesVol IIIDhabalia AshvinNo ratings yet

- Introduction To Electrical System and Equipment CommissioningDocument26 pagesIntroduction To Electrical System and Equipment Commissioningbookbum100% (3)

- Apscl 2011Document22 pagesApscl 2011VoiNo ratings yet

- 1901106-Basic Electrical and Electronics Engineering PDFDocument15 pages1901106-Basic Electrical and Electronics Engineering PDFSuryaraj C.KNo ratings yet