Professional Documents

Culture Documents

Advantages of Light Gauge Steel

Uploaded by

Abel GetachewOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advantages of Light Gauge Steel

Uploaded by

Abel GetachewCopyright:

Available Formats

Frameclad Limited, Building 33 Bay 9, Second Avenue, The Pensnett Estate, Kingswinford, DY6 7UG

t: 01384 401114 e: enquiries@frameclad.com w: www.frameclad.com

STEEL FRAME - THE ADVANTAGES

TIME

Speed of Erection At least 30% faster than traditional build Reduced fixed site costs, facilities and management.

Lower interest costs on borrowing. Swifter return on

investment, with early rental income or business use.

Less disruption on site.

Rapid Dry Envelope Can reduce to 20% of the time required for traditional Allows first fix in quickly and keeps the scheme to

brickwork programme

Predictability Can be installed in wet and inclement conditions Lessens the risk of programme slippage

QUALITY AND

PERFORMANCE

Factory Quality Control High degrees of tolerance and dimensional accuracy Straight and plumb lines for following trades

Fully Engineered System Option for thinner walls Potential to increase floor space or even the number of

plots on a site

Dry Construction Reduced moisture in the building, no cracking or long Call backs' to rectify cracking and damage are virtually

term movement due to shrinkage eliminated

Stability Steel does not rot, shrink or creep under load Costs saving from reduced call backs, improved client

satisfaction. No wait during construction process for

settlement

Meets And Exceeds Typical2 storey house consumes 100-150kWh/m2pa Delivers energy directives. Exceeds part L and E

Thermal And Acoustic in service (per 100m2 floor area) up to 30% less than requirements. Conforms with Code for Sustainable

Requirements traditional buildings Homes

U values as low as 0.15W/m20C

Acoustic values >60dB sound reduction

Long Span Construction Spans of over 7 metres achievable Design flexibility, creation of open plan space, inventive

use of roof space

Pre-Fabricated Aesthetic Balconies, penthouses, walkways, lift shafts, porches Design flexibility

Components built into the basic design

Durability All components are zinc coated Protection from any corrosion for the life of the structure

SUSTAINABILITY

Lightweight In housing and low rise the steel frame is only 10% of Reduces foundation/piling requirements and ideal for

the weight of a concrete frame and less than timber, brownfield sites

typically 20kg/m2

Recyclable 100% recyclable. All EU produced steel currently Addresses political and public pressure for environmentally

has 50% scrap content A+ or A rated in BRE Green sustainable solutions. Meets Code for Sustainable

Guide to Housing Specification 2007 Homes standards

Minimises Waste Made to measure components and efficiencies of Reduced waste charges as no material sent to landfill.

factory production reduce waste. 98% of waste is Addresses issues covered in Site Waste Management

recycled. Planning

Transport Materials transported efficiently in bulk 'just in time' Positive impact on cashflow, reduced site security risk as

little material stored on site. Reduced environmental impact

OTHER FEATURES

Highly adaptable and flexible Late design charges can be accommodated

Reduced on site work and elimination of the internal Can increase the output of site bricklayers by up to 50%

block work

Warm frame construction Reduced risk of condensation

Non-combustible material Reduced fire risk during build

Registered in England No. 07084030. Registered Office: Maria House, 35 Millers Road, Brighton, East Sussex BN1 5NP. VAT Registration No. 982 2361 12.

You might also like

- Logic and Critical Thinking Quiz 3: Square of Oppositions Truth Test TableDocument3 pagesLogic and Critical Thinking Quiz 3: Square of Oppositions Truth Test TableGabriela Marie F. Palatulan100% (2)

- RadiationDocument89 pagesRadiationsugiarto80% (5)

- Joseph Abrusci - Professional Homemade Cherry BombsDocument26 pagesJoseph Abrusci - Professional Homemade Cherry BombsLê Nguyên ĐứcNo ratings yet

- Modular Construction BrochureDocument12 pagesModular Construction BrochureNguyễn Xuân NamNo ratings yet

- Business Qantas Case StudyDocument20 pagesBusiness Qantas Case StudyPSiloveyou49100% (3)

- Incinerator DesignDocument5 pagesIncinerator DesignOrlando Barrios50% (2)

- Aerated Concrete-A Sustainable Building MaterialDocument9 pagesAerated Concrete-A Sustainable Building MaterialDurga Prasad GuptaNo ratings yet

- Light Gauge Steel 1Document15 pagesLight Gauge Steel 1Muhammad UmarNo ratings yet

- Green Roof Fact SheetDocument2 pagesGreen Roof Fact SheetGarden GorillaNo ratings yet

- Precast Concrete SolutionsDocument27 pagesPrecast Concrete SolutionsMohammed IkramaliNo ratings yet

- 1.nickel Laterite ProcessingDocument37 pages1.nickel Laterite Processingyasminelewis100% (4)

- AAC Blocks Seminar PresentationDocument26 pagesAAC Blocks Seminar PresentationMahaManthra67% (3)

- 2 10 MW Biomass Plant Feasibility Study FinalDocument55 pages2 10 MW Biomass Plant Feasibility Study Finalairlanggaputra100% (1)

- Low Cost HousingDocument42 pagesLow Cost HousingruksarNo ratings yet

- The New Standard DIN 1986-100Document9 pagesThe New Standard DIN 1986-100alvinchuanNo ratings yet

- Cogeneration PDFDocument19 pagesCogeneration PDFMandeep Singh100% (1)

- Prefabricated Building TechnologyDocument45 pagesPrefabricated Building TechnologySyed Ashique Hussain HamdaniNo ratings yet

- Steel Build Engineering Catalogue PDFDocument6 pagesSteel Build Engineering Catalogue PDFArshalNo ratings yet

- Hotel Sector Brochure 2016 PDFDocument32 pagesHotel Sector Brochure 2016 PDFcrisNo ratings yet

- Precast Concrete: Building Construction 2Document5 pagesPrecast Concrete: Building Construction 2tahlaNo ratings yet

- Benefits of PPVCDocument1 pageBenefits of PPVCtoeNo ratings yet

- An Overview of Pre-Engineered Building Systems in India: Saurabh A. Shah, Madhav B.KumthekarDocument6 pagesAn Overview of Pre-Engineered Building Systems in India: Saurabh A. Shah, Madhav B.Kumthekarshashank adigaNo ratings yet

- Aerocon Blocks Product Literature FOLDER A4Document2 pagesAerocon Blocks Product Literature FOLDER A4subhaschandraNo ratings yet

- Emerging Lecture (Walling)Document46 pagesEmerging Lecture (Walling)izim izimNo ratings yet

- FormworkDocument3 pagesFormworkKareem AlselawyNo ratings yet

- Benefits of SIPs InfographicDocument2 pagesBenefits of SIPs InfographicMarvilla ConstructoraNo ratings yet

- Prefabrication Unit I IntroductionDocument30 pagesPrefabrication Unit I Introductiondhanabal100% (2)

- Sikalastic 625 UK PDS - Metal & Asbestos RoofsDocument12 pagesSikalastic 625 UK PDS - Metal & Asbestos RoofsstilpgNo ratings yet

- bmct GYPSUMDocument17 pagesbmct GYPSUMtheinteriorlaneNo ratings yet

- Merits of SteelDocument6 pagesMerits of SteelArshdeep KaurNo ratings yet

- Siniat Weather Defence Technical Manual - AU - 20.06 - Rev3Document36 pagesSiniat Weather Defence Technical Manual - AU - 20.06 - Rev3Eros BellioNo ratings yet

- v5 7746JAP FacadeDocument4 pagesv5 7746JAP FacadefirefoxextslurperNo ratings yet

- CkyDocument1 pageCkykhalishaNo ratings yet

- Benefits of Aerated Autoclaved Concrete (AAC) BlocksDocument26 pagesBenefits of Aerated Autoclaved Concrete (AAC) BlocksJakka hitheshiniNo ratings yet

- bmct GYPSUM finalDocument17 pagesbmct GYPSUM finaltheinteriorlaneNo ratings yet

- Sustainable Precast Concrete Design, Production and ConstructionDocument4 pagesSustainable Precast Concrete Design, Production and ConstructionAfsin Ecer.No ratings yet

- Kingspan Tek Building System Specification Manual en GB IeDocument32 pagesKingspan Tek Building System Specification Manual en GB IeNiallburkeNo ratings yet

- Strength Through Adversity: The Global First ChoiceDocument2 pagesStrength Through Adversity: The Global First ChoiceAnil Kumar JhaNo ratings yet

- RMIT Design Hub's Striking Galvanized Steel FaçadeDocument4 pagesRMIT Design Hub's Striking Galvanized Steel FaçadePavani MalajiNo ratings yet

- Sikaflex Construction Plus PDFDocument4 pagesSikaflex Construction Plus PDFMadelein RossiNo ratings yet

- Topic3.1GreenBuildingConcept NewDocument24 pagesTopic3.1GreenBuildingConcept NewnurbazilahNo ratings yet

- Efficiency Vermont BBD Utilizing Insulated Concrete FormsDocument59 pagesEfficiency Vermont BBD Utilizing Insulated Concrete FormsEd Carlo Rosa PaivaNo ratings yet

- Benefits From The Use of Standard Prefabricated Building Components IncludeDocument3 pagesBenefits From The Use of Standard Prefabricated Building Components Includeप्रणव कडूNo ratings yet

- Study online at quizlet.comDocument42 pagesStudy online at quizlet.comEmerson HernandezNo ratings yet

- Pre Fab ConstructionDocument18 pagesPre Fab Constructionar nedungadiNo ratings yet

- Porotherm Intro BrochureDocument12 pagesPorotherm Intro Brochurestone_baluNo ratings yet

- Prefabrication and Modular Cordination Assignment: Q. What Is Prefabrication?Document4 pagesPrefabrication and Modular Cordination Assignment: Q. What Is Prefabrication?Sadiya SharminNo ratings yet

- Precast Construction AdvantagesDocument11 pagesPrecast Construction AdvantagesjanaNo ratings yet

- The Adv of Using Shear Wall SystemDocument15 pagesThe Adv of Using Shear Wall SystembkkdennisNo ratings yet

- Ficha Tecnica de Rooftop 60000btuDocument5 pagesFicha Tecnica de Rooftop 60000btuGary Estay MonasteriosNo ratings yet

- GRP05 External FinishesDocument1 pageGRP05 External Finishes3238NDNo ratings yet

- Holcim CementDocument3 pagesHolcim CementTito GarciaNo ratings yet

- COMPANY PROFILE 2016 - Rev1a PDFDocument12 pagesCOMPANY PROFILE 2016 - Rev1a PDFMayapada TangerangNo ratings yet

- Green Building DefinitionDocument3 pagesGreen Building DefinitionHariz HilmanNo ratings yet

- Permanent Wood Foundations CWCDocument6 pagesPermanent Wood Foundations CWCsantiagoNo ratings yet

- TEK Specification Manual 12th Issue Nov 2018 PDFDocument32 pagesTEK Specification Manual 12th Issue Nov 2018 PDFriteish singhNo ratings yet

- H+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductsDocument12 pagesH+H Uk LTD Quinn Group Tarmac Topblock Limited Hanson Building ProductspseudosilNo ratings yet

- LGS SCP PresentationDocument25 pagesLGS SCP PresentationTCTPL CXONo ratings yet

- Cembrit-Factsheet Breeam Fa FinalDocument5 pagesCembrit-Factsheet Breeam Fa FinalBertrand LaffontNo ratings yet

- Birla Aerocon AAC Blocks - Literature V01 PDFDocument4 pagesBirla Aerocon AAC Blocks - Literature V01 PDFdhruvNo ratings yet

- Renewable Energy - Energy Conservation Site and Building Design - 201307120757371780Document4 pagesRenewable Energy - Energy Conservation Site and Building Design - 201307120757371780DaveRaphaelDumanatNo ratings yet

- Posi-Strut_Brochure_2011Document2 pagesPosi-Strut_Brochure_2011lekhanathpaudel2022No ratings yet

- Hafiz (Low Coast Building Design Architecture)Document14 pagesHafiz (Low Coast Building Design Architecture)Mig TigNo ratings yet

- Green Rooftops: Impervious Surface ReductionDocument6 pagesGreen Rooftops: Impervious Surface ReductionGreater Charlotte Harbor Sierra ClubNo ratings yet

- Precast Concrete - Precast Building System Solutions: December 2018Document22 pagesPrecast Concrete - Precast Building System Solutions: December 2018hhooww999No ratings yet

- Speed construction and lower costs with precast concrete building solutionsDocument22 pagesSpeed construction and lower costs with precast concrete building solutionshhooww999No ratings yet

- Presentation - Slides Mass Timber Construction 211214Document93 pagesPresentation - Slides Mass Timber Construction 211214Abel GetachewNo ratings yet

- 3 - Robust Multi-Storey Engineerd Timber DesignDocument33 pages3 - Robust Multi-Storey Engineerd Timber DesignAbel GetachewNo ratings yet

- Presentation - Slides LANDREMAN Mass Timber Construction 5 6 27 21 Final SeminarDocument113 pagesPresentation - Slides LANDREMAN Mass Timber Construction 5 6 27 21 Final SeminarAbel GetachewNo ratings yet

- Presentation - Slides - Bartlett Mass Timber Construction MultifamilyDocument65 pagesPresentation - Slides - Bartlett Mass Timber Construction MultifamilyAbel GetachewNo ratings yet

- 2 - Creative and Innovative Use of TimberDocument85 pages2 - Creative and Innovative Use of TimberAbel GetachewNo ratings yet

- Mass Timber BuildingDocument44 pagesMass Timber BuildingAbel GetachewNo ratings yet

- Waste Management in Dental Practice: Sadj May 2014, Vol 69 No 4 P178 - P181Document4 pagesWaste Management in Dental Practice: Sadj May 2014, Vol 69 No 4 P178 - P181Nabila BelaNo ratings yet

- Volute Dewatering PressDocument4 pagesVolute Dewatering PressPj EboraNo ratings yet

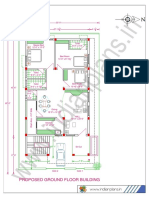

- WWW - Indianplans.in: Proposed Ground Floor BuildingDocument1 pageWWW - Indianplans.in: Proposed Ground Floor BuildingvetriNo ratings yet

- Application Note: 2017-2: SPT, The "Sample Pre-Concentration Trap" Integrated ConcentratorDocument3 pagesApplication Note: 2017-2: SPT, The "Sample Pre-Concentration Trap" Integrated ConcentratorMeriady MeriadyNo ratings yet

- Akshaya Patra Foundation Engineer - WikipediaDocument8 pagesAkshaya Patra Foundation Engineer - WikipediaKaustubh kcNo ratings yet

- Development and Acceptability of Taro StemDocument7 pagesDevelopment and Acceptability of Taro StemDonabel AngoluanNo ratings yet

- Analysis of Chemical and Heavy Metal Concentrations of Leachates and Impact On Groundwater Quality Near Dhapa Dumping Ground, KolkataDocument21 pagesAnalysis of Chemical and Heavy Metal Concentrations of Leachates and Impact On Groundwater Quality Near Dhapa Dumping Ground, KolkataGOUTAM DASNo ratings yet

- White Paper For Gold Mining ProcessDocument3 pagesWhite Paper For Gold Mining ProcessAdriapratama MunardiNo ratings yet

- HSEQ S7 Environmental Posters 2023 V02Document4 pagesHSEQ S7 Environmental Posters 2023 V02Robert PilloraNo ratings yet

- Municipal Wastewater Recycling in Cotton Textile Wet Processing - A ReviewDocument9 pagesMunicipal Wastewater Recycling in Cotton Textile Wet Processing - A ReviewEditor IJRITCC0% (1)

- Response To Public Concerns About RumpkeDocument32 pagesResponse To Public Concerns About RumpkeCameron Knight100% (1)

- ITT VEAM PowerLock and SnapLock Catalog 112014 FINAL ToC2 V5 PDFDocument36 pagesITT VEAM PowerLock and SnapLock Catalog 112014 FINAL ToC2 V5 PDFHoangNo ratings yet

- Cogeneration: Recover Waste Heat to Increase EfficiencyDocument27 pagesCogeneration: Recover Waste Heat to Increase EfficiencyArchit MadaanNo ratings yet

- World 02 - 03 - 16Document40 pagesWorld 02 - 03 - 16The WorldNo ratings yet

- Review of H2S Sorbents at Low-Temperature Desulfurization of BiogasDocument7 pagesReview of H2S Sorbents at Low-Temperature Desulfurization of BiogasHamed HpNo ratings yet

- GU - IMPCA - Methanol Product Carbon Footprint and CertificationDocument44 pagesGU - IMPCA - Methanol Product Carbon Footprint and CertificationHamed MolaviNo ratings yet

- Eba Statistical Report 2021 Short Version PDFDocument17 pagesEba Statistical Report 2021 Short Version PDFjoshua abrahamNo ratings yet

- Manual: SLC Safety Light Curtain/ Safety Light GridDocument52 pagesManual: SLC Safety Light Curtain/ Safety Light GridWeverton ClementeNo ratings yet

- Final PPT 11-9-18 Changes1Document19 pagesFinal PPT 11-9-18 Changes1aniket naikNo ratings yet

- Gorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsDocument8 pagesGorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsVic Van PeborghNo ratings yet

- ASEAN Green Hotel Standards CriteriaDocument5 pagesASEAN Green Hotel Standards CriteriaShikainah May RafolsNo ratings yet