Professional Documents

Culture Documents

Signed

Signed

Uploaded by

Ahmed Boraey0 ratings0% found this document useful (0 votes)

12 views6 pagesOriginal Title

Signed Copy

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views6 pagesSigned

Signed

Uploaded by

Ahmed BoraeyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Qok

‘Company Name:

NDT CORROSION CONTROL SERVICES CO.

DAMMAM

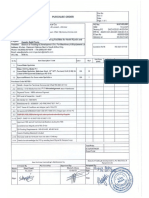

PROCEDURE QUALIFICATION RECORD (PQR)

‘M/s. NEW HORIZONS COMPANY

Procedure Guaaton Recor No, _PQR/NHC-039 Te Dae oTOL208

WPSNo._WPSINHC-039 Repon No: M7L=5220

Weting Presses). GTAW= SMAW ca

‘Types (Manual, Automatic, Ser to): MANUAL

CODE: ASME Ix apitio4 CO] Aws 01.1 0 OTHER (S): ASME B31.3

JOINT be (Qw-402) BEAD SEQUENCE

{27m peer

a eS

vam my

JOINT DESIGN USED: Jig ey

veoRoove YY

oO

BASE METALS (QW403) PREHEAT (@W-08)

Naira Spec AGL yy ——afst—| rene Terp. —_aMBinr @ a

Type Grade/ UNS ran — Yo —r an —| nr pase Temp, nso MA

Pino, Gow? ——~ ToR NG. iGmup? | Oher

Trikes aie

Darter v9

Lot Heat No, “ear

Paes hkness Max SA 3 BOST WELD HEAT TREATMENT (GW207)

Tenpraure NONE

Seeking Time “HONE

Heating ! Cooling rate _NONE

FILLER METALS (GW-404) Others

Weld Metal Analysis A No 1 GAS (GW-408)

Size of Electrode 24MM o. Type of Shielding Gas: ‘ARGON

Filler Metal F No. 76 Composition of Shielding Gas Miture: _99.09796

SFA Specification 5.18 Others: _ Rate of shieiaing gas flow 15:30 CFH

AWS Classification [ERTOS-2 | E7OI8 HAR | Purging: No becking /No Traling gas used

Filler Metal product form ‘SOLD. =

Weld metal thickness. 25mm | 02mm

Others: E988 OK Tarod 1262 Lot x Pvsose7z784

SAB, On 48.00, Lot#SFSS9125,SFSI9107

POSITION (QW-408) TECHNIQUE (QW-410)

Position of Groove oi —_] Travel Speed ‘SEE TABLE BELOW _ =

‘Weld Progression (Uphil, Downhill) String orWeave BOTH.

Other Oscilaton =

Mult pass or Single Pass (per side) __ MULTI

Single or Mutiple Electrodes / Filler SINGLE

Closed to cut chamber (GTAW) NO

Use of thermal process NO.

ELECTRICAL CHARACTERISTIC (QW-408) Other TUNGSTEN ELECTRODE 2% THORIATED.

Filer tata Curent vot | Travel Speed | Heat input

weld Layers) | Process ‘Amp Range | Range Range ‘aim

Clase Dia | Type Polarty [APR o mena ‘avg

Roor(#) craw | eR70s2 | 24MM ‘DCE 4100 | 94 3058 1.328

HOT PASS (2) craw | eR70s2 | 24MM cen | teas; | ott ate 0.980

FLL) swaw | evoranar | 25mm ‘DceP as100 | 2026 ase 1.136

FLL 20a) swaw | evorenan | 32mm cer | tisasa | 2026 ed 1.959

FILL 3 66) ‘swaw | e7o1enaR | 32MM cer | to4se | 2026 7a 1755

CAP (T-8) | swaw | evotenan | 25mm ‘DCEP sos | 2026 70164 1.064

WELDING WITNESSED BY: P, WILLIAM &.

Page 1 of 3

NDT Corrosion Control Servicos Co.

MOE rosox'sz2

Darmam= 214%, Saud Arabi

Te s806:03-4468328 417464 / 8447700

Fax: 9488253

WELDING PROCEDURE QUALIFICATION TEST REPORT

Company : NEW HORIZONS COMPANY Report No.: MTL-5220

PQR No. : PQR/NHC-033 Report Date: 10-Jul-2019

Process : GTAW+ SMAW Test Date: 10-Jul-2019

Materials : APISL Gr. BN To APISL Gr. BN Receipt Date: 4-Ju/-2019

Dia. /Thk: 8"O x 12.7 MM

TENSILE TEST (QW.-150)

YELD. ULTIMATE

SPECIMEN] wiDTH |THiCKNEss| AREA % FAILURE

na uf se eA [ toan | stress | .oan [stress] grey | Locavion

z mp mmf mc] tear em | ay

m1 | 1907 | 1208 | 241.800 2 taz9 | 514 - Bu

v2 | 1900 | 1270 | 201808 | ~ 2 vor | 530 = eu

JResuut: Jacceprasue

GUIDED BEND TEST (QW-160)

Ne. TYPE OF SEND [DEGREE OF SEND _[ OBSERVATION RESULT

7 SIDE BEND-1 180 SATISFACTORY, ACCEPTABLE,

z SIDE BEND-2 100 SATISFACTORY, ACCEPTABLE:

z SIDE BENDS 160 SATISFACTORY, ‘ACCEPTABLE

4 SIDE BEND-4 100 SATISFACTORY, (ACCEPTABLE

(CHARPY IMPACT TOUGHNESS TEST (aW-170) FILLET WELD TEST (QW-180)

TEST | IMPACT

SPECIMEN) SIZE | NOTCH | Temp. | VALUES -sarisractory = ves] xo

io. | em | vocarion

Deg.f | (NM)

PENETRATION INTO 2O w O

PARENT METAL

MACRO TEST RESULT

=

OTHER TESTS

HARDNESS TEST RADIOGRAPHIC TEST: REPORT ENCLOSED

ICoGATION | —WiGH LOW [AVERAGE] Remarks Rrag1659

law

az REPORT ENCLOSED

[aw I I

WELDER'S NAME: _USMAN ALI (10426)

Test Conducted by: ABDUL QUDDUS Signature

TE CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE TEST SPECIMENS WERE PREPARED AND

TESTED IN ACCORDANCE WITH THE REQUIREMENTS OF BOILER AND PRESSURE VESSEL CODE ASME SEC. 1.2019 EDITION

Dr. KESHAB BARAI

Division Head (Metallurgy & Lab),

NDT Corrosion Control Services Co

Ses

Page 2 of 3 NOTCCSILABISOPI0 Ra) Revs

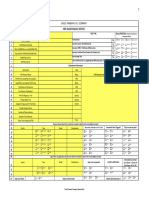

NDT CORROSION CLIENT INEW HORIZONS COMPANY JTESTDATE [10-Jul-2019

CONTROL SERVICES CO. oar no PQR/NHC-033 RECEIPT DATE |4-Jul-2019

IBASE MATERIAL (S}|APISL Gr. BN To API SL Gr. BN DIMENSION |8"d

M 6) le STD. BLOCK HV 197 THICKNESS — 12.7 MM

CODE / STANDARD} ASTM E92 REPORT NO. |MTL-5220

VICKERS HARDNESS (HV-10 Kgf) TEST REPORT

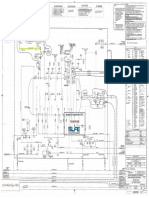

SAUDI ARAMCO DRAWING # AB-036386-001

2.5-1.0nm

cachogs FNAL

Pas)

oes

=

= cen \

ae BASE METAL R

oeran

SAMPLE-1 V-GROOVE SAMPLE-2

Near 12 o'clock Position Near 60' clock Position

PORT wanoness [=] _wanoness area P| wanoness "| _ wanoness

a] owe [a | siz pasewera | a aes | | tees

2] aaa | az | a2 2 101 | 2] a0

HEAT AFFECTED

3 | sss [as | asa = 3 2 fel ome |.

a | ws [a | ave 4 woo | «| 79s

s | 159 [as | 607 5 was | as | 1692

WeLD METAL

6 | sa [as | aes 6 167 | 16 | 1659

7 | 258 [ar | as 7 151 | 7 | ese

HEAT AFFECTED

3 | wa [as] soa pies 8 ais | ws | 1693

9 | ws7 [as] ime ° wes | 19 | 1684

w | 168 | 2 | — s644 sasemera | a0 | 1555 | 20 | s019

TEST PERFORMED BY "APPROVED BY

ABDUL QUDDUS Dr. KESHAB BARAI a

LAB TECHNICIAN. DIVISION HEAD (Metallurgy & Lab)

Page 3 of 3 (NDTCCS/LAB/SOP13.R2) Rev.1

P.O. BOX 322, DAMMAM ~31411, KSA

Tel: +966-3-8468328 / 8417464, Fax 8468353, E-mall info@ndtcorrosion

P.O. Box No: 322, Dammam - 31411. KSA

NDT CORROSION CONTROL SERVICES CO.

WELDER PERFORMANCE QUALIFICATION TEST RECORD

Cert, No: 69780

Company. M/s. NEW HORIZANS COMPANY

Wilders Nome USMAN AL! KHADIM HUSSAIN Symbol/1d. No. W10426 Date: 40.JUL-2019,

Test Description

Identification of WPS followed PQR/NHC-033 a ___ Bi Test coupon 11 Production weld

Speciation of base metals) APISL Gr. BN To APISL Gr. BN Thickness 12.7 MM

Testing Conditions and Qualifications Limits

Welding Variabies (QW-350) Actual values Range Qualified

\Weicing processes) GTAW/SmaW GTAW/SMAW

“Type (e: manual, semi-auto) used MANUAL MANUAL

Backing (metal, weld metal, dovblesnelded. etc) SEyamourancrne EER mouT acs

Cl Plate Pipe (enter diameter if pipe or tube) 8" (2-7/8"0D TO UNLIMITED

——srrop Tan pre Pae pat —

Base metal P- or S-Number to P- or S-number PITOPY THRU Pao

Filer metal or electrodes specticatons) (SFA) nfo. ony) TSFASSO/SFASA =

Filer metal or electrode classication() (no. only) ERTOS-2/ E7010 HAR

Filer metal F-number(s) FFA

Consumable inset (GTAW or PAW) 2

Filer ype (sole metal ofux cored / powder) (GTAW or PAW)

Depesit thickness foreach process

Process 1: GTAW Slayers minimum [ Yes CIN.

Process 2: SMAW Slayers minimum Yes CINo

Psion qualified (26, 86, 9F, etc.)

Vertical progression (uphill or wohl)

‘Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW) WITHOUT BACKING

“Transfer mode (spray/globular/ or pulse to short circuit-GMAW)

GTAW current typelpolaity (AC, DCEP, DCEN) (GTAW-DCEN/SMAW.DCEP

RESULTS.

Visual examination of Completed Weld (QW-302.4) ACCEPTABLE

1 Bend Test: Transverse root and face [QW462 342); [] Longtudina oot and face [aW-462 3(0), [) Side (aW-4822)

1D Pipe nena specimen, corosion-esistant overlay [QIN-462.5c); C] Plate bend specimen, corosion-resistant overay [QW462.5())

1D Maco test for fusion (2-462, 50). Macro tes or fusion [QN-462 5

‘Type suit "Type. osu Type Result

‘Altemative radiographic examination resut (QW-191) _ ACCEPTABLE Report No. RT/9/1659

Fillet weld ~ fracture test (QW-122) Length and percent of defects

‘Macro examination (QW-184)_—- Filet size (in) == X= CConcavty! corwexty (in)_==

‘Other tesis MECHANICAL TEST

Film / specimens evaluated by _M. S. SALEEM / ABDUL QUDDUS __ company _NDT CCS

Mechanical tests conducted by _NDT CCS CO. Laboratory test no, _MTL-5220

Welding supervised by _P, WILLIAM ‘TestDate: _30-JUN-2019

We cert that he statements in tis record are corect and tha the test coupons were prepared, welded, and tested in accordance withthe

Fequremerts of ASME Sec. 2010.

“Customers encouraged validate te cerca in our oficial website”

Organization _NDT CORROSION CONTROL SERVICES CO.

By

[&_ NDT Corrosion Control Services Co

Dammam

WELDER PERFORMANCE CARD

We certify that the statements in this record

are correct and that the test coupons were

prepared, welded and tested in accordar

with the requirements of ASME SEC i

AWSDL1 D214 D1 6LAPLLIDA CODE lat

‘umomer encouraged valent he ceateln our ot wet

Inspector Approved

WILLIAM P.BASKAR

Name Name p.

wD ap ME

WELDER PERFORMANCE CARD

Company

‘We’ Nama. USMAN ALI READIN HOSSAIN

‘Weiaaae

Symbol. No

iaama Poser; 2889042858

‘GTA / SMa.

‘Wong Press sk .

(aan Sener tomatic... HANUAL,

Pee al NCES

i Bi

ced niinm Ok SRR TOUTS OTT ow

ge Oued

st Pstin oe 88 Foci Quan ALL

Denon cn ERTS EVES HAR yy FO) Fa

WisRoove Rr & MECHANICAL

son pe: waned:

Testing 0. He. carta ‘Bo780

Date of re 218 race of tue. DAMMAM,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CertificateOfCompletion - SAP ERP Essential TrainingDocument1 pageCertificateOfCompletion - SAP ERP Essential TrainingAhmed BoraeyNo ratings yet

- 01-Socket PanelDocument6 pages01-Socket PanelAhmed BoraeyNo ratings yet

- Annexure - 11.1 Code of ConductDocument3 pagesAnnexure - 11.1 Code of ConductAhmed BoraeyNo ratings yet

- Annexure - 11.2 Nda For SubcontractorDocument1 pageAnnexure - 11.2 Nda For SubcontractorAhmed BoraeyNo ratings yet

- Annexure - 1 Part D Subcontract Agreement (Sample Copy)Document6 pagesAnnexure - 1 Part D Subcontract Agreement (Sample Copy)Ahmed BoraeyNo ratings yet

- Estimara - 9533 DbaDocument1 pageEstimara - 9533 DbaAhmed BoraeyNo ratings yet

- BS 4 - Grade 7Document2 pagesBS 4 - Grade 7Ahmed BoraeyNo ratings yet

- Procurement Officer, KSADocument3 pagesProcurement Officer, KSAAhmed BoraeyNo ratings yet

- EPM Mobile Terms of UseDocument2 pagesEPM Mobile Terms of UseAhmed BoraeyNo ratings yet

- CVJ 79126225 20231031083643Document5 pagesCVJ 79126225 20231031083643Ahmed BoraeyNo ratings yet

- Skilled WorkerDocument68 pagesSkilled WorkerAhmed BoraeyNo ratings yet

- BGSQ2Document3 pagesBGSQ2Ahmed BoraeyNo ratings yet

- 603 Stairways and LaddersDocument40 pages603 Stairways and LaddersAhmed BoraeyNo ratings yet

- 4ad07b0d01412b9650d4d2cb0e0de04dDocument49 pages4ad07b0d01412b9650d4d2cb0e0de04dAhmed BoraeyNo ratings yet

- باقات التشطيبDocument13 pagesباقات التشطيبAhmed Boraey100% (1)

- SPDRequestfor Bids GOODS1 Envelope OCT2017Document139 pagesSPDRequestfor Bids GOODS1 Envelope OCT2017Ahmed BoraeyNo ratings yet

- EPM Mobile Privacy PolicyDocument4 pagesEPM Mobile Privacy PolicyAhmed BoraeyNo ratings yet

- Risk LectureDocument75 pagesRisk LectureAhmed BoraeyNo ratings yet

- Meant of High ViscosityDocument1 pageMeant of High ViscosityAhmed BoraeyNo ratings yet

- خطة دراسة ذاتية للمبتدئين A1 جديدةDocument18 pagesخطة دراسة ذاتية للمبتدئين A1 جديدةAhmed BoraeyNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- CIPP CIPM Bilingual Brochure1Document14 pagesCIPP CIPM Bilingual Brochure1Ahmed BoraeyNo ratings yet

- Rading Development-Reda-Nozzles - AckDocument5 pagesRading Development-Reda-Nozzles - AckAhmed BoraeyNo ratings yet

- QA-QC RequirementDocument4 pagesQA-QC RequirementAhmed BoraeyNo ratings yet

- Diameter Ofof NozzelDocument16 pagesDiameter Ofof NozzelAhmed BoraeyNo ratings yet

- CPVC MentDocument5 pagesCPVC MentAhmed BoraeyNo ratings yet

- Ford Flow ViscosityDocument8 pagesFord Flow ViscosityAhmed BoraeyNo ratings yet

- RB-666247.006 RevDocument1 pageRB-666247.006 RevAhmed BoraeyNo ratings yet

- Rotothinner ViscosityDocument1 pageRotothinner ViscosityAhmed BoraeyNo ratings yet

- WPS CladedDocument2 pagesWPS CladedAhmed Boraey100% (1)