Professional Documents

Culture Documents

1 FEED Engineering Man Hour 산정 기준

1 FEED Engineering Man Hour 산정 기준

Uploaded by

Mohsen Hamdi0 ratings0% found this document useful (0 votes)

127 views8 pagesThe document outlines the engineering tasks and estimated man-hours for a FEED (Front End Engineering Design) project. It lists 13 engineering disciplines with codes T3 to T13. Under each discipline are the engineering tasks like diagrams, studies, schedules and lists, specifications and drawings. Descriptions are provided for each task explaining the engineering work.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the engineering tasks and estimated man-hours for a FEED (Front End Engineering Design) project. It lists 13 engineering disciplines with codes T3 to T13. Under each discipline are the engineering tasks like diagrams, studies, schedules and lists, specifications and drawings. Descriptions are provided for each task explaining the engineering work.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

127 views8 pages1 FEED Engineering Man Hour 산정 기준

1 FEED Engineering Man Hour 산정 기준

Uploaded by

Mohsen HamdiThe document outlines the engineering tasks and estimated man-hours for a FEED (Front End Engineering Design) project. It lists 13 engineering disciplines with codes T3 to T13. Under each discipline are the engineering tasks like diagrams, studies, schedules and lists, specifications and drawings. Descriptions are provided for each task explaining the engineering work.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 8

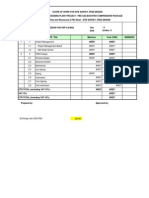

FEED Engineering Man-hour 산정 기준

설계 구분 Code 공종 Task (대분류)

FEED Engineering T3 General Familiarization

FEED Engineering T3 General Familiarization

FEED Engineering T3 General Familiarization

FEED Engineering T3 General Departmental reporting

FEED Engineering T3 General Departmental reporting

FEED Engineering T3 General Departmental reporting

FEED Engineering T3 General Authorities

FEED Engineering T3 General Meetings & Site visits

FEED Engineering T3 General Meetings & Site visits

FEED Engineering T3 General Tender preparation

FEED Engineering T3 General Personnel

FEED Engineering T3 General Estimate development

FEED Engineering T4 Process Diagrams

FEED Engineering T4 Process Diagrams

FEED Engineering T4 Process Diagrams

FEED Engineering T4 Process Studies

FEED Engineering T4 Process Studies

FEED Engineering T4 Process Studies

FEED Engineering T4 Process Equipment

FEED Engineering T4 Process Schedules& Lists

FEED Engineering T4 Process Schedules& Lists

FEED Engineering T4 Process Schedules& Lists

FEED Engineering T5 Mechanical Schedules & Lists

FEED Engineering T5 Mechanical Schedules & Lists

FEED Engineering T5 Mechanical Equipment

FEED Engineering T6 Piping Diagrams

FEED Engineering T6 Piping Diagrams

FEED Engineering T6 Piping Diagrams

FEED Engineering T6 Piping Studies

FEED Engineering T6 Piping Studies

FEED Engineering T6 Piping Studies

FEED Engineering T6 Piping Schedules & Lists

FEED Engineering T6 Piping Schedules & Lists

FEED Engineering T6 Piping Schedules & Lists

FEED Engineering T6 Piping Specification(Design)

FEED Engineering T6 Piping Specification(Design)

FEED Engineering T6 Piping Specification(Design)

FEED Engineering T6 Piping Specification(Design)

FEED Engineering T7 Civil Specification(Design)

FEED Engineering T7 Civil Detail Drawings

FEED Engineering T7 Civil Detail Drawings

FEED Engineering T7 Civil Detail Drawings

FEED Engineering T7 Civil Detail Drawings

FEED Engineering T7 Civil Lay-outs & Plot plans

FEED Engineering T7 Civil Lay-outs & Plot plans

FEED Engineering T7 Civil Lay-outs & Plot plans

FEED Engineering T8 Instrumentation Configuration & Specification

FEED Engineering T8 Instrumentation Configuration & Specification

FEED Engineering T8 Instrumentation Configuration & Specification

FEED Engineering T8 Instrumentation Design Specification

FEED Engineering T8 Instrumentation Design Specification

FEED Engineering T8 Instrumentation Studies

FEED Engineering T8 Instrumentation Studies

FEED Engineering T8 Instrumentation Studies

FEED Engineering T8 Instrumentation Studies

FEED Engineering T8 Instrumentation Schedules & Lists

FEED Engineering T8 Instrumentation Schedules & Lists

FEED Engineering T8 Instrumentation Schedules & Lists

FEED Engineering T8 Instrumentation Diagrams

FEED Engineering T8 Instrumentation Diagrams

FEED Engineering T8 Instrumentation Diagrams

FEED Engineering T8 Instrumentation Diagrams

FEED Engineering T8 Instrumentation Lay-outs & Plot plans

FEED Engineering T8 Instrumentation Lay-outs & Plot plans

FEED Engineering T8 Instrumentation Lay-outs & Plot plans

FEED Engineering T9 Electrical Diagrams

FEED Engineering T9 Electrical Diagrams

FEED Engineering T9 Electrical Diagrams

FEED Engineering T9 Electrical Diagrams

FEED Engineering T9 Electrical Diagrams

FEED Engineering T9 Electrical Lay-outs & Plot plans

FEED Engineering T9 Electrical Lay-outs & Plot plans

FEED Engineering T9 Electrical Lay-outs & Plot plans

FEED Engineering T9 Electrical Lay-outs & Plot plans

FEED Engineering T10 Procurement Studies

FEED Engineering T10 Procurement Studies

FEED Engineering T10 Procurement Studies

FEED Engineering T11 Construction Man Contract Documents

FEED Engineering T11 Construction Man Contract Documents

FEED Engineering T11 Construction Man Contract Documents

FEED Engineering T12 Project ManagemeReports

FEED Engineering T12 Project ManagemeReports

FEED Engineering T12 Project ManagemeQuality

FEED Engineering T12 Project ManagemeDepartmental Control

FEED Engineering T12 Project ManagemeDepartmental Control

FEED Engineering T12 Project ManagemeDepartmental Control

FEED Engineering T12 Project ManagemeSpecial FEL Tasks

FEED Engineering T13 Safety Inventory

FEED Engineering T13 Safety Ergonomics

FEED Engineering T13 Safety Ergonomics

FEED Engineering T13 Safety Health, Safety,Environment

FEED Engineering T13 Safety Health, Safety,Environment

FEED Engineering T13 Safety Health, Safety,Environment

FEED Engineering T13 Safety Health, Safety,Environment

Descriptions

Data retrieval, meetings, read scope, etc.

Data retrieval, meetings, read scope, etc.

Data retrieval, meetings, read scope, etc.

Activity Control Chart (ACC) & Document Control Chart (DCC), Progress (meetings), etc.

Activity Control Chart (ACC) & Document Control Chart (DCC), Progress (meetings), etc.

Activity Control Chart (ACC) & Document Control Chart (DCC), Progress (meetings), etc.

Labor inspection, local laws, inspection procedures, etc.

Meetings with clients and vendors, surveys, site visits, etc.

Meetings with clients and vendors, surveys, site visits, etc.

Write tender at the end of basic engineering (depends on contract strategy)

Extra personnel needed on the project

Input to 30% (basic), 20% (basic) and 10% (detail) estimate

PFD, P&ID, UFD, ESD. Need to be set-up

PFD, P&ID, UFD, ESD. Need to be set-up

PFD, P&ID, UFD, ESD. Need to be set-up

All equipment items require studies.General studies refers to studies like HAZOP, Design conditions

All equipment items require studies.General studies refers to studies like HAZOP, Design conditions

All equipment items require studies.General studies refers to studies like HAZOP, Design conditions

Preparation of datasheets per piece of equipment type.

Equipment list, Data sheets instrumentation, Line destination table.

Equipment list, Data sheets instrumentation, Line destination table.

Equipment list, Data sheets instrumentation, Line destination table.

Equipment & Insulation input to process, spare parts list, etc.

Equipment & Insulation input to process, spare parts list, etc.

Preparation of datasheets as well as the requisition and handling of this document

It represents the time needed to add to each diagram defined by process.

It represents the time needed to add to each diagram defined by process.

It represents the time needed to add to each diagram defined by process.

Stress analysis, Site & plot plans, Piping route study

Stress analysis, Site & plot plans, Piping route study

Stress analysis, Site & plot plans, Piping route study

Tie-in list, Drawing list, Line list etc.

Tie-in list, Drawing list, Line list etc.

Tie-in list, Drawing list, Line list etc.

For piping, erection, ewlding, painting, etc.

For piping, erection, ewlding, painting, etc.

For piping, erection, ewlding, painting, etc.

For piping, erection, ewlding, painting, etc.

Update owner specifications to the current project, e.g. for paving, painting, etc.

Drawings for structural, construction, architectural and underground

Drawings for structural, construction, architectural and underground

Drawings for structural, construction, architectural and underground

Drawings for structural, construction, architectural and underground

Paving drawings (new or update), Soil Report, Draingae lay-outs, etc.

Paving drawings (new or update), Soil Report, Draingae lay-outs, etc.

Paving drawings (new or update), Soil Report, Draingae lay-outs, etc.

Software specifications, I/O configurations, control system, etc.

Software specifications, I/O configurations, control system, etc.

Software specifications, I/O configurations, control system, etc.

E.g. Fire & gas detection spec, plant automation spec

E.g. Fire & gas detection spec, plant automation spec

Per piece of equipment a study needs to be made. Also studies for analyzers, temperature, level, etc.

Per piece of equipment a study needs to be made. Also studies for analyzers, temperature, level, etc.

Per piece of equipment a study needs to be made. Also studies for analyzers, temperature, level, etc.

Per piece of equipment a study needs to be made. Also studies for analyzers, temperature, level, etc.

Cable schedules, drawing lists, process data sheets (input to process). One list of each is required

Cable schedules, drawing lists, process data sheets (input to process). One list of each is required

Cable schedules, drawing lists, process data sheets (input to process). One list of each is required

Many diagrams need to be made by instrumentation e.g. input on PFDs, P&IDs, but also cause & effect cha

Many diagrams need to be made by instrumentation e.g. input on PFDs, P&IDs, but also cause & effect cha

Many diagrams need to be made by instrumentation e.g. input on PFDs, P&IDs, but also cause & effect cha

Many diagrams need to be made by instrumentation e.g. input on PFDs, P&IDs, but also cause & effect cha

Input to lay-outs & plot plans need to be made. For control rooms, cables, etc.

one

Inputdrawing needs

to lay-outs to beplans

& plot prepared

need to be made. For control rooms, cables, etc.

one drawing needs to be prepared

Input to lay-outs & plot plans need to be made. For control rooms, cables, etc.

one drawing needs to be prepared

A number of diagrams need to be setup once, and require minimum 1 update e.g. logic, key on line, panel

A number of diagrams need to be setup once, and require minimum 2 update e.g. logic, key on line, panel

A number of diagrams need to be setup once, and require minimum 3 update e.g. logic, key on line, panel

A number of diagrams need to be setup once, and require minimum 4 update e.g. logic, key on line, panel

A number of diagrams need to be setup once, and require minimum 5 update e.g. logic, key on line, panel

Input to lay-outs & plot plans need to be made. For lighting, earthing, power etc. one lay-out drawing nee

Input to lay-outs & plot plans need to be made. For lighting, earthing, power etc. one lay-out drawing nee

Input to lay-outs & plot plans need to be made. For lighting, earthing, power etc. one lay-out drawing nee

Input to lay-outs & plot plans need to be made. For lighting, earthing, power etc. one lay-out drawing nee

The following studies need to be made by procurement: Procurement plan, purchase procedure, subcontr

The following studies need to be made by procurement: Procurement plan, purchase procedure, subcontr

The following studies need to be made by procurement: Procurement plan, purchase procedure, subcontr

E.g. constructibility procedure, subcontracting plan, temporary site facilities plan need to be setup by cons

E.g. constructibility procedure, subcontracting plan, temporary site facilities plan need to be setup by cons

E.g. constructibility procedure, subcontracting plan, temporary site facilities plan need to be setup by cons

For example, Value Improvement Processes report, Project basis of design

For example, Value Improvement Processes report, Project basis of design

Quality audit plan need to be set up which describes when and how quality audits will be held

All kind of procedures are made, e.g. control, progress and planning procedures.

All kind of procedures are made, e.g. control, progress and planning procedures.

All kind of procedures are made, e.g. control, progress and planning procedures.

ITBs for contract need to be made and send out to contractors

An inventory of all necessary safety activities must be made

Reviews are needed to check if design applies to ergonomic standards. Also, a checklist must be set up

Reviews are needed to check if design applies to ergonomic standards. Also, a checklist must be set up

HSE contains e.g. Noise allocation report, Fire & gas review, Fire fighting study, Escape routing review

HSE contains e.g. Noise allocation report, Fire & gas review, Fire fighting study, Escape routing review

HSE contains e.g. Noise allocation report, Fire & gas review, Fire fighting study, Escape routing review

HSE contains e.g. Noise allocation report, Fire & gas review, Fire fighting study, Escape routing review

Man-hour Metrics Man-hour Metrics

Task (중분류) (Min.) (Max.) Unit

Data retrieval 9 24 hrs/department

Meetings 1 1 meeing/month

Read scope 1 week

ACC & DCC

update of ACC & DCC, progress control 1 1 a week

progress planning meeting 1 1 a month

Collect information of what's needed at the projec

Site visit 1 1 day/visit

Meetings

Tender preparation 2 3 weeks/discipline

Define per discipline the extra personnel needed

PFD(5 equipm./PFD) 3 5 days/PFD

P&ID (4 equipm/P&ID) 14 20 hrs/P&ID

UFD (3 equipm./UFD) 18 24 hrs/UFD

1 study/equipment 15 25 hr/study

1 HAZOP study 200 300 hr

Design conditions 60 100 hrs

depending on complexity of equipment 5 20 hr/equipment

Equipment list 2 3 hrs/equipment

Data sheets 2 4 hrs/control or relief valve

Line dest. Table 0.5 1 hrs/line number

Equipment & Insulation input

Spare parts list

depending on type of equipment and complexity 20 100 hrs/equipment type

12 18 hrs/PFD

26 34 hrs/P&ID

20 24 hrs/UFD

Stress analysis 28 36 hrs/stress isometric

Site & plot plans 22 30 hrs/unit or on-site plan

Piping route study 38 46 hrs/main equipment and main pipe rack

Tie-in list: 20 tie-ins/sheet 36 40 hrs/sheet

Drawing list: 24/sheet 14 18 hrs/sheet

Line list 60 70 hrs

Piping 20 24 piping class

Erection 16 20 specification

Welding 8 12 hrs/welding class

Painting 8 12 hrs/specification

8 12 hrs/specification

Structure plan 70 80 hrs/plan

Construction plan: e.g. foundation location plan 40 50 hrs/plan

Architectural: e.g. elevation plan 30 40 hrs/plan

Underground: e.g. drainage details 40 45 hrs/drawing

paving 65 75 hrs/drawing

Soil report 120 140 hrs/report

Drainage lay-outs 18 25 hrs/drawing

Software specification 10 15 hrs/specification

I/O configuration 20 30 hrs/configuration

Control system 35 40 hrs/specification

Fire & detection spec 75 85 hrs

Plant auotmation spec 20 28 hrs

Per piece of equipment 18 25 hrs/study

Analyzers 14 20 hrs/study

Temperature 6 10 hrs/study

Level 6 10 hrs/study

Cable schedules 28 35 hrs/schedule

Drawing list 15 20 hrs/list

Process data sheets 5 10 hrs/data sheet

Input to PFD/P&ID 8 12 hrs/diagram

Cause & effect chart 40 50 hrs/chart

I/O index 60 70 hrs

Cable routing 30 40 hrs/diagram

Input to lay-outs & plot plans 80 100 hrs/lay-out & plot plan

Control room 20 25 hrs

Cable drawing 25 30 hrs

Logic diagram 50 60 hrs

Key one line diagram 60 70 hrs

Panel wiring diagram 70 80 hrs

Interconnection diagram 70 80 hrs

Updates require 20 30 hrs less

Input to lay-outs & plot plans 70 80 hrs/lay-out

Lighting lay-out 10 15 hrs/lay-out

Earthing lay-out 50 60 hrs/lay-out

Power lay-out 10 15 hrs/lay-out

Procurement plan 100 120 hrs

Purchase procedure 100 120 hrs

Subcontract procedure 80 100 hrs

Constructibility procedure 60 75 hrs

Subcontracting plan 60 75 hrs

Temporary site facilities plan 35 50 hrs

VIP report 200 240 hrs

Project basis of design 70 100 hrs

Quality audit plan 30 45 hrs

Project control procedure 40 60 hrs

Progress procedure 40 60 hrs

Planning procedure 30 45 hrs

Setting up and sending out ITBS 200 300 hrs

Inventory of safety activities 18 25 hrs

Reviews at 30%, 60%, 90% of (model) progress 80 120 hrs/review

Checklist 70 90 hrs

Noise allocation report 100 130 hrs

Fire & gas review 30 40 hrs

Fire fighting study 50 60 hrs

Escape routing review 30 40 hrs

Man-hour Metrics

(기타)

Based On no of Document & activities

Find out requirements

Strongly depends on project size

ment and main pipe rack

You might also like

- CTR-InPK Fertilizer Plant Project-FEED DesignDocument7 pagesCTR-InPK Fertilizer Plant Project-FEED DesignNoman Abu-FarhaNo ratings yet

- Sae-j533Flare Tube SpecificationsDocument6 pagesSae-j533Flare Tube SpecificationsSandeep Goud Chatla100% (5)

- Project Status Report, Sample 1Document9 pagesProject Status Report, Sample 1nbnbNo ratings yet

- List of DeliverablesDocument3 pagesList of DeliverablesPrad1979No ratings yet

- Plant Cost EstimationDocument27 pagesPlant Cost EstimationChamsae 99No ratings yet

- ShearDocument37 pagesShearKarthik Mandya0% (1)

- Detail Engineering Cost EstimationDocument2 pagesDetail Engineering Cost EstimationSubhojit Adhikary100% (1)

- How To Estimate The Oil and Gas EPC Projects Duration by Herve BaronDocument2 pagesHow To Estimate The Oil and Gas EPC Projects Duration by Herve BaronAtifNo ratings yet

- Contract Award: Generic Epc ScheduleDocument4 pagesContract Award: Generic Epc ScheduleNhel G. Pascual100% (1)

- (Eptco) Basic Engineering & Detail Engineering Work For Fuel Storage Tank - ElectricalDocument6 pages(Eptco) Basic Engineering & Detail Engineering Work For Fuel Storage Tank - ElectricalCharles Robiansyah50% (2)

- 2 A Piping Estimate Summary ExampleDocument23 pages2 A Piping Estimate Summary Exampleans99No ratings yet

- EPC Level 4 Schedule PDFDocument7 pagesEPC Level 4 Schedule PDFGeetha_jagadish30No ratings yet

- Pipeline FEED PackageDocument1 pagePipeline FEED PackageSamvendan JohnjacobNo ratings yet

- Phase Control For P&IDDocument1 pagePhase Control For P&IDPichai Chaibamrung100% (1)

- Project Controller (: Schedule and Cost ControllingDocument5 pagesProject Controller (: Schedule and Cost ControllinghichemokokNo ratings yet

- Project Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsDocument32 pagesProject Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsAziz EL100% (1)

- Standard Deliverable List For Feasibility Conceptual FEED Detailed DesignDocument190 pagesStandard Deliverable List For Feasibility Conceptual FEED Detailed Designkere_hore00740% (5)

- PT Borneo Mitra Sinergi: Project Close Out PlanDocument4 pagesPT Borneo Mitra Sinergi: Project Close Out PlanaswarNo ratings yet

- Energy Conservation Building CodeDocument5 pagesEnergy Conservation Building CodeVisalakshi ChockalingamNo ratings yet

- AWP The Silver BulletDocument32 pagesAWP The Silver BulletQiuniuNo ratings yet

- Construction Work Package Steps (G0)Document9 pagesConstruction Work Package Steps (G0)Kamyar KhosraviNo ratings yet

- FEEDDocument6 pagesFEEDxam marNo ratings yet

- Lire KZHXQ PDFDocument1 pageLire KZHXQ PDFأصلان أصلانNo ratings yet

- Deliverables List FEED Vs Detail EngineeringDocument9 pagesDeliverables List FEED Vs Detail EngineeringAnonymous QSfDsVxjZ83% (6)

- 8474L-000-PP-302-B Project Work Breakdown Structure PDFDocument18 pages8474L-000-PP-302-B Project Work Breakdown Structure PDFthanhvutn@yahoo.comNo ratings yet

- Documents Required-Engineering-20210821Document133 pagesDocuments Required-Engineering-20210821Abdelhay MarocainNo ratings yet

- LysaghtArchitecturalDetailingManualRoofWallFlashingApril14 PDFDocument40 pagesLysaghtArchitecturalDetailingManualRoofWallFlashingApril14 PDFthailanNo ratings yet

- Manhours REV 1 - 15-02-2015Document6 pagesManhours REV 1 - 15-02-2015Pavan Kumar100% (1)

- STOD OTP PMT 0808 PM PRO 0001 Progress Measurement ProcedureDocument21 pagesSTOD OTP PMT 0808 PM PRO 0001 Progress Measurement Procedurejfl2096No ratings yet

- Project Engineering Deliverables: Functional Responsibility Description Type of Deliverable Cost (L.E.)Document2 pagesProject Engineering Deliverables: Functional Responsibility Description Type of Deliverable Cost (L.E.)MJ MagdyNo ratings yet

- Typical FEED ScheduleDocument1 pageTypical FEED ScheduleVinh Do Thanh100% (1)

- PMS Deliverable List-MDDR-16 in AQP-Rev 1-MWS MarkupDocument2 pagesPMS Deliverable List-MDDR-16 in AQP-Rev 1-MWS MarkupMAT-LIONNo ratings yet

- Schedule LevelsDocument4 pagesSchedule LevelsNalini TiwariNo ratings yet

- How To Get Costing of Labor?: Preparing Detailed EstimateDocument21 pagesHow To Get Costing of Labor?: Preparing Detailed Estimatecass0608No ratings yet

- Planners and EPC ScopeDocument7 pagesPlanners and EPC ScopeRoshin99No ratings yet

- Design Basis Memorandum1Document166 pagesDesign Basis Memorandum1AnaNo ratings yet

- GUIDELINE - Deliverables List For Projects in The Fertilizer IndustryDocument17 pagesGUIDELINE - Deliverables List For Projects in The Fertilizer IndustryMarin PopescuNo ratings yet

- EPC Level 3 ScheduleDocument72 pagesEPC Level 3 ScheduleGeetha_jagadish300% (1)

- 2271 Aaa JSM 301 - B PDFDocument65 pages2271 Aaa JSM 301 - B PDFNorgjieNo ratings yet

- Master Document Register-Attachment 10Document6 pagesMaster Document Register-Attachment 10DAYONo ratings yet

- MB 0024 - 20 Applying Process Safety During Concept Select Phase of A Project GuidanceDocument36 pagesMB 0024 - 20 Applying Process Safety During Concept Select Phase of A Project GuidanceMohsen HamdiNo ratings yet

- Monitor The Construction Status of Piping InterfaceDocument8 pagesMonitor The Construction Status of Piping InterfaceAsraf Ali100% (1)

- Flexible & Rigid PVC Pipe Size IdentificationDocument4 pagesFlexible & Rigid PVC Pipe Size IdentificationAziz Khan KakarNo ratings yet

- Front End Engineering Design (FEED) - Typical Engineering Schedule Project MonthDocument1 pageFront End Engineering Design (FEED) - Typical Engineering Schedule Project MonthAlbertoNo ratings yet

- Master Deliverable Register: C Electrical C1Document2 pagesMaster Deliverable Register: C Electrical C1LaelaeNo ratings yet

- Engineering Project: TK-4094 Prarancangan Pabrik Kimia Semester 2 - 2015/2016Document9 pagesEngineering Project: TK-4094 Prarancangan Pabrik Kimia Semester 2 - 2015/2016Wilson LiangNo ratings yet

- FEED Deliverable List (Sample) - The Project Definition PDFDocument5 pagesFEED Deliverable List (Sample) - The Project Definition PDFbecpavanNo ratings yet

- EPC Project - Typical Engineering Schedule Time (Project Month) Disc. ActivityDocument1 pageEPC Project - Typical Engineering Schedule Time (Project Month) Disc. ActivityDANIELNo ratings yet

- AWP - E2E Approach - Rev 2Document16 pagesAWP - E2E Approach - Rev 2PilarNo ratings yet

- Theory and Practice in Earthquake Engineering and Technology SitharamDocument375 pagesTheory and Practice in Earthquake Engineering and Technology SitharamJeisson Castillo100% (1)

- Meindo SAKA - MDR BEIDocument6 pagesMeindo SAKA - MDR BEIperdana kusumaNo ratings yet

- P6 New 2Document30 pagesP6 New 2jkNo ratings yet

- Detailed Design and Engineering Deliverable List (Sample) - The Project Definition PDFDocument5 pagesDetailed Design and Engineering Deliverable List (Sample) - The Project Definition PDFMouayed ZeadanNo ratings yet

- Man-Hour Estimation ExampleDocument22 pagesMan-Hour Estimation ExampleAmine DabbabiNo ratings yet

- Water Stop DesignDocument4 pagesWater Stop DesignVSMS8678No ratings yet

- Engineering Standard MilestoneDocument23 pagesEngineering Standard MilestonegarciahoNo ratings yet

- ISO 26262 OverviewDocument62 pagesISO 26262 OverviewSrinivasanNo ratings yet

- Saih Rawl PS Level 3 ScheduleDocument16 pagesSaih Rawl PS Level 3 Schedulerajkumar4684No ratings yet

- Lire FVGJXDocument2 pagesLire FVGJXThiruThirunavukkarasuNo ratings yet

- Engineering Deliverable For Chemical OilGas ProjectsDocument6 pagesEngineering Deliverable For Chemical OilGas Projectskamala 123100% (1)

- Presentasi EPCDocument34 pagesPresentasi EPCtiantaufikNo ratings yet

- Bases FEED EPC Parte 3viDocument229 pagesBases FEED EPC Parte 3viAbdelhamid LaroussiNo ratings yet

- Why Buildings Leak UVADocument94 pagesWhy Buildings Leak UVAy2kareinNo ratings yet

- Systems Completion - Area Plan: Banyu Urip ProjectDocument13 pagesSystems Completion - Area Plan: Banyu Urip Projectsayafrands6252No ratings yet

- Process DeliverablesDocument6 pagesProcess DeliverablesAnonymous QSfDsVxjZNo ratings yet

- Continually Enhancing Value For Our Global Customers: RishabhDocument4 pagesContinually Enhancing Value For Our Global Customers: RishabhsuryamavuriNo ratings yet

- B224-125-16-51-VDR-7207 Vendor Data Requirements For InstrumentationDocument4 pagesB224-125-16-51-VDR-7207 Vendor Data Requirements For InstrumentationmanuneedhiNo ratings yet

- A Guide Line To Perform: EPC Project Contract Cost EstimationDocument60 pagesA Guide Line To Perform: EPC Project Contract Cost EstimationieltsabadanNo ratings yet

- TerraFirma Final Profile - CompressedDocument13 pagesTerraFirma Final Profile - CompressedsanusiibrahimNo ratings yet

- Document TypeDocument50 pagesDocument TypeFrancisco A. Rivera MedinaNo ratings yet

- Dokumen - Tips - Hazop-Oil-Gas 16Document2 pagesDokumen - Tips - Hazop-Oil-Gas 16Mohsen HamdiNo ratings yet

- Insulation THK Calc Cryogenic Piping MMD 00Document7 pagesInsulation THK Calc Cryogenic Piping MMD 00Mohsen HamdiNo ratings yet

- Line List: CFI Holding Pte. LimitedDocument12 pagesLine List: CFI Holding Pte. LimitedMohsen HamdiNo ratings yet

- VelocityDocument3 pagesVelocityMohsen HamdiNo ratings yet

- C116-10EMD-001 - Rev C - BASIS OF DESIGNDocument122 pagesC116-10EMD-001 - Rev C - BASIS OF DESIGNMohsen HamdiNo ratings yet

- Arfmtsv92 N1 P39 50Document12 pagesArfmtsv92 N1 P39 50Mohsen HamdiNo ratings yet

- ISA TR18 2 4 2012 - TOC ExcerptDocument12 pagesISA TR18 2 4 2012 - TOC ExcerptMohsen HamdiNo ratings yet

- Offloading Ammonia TankerDocument4 pagesOffloading Ammonia TankerMohsen Hamdi0% (1)

- OQ PHG EN V1 2-EthylhexanolDocument2 pagesOQ PHG EN V1 2-EthylhexanolMohsen HamdiNo ratings yet

- Design of A Propylene Storage FacilityDocument6 pagesDesign of A Propylene Storage FacilityMohsen HamdiNo ratings yet

- HAZOP Study of LBDPDocument36 pagesHAZOP Study of LBDPMohsen HamdiNo ratings yet

- CSC PHD ListDocument70 pagesCSC PHD ListAli AzamNo ratings yet

- ABET ENVE Program ReviewDocument252 pagesABET ENVE Program ReviewDien NoelNo ratings yet

- ASIC Design Flow How To Design Your Own Chip: Frank K. G UrkaynakDocument77 pagesASIC Design Flow How To Design Your Own Chip: Frank K. G UrkaynakpdnoobNo ratings yet

- Imp-Pvp2012-78359-Elastic-Plastic Fatigue Evaluation of A Heavy Wall Nozzle Subject To Rapid Thermal TransientsDocument10 pagesImp-Pvp2012-78359-Elastic-Plastic Fatigue Evaluation of A Heavy Wall Nozzle Subject To Rapid Thermal TransientsbomikaNo ratings yet

- Ar08 PDFDocument240 pagesAr08 PDFSaikat DawanNo ratings yet

- Example - Cleaning ProcessDocument6 pagesExample - Cleaning ProcessKar GayeeNo ratings yet

- Mapping of Co PoDocument37 pagesMapping of Co PoUdaysingh PatilNo ratings yet

- Super Duplex Stainless Steel PipesDocument3 pagesSuper Duplex Stainless Steel Pipeskumar sandeepNo ratings yet

- INTERTEK Fire Resistance Floor PanelDocument59 pagesINTERTEK Fire Resistance Floor PanelGino Randy Llanca GarniqueNo ratings yet

- A Reconfigurable Snake Robot Based On Can-Bus: AbstractDocument4 pagesA Reconfigurable Snake Robot Based On Can-Bus: AbstractsrcembeddedNo ratings yet

- ResumeDocument3 pagesResumeRishavaNo ratings yet

- How To Maintain Your Power Factor Correction UnitDocument5 pagesHow To Maintain Your Power Factor Correction UnitMichael ManuelNo ratings yet

- What Is The Difference Between Plum Concrete and Plain ConcreteDocument13 pagesWhat Is The Difference Between Plum Concrete and Plain ConcreteSajjad Amin AminNo ratings yet

- Ms 1934 Part 2 2007-Methods of Test For Masonry Part 2 Determination of Flexural Strength-850457Document16 pagesMs 1934 Part 2 2007-Methods of Test For Masonry Part 2 Determination of Flexural Strength-850457Fauziah AzizNo ratings yet

- Education, Training and Learning in Geo-Sciences For Civil EngineeringDocument4 pagesEducation, Training and Learning in Geo-Sciences For Civil EngineeringAnonymous GnfGTwNo ratings yet

- Lista TytulowREAD Elsevier2022 2024 1Document124 pagesLista TytulowREAD Elsevier2022 2024 1HhhgyhhNo ratings yet

- Field Survey ReportDocument10 pagesField Survey ReportPavan PatchigollaNo ratings yet

- 2018 Module 4 CS PDFDocument108 pages2018 Module 4 CS PDFPrasanth prasanthNo ratings yet

- PNRA Application FormDocument2 pagesPNRA Application FormZohaib Alam WarraichNo ratings yet

- Design of Steel Structures-07a60103Document7 pagesDesign of Steel Structures-07a60103Ram KrishnaNo ratings yet