Professional Documents

Culture Documents

Hre Saq-26

Uploaded by

Mariane Joyce GaluraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hre Saq-26

Uploaded by

Mariane Joyce GaluraCopyright:

Available Formats

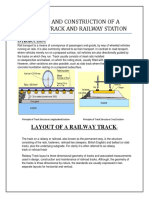

SAQ 26:

Identify and describe innovations in railway track repair and maintenance shown in the videos.

New innovations in railway track repair and maintenance:

Railway track laying – Track Laying Machines prepare the rails, sleepers, and fastenings for use.

Railway construction is also known as track laying and ballasting. It is the process of laying

railway sleepers and tracks on the track bed. The new rails required for this laying technique are

carried on suitable wagons and transported ahead of the laying unit using a rail conveying unit.

Railway rail grinding – Rail grinding is the most efficient way to keep steel rail in good condition.

The railway track working principle is well known, and railway actually provides a continuous

and elastic foundation for train operation. Steel rail, as the main component of the railway track

system, directly attaches wheels that bear a significant amount of load from the train. A portion

of the load is absorbed by the steel rail, while the remainder causes rail wears such as surface

fatigue, crack, scratch, deformation, and so on. Rail wear can reduce steel rail service life,

increase maintenance work, increase maintenance costs, and negatively impact railway

operation. As a result, rail grinding has become an essential process for the railway track.

Railway ballast cleaning – Ballast cleaning involves removing the worn ballast, screening it, and

replacing the "dirty" worn ballast with new ballast. The benefit of ballast cleaning is that it can

be performed by an on-track machine without removing the rail and sleepers, making it less

expensive than a total excavation.

Railway track deep screening – The Indian railways use deep screening to renovate or replace

damaged sleepers with new sleepers. This is known as deep screening of railway tracks. For this

work, Indian railways employ a variety of methods.

You might also like

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Assignment 2Document10 pagesAssignment 2thineshNo ratings yet

- Coimbatore Railway: Kanishka.TDocument6 pagesCoimbatore Railway: Kanishka.TAravindhanNo ratings yet

- Intro Railway DesignDocument5 pagesIntro Railway DesignNarte, Angelo C.No ratings yet

- Technical ReportDocument10 pagesTechnical ReportMaalmalan KeekiyyaaNo ratings yet

- Track SystemDocument31 pagesTrack SystemPrince RamosNo ratings yet

- Railway Track: - Railway Track Components - Functions of Track Components - Track ForcesDocument23 pagesRailway Track: - Railway Track Components - Functions of Track Components - Track ForcesAbdullah Abbas SabbarNo ratings yet

- Fatigue Analysis of Rail Joint Using Finite Element Method: Sunil Patel, Veerendra Kumar, Raji NareliyaDocument5 pagesFatigue Analysis of Rail Joint Using Finite Element Method: Sunil Patel, Veerendra Kumar, Raji NareliyaAnonymous tKjZMWnoNo ratings yet

- Slab TrackDocument4 pagesSlab TrackVemmy KurniawanNo ratings yet

- Railway EngineeringDocument30 pagesRailway EngineeringMohit Patel0% (1)

- Rail Unlocked PDFDocument115 pagesRail Unlocked PDFsh tanimNo ratings yet

- Lec3 Railway TrackDocument23 pagesLec3 Railway Trackم.علي سعدي الجنابيNo ratings yet

- Layout and Construction of A Railway Track and Railway StationDocument18 pagesLayout and Construction of A Railway Track and Railway StationUmer KhanNo ratings yet

- 1.1 GeneralDocument22 pages1.1 GeneralshahzilezNo ratings yet

- V 6Qxadqe4Ix8: What Is Rail Joint and Explain Its Parts? AnswerDocument6 pagesV 6Qxadqe4Ix8: What Is Rail Joint and Explain Its Parts? AnswerSaeed AyeenNo ratings yet

- Permanent Way: Components and Their FunctionsDocument32 pagesPermanent Way: Components and Their FunctionsRahul RahulNo ratings yet

- Transportation Engineering: Types of Rails Spacing and Stifness of RailsDocument30 pagesTransportation Engineering: Types of Rails Spacing and Stifness of Railsyousaf khanNo ratings yet

- Transportation and Planning Assignment#2: Department of Civil EngineeringDocument11 pagesTransportation and Planning Assignment#2: Department of Civil EngineeringALi niaziNo ratings yet

- Considerations For Installing Special Trackwork On Vertical GradientsDocument10 pagesConsiderations For Installing Special Trackwork On Vertical GradientsAhmed Khalil100% (1)

- P WayDocument6 pagesP WayDHARMENDRANo ratings yet

- Summer Training Report PP TDocument53 pagesSummer Training Report PP TPrashant JainNo ratings yet

- Time Table Spring 2017 18Document6 pagesTime Table Spring 2017 18Hunny VermaNo ratings yet

- Assessment of The Track Geometry Quality From The Aspect of Safe and Reliable Operation of The Railway TrackDocument7 pagesAssessment of The Track Geometry Quality From The Aspect of Safe and Reliable Operation of The Railway TrackBIRUK FEKADUNo ratings yet

- Summary On Evolution, Test and Durability of Trough Girders in Rail TransitDocument4 pagesSummary On Evolution, Test and Durability of Trough Girders in Rail TransitAnuj ChaudharyNo ratings yet

- Transportation Engineering Lecture-1Document20 pagesTransportation Engineering Lecture-1Avishya JaswalNo ratings yet

- Chapter-3 TrackDocument77 pagesChapter-3 TrackGoytom yigezuNo ratings yet

- Transport 702Document64 pagesTransport 702ASHJAEE MANSIB CHOWDHURYNo ratings yet

- RDSO Training Report WagonDocument55 pagesRDSO Training Report WagonGaurav Pathak0% (1)

- My Railway EnggDocument77 pagesMy Railway EnggAndrea Deleon100% (8)

- Inspection and Maintenance of Steel Girders-2Document10 pagesInspection and Maintenance of Steel Girders-2vpmohammedNo ratings yet

- Week 4: Introduction To Railway Engineering: CourseDocument37 pagesWeek 4: Introduction To Railway Engineering: CourseKika CalafatNo ratings yet

- Chenab Bidge ReportDocument19 pagesChenab Bidge ReportRahul PatelNo ratings yet

- Illustrated Design of Reinforced Concrete BuildingsDocument24 pagesIllustrated Design of Reinforced Concrete BuildingsAjitesh YelisettyNo ratings yet

- Railway PDFDocument42 pagesRailway PDFSarankumar ThathuruNo ratings yet

- RailroadDocument3 pagesRailroadHBr26No ratings yet

- Layout and Construction of A Railway Track and Railway StationDocument12 pagesLayout and Construction of A Railway Track and Railway StationAli Hassan LatkiNo ratings yet

- Anup KR Guru - AFCON - Construction Method For - (10!11!2017)Document11 pagesAnup KR Guru - AFCON - Construction Method For - (10!11!2017)WalterGentileNo ratings yet

- Railway EngineeringDocument15 pagesRailway EngineeringSheikh UbaidNo ratings yet

- Bridge ManualDocument346 pagesBridge ManualKapil Grover100% (2)

- Updated Indian Railway Bridge ManualDocument355 pagesUpdated Indian Railway Bridge Manualradhakrishnang75% (4)

- Inspection and Diagnostics of Railway Reinforced Concrete Bridge in Andijan-Khanabad PeregonDocument7 pagesInspection and Diagnostics of Railway Reinforced Concrete Bridge in Andijan-Khanabad PeregonGARBA Ahmad AliNo ratings yet

- Track StructureDocument6 pagesTrack StructureJoseEdgarNolascoLucesNo ratings yet

- Cylindrical BearingsDocument8 pagesCylindrical BearingsmabuhamdNo ratings yet

- Ballast and Non-Ballast in RailwayDocument3 pagesBallast and Non-Ballast in RailwayJhon David Butar-butarNo ratings yet

- DPR CorrectedDocument23 pagesDPR CorrectedVikhyat GoudNo ratings yet

- CNM NotesDocument14 pagesCNM NotesMicaiah HendricksNo ratings yet

- Internship ReportDocument17 pagesInternship ReportSrijan PramanikNo ratings yet

- 20 Component of RailDocument4 pages20 Component of RailArrina Saidatur RohmahNo ratings yet

- RBE-CE4 Railway Track and Track MaintenanceDocument5 pagesRBE-CE4 Railway Track and Track MaintenanceGajanan SurwaseNo ratings yet

- TD rw11 PDFDocument5 pagesTD rw11 PDFMin Chan MoonNo ratings yet

- Id 012Document10 pagesId 012nenad lazicNo ratings yet

- VDF School of Polytechnic, Latur.: Name Roll No Class Topic Subject Subject TeacherDocument20 pagesVDF School of Polytechnic, Latur.: Name Roll No Class Topic Subject Subject TeacherRavindra BhutadaNo ratings yet

- Introduction To Ballastless Track - EditedDocument26 pagesIntroduction To Ballastless Track - Editedabhijitroy333100% (1)

- Lecture Te 2Document34 pagesLecture Te 2SRUTHI PNo ratings yet

- Chapter 3 TrackDocument78 pagesChapter 3 TrackBabangida Gida NessreNo ratings yet

- 1 s2.0 S18777058150138243 MainDocument7 pages1 s2.0 S18777058150138243 MainMahdi FaqirzadaNo ratings yet

- Innovations PDFDocument12 pagesInnovations PDFAli Tavakoli NiaNo ratings yet

- Worksheet 6Document3 pagesWorksheet 6John Angelo CompetenteNo ratings yet

- Rails, Creep, Failures, Joints and Welding: Prepared by Khushbu Bhatt Parul University VadodaraDocument163 pagesRails, Creep, Failures, Joints and Welding: Prepared by Khushbu Bhatt Parul University VadodaraKaushal MehtaNo ratings yet

- Part 2Document20 pagesPart 2Vaibhav GuptaNo ratings yet

- Hre Saq-24Document1 pageHre Saq-24Mariane Joyce GaluraNo ratings yet

- CELEC RevisedDocument85 pagesCELEC RevisedMariane Joyce GaluraNo ratings yet

- LEADERDocument14 pagesLEADERMariane Joyce GaluraNo ratings yet

- CLAIMSDocument4 pagesCLAIMSMariane Joyce GaluraNo ratings yet

- The Digital SelfDocument35 pagesThe Digital SelfMariane Joyce GaluraNo ratings yet