Professional Documents

Culture Documents

STS Concave Adjustment Tube and Sensor: John Deere Harvester Works H178221 Issue D1 (10APR01)

Uploaded by

Alejandro DhoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STS Concave Adjustment Tube and Sensor: John Deere Harvester Works H178221 Issue D1 (10APR01)

Uploaded by

Alejandro DhoCopyright:

Available Formats

STS Concave

Adjustment Tube and

Sensor

INSTALLATION

INSTRUCTIONS

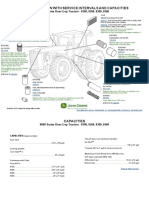

9650 STS (Serial No. 690000-690779), 9750

STS (Serial No. 690000-690779)

John Deere Harvester Works

H178221 Issue D1 (10APR01)

ENGLISH

COPYRIGHT 2001

DEERE & COMPANY

Moline, Illinois

All rights reserved

A John Deere ILLUSTRUCTION Manual

H178221 Issue D1-19-10APR01

Installation Instructions

Remove Concave Adjusting Tube And

Sensor

1. Remove shields and separator inspection covers (A).

A—Covers

–UN–08MAY00

H63811

OUO6035,0000002 –19–18SEP00–1/5

2. Disconnect harness connector (A) from concave

position sensor assembly (B).

3. Remove and retain cap screw (C) and nut (D).

4. Remove and discard position sensor assembly.

–UN–20SEP00

5. Remove and discard shaft (E) from concave adjusting

tube.

H64881

A—Harness Connector

B—Sensor Assembly

C—Cap Screw

D—Nut

E—Shaft

OUO6035,0000002 –19–18SEP00–2/5

6. Support concave with block.

7. Remove cotter pin (A) and pin (B) from both concave

eyebolts.

A—Cotter Pin

B—Pin –UN–23FEB99

H54153

Continued on next page OUO6035,0000002 –19–18SEP00–3/5

H178221 Issue D1 (10APR01) 1 Installation Instructions

041001

PN=3

Installation Instructions

8. Remove spring pin (A) and sector gear.

A—Spring Pin

–UN–23FEB99

H54151

OUO6035,0000002 –19–18SEP00–4/5

9. Slide tube (A) toward front of machine to remove end

from adjusting motor support; then slide toward rear to

remove from machine.

10. Remove and retain eyebolts (B) and hardware.

–UN–25SEP00

A—Tube

B—Eyebolt

H64885

OUO6035,0000002 –19–18SEP00–5/5

Install Concave Adjusting Tube and Sensor

1. Install two eyebolts (B) onto new adjusting tube (A)

and retain with previously removed hardware.

2. Slide adjusting tube forward into front bulkhead; then

–UN–25SEP00

slide rearward into adjusting motor support.

A—Tube

B—Eyebolt

H64885

OUO6035,0000004 –19–20SEP00–1/4

3. Install sector gear and retain with spring pin (A).

A—Spring Pin

–UN–23FEB99

H54151

Continued on next page OUO6035,0000004 –19–20SEP00–2/4

H178221 Issue D1 (10APR01) 2 Installation Instructions

041001

PN=4

Installation Instructions

4. Retain eyebolts to concave with pin (B) and cotter pin

(A).

A—Cotter Pin

B—Pin

–UN–23FEB99

H54153

OUO6035,0000004 –19–20SEP00–3/4

5. Install new sensor assembly (A) onto front end of

adjusting tube and retain to bulkhead with cap screw

(B) and nut (C).

A—Sensor Assembly

B—Cap Screw

–UN–20SEP00

C—Nut

H64887

OUO6035,0000004 –19–20SEP00–4/4

Replace Sensor Connector

1. Cut connector (A) off of harness (B) just behind

connector body.

A—Connector

–UN–28SEP00

B—Harness

H64904

OUO6035,0000005 –19–20SEP00–1/5

2. Strip 6 mm (1/4 in.) of insulation from each wire (A).

A—Wire

–UN–16OCT00

H64932

Continued on next page OUO6035,0000005 –19–20SEP00–2/5

H178221 Issue D1 (10APR01) 3 Installation Instructions

041001

PN=5

Installation Instructions

3. Slide wires (A-C) through seal (E) and connector body

(D) according to chart and illustration.

Pin Number Circuit Code

A 801

B 802

–UN–16OCT00

C 800

H64933

A—Wire

B—Wire

C—Wire

D—Connector Body

E—Seal

–UN–23APR99

H54481

OUO6035,0000005 –19–20SEP00–3/5

4. Install and crimp terminals (A) onto wires (B).

5. Pull terminal wires into connector body (C) until seated.

A—Terminal

B—Wire

–UN–16OCT00

C—Connector Body

H64934

OUO6035,0000005 –19–20SEP00–4/5

6. Plug wiring harness connector (A) into concave

position sensor (B).

A—Connector

B—Sensor

–UN–21SEP00

H64895

OUO6035,0000005 –19–20SEP00–5/5

H178221 Issue D1 (10APR01) 4 Installation Instructions

041001

PN=6

Installation Instructions

Adjust Concave Level

1. Back off stop bolts (A) and (B).

A—Stop Bolt

B—Stop Bolt

–UN–15MAY00

H63912

–UN–15MAY00

H63911

OUO6035,000000A –19–28SEP00–1/9

2. Loosen jam nuts (A) and back off nuts (B) five turns

each.

3. Close concave fully.

A—Jam Nut (2 used)

B—Nut (2 used)

–UN–16FEB99

H51982

Continued on next page OUO6035,000000A –19–28SEP00–2/9

H178221 Issue D1 (10APR01) 5 Installation Instructions

041001

PN=7

Installation Instructions

4. Check to see that sector gear (A) is advanced

completely on worm gear (B).

A—Sector Gear

B—Worm Gear

–UN–21SEP00

H64883

OUO6035,000000A –19–28SEP00–3/9

5. Remove upper cap screws (A) and lower cap screws

(B) to remove one grate section.

A—Cap Screws

B—Cap Screws

–UN–25SEP00

H64911

OUO6035,000000A –19–28SEP00–4/9

6. Shift STS Rotor drive gear case shift handle (A) to

neutral position (B).

A—Shift Handle

B—Neutral Position

–UN–12APR00

H63544

Continued on next page OUO6035,000000A –19–28SEP00–5/9

H178221 Issue D1 (10APR01) 6 Installation Instructions

041001

PN=8

Installation Instructions

7. Back off lower nut on front and rear eyebolts.

NOTE: If nut on eyebolt is tightened five turns without

contacting high element, top nut of rear eyebolt

must be tightened five turns before proceeding

with adjustment. If element contacts middle or

–UN–16FEB99

rear concave section before front, loosen top nut

of rear eyebolt and tighten bottom nut to provide

clearance.

H51983

8. Rotate STS Rotor while tightening top nut (A) on front

eyebolt until high element “ticks” front concave section.

Back nut off one turn.

A—Top Nut—Front Eyebolt

9. Rotate STS Rotor while tightening top nut of rear B—Top Nut—Rear Eyebolt

eyebolt (B) until high element “ticks” rear concave

section. Back nut off one turn.

NOTE: Top nut on eyebolt can be adjusted one full turn

for each millimeter out of level.

10. Tighten bottom nuts on front and rear eyebolts.

Tighten all jam nuts.

OUO6035,000000A –19–28SEP00–6/9

NOTE: There should be approximately 2 mm (3/32 in.) of

clearance between the tight concave bar and the

high threshing bar when the concaves are

properly set and leveled.

11. Set stop bolts (A) by lowering until they contact plate

–UN–16MAY00

(B) of concave hanger. Tighten nuts on stop bolts.

A—Stop Bolt (2 used)

B—Plate

H63920

–UN–16MAY00

H63921

Continued on next page OUO6035,000000A –19–28SEP00–7/9

H178221 Issue D1 (10APR01) 7 Installation Instructions

041001

PN=9

Installation Instructions

12. Install grate section and retain with cap screws (A

and B).

A—Cap Screws

B—Cap Screws

–UN–25SEP00

H64911

OUO6035,000000A –19–28SEP00–8/9

13. Install separator inspection covers (A) and shields.

14. Place rotor drive gear case in desired speed range.

A—Covers

–UN–08MAY00

H63811

OUO6035,000000A –19–28SEP00–9/9

Reprogram Cornerpost

1. Turn key switch to RUN position.

2. Press the diagnostic button (Open Manual). DIA will

display on the triple display monitor.

–UN–24JUN99

H54583

Continued on next page OUO6035,0000008 –19–28SEP00–1/6

H178221 Issue D1 (10APR01) 8 Installation Instructions

041001

PN=10

Installation Instructions

3. Press the up or down arrow button until C03 is

displayed.

–UN–15DEC99

H62034

OUO6035,0000008 –19–28SEP00–2/6

4. Press the enter button.

–UN–15DEC99

H62033

Continued on next page OUO6035,0000008 –19–28SEP00–3/6

H178221 Issue D1 (10APR01) 9 Installation Instructions

041001

PN=11

Installation Instructions

5. Press up arrow until first line of bottom display reads

233.

6. Check display for software part number 174761.

–UN–29SEP00

H64943

OUO6035,0000008 –19–28SEP00–4/6

7. Press up arrow until first line of bottom display reads

234.

IMPORTANT: Concave position sensor installed in

previous steps requires software

version 2.2 in cornerpost. If Diagnostic

Address 234 indicates software version

2.2, no reprogramming of cornerpost is

necessary.

If Diagnostic Address 234 indicates

software version 2.1, reprogram

cornerpost according to following

procedure.

8. Check display for software version number 2.1.

–UN–29SEP00

H64944

Continued on next page OUO6035,0000008 –19–28SEP00–5/6

H178221 Issue D1 (10APR01) 10 Installation Instructions

041001

PN=12

Installation Instructions

–19–09APR01

H65036A

A—Software Number B—Reprogram Cornerpost

Dialogue Box

IMPORTANT: Be sure the December 2000 release 10. Enter number for software H174761 version 2.2

of the SERVICE ADVISOR DVD (A) into Reprogram Cornerpost dialogue box (B).

data disk set is installed on

SERVICE ADVISOR unit before 11. Select OK to continue or Cancel to abort

proceeding with following steps. programming.

9. Using SERVICE ADVISOR unit, reprogram 12. Continue programming according to instruction

cornerpost (see instruction SERVICE ADVISOR SERVICE ADVISOR Programming.

Programming).

SERVICE ADVISOR is a trademark of Deere & Company OUO6035,0000008 –19–28SEP00–6/6

H178221 Issue D1 (10APR01) 11 Installation Instructions

041001

PN=13

Installation Instructions

Concave Sensor Zero Calibration

The concave position sensor is calibrated using the

concave calibration procedure. The concave calibration

procedure must be performed before initial use or when

the concave sensor is replaced.

NOTE: If the sensor has been replaced, be certain

concave and separator are clear of crop material.

1. Turn the key switch to run position or start the

combine.

2. Press the diagnostics switch. DIA will display on the

triple display tachometer.

–UN–24JUN99

H54583

OUO6035,000000B –19–28SEP00–1/6

3. Press the calibration switch. CAL and conc will appear

on the tachometer.

–UN–24JUN99

H54595

Continued on next page OUO6035,000000B –19–28SEP00–2/6

H178221 Issue D1 (10APR01) 12 Installation Instructions

041001

PN=14

Installation Instructions

4. Press the enter switch, conc will appear on the upper

line of the display. CLOS will appear on the second

line of the display.

–UN–16JUN99

H54602

OUO6035,000000B –19–28SEP00–3/6

5. Press and hold the (-) symbol on the concave

clearance switch until the concave is completely closed

(clicking sound will be heard). As the (-) symbol is

being pressed, the numbers in middle line of the

display will decrease until the concave is completely

–UN–06MAR00

closed.

H62893

–UN–16JUN99

H54603

Continued on next page OUO6035,000000B –19–28SEP00–4/6

H178221 Issue D1 (10APR01) 13 Installation Instructions

041001

PN=15

Installation Instructions

6. Press the calibration switch. Zero (0) will be displayed

on the tachometer for two seconds then EOC will be

displayed.

–UN–16JUN99

H54604

Continued on next page OUO6035,000000B –19–28SEP00–5/6

H178221 Issue D1 (10APR01) 14 Installation Instructions

041001

PN=16

Installation Instructions

7. Press the ENTER switch to store the calibration value

or press the back arrow switch to abort calibration (and

not save values).

8. Press back arrow switch to return to normal operation.

–UN–27MAY99

H54605

OUO6035,000000B –19–28SEP00–6/6

H178221 Issue D1 (10APR01) 15 Installation Instructions

041001

PN=17

Installation Instructions

H178221 Issue D1 (10APR01) 16 Installation Instructions

041001

PN=18

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TM110219Document5 pagesTM110219Alejandro DhoNo ratings yet

- Ansys Known Issues and LimitationsDocument44 pagesAnsys Known Issues and Limitationstalabiz0% (1)

- Ezbass: This Manual Applies To Version 1.0.0 of EzbassDocument84 pagesEzbass: This Manual Applies To Version 1.0.0 of EzbassClaire OctorsNo ratings yet

- Warehousing Manual in Infor LNDocument349 pagesWarehousing Manual in Infor LNSiaNo ratings yet

- Customer Relationship ManagementDocument56 pagesCustomer Relationship Managementsnehachandan91No ratings yet

- PHP Lab Programs V SemDocument19 pagesPHP Lab Programs V SemhafsaadnNo ratings yet

- Parts ListDocument6 pagesParts ListAlejandro DhoNo ratings yet

- Parts ListDocument5 pagesParts ListAlejandro DhoNo ratings yet

- Parts ListDocument4 pagesParts ListAlejandro DhoNo ratings yet

- AMS Products Universal Applications IntroductionDocument5 pagesAMS Products Universal Applications IntroductionAlejandro DhoNo ratings yet

- Stripper Header Brochure 2023Document15 pagesStripper Header Brochure 2023Alejandro DhoNo ratings yet

- Reduced Pressure Wiper Arm: John Deere Harvester Works H176776 (31JUL00)Document6 pagesReduced Pressure Wiper Arm: John Deere Harvester Works H176776 (31JUL00)Alejandro DhoNo ratings yet

- 9650 STS 9750 STS Series Combines Filter Overview With Service Intervals and CapacitiesDocument2 pages9650 STS 9750 STS Series Combines Filter Overview With Service Intervals and CapacitiesAlejandro DhoNo ratings yet

- Service Advisor Programming: John Deere Harvester Works H174217 (08MAY00)Document10 pagesService Advisor Programming: John Deere Harvester Works H174217 (08MAY00)Alejandro DhoNo ratings yet

- Replace Circuit Board: John Deere Harvester Works H201594 (23JAN01)Document6 pagesReplace Circuit Board: John Deere Harvester Works H201594 (23JAN01)Alejandro DhoNo ratings yet

- Preview Only: 7 (&+1,&$/ 0$18$/ 6Shhg 367 2shudwlrqv 7Hvw DQG 'LDJQRVWLFV:LWK 3&8 &rqwuroohuDocument5 pagesPreview Only: 7 (&+1,&$/ 0$18$/ 6Shhg 367 2shudwlrqv 7Hvw DQG 'LDJQRVWLFV:LWK 3&8 &rqwuroohuAlejandro DhoNo ratings yet

- Filter Overview With Service Intervals and Capacities: 8000 Series Row-Crop Tractors - 8100, 8200, 8300, 8400Document2 pagesFilter Overview With Service Intervals and Capacities: 8000 Series Row-Crop Tractors - 8100, 8200, 8300, 8400Alejandro DhoNo ratings yet

- Level 200 Deck David J. Rosenthal CEO, Atidan October 15, 2015 Microsoft Technology Center, NYCDocument33 pagesLevel 200 Deck David J. Rosenthal CEO, Atidan October 15, 2015 Microsoft Technology Center, NYCLigang JinNo ratings yet

- Audit ManagerDocument125 pagesAudit Managerritu rajNo ratings yet

- DevOps The IBM Approach - White PaperDocument8 pagesDevOps The IBM Approach - White PaperUsama RashwanNo ratings yet

- Documentation: Egotype Sirius Series Project PortfolioDocument3 pagesDocumentation: Egotype Sirius Series Project PortfolioHandoko MuhammadNo ratings yet

- Amber Naag Maria Series 2 (Firon Ki Tabahi)Document73 pagesAmber Naag Maria Series 2 (Firon Ki Tabahi)WWW.BIGBRAND.PK67% (3)

- Archexteriors Vol 34Document10 pagesArchexteriors Vol 34Thanh NguyenNo ratings yet

- LogDocument8 pagesLogSama Nur AiniNo ratings yet

- DFTDocument23 pagesDFTRobby Setiabudi TjangNo ratings yet

- ETS User Manual: EDPF-NT PlusDocument27 pagesETS User Manual: EDPF-NT Plustayyab zafarNo ratings yet

- ODI 12c - Mapping - Table To Flat FileDocument31 pagesODI 12c - Mapping - Table To Flat Filerambabuetlinfo149No ratings yet

- Get and Put Stream PointersDocument4 pagesGet and Put Stream PointersgurusodhiiNo ratings yet

- Company Profile Koperasi Indonusa Mitra Usaha Pages 1 - 10 - Flip PDF Download - FlipHTML5Document11 pagesCompany Profile Koperasi Indonusa Mitra Usaha Pages 1 - 10 - Flip PDF Download - FlipHTML5Tanto Fransnigo SophianNo ratings yet

- Unit 1Document144 pagesUnit 1AkilaNo ratings yet

- Prasad ResumeDocument3 pagesPrasad ResumePrasad R. BhambaleNo ratings yet

- Jacob Andrew Kelleys ResumeDocument1 pageJacob Andrew Kelleys Resumeredditor1276No ratings yet

- Operating System Overview and System Structures 2marks: Unit - IDocument6 pagesOperating System Overview and System Structures 2marks: Unit - I21AUCS012 - RAJALAKSHMI J B.SC. COMPUTER SCIENCENo ratings yet

- Genesis 30uvDocument42 pagesGenesis 30uvCARLOSNo ratings yet

- Assert SelectDocument2 pagesAssert SelectkhuonglhNo ratings yet

- Lecture 16,17, 18 Mutual Exclusion AlgorithmsDocument90 pagesLecture 16,17, 18 Mutual Exclusion AlgorithmsBlack KnightNo ratings yet

- 1CDDocument111 pages1CDrapeislNo ratings yet

- Quick Start Guide Rosemount 3095ma MV en 74230Document32 pagesQuick Start Guide Rosemount 3095ma MV en 74230aminebenyagoub0009No ratings yet

- Hospital Management System OriganalDocument82 pagesHospital Management System OriganalChandan SrivastavaNo ratings yet

- Cs6413-Os Lab Manual-Backup 2 NewDocument113 pagesCs6413-Os Lab Manual-Backup 2 NewjegadeepaNo ratings yet

- LmsDocument19 pagesLmsKalyan ReddyNo ratings yet