Professional Documents

Culture Documents

Module 9

Module 9

Uploaded by

Ericka Mae AbreaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 9

Module 9

Uploaded by

Ericka Mae AbreaCopyright:

Available Formats

Name: Abrea, Ericka Mae G.

Year/Section: 4-Bravo

Activity

Learning Check

I. What are the stages in the manufacture of barrels? Briefly discuss each.

Answer: The four (4) stages manufactured of barrels are drilling, reaming, rifling and lapped. To

begin with, drilling is a special deep hole that used and at this stage, the interior surface of the

barrel will bear numerous scars and scratches resulting from the irregular cutting of the drill and

the metal chips which mark the finish under pressure. On the other hand, is the reaming stage, in

this process, some of the scars or scratches left by the drilling operation are removed. It includes

roughly finishing and burnishing the reamer to have a smooth bore barrel. Another stage is

rifling; this process is necessary for the making of the holiday proves inside the barrel. Rifling in

the bore of the firearm is a helical groove consisting of the depressed portion (grooves) and an

elevated portion (lands) which is responsible for the rotation motion of the projectile as it leaves

the gun muzzle. The last stage is lapped which is the polishing operation in which a lead plug

closely fitting the inside of the barrel is drawn back and forth on a rod carrying with it a

polishing compound.

II. Differentiate Class from individual characteristics and give examples.

Answer: Let’s begin with bore diameter which it is the diameter to which the bore was reamed,

and it is the distance measured between two opposite lands inside the bore in hundredths or

thousandths of an inch. Example of this is in shotguns, they are either in gauge or an inch, such

as 10 gauge (.775), 12 gauge (.729), 20 gauge (.615), 24 gauge (.579), 30 gauge (.537) 36 gauge

(.506), and the smallest of which is gauge .410. While on number of lands and grooves this class

refers to the number of lands and grooves inside the barrel of a given firearm are always the

same or equal. It may run from 3 to 8, but the most in the modern firearm are five and six. On the

other hand, width of the lands is a dependent class upon the bore diameter of the gun, grooves,

width, and number. Proceeding to the width of the Grooves which this class is measured as the

shortest distance between the two dies or the edge of a groove while the direction of twist is for

the rifling inside the barrel of the gun and it could be either twisted to the left or to the right

which causes the bullet to rotate as it passes through the bore, in order to ensure gyroscopic

stability in its flight. Another class is what we called pitch of Rifling, the pitch of rifling is the

measure of the twisting of the lands and grooves. And the last class is the depth of the grooves,

the groove’s depth is measured on the radius of the bore.

You might also like

- XOC-01 15PPM Bilge Alarm ManualDocument14 pagesXOC-01 15PPM Bilge Alarm ManualAE EM75% (8)

- Digital Systems EngineeringDocument5 pagesDigital Systems Engineeringpo23No ratings yet

- Gundrilling HandbookDocument49 pagesGundrilling HandbookBooks for the lot100% (1)

- Marshall DSL1-60-02-v02Document1 pageMarshall DSL1-60-02-v02b heig100% (1)

- Head SpaceDocument18 pagesHead Spaceglitch1187100% (2)

- The Well Guided Bullet (PartI)Document10 pagesThe Well Guided Bullet (PartI)blowmeasshole1911100% (2)

- Don Honorio Ventura State University: Laboratory Experiment No. 1B Diode CharacteristicsDocument11 pagesDon Honorio Ventura State University: Laboratory Experiment No. 1B Diode CharacteristicsArchie CoNo ratings yet

- BS 03288 3 1989 1999Document30 pagesBS 03288 3 1989 1999André FerreiraNo ratings yet

- Hertz EP4 Tech EngDocument2 pagesHertz EP4 Tech EngturkmavzeriNo ratings yet

- Forensic Ballistics - 7Document12 pagesForensic Ballistics - 7Catherine AcedoNo ratings yet

- DocumentDocument3 pagesDocumentGlenmarc DequiñaNo ratings yet

- Cri 414L - Unit 4 - Ulo ADocument12 pagesCri 414L - Unit 4 - Ulo Avworldpeace yanibNo ratings yet

- Module 9Document11 pagesModule 9Dethzaida AsebuqueNo ratings yet

- Forensic Ballistics Module 9Document11 pagesForensic Ballistics Module 920-0383.dizorNo ratings yet

- Rifling: Navigation SearchDocument12 pagesRifling: Navigation Searchyad1020No ratings yet

- F - Topic 9 Firearms CharacteristicsDocument31 pagesF - Topic 9 Firearms CharacteristicsJent Denise DisepedaNo ratings yet

- Chapter 8Document6 pagesChapter 8BOOBSIE B.No ratings yet

- CHAPTER 8 1 64 Slides Forensic Ballistics 2Document64 pagesCHAPTER 8 1 64 Slides Forensic Ballistics 2Fionna Lou M. CarandangNo ratings yet

- Wear and Erosion in Large Caliber Gun BarrelsDocument15 pagesWear and Erosion in Large Caliber Gun Barrelscjnjr1No ratings yet

- The Wear of Single Flute Gun Drill and Tool Life Tests: I. Sihvo, J. VarisDocument6 pagesThe Wear of Single Flute Gun Drill and Tool Life Tests: I. Sihvo, J. VarisarvinupNo ratings yet

- For6 MidtermDocument103 pagesFor6 MidtermChristianJohn NunagNo ratings yet

- Forensic BallisticsDocument5 pagesForensic BallisticsJett Brondial RaymundoNo ratings yet

- Wear and Erosion in Large Caliber Gun Barrels: PrefaceDocument14 pagesWear and Erosion in Large Caliber Gun Barrels: Prefacejitendra25252No ratings yet

- DJJ10033-chapter 2Document52 pagesDJJ10033-chapter 2Abbas SeuNo ratings yet

- ReportDocument20 pagesReportjaylou taboriteNo ratings yet

- Forensic BallisticDocument12 pagesForensic BallisticYash GuptaNo ratings yet

- About Barrels..Document5 pagesAbout Barrels..Ikkasama NaguenneNo ratings yet

- Driil CollersDocument15 pagesDriil Collersamol modakNo ratings yet

- Barrel1оружие 12Document8 pagesBarrel1оружие 12Сергей МельничукNo ratings yet

- Drilling Methods: Kuliah-9 Teknik EksplorasiDocument26 pagesDrilling Methods: Kuliah-9 Teknik EksplorasiWakkal M Malinta'No ratings yet

- Firearms and Toolmark PPT 2013Document15 pagesFirearms and Toolmark PPT 2013Adda AnaNo ratings yet

- Forensic Ballistics Intro 1Document32 pagesForensic Ballistics Intro 1Angie SangagNo ratings yet

- The Rifle Barrel: Chuck HawksDocument6 pagesThe Rifle Barrel: Chuck Hawksmrek68100% (1)

- BallisticsDocument6 pagesBallisticsAntonette NavarroNo ratings yet

- Drilling Reaming & TappingDocument17 pagesDrilling Reaming & TappingLeo HsiehNo ratings yet

- CarriageDocument25 pagesCarriageSamir SinghNo ratings yet

- Chapter 7 and 8Document33 pagesChapter 7 and 8Fionna Lou M. CarandangNo ratings yet

- Firearm Injuries: Forensic MedicineDocument71 pagesFirearm Injuries: Forensic MedicineHamzaNo ratings yet

- 2 هندسة الانتاج والمعادن ملزمة طرق تصنيع مرحلةDocument23 pages2 هندسة الانتاج والمعادن ملزمة طرق تصنيع مرحلةAhmed KhalidNo ratings yet

- BallisticsDocument24 pagesBallisticsMarkDulnuanNo ratings yet

- Corbin Technical Bulletin Volume 1Document38 pagesCorbin Technical Bulletin Volume 1aikidomoyses50% (2)

- Q and A BallisticsDocument12 pagesQ and A BallisticsQayes Al-Quqa100% (7)

- Week5 AmmunitionDocument6 pagesWeek5 Ammunitionruui chizakuraNo ratings yet

- Drill String ComponentsDocument8 pagesDrill String ComponentsMUHAMMED FUADNo ratings yet

- 5chapter Five Thread CuttingDocument5 pages5chapter Five Thread CuttingKenasa JambareNo ratings yet

- Answers For Apm 214 EssayDocument2 pagesAnswers For Apm 214 EssaymichealNo ratings yet

- Chap 8Document11 pagesChap 8Michael Chuquiruna MuñozNo ratings yet

- Unit - III - Ammunition-1Document39 pagesUnit - III - Ammunition-1Nived K KNo ratings yet

- Ex. No Date Name of The Experiment Mark No Staff SignatureDocument35 pagesEx. No Date Name of The Experiment Mark No Staff SignaturesivagamipalaniNo ratings yet

- Design Criteria For Shooting RangesDocument8 pagesDesign Criteria For Shooting Rangesrickoshea160No ratings yet

- PE 313 Lab - 1 Wellbore SchematicsDocument5 pagesPE 313 Lab - 1 Wellbore Schematicsjaknpong sangwanpathNo ratings yet

- Lab Session 11Document5 pagesLab Session 11Rahmat aliNo ratings yet

- Forensic Ballistics - 4Document13 pagesForensic Ballistics - 4Catherine Acedo100% (1)

- RIVETSDocument16 pagesRIVETSعبدالرحمن سيدNo ratings yet

- Fluted and Annular Grooved Barrel Chambers in FirearmsDocument11 pagesFluted and Annular Grooved Barrel Chambers in Firearmssnizz100% (6)

- Design of Jig BushDocument15 pagesDesign of Jig BushsimiyandcNo ratings yet

- Headspace GuideDocument7 pagesHeadspace Guideusn212100% (2)

- Lecture Forensic BallisticsDocument86 pagesLecture Forensic Ballisticsmaryjeanalisoso20No ratings yet

- WST - Perforation Part 2Document27 pagesWST - Perforation Part 2NorNo ratings yet

- Barrel and Rifling ManufacturingDocument15 pagesBarrel and Rifling Manufacturingwensly intongNo ratings yet

- Firearm Ammunition and Cartridge CasesDocument5 pagesFirearm Ammunition and Cartridge CasesDomingo John-h Wyler CainoyNo ratings yet

- The Development of Armor-piercing Shells (With Suggestions for Their Improvement)From EverandThe Development of Armor-piercing Shells (With Suggestions for Their Improvement)No ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Module 7 Act Answer in Therapeutic ModalitiesDocument2 pagesModule 7 Act Answer in Therapeutic ModalitiesEricka Mae AbreaNo ratings yet

- Initial Incident Report - Abrea, Ericka Mae G.Document2 pagesInitial Incident Report - Abrea, Ericka Mae G.Ericka Mae AbreaNo ratings yet

- Module 10Document3 pagesModule 10Ericka Mae AbreaNo ratings yet

- Module 11Document3 pagesModule 11Ericka Mae AbreaNo ratings yet

- Expectations-Abrea, Ericka MaeDocument1 pageExpectations-Abrea, Ericka MaeEricka Mae AbreaNo ratings yet

- Module 12 ActDocument4 pagesModule 12 ActEricka Mae AbreaNo ratings yet

- MODULE 4 - ActivityDocument5 pagesMODULE 4 - ActivityEricka Mae AbreaNo ratings yet

- Module 5 ActivityDocument12 pagesModule 5 ActivityEricka Mae AbreaNo ratings yet

- MODULE 3 ActivityDocument5 pagesMODULE 3 ActivityEricka Mae AbreaNo ratings yet

- RegtrpoDocument46 pagesRegtrpomarjorieqlNo ratings yet

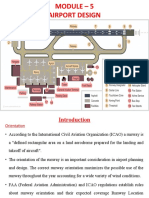

- Module 5 (Airport Design)Document23 pagesModule 5 (Airport Design)Akshay AradhyaNo ratings yet

- BELL 429: One Aircraft. Endless PossibilitiesDocument2 pagesBELL 429: One Aircraft. Endless PossibilitiesJUAN CARLOS HENRIQUEZ100% (1)

- 220KV/132KV/33KV BODHGAYA GSS: Presented By:-B.Tech, Ece 7 Semester Arya College of Engineering & I.T. (Jaipur)Document21 pages220KV/132KV/33KV BODHGAYA GSS: Presented By:-B.Tech, Ece 7 Semester Arya College of Engineering & I.T. (Jaipur)Ratnesh KumarNo ratings yet

- Hailo Runged Ladders 9312-507 enDocument3 pagesHailo Runged Ladders 9312-507 encs9218No ratings yet

- Computech Staff Edison Computech 7-8Document1 pageComputech Staff Edison Computech 7-86wpzzgdy2qNo ratings yet

- CHARGING+SYSTEM 1hz, 1hdDocument19 pagesCHARGING+SYSTEM 1hz, 1hdLeonardNo ratings yet

- DoctronicsDocument24 pagesDoctronicsMavia DahulueNo ratings yet

- Cd00020086 Sensorless BLDC Motor Control and Bemf Sampling Methods With St7mc StmicroelectronicsDocument35 pagesCd00020086 Sensorless BLDC Motor Control and Bemf Sampling Methods With St7mc StmicroelectronicsmortezaNo ratings yet

- Power Amplifier Applications Driver Stage Amplifier ApplicationsDocument5 pagesPower Amplifier Applications Driver Stage Amplifier ApplicationsJuan CarlosNo ratings yet

- AS AS Solutions AS: HCI 434D/444D - Winding 311Document9 pagesAS AS Solutions AS: HCI 434D/444D - Winding 311Renzo zuñiga ahonNo ratings yet

- Service Manual: Colour TelevisionDocument48 pagesService Manual: Colour TelevisionRoosevelt Vega SanchezNo ratings yet

- Acti9 C60NA-DC - C120NA-DC - SW60-DC - A9N61690Document2 pagesActi9 C60NA-DC - C120NA-DC - SW60-DC - A9N61690htnemade0% (1)

- STATCOM Review PDFDocument6 pagesSTATCOM Review PDFMoataz JabarNo ratings yet

- NAME PLATE DETAILS List of Experiments1Document7 pagesNAME PLATE DETAILS List of Experiments1Ravindra VankinaNo ratings yet

- Diagrama Fuente MCV903Document1 pageDiagrama Fuente MCV903Ruben Dario Dulcey Leon100% (1)

- Instruction Manual Safety SystemDocument99 pagesInstruction Manual Safety SystemAndrey AndreyNo ratings yet

- 40030D Volant CRTi3 7.0 AssemblyandOperationsManualDocument76 pages40030D Volant CRTi3 7.0 AssemblyandOperationsManualNelsonParedesNo ratings yet

- DIY Automatic Alcohol Dispenser No Arduino NeededDocument16 pagesDIY Automatic Alcohol Dispenser No Arduino NeededLuigi Ceda100% (1)

- Triac QuadrantDocument15 pagesTriac QuadrantJohn Paul BaquiranNo ratings yet

- Lightning Protection System Testing & Commissioning Method StatementDocument3 pagesLightning Protection System Testing & Commissioning Method Statementvin ssNo ratings yet

- Alternador Leroy Somer LSA 47.2Document12 pagesAlternador Leroy Somer LSA 47.2YERKO OVIEDONo ratings yet

- Nema Espg PDFDocument106 pagesNema Espg PDFKalpit ShahNo ratings yet

- EXERCISE CHAPTER 2 - Grade 9 - Dynamic Electricity A. Electric Current and Voltage Definition Term AnalogyDocument4 pagesEXERCISE CHAPTER 2 - Grade 9 - Dynamic Electricity A. Electric Current and Voltage Definition Term Analogyherawati100% (1)