Professional Documents

Culture Documents

Coating Fults

Uploaded by

Ahmed BoraeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coating Fults

Uploaded by

Ahmed BoraeyCopyright:

Available Formats

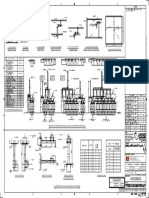

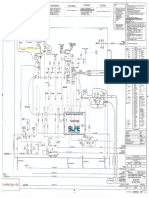

UP STANDARD DETAIL REFERENCE DRAWINGS

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

AWAY

INSULATION DETAILS FOR HOT PIPING AA-036911

INSULATION DETAILS FOR COLD PIPING AA-036913

INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

SHOP MATERIALS

TOWARD

TOWARD

PT NPD NOTES

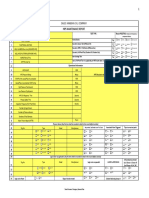

DOWN NO DESCRIPTION (IN) CMDTY CODE QTY 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

PIPE 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

CA 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

L 1 PIPE, API 5L GR. B, FBE LINED, B36.10M, 10 PAAEAP-SA 2.8 M

NO LED

(B) BOLT HOLES ON FLANGES STRADDLE C. (C) WELDING ELBOWS ARE LONG RADIUS.

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

RT

H

SMLS, BE, S-40 6. GASKET ALLOWANCE REFER TO BILL OF MATERIALS .

7. PIPING MATERIAL IS

FITTINGS PIPE SIZE SCHEDULE SPECIFICATION

2 WELDOLET, A105N, MSS SP-97, BW, S-STD X 20X10 WNAYAF-SA 1 10 " S-40 1LE0P01

S-STD

3 ELBOW 90, A234 GR. WPB, FBE LINED, 10 WLAEAP-SA 3

B16.9, SMLS, BW, S-40

FLANGES 8. WELDING STRESS RELIEF - YES NO X

CONT. ON

4 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 10 HAAEXP-SA 6 RADIOGRAPHY % 100% X-RAY SPOT X-RAY 01-SAMSS-10 SHOP X FIELD

RB-666210 SHT. 002 9. TESTING SHOP HYDROSTATIC TEST - YES X NO

CL 150, S-40

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

E 9109497 THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

5 FLANGE WITH JACKSCREWS, A105N, FBE 10 HAAEXPJ-SA 1

N 9770918 LINED, B16.5, AC-036630, WN, FF, CL 150,

FLANGED. HYDROSTATIC PRESSURE

TEST MEDIUM

EL +103267 6210-001-SPL-003 S-40 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION

SAES-L-105 CLASS 1LE0P01 . ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

11. INSULATION REQUIRED - YES NO X

PIPE SUPPORTS INSULATION SHOWN ON DRAWING NA

INSULATION THICKNESS -

12 1 12 6 REST 10 PS-340 1 INSULATION TYPE -

85

10

12. STRESS ANALYSIS REQUIRED - YES NO X

"N 13. PAINTING - YES X NO

PD 11EC 14. ALL DIMENSIONS AND ELEVATIONS ARE IN METRIC UNITS (MILLIMETER) UNLESS OTHERWISE NOTED.

FIELD MATERIALS 15. ALL DIMENSIONS AND COORDINATES SHALL BE FIELD VERIFIED BEFORE CONSTRUCTION.

F4 G8 B9 16. ALL A/G & U/G GROUND METALLIC PIPING SHALL BE EXT. PAINTED IN ACCORDANCE WITH SAES-H-001/002.

74 17. BEVEL HEAVY WALL THICKNESS FITTINGS AND FLANGES PRIOR TO FBE COATING, TO MATCH PIPE

S6 2 PT NPD THICKNESS.

18. ALL VENTS, DRAINS, ANCHOR FLANGE, SUPPORT WEAR PAD, SADDLE PLATE CONNECTION OR ANY OTHER

REST NO DESCRIPTION (IN) CMDTY CODE QTY WELDING WHICH MAY DAMAGE INT./EXT. FBE COATING OF THE PIPE SHALL BE CARRIED OUT ON BARE PIPE

481 SPOOLS PRIOR TO INT./EXT. FBE COATING.

PS-340 FITTINGS 19. BREAK FLANGES HAVE BEEN PROVIDED FOR FRE COATING BASED ON RECEIVED SUPPLIER PROCEDURES,

09EC 3 ISOMETRIC DRAWINGS TO BE SENT FOR FRE CONTRACTOR FOR REVIEW AND CONFIRMATION PRIOR TO

FABRICATION.

6210-001-SPL-002 7 SPECTACLE PLATE, A516 GR. 70, FBE LINED, 10 ZDAAAP-SA 1

AS PER STD AD-036631-001, FF, CL 150 SPOOLS TO BE FABRICATED BY VENDOR

F4 G8 B9 NO. WEIGHT NO. WEIGHT

3239

3410 GASKETS PIECES

MARK NO. SIZE

LBS PIECES

MARK NO. SIZE

LBS

77

07 11 1 10 8 GASKET, FULL FACE, FLAT RING, 1.6MM, 10 XAAANN-SA 6

F4 SELF CENTERING, B16.21, SYNTHETIC FIBER,

CL 150

08

F4 3 BOLTS

3 EL +103267

9 STUD BOLT, A193 GR. B7 / A194 GR. 2H 7/8 YZZZFO-SA 48

06EC NUT, ASME B1.1, SEMI FINISHED HEAVY

05EC PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER

481 COATED, 115MM LENGTH

10 STUD BOLT, A193 GR. B7 / A194 GR. 2H 7/8 YZZZFO-SA 12 SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

F4 G8 B9 04EC NUT, ASME B1.1, SEMI FINISHED HEAVY NO. NO.

MARK NO. SIZE MARK NO. SIZE

PIECES

PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER PIECES

COATED, 130MM LENGTH

481

VALVES/INLINE ITEMS

11 GATE VALVE, A216 WCB WITH FBE LINED 10 AA274E-SA 1

1

BODY, BB, OS&Y, GRAPHITE PACKING, TRIM

ASTM A182 F55, API 600, 04-SAMSS-001,

FF, CL 150, HW

1729

481

850

6210-001-SPL-001

REFERENCE DRAWINGS

DWG. CONTROL FOR J.O. 10-09461-0001 RD-665936

PIPING PLAN DA-780049.001

P&ID RA-665948.001

LINE DESIGNATION TABLE RD-6615980

PIPING MATERIAL SPECIFICATION RE-666005

03 PIPE SUPPORT DETAILS RC-666265

7

TAIL S Operating 5.2 55.6

F5 G8 17 330 Design 15.5 93.3

Condition PRESSURE TEMP

barg DEG. C

432

11 G8 B10 REVISION VALIDATION

STEM SOUTH

F4 G8 B9 PD THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

0 "N REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

2 2 10-09641-0001-001

PD 20X10"NPD

2 0" N TIE-IN No.

DESIGN CERTIFICATION

(DESIGN AGENCY)

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

OTHER

CONT. ON 10-09461-0001 ENGG./DATE CERTIFIED BY / DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

AAI SSQ SSQ HMM

G57 001 01/24/21 01/24/21 01/24/21 01/24/21

LINE NO.:20"-SW-946-1A1M REV. NO. DATE REVISION DESCRIPTION

E 9107837 00 01/24/21 ISSUED FOR CONSTRUCTION

N 9768668 JOB ORDER/EWO NO. THIS REVISION IS NOT TO BE USED FOR

EL +100754 10-09461-0001 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

ISO: 10"-P-9828-1LE0P01 ISO

RECOVERED OIL SYSTEM

DESIGN OPERATING TEST PRESS. TEST RADIOGRAPHY % INSULATION TRACING PAINTING STRESS LINE ID

CHEMICAL

CLEANING TEMP. PRESS. TEMP. PRESS. (PSIG) MEDIUM SHOP FIELD THK. TYPE SYS NO. WET CRUDE FACILITIES

(PSIG) (INCH.)

(DEG. F) (DEG. F) (PSIG) SAFANIYA SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

NO 200.0 225.0 132.0 75.4 375.0 WATER 10% - - NO YES P-9828

G26 L RB-666210 001 00

Saudi Aramco 2825 ENG. (05/05)

PipngG26G26_R0 RESTRICTED SMART CADD-03

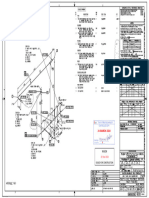

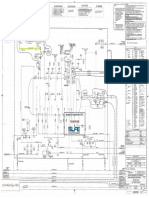

UP STANDARD DETAIL REFERENCE DRAWINGS

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

AWAY

INSULATION DETAILS FOR HOT PIPING AA-036911

INSULATION DETAILS FOR COLD PIPING AA-036913

INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

SHOP MATERIALS

TOWARD

TOWARD

PT NPD NOTES

DOWN NO DESCRIPTION (IN) CMDTY CODE QTY 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

PIPE 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

CA 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

L 1 PIPE, API 5L GR. B, FBE LINED, B36.10M, 10 PAAEAP-SA 10.6 M

NO LED

(B) BOLT HOLES ON FLANGES STRADDLE C. (C) WELDING ELBOWS ARE LONG RADIUS.

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

RT

H

SMLS, BE, S-40 6. GASKET ALLOWANCE REFER TO BILL OF MATERIALS .

2 PIPE, CU/NI 90-10, UNS C7060X, EEMUA 1 PAAMCN-SA 0.1 M 7. PIPING MATERIAL IS

234, SMLS, BE, PN 16 PIPE SIZE SCHEDULE SPECIFICATION

10 " S-40 1LE0P01

FITTINGS 2" S-XS 1LE0P01

3 WELDOLET, A105N, FBE LINED, MSS SP-97, 10X2 WNAXAP-SA 1 1" 2.5 MM 1BD0U01

BW, S-40 X S-XS

4 ELBOW 90, A234 GR. WPB, FBE LINED, 10 WLAEAP-SA 1

B16.9, SMLS, BW, S-40 8. WELDING STRESS RELIEF - YES NO X

5 CONNECTOR, CU/NI 90-10, UNS C7060X, 1 ZOZUCN-SA 1 RADIOGRAPHY % 100% X-RAY SPOT X-RAY 01-SAMSS-10 SHOP X FIELD

EEMUA 234, SMLS, SW X MNPT, PN 16 9. TESTING SHOP HYDROSTATIC TEST - YES X NO

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

FLANGES FLANGED. HYDROSTATIC PRESSURE

TEST MEDIUM

6 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 10 HAAEXP-SA 4 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION

SAES-L-105 CLASS 1LE0P01 . ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

CL 150, S-40 11. INSULATION REQUIRED - YES NO X

7 REDUCING FLANGE, CU/NI 90-10, UNS 2X1 JAAZCN-SA 1 INSULATION SHOWN ON DRAWING NA

6210-001-SPL-005 C7060X, SOLID SLIP-ON TYPE, EEMUA 234, INSULATION THICKNESS -

-

INSULATION TYPE

SW, FF, PN 16 12. STRESS ANALYSIS REQUIRED - YES NO X

8 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 2 HAAXXP-SA 1 13. PAINTING - YES X NO

CL 150, S-XS 14. ALL DIMENSIONS AND ELEVATIONS ARE IN METRIC UNITS (MILLIMETER) UNLESS OTHERWISE NOTED.

15. ALL DIMENSIONS AND COORDINATES SHALL BE FIELD VERIFIED BEFORE CONSTRUCTION.

CLASS: 16. ALL A/G & U/G GROUND METALLIC PIPING SHALL BE EXT. PAINTED IN ACCORDANCE WITH SAES-H-001/002.

1BD0U01 E 9109497 18 VALVES/INLINE ITEMS 17. BEVEL HEAVY WALL THICKNESS FITTINGS AND FLANGES PRIOR TO FBE COATING, TO MATCH PIPE

THICKNESS.

N 9778574 9 GATE VALVE, BRONZE B61 BODY, SCR. BNT., 1 AR647-SA 1

18. ALL VENTS, DRAINS, ANCHOR FLANGE, SUPPORT WEAR PAD, SADDLE PLATE CONNECTION OR ANY OTHER

WELDING WHICH MAY DAMAGE INT./EXT. FBE COATING OF THE PIPE SHALL BE CARRIED OUT ON BARE PIPE

EL +103692 ISRS, TRIM AL-BR, MSS SP-80, FNPT, CL SPOOLS PRIOR TO INT./EXT. FBE COATING.

17 19. BREAK FLANGES HAVE BEEN PROVIDED FOR FRE COATING BASED ON RECEIVED SUPPLIER PROCEDURES,

20 300, HW (TYPE 2) ISOMETRIC DRAWINGS TO BE SENT FOR FRE CONTRACTOR FOR REVIEW AND CONFIRMATION PRIOR TO

FABRICATION.

4 10

9 SPOOLS TO BE FABRICATED BY VENDOR

166

16 FIELD MATERIALS NO. WEIGHT NO. WEIGHT

CLASS: C5 STEM NORTH PIECES

MARK NO. SIZE

LBS PIECES

MARK NO. SIZE

LBS

1LE0P01 1 PT NPD

16 NO DESCRIPTION (IN) CMDTY CODE QTY

2

06 237

2147

727 F7 15 6210-001-SPL-004

FITTINGS

481 2X1"NPD

1

10"NPD

10 PLUG, CU/NI 90-10, UNS C7060X, HEXAGONAL 1 TVZZCN-SA 1

34 F8 G12 B14 HEAD, EEMUA 234, MNPT

4

1

21EC GASKETS

N 9778574

3 Design Pipe Assembly 11 GASKET, FULL FACE, FLAT RING, 1.6MM, 10 XAAANN-SA 2

F6 G11 B13 F6 G11 B13 F6 10X2"NPD REST SELF CENTERING, B16.21, SYNTHETIC FIBER,

CL 150 SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

NO.

CONT. ON 12 INSULATING GASKET SET, GLASS REINFORCED 2 ZBAAAG-SA 1 NO.

PIECES

MARK NO. SIZE

PIECES

MARK NO. SIZE

RB-666210 SHT. 003 14 EPOXY NEMA G10 OR G11 W/TEFLON SEALS

E 9109497 1/8" THK, SLEEVES AND WASHERS, SASD.

N 9780526 AA-036865, FF, CL 150

19EC EL +101118 13

76 BOLTS

56

13A 13 STUD BOLT, A193 GR. B7 / A194 GR. 2H 7/8 YZZZFO-SA 24

NUT, ASME B1.1, SEMI FINISHED HEAVY

10 PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER

"N

40 PD COATED, 115MM LENGTH

58

14 STUD BOLT, A193 GR. B7 / A194 GR. 2H 5/8 YZZZFO-SA 4

F6 NUT, ASME B1.1, SEMI FINISHED HEAVY REFERENCE DRAWINGS

PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER

COATED, 100MM LENGTH DWG. CONTROL FOR J.O. 10-09461-0001 RD-665936

PIPING PLAN DA-780049.001

P&ID RA-665948.001

LINE DESIGNATION TABLE RD-6615980

CONT. TO PIPING MATERIAL SPECIFICATION RE-666005

RB-666210 SHT. 001 PIPE SUPPORT DETAILS RC-666265

E 9109497

N 9770918 Operating 5.2 55.6

EL +103267

Design 15.5 93.3

Condition PRESSURE TEMP

barg DEG. C

REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

10-09641-0001-001

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY / DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

AAI SSQ SSQ HMM

01/24/21 01/24/21 01/24/21 01/24/21

REV. NO. DATE REVISION DESCRIPTION

00 01/24/21 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO. THIS REVISION IS NOT TO BE USED FOR

10-09461-0001 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

ISO: 10"-P-9828-1LE0P01 ISO

RECOVERED OIL SYSTEM

DESIGN OPERATING TEST PRESS. TEST RADIOGRAPHY % INSULATION TRACING PAINTING STRESS LINE ID

CHEMICAL

CLEANING TEMP. PRESS. TEMP. PRESS. (PSIG) MEDIUM SHOP FIELD THK. TYPE SYS NO. WET CRUDE FACILITIES

(PSIG) (INCH.)

(DEG. F) (DEG. F) (PSIG) SAFANIYA SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

NO 200.0 225.0 132.0 75.4 375.0 WATER 10% - - NO YES P-9828

G26 L RB-666210 002 00

Saudi Aramco 2825 ENG. (05/05)

PipngG26G26_R0 RESTRICTED SMART CADD-03

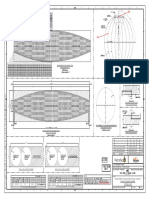

UP STANDARD DETAIL REFERENCE DRAWINGS

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

AWAY

INSULATION DETAILS FOR HOT PIPING AA-036911

INSULATION DETAILS FOR COLD PIPING AA-036913

INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

SHOP MATERIALS

TOWARD

TOWARD

PT NPD NOTES

DOWN NO DESCRIPTION (IN) CMDTY CODE QTY 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

PIPE 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

CA 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

L 1 PIPE, API 5L GR. B, FBE LINED, B36.10M, 10 PAAEAP-SA 14.5 M

NO LED

(B) BOLT HOLES ON FLANGES STRADDLE C. (C) WELDING ELBOWS ARE LONG RADIUS.

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

RT

H

SMLS, BE, S-40 6. GASKET ALLOWANCE REFER TO BILL OF MATERIALS .

2 PIPE, CU/NI 90-10, UNS C7060X, EEMUA 1 PAAMCN-SA 0.2 M 7. PIPING MATERIAL IS

234, SMLS, BE, PN 16 PIPE SIZE SCHEDULE SPECIFICATION

10 " S-40 1LE0P01

FITTINGS 2" S-XS 1LE0P01

3 WELDOLET, A105N, FBE LINED, MSS SP-97, 10X2 WNAXAP-SA 2 1" 2.5 MM 1BD0U01

BW, S-40 X S-XS

4 ELBOW 90, A234 GR. WPB, FBE LINED, 10 WLAEAP-SA 1

B16.9, SMLS, BW, S-40 8. WELDING STRESS RELIEF - YES NO X

5 CONNECTOR, CU/NI 90-10, UNS C7060X, 1 ZOZUCN-SA 2 RADIOGRAPHY % 100% X-RAY SPOT X-RAY 01-SAMSS-10 SHOP X FIELD

EEMUA 234, SMLS, SW X MNPT, PN 16 9. TESTING SHOP HYDROSTATIC TEST - YES X NO

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

FLANGES FLANGED. HYDROSTATIC PRESSURE

TEST MEDIUM

6210-003-SPL-001 6 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 10 HAAEXP-SA 6 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION

SAES-L-105 CLASS 1LE0P01 . ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

CL 150, S-40 11. INSULATION REQUIRED - YES NO X

7 REDUCING FLANGE, CU/NI 90-10, UNS 2X1 JAAZCN-SA 2 INSULATION SHOWN ON DRAWING NA

6210-003-SPL-002 CONT. TO C7060X, SOLID SLIP-ON TYPE, EEMUA 234, INSULATION THICKNESS -

RB-666210 SHT. 002 SW, FF, PN 16 INSULATION TYPE -

12. STRESS ANALYSIS REQUIRED - YES NO X

E 9109497 8 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 2 HAAXXP-SA 2 13. PAINTING - YES X NO

N 9780526 CL 150, S-XS 14. ALL DIMENSIONS AND ELEVATIONS ARE IN METRIC UNITS (MILLIMETER) UNLESS OTHERWISE NOTED.

E 9108564 15. ALL DIMENSIONS AND COORDINATES SHALL BE FIELD VERIFIED BEFORE CONSTRUCTION.

EL +101118 16. ALL A/G & U/G GROUND METALLIC PIPING SHALL BE EXT. PAINTED IN ACCORDANCE WITH SAES-H-001/002.

N 9780538 VALVES/INLINE ITEMS 17. BEVEL HEAVY WALL THICKNESS FITTINGS AND FLANGES PRIOR TO FBE COATING, TO MATCH PIPE

6210-003-SPL-003 03A THICKNESS.

F8 G15 B17 9 GATE VALVE, BRONZE B61 BODY, SCR. BNT., 1 AR647-SA 2

18. ALL VENTS, DRAINS, ANCHOR FLANGE, SUPPORT WEAR PAD, SADDLE PLATE CONNECTION OR ANY OTHER

WELDING WHICH MAY DAMAGE INT./EXT. FBE COATING OF THE PIPE SHALL BE CARRIED OUT ON BARE PIPE

F6 G14 B16 ISRS, TRIM AL-BR, MSS SP-80, FNPT, CL SPOOLS PRIOR TO INT./EXT. FBE COATING.

05EC 3 19. BREAK FLANGES HAVE BEEN PROVIDED FOR FRE COATING BASED ON RECEIVED SUPPLIER PROCEDURES,

300, HW (TYPE 2) ISOMETRIC DRAWINGS TO BE SENT FOR FRE CONTRACTOR FOR REVIEW AND CONFIRMATION PRIOR TO

10X2"NPD 01 FABRICATION.

06 05A 03 PIPE SUPPORTS SPOOLS TO BE FABRICATED BY VENDOR

622 1384 NO. WEIGHT NO. WEIGHT

05B 10"NPD 10 DS-A-8-462-Y-10-P 10 PS-339 1 MARK NO. SIZE MARK NO. SIZE

934

PIECES LBS PIECES LBS

CLASS:

1LE0P01

18 555 F6 11 REST 10 SL-350 1

09

12 GG-A-10-3 10 GUIDE 1

F6 G14 B16 1 481

07 E 9108564

N 9780538 3 FIELD MATERIALS

616 6

2

F6 G14 B16 EL +100211 643 04 PT NPD

237 NO DESCRIPTION (IN) CMDTY CODE QTY

F6 166

CLASS: C5

FITTINGS SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

1LE0P01 02

1 10 11 13 13 PLUG, CU/NI 90-10, UNS C7060X, HEXAGONAL 1 TVZZCN-SA 2 NO.

PIECES

MARK NO. SIZE

NO.

PIECES

MARK NO. SIZE

E 9093916 DRAIN HEAD, EEMUA 234, MNPT

N 9780738 3

730 4 GASKETS

F6 G14 B16 F7 EL +100637

S11 2X1"NPD 14 GASKET, FULL FACE, FLAT RING, 1.6MM, 10 XAAANN-SA 5

SELF CENTERING, B16.21, SYNTHETIC FIBER,

19 REST

330 353 89.2° SL-350

9 CL 150

STEM UP CLASS: STEM EAST 15 INSULATING GASKET SET, GLASS REINFORCED 2 ZBAAAG-SA 2

1BD0U01 EPOXY NEMA G10 OR G11 W/TEFLON SEALS

2 67 S10 1/8" THK, SLEEVES AND WASHERS, SASD.

1 16 WELDED SUPPORT

G14 B16 F8 G15 B17 AA-036865, FF, CL 150

CLASS: DS-A-8-462-Y-10-P

1BD0U01 REFERENCE DRAWINGS

3 PS-339 BOLTS

DWG. CONTROL FOR J.O. 10-09461-0001 RD-665936

2

10X2"NPD

16 STUD BOLT, A193 GR. B7 / A194 GR. 2H 7/8 YZZZFO-SA 60 DA-780049.001

237 PIPING PLAN

08 S12 NUT, ASME B1.1, SEMI FINISHED HEAVY

F7 166 C5 PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER P&ID RA-665948.001

GG-A-10-3

2X1"NPD COATED, 115MM LENGTH LINE DESIGNATION TABLE RD-6615980

14 GUIDE 17 STUD BOLT, A193 GR. B7 / A194 GR. 2H 5/8 YZZZFO-SA 8

PIPING MATERIAL SPECIFICATION RE-666005

22 NUT, ASME B1.1, SEMI FINISHED HEAVY

13 2 PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER PIPE SUPPORT DETAILS RC-666265

DRAIN 9 COATED, 100MM LENGTH

STEM EAST 15

Operating 5.2 55.6

VALVES/INLINE ITEMS

CONT. ON E 9093916 Design 15.5 93.3

RB-666210 SHT. 004 N 9780738 18 CHECK VALVE, A216 WCB WITH FBE LINED 10 CA274E-SA 1 Condition PRESSURE TEMP

barg

EL +100211 BODY, BC, SWING TYPE, TRIM ASTM A182 DEG. C

E 9093230 F55, API 594, 04-SAMSS-005, FF, CL 150

N 9780748 19 GATE VALVE, A216 WCB WITH FBE LINED 10 AA274E-SA 1 REVISION VALIDATION

EL +100637 BODY, BB, OS&Y, GRAPHITE PACKING, TRIM

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

ASTM A182 F55, API 600, 04-SAMSS-001, REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

FF, CL 150, HW 10-09641-0001-001

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

6210-003-SPL-004 ENGG./DATE CERTIFIED BY / DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

AAI SSQ SSQ HMM

01/24/21 01/24/21 01/24/21 01/24/21

REV. NO. DATE REVISION DESCRIPTION

00 01/24/21 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO. THIS REVISION IS NOT TO BE USED FOR

10-09461-0001 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

ISO: 10"-P-9828-1LE0P01 ISO

RECOVERED OIL SYSTEM

DESIGN OPERATING TEST PRESS. TEST RADIOGRAPHY % INSULATION TRACING PAINTING STRESS LINE ID

CHEMICAL

CLEANING TEMP. PRESS. TEMP. PRESS. (PSIG) MEDIUM SHOP FIELD THK. TYPE SYS NO. WET CRUDE FACILITIES

(PSIG) (INCH.)

(DEG. F) (DEG. F) (PSIG) SAFANIYA SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

NO 200.0 225.0 132.0 75.4 375.0 WATER 10% - - NO YES P-9828

G26 L RB-666210 003 00

Saudi Aramco 2825 ENG. (05/05)

PipngG26G26_R0 RESTRICTED SMART CADD-03

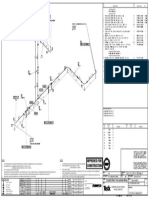

UP STANDARD DETAIL REFERENCE DRAWINGS

DETAIL OF HEAVY WELDING BOSSES FOR THREADED CONNECTIONS AE-036175

AWAY CONSTRUCTION-NOTES AND DETAILS FOR ISOMETRIC PIPING AD-036627

AWAY

INSULATION DETAILS FOR HOT PIPING AA-036911

INSULATION DETAILS FOR COLD PIPING AA-036913

INSTALLATION OF JACK SCREWS FOR FLANGED JOINTS AC-036630

SHOP MATERIALS

TOWARD

TOWARD

PT NPD NOTES

DOWN NO DESCRIPTION (IN) CMDTY CODE QTY 1. MATERIAL SHOWN WITH A BROKEN LINE AND SPOOLS LISTED IN THE SAUDI ARAMCO

FABRICATION LIST ARE NOT TO BE FURNISHED BY THE VENDOR.

2. PIPING DETAILS SHALL BE CUT AT ALL POINTS MARKED F.W. (FIELD WELD).

PIPE 3. EACH FABRICATED SECTION SHALL BE CLEARLY MARKED WITH ITS CODE NUMBER.

CA 4. UNLESS OTHERWISE NOTED. (A) ALL DIMENSIONS ARE TO C OR FACE OF FLANGES.

L 1 PIPE, API 5L GR. B, FBE LINED, B36.10M, 10 PAAEAP-SA 3.6 M

NO LED

(B) BOLT HOLES ON FLANGES STRADDLE C. (C) WELDING ELBOWS ARE LONG RADIUS.

5. FABRICATION SHALL BE IN ACCORDANCE WITH SAUDI ARAMCO SPECIFICATION 01-SAMSS-10.

RT

H

SMLS, BE, S-40 6. GASKET ALLOWANCE REFER TO BILL OF MATERIALS .

2 PIPE, CU/NI 90-10, UNS C7060X, EEMUA 1 PAAMCN-SA 0.1 M 7. PIPING MATERIAL IS

234, SMLS, BE, PN 16 PIPE SIZE SCHEDULE SPECIFICATION

10 " S-40 1LE0P01

FITTINGS 2" S-XS 1LE0P01

3 WELDOLET, A105N, FBE LINED, MSS SP-97, 10X2 WNAXAP-SA 1 1" 2.5 MM 1BD0U01

BW, S-40 X S-XS

4 CONNECTOR, CU/NI 90-10, UNS C7060X, 1 ZOZUCN-SA 1

EEMUA 234, SMLS, SW X MNPT, PN 16 8. WELDING STRESS RELIEF - YES NO X

RADIOGRAPHY % 100% X-RAY SPOT X-RAY 01-SAMSS-10 SHOP X FIELD

FLANGES 9. TESTING SHOP HYDROSTATIC TEST - YES X NO

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL, OR IN PART, SHALL BE OBTAINED FROM THIS DRAWING WITHOUT THE WRITTEN CONSENT OF SAUDI ARAMCO.

THE SHOP HYDROSTATIC TEST SHALL BE CARRIED OUT ON PIECES HAVING ALL ENDS

5 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 10 HAAEXP-SA 4 FLANGED. HYDROSTATIC PRESSURE

CL 150, S-40 TEST MEDIUM

6 REDUCING FLANGE, CU/NI 90-10, UNS 2X1 JAAZCN-SA 1 10. ALL PIPING MATERIAL IS IN ACCORDANCE WITH SAUDI ARAMCO ENGINEERING SPECIFICATION

SAES-L-105 CLASS 1LE0P01 . ALL EXCEPTIONS ARE NOTED ON THE ISOMETRIC.

C7060X, SOLID SLIP-ON TYPE, EEMUA 234, 11. INSULATION REQUIRED - YES NO X

SW, FF, PN 16 INSULATION SHOWN ON DRAWING NA

7 FLANGE, A105N, FBE LINED, B16.5, WN, FF, 2 HAAXXP-SA 1 INSULATION THICKNESS -

-

INSULATION TYPE

CL 150, S-XS 12. STRESS ANALYSIS REQUIRED - YES NO X

13. PAINTING - YES X NO

VALVES/INLINE ITEMS 14. ALL DIMENSIONS AND ELEVATIONS ARE IN METRIC UNITS (MILLIMETER) UNLESS OTHERWISE NOTED.

15. ALL DIMENSIONS AND COORDINATES SHALL BE FIELD VERIFIED BEFORE CONSTRUCTION.

8 GATE VALVE, BRONZE B61 BODY, SCR. BNT., 1 AR647-SA 1 16.

17.

ALL A/G & U/G GROUND METALLIC PIPING SHALL BE EXT. PAINTED IN ACCORDANCE WITH SAES-H-001/002.

BEVEL HEAVY WALL THICKNESS FITTINGS AND FLANGES PRIOR TO FBE COATING, TO MATCH PIPE

ISRS, TRIM AL-BR, MSS SP-80, FNPT, CL THICKNESS.

18. ALL VENTS, DRAINS, ANCHOR FLANGE, SUPPORT WEAR PAD, SADDLE PLATE CONNECTION OR ANY OTHER

300, HW (TYPE 2) WELDING WHICH MAY DAMAGE INT./EXT. FBE COATING OF THE PIPE SHALL BE CARRIED OUT ON BARE PIPE

CONT. TO SPOOLS PRIOR TO INT./EXT. FBE COATING.

19. BREAK FLANGES HAVE BEEN PROVIDED FOR FRE COATING BASED ON RECEIVED SUPPLIER PROCEDURES,

RB-666210 SHT. 003 INSTRUMENTS ISOMETRIC DRAWINGS TO BE SENT FOR FRE CONTRACTOR FOR REVIEW AND CONFIRMATION PRIOR TO

FABRICATION.

E 9093230 9 INST 10 G26-ZV-5961 1

N 9780748 SPOOLS TO BE FABRICATED BY VENDOR

EL +100637 PIPE SUPPORTS NO.

PIECES

MARK NO. SIZE

WEIGHT

LBS

NO.

PIECES

MARK NO. SIZE

WEIGHT

LBS

E 9091676 10 REST 10 SL-349 1

N 9780769 850

4

155 FIELD MATERIALS

NPD

10"

F5 PT NPD

F5 G12 B14

G26 NO DESCRIPTION (IN) CMDTY CODE QTY

ZV 165 281

FITTINGS

5961

S10 11 PLUG, CU/NI 90-10, UNS C7060X, HEXAGONAL 1 TVZZCN-SA 1

9 1 HEAD, EEMUA 234, MNPT SPOOLS TO BE FABRICATED BY SAUDI ARAMCO

REST

NO.

F5 G12 SL-349

NO.

MARK NO. SIZE MARK NO. SIZE

GASKETS PIECES PIECES

9 12 GASKET, FULL FACE, FLAT RING, 1.6MM, 10 XAAANN-SA 2

211 237 SELF CENTERING, B16.21, SYNTHETIC FIBER,

3

CL 150

10X2"NPD

2

CLASS: 13 INSULATING GASKET SET, GLASS REINFORCED 2 ZBAAAG-SA 1

F7 G13 B15 EPOXY NEMA G10 OR G11 W/TEFLON SEALS

1LE0P01 1/8" THK, SLEEVES AND WASHERS, SASD.

1 AA-036865, FF, CL 150

F5

166

CLASS: BOLTS

1BD0U01 C4 E 9091676

89.2° 14 STUD BOLT, A193 GR. B7 / A194 GR. 2H 7/8 YZZZFO-SA 12 REFERENCE DRAWINGS

N 9780769

11 NUT, ASME B1.1, SEMI FINISHED HEAVY

22 EL +100211 PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER DWG. CONTROL FOR J.O. 10-09461-0001 RD-665936

41 8 DRAIN

COATED, 280MM LENGTH PIPING PLAN DA-780049.001

STEM EAST 15 STUD BOLT, A193 GR. B7 / A194 GR. 2H 5/8 YZZZFO-SA 4 P&ID RA-665948.001

F6 NUT, ASME B1.1, SEMI FINISHED HEAVY

LINE DESIGNATION TABLE RD-6615980

2X1"NPD PATTERN W/ HEAVY HEX NUTS, FLUOROPOLYMER

56 COATED, 100MM LENGTH PIPING MATERIAL SPECIFICATION RE-666005

PIPE SUPPORT DETAILS RC-666265

CONT. ON

Operating 5.2 55.6

LINE NO.:10"-P-9825-1LE0P01 Design 15.5 93.3

E 9089108 Condition PRESSURE

barg

TEMP

DEG. C

N 9780804

EL +100637

REVISION VALIDATION

THIS REVISION NO. 00 IS COVERED, FOR ALL APPROVAL AND CERTIFICATION

REQUIREMENTS, PER SAEP-334, UNDER DRAWING COMPLETION CERTIFICATE NO:

10-09641-0001-001

DESIGN CERTIFICATION REVIEW FOR KEY DRAWINGS OTHER

(DESIGN AGENCY) REQUIRED (SAUDI ARAMCO)

ENGG./DATE CERTIFIED BY / DATE CONST. AGENCY/DATE OPERATIONS/DATE BY/DATE

AAI SSQ SSQ HMM

01/24/21 01/24/21 01/24/21 01/24/21

REV. NO. DATE REVISION DESCRIPTION

00 01/24/21 ISSUED FOR CONSTRUCTION

JOB ORDER/EWO NO. THIS REVISION IS NOT TO BE USED FOR

10-09461-0001 CONSTRUCTION UNTIL CERTIFIED AND DATED

SAUDI ARABIAN OIL COMPANY

DRAWING TYPE

ISO: 10"-P-9828-1LE0P01 ISO

RECOVERED OIL SYSTEM

DESIGN OPERATING TEST PRESS. TEST RADIOGRAPHY % INSULATION TRACING PAINTING STRESS LINE ID

CHEMICAL

CLEANING TEMP. PRESS. TEMP. PRESS. (PSIG) MEDIUM SHOP FIELD THK. TYPE SYS NO. WET CRUDE FACILITIES

(PSIG) (INCH.)

(DEG. F) (DEG. F) (PSIG) SAFANIYA SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

NO 200.0 225.0 132.0 75.4 375.0 WATER 10% - - NO YES P-9828

G26 L RB-666210 004 00

Saudi Aramco 2825 ENG. (05/05)

PipngG26G26_R0 RESTRICTED SMART CADD-03

You might also like

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- Starbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendDocument56 pagesStarbucks: General Notes Project Contacts Index of Sheets Abbreviations Architectural Symbol LegendMmr Pré MoldadosNo ratings yet

- Safety Requirements for ScaffoldsDocument16 pagesSafety Requirements for ScaffoldschassasNo ratings yet

- QA/QC Requirements for Sprinkler NozzlesDocument4 pagesQA/QC Requirements for Sprinkler NozzlesAhmed BoraeyNo ratings yet

- Planos Electricos Invertex 2 Serie 31875 UpDocument23 pagesPlanos Electricos Invertex 2 Serie 31875 UpHéctorHernándezDíazNo ratings yet

- FM-200 - 068-007 SHT of 1 Installation & Mounting DetailsDocument1 pageFM-200 - 068-007 SHT of 1 Installation & Mounting DetailsAhmed SweetNo ratings yet

- Field Joint Samples ProvidedDocument11 pagesField Joint Samples ProvidedSAGARNo ratings yet

- FB Hotel Tower and Convention Center Structural Drawings: Oudie SsociatesDocument36 pagesFB Hotel Tower and Convention Center Structural Drawings: Oudie Ssociatesabet hilarioNo ratings yet

- Design Fluidized Bed Reactor for Acrylic Acid ProductionDocument46 pagesDesign Fluidized Bed Reactor for Acrylic Acid Productionlily89% (9)

- Annexure - 1 Part D Subcontract Agreement (Sample Copy)Document6 pagesAnnexure - 1 Part D Subcontract Agreement (Sample Copy)Ahmed BoraeyNo ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- General Notes: Abbrevations: Symbols: Fire Protection:: Schedule of Equipments Vicinity MapDocument12 pagesGeneral Notes: Abbrevations: Symbols: Fire Protection:: Schedule of Equipments Vicinity MapHelios100% (1)

- R901085031P00Document1 pageR901085031P00Rene HebaNo ratings yet

- R82-002 - Done 5Document1 pageR82-002 - Done 5rsmjuleyNo ratings yet

- R901085037P00Document1 pageR901085037P00Rene HebaNo ratings yet

- R901085028P00Document1 pageR901085028P00Rene HebaNo ratings yet

- R901085032P00Document1 pageR901085032P00Rene HebaNo ratings yet

- R901085036P00Document1 pageR901085036P00Rene HebaNo ratings yet

- T013515002V0F1Document1 pageT013515002V0F1haseebrazvi1No ratings yet

- T013461001V0F1Document1 pageT013461001V0F1haseebrazvi1No ratings yet

- T013512001V0F1Document1 pageT013512001V0F1haseebrazvi1No ratings yet

- T013514004V0F1Document1 pageT013514004V0F1haseebrazvi1No ratings yet

- T013514003V0F1Document1 pageT013514003V0F1haseebrazvi1No ratings yet

- T013482001V0F1Document1 pageT013482001V0F1haseebrazvi1No ratings yet

- ISOMETRIC ROUTING AND MATERIAL DETAILS FOR GP TRAINS 02/03/04Document1 pageISOMETRIC ROUTING AND MATERIAL DETAILS FOR GP TRAINS 02/03/04Sajeed ZaheerNo ratings yet

- T013482002V0F1Document1 pageT013482002V0F1haseebrazvi1No ratings yet

- T013458001V0F1Document1 pageT013458001V0F1haseebrazvi1No ratings yet

- T013519001V0F1Document1 pageT013519001V0F1haseebrazvi1No ratings yet

- C254977001P Rev01cDocument1 pageC254977001P Rev01cRAJA MOHD IRFAN KHANNo ratings yet

- Erection Materials: DetailDocument1 pageErection Materials: DetailMohammed Omer AliNo ratings yet

- Cable ladder tray material summaryDocument1 pageCable ladder tray material summaryaung aungNo ratings yet

- Site LayoutDocument1 pageSite LayoutMbalekelwa MpembeNo ratings yet

- Perspective View: Schedule of DrawingsDocument9 pagesPerspective View: Schedule of DrawingsChristel JuañoNo ratings yet

- Dish End Dimension ListDocument1 pageDish End Dimension ListShanmuganathan ShanNo ratings yet

- C MEC DWG 730 40554 B - Code 1Document1 pageC MEC DWG 730 40554 B - Code 1Ramzi ZoghlamiNo ratings yet

- CA-033700-011 - 00a - P&id - Interconnects - Process Waste WaterDocument1 pageCA-033700-011 - 00a - P&id - Interconnects - Process Waste Watermigen0831No ratings yet

- Equipment Schedule - Ventilation Basement and 2Nd Floor A/C Ground FloorDocument1 pageEquipment Schedule - Ventilation Basement and 2Nd Floor A/C Ground FloorprokjongNo ratings yet

- Piping SystemDocument1 pagePiping SystemJephthah Jude Tadeo GaleosNo ratings yet

- Bill of Materials: Standard Detail Reference DrawingsDocument8 pagesBill of Materials: Standard Detail Reference Drawingsadeelaslam1211No ratings yet

- VVCMC - C&D - WASTE - TIMBER, GLASS & PLASTIC SHED 20X35 - 08-24-23-Layout2Document1 pageVVCMC - C&D - WASTE - TIMBER, GLASS & PLASTIC SHED 20X35 - 08-24-23-Layout2samir bendreNo ratings yet

- Symbols Description Symbols VSD VariableDocument24 pagesSymbols Description Symbols VSD VariableRifqi IsbillyNo ratings yet

- 1778 4601 TH DWG 003e 3Document1 page1778 4601 TH DWG 003e 3Asyifa AldanaNo ratings yet

- Plan View and Notes for WHP03-PMC2-ASJAA-10-Q45025-0001_rev00Document3 pagesPlan View and Notes for WHP03-PMC2-ASJAA-10-Q45025-0001_rev00Minh DoNo ratings yet

- Block A2 - FEB 24 2021Document15 pagesBlock A2 - FEB 24 2021soso.doniNo ratings yet

- 0550 33010 C1e2b WWS 01 - 0Document1 page0550 33010 C1e2b WWS 01 - 0Matias espinozaNo ratings yet

- 0550 33001 C1e2b We 01 - 0Document1 page0550 33001 C1e2b We 01 - 0Matias espinozaNo ratings yet

- 1914 Boronia Park - A503 (A) DetailsDocument1 page1914 Boronia Park - A503 (A) DetailsariNo ratings yet

- Anchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedDocument1 pageAnchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedbillNo ratings yet

- Girder DWGDocument1 pageGirder DWGAKILESH RAONo ratings yet

- Foundation Offset To ExcavtionDocument1 pageFoundation Offset To ExcavtionAhmed KarimNo ratings yet

- Plan Layout of C.I. Drain: List of Materials NotesDocument1 pagePlan Layout of C.I. Drain: List of Materials NotesHonesto BautistaNo ratings yet

- Longitudinal Elevation: Issue RecordDocument1 pageLongitudinal Elevation: Issue RecordSwapan Kumar BoseNo ratings yet

- YSS SUSPENSION UPGRADES FOR APRILIA SCOOTERSDocument22 pagesYSS SUSPENSION UPGRADES FOR APRILIA SCOOTERSRt OpNo ratings yet

- Re-Issued For Construction: Saudi Arabian Oil CompanyDocument1 pageRe-Issued For Construction: Saudi Arabian Oil CompanyRene HebaNo ratings yet

- KAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFDocument1 pageKAAR COW PW IC NTU FZS DWG STR 24623 Rev.01 PDFSatyanarayana MukkuNo ratings yet

- A17018 Structural DrawingsDocument10 pagesA17018 Structural DrawingsShaheer RizwanNo ratings yet

- Stair ExampleDocument1 pageStair ExampleWinata WinataNo ratings yet

- 01 - General Tracker-1Document4 pages01 - General Tracker-1MAGED ELSADIGNo ratings yet

- TB135483 009Document1 pageTB135483 009Rene HebaNo ratings yet

- Desalination Plant Asbuilt S2Document1 pageDesalination Plant Asbuilt S2Berlin Andrew SionNo ratings yet

- Building permit revision documentsDocument1 pageBuilding permit revision documentskddcNo ratings yet

- Product Specification: Confidential: Property of Strain Measurement Devices, IncDocument1 pageProduct Specification: Confidential: Property of Strain Measurement Devices, IncAbdo RsvNo ratings yet

- Caterpillar IPP Product Line Diesel 3516 GensetsDocument28 pagesCaterpillar IPP Product Line Diesel 3516 GensetsDelio DuranNo ratings yet

- Rawabi Project: Design CriteriaDocument1 pageRawabi Project: Design CriteriaaliiiiiiiiiiNo ratings yet

- 1778 4601 TH DWG 003e 2Document1 page1778 4601 TH DWG 003e 2Asyifa AldanaNo ratings yet

- 01 - General Tracker-2Document22 pages01 - General Tracker-2MAGED ELSADIGNo ratings yet

- Annexure - 11.1 Code of ConductDocument3 pagesAnnexure - 11.1 Code of ConductAhmed BoraeyNo ratings yet

- Skilled WorkerDocument68 pagesSkilled WorkerAhmed BoraeyNo ratings yet

- Annexure - 11.2 Nda For SubcontractorDocument1 pageAnnexure - 11.2 Nda For SubcontractorAhmed BoraeyNo ratings yet

- BS 4 - Grade 7Document2 pagesBS 4 - Grade 7Ahmed BoraeyNo ratings yet

- CVJ 79126225 20231031083643Document5 pagesCVJ 79126225 20231031083643Ahmed BoraeyNo ratings yet

- SPDRequestfor Bids GOODS1 Envelope OCT2017Document139 pagesSPDRequestfor Bids GOODS1 Envelope OCT2017Ahmed BoraeyNo ratings yet

- Risk LectureDocument75 pagesRisk LectureAhmed BoraeyNo ratings yet

- Rading Development-Reda-Nozzles - AckDocument5 pagesRading Development-Reda-Nozzles - AckAhmed BoraeyNo ratings yet

- 603 Stairways and LaddersDocument40 pages603 Stairways and LaddersAhmed BoraeyNo ratings yet

- CertificateOfCompletion - SAP ERP Essential TrainingDocument1 pageCertificateOfCompletion - SAP ERP Essential TrainingAhmed BoraeyNo ratings yet

- CPVC MentDocument5 pagesCPVC MentAhmed BoraeyNo ratings yet

- Sand Test Report Azmil SourseDocument4 pagesSand Test Report Azmil SourseAhmed BoraeyNo ratings yet

- Diameter Ofof NozzelDocument16 pagesDiameter Ofof NozzelAhmed BoraeyNo ratings yet

- Manual-Performing PNS SecurityDocument60 pagesManual-Performing PNS SecurityAhmed BoraeyNo ratings yet

- Ford Flow ViscosityDocument8 pagesFord Flow ViscosityAhmed BoraeyNo ratings yet

- Signed Manifold PackageDocument117 pagesSigned Manifold PackageAhmed BoraeyNo ratings yet

- Batching Plant Document Requirement Front PageDocument1 pageBatching Plant Document Requirement Front PageAhmed BoraeyNo ratings yet

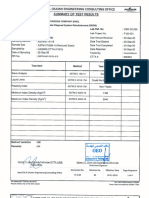

- Saudi Aramco Leak Test ReportDocument1 pageSaudi Aramco Leak Test ReportAhmed BoraeyNo ratings yet

- S NHC CT 005Document7 pagesS NHC CT 005Ahmed BoraeyNo ratings yet

- CounterweightDocument25 pagesCounterweightLami BojaNo ratings yet

- Centrifugal pump lab experimentDocument17 pagesCentrifugal pump lab experimentKarla PerezNo ratings yet

- Handbook of Sewage Treatment PlantDocument7 pagesHandbook of Sewage Treatment PlantVineet ChaudharyNo ratings yet

- Exercises Problem 4 Heat TransferDocument3 pagesExercises Problem 4 Heat TransferMeeko TanNo ratings yet

- MMF feed pump data sheet and performance curveDocument7 pagesMMF feed pump data sheet and performance curveWidhiAhmadNo ratings yet

- ReviewerDocument14 pagesReviewerLigaya FlamehazeNo ratings yet

- Mueller REFRIGERATION PRODUCTSDocument22 pagesMueller REFRIGERATION PRODUCTSgerardoddNo ratings yet

- Thermodynamics Homework - April 9 of 2019Document4 pagesThermodynamics Homework - April 9 of 2019Elias Jose Akle VillarealNo ratings yet

- 35Pfr Plunger Pump Service Manual: 35 Frame Split Manifold: 3507 and 3517Document8 pages35Pfr Plunger Pump Service Manual: 35 Frame Split Manifold: 3507 and 3517Jordan aguilarNo ratings yet

- Thermal Lab Manual GuideDocument100 pagesThermal Lab Manual GuideNegese TeklearegayNo ratings yet

- HYSYS Depressurisation ExampleDocument2 pagesHYSYS Depressurisation ExampleMuhammad Saquib67% (3)

- Certificate: Neltex Development Company IncorporatedDocument3 pagesCertificate: Neltex Development Company IncorporatedEva MarquezNo ratings yet

- Carbofill Dec08Document4 pagesCarbofill Dec08Cristian Andres Araya CisternasNo ratings yet

- EVAPORATION AND DEHYDRATION TECHNIQUESDocument23 pagesEVAPORATION AND DEHYDRATION TECHNIQUESRogelyn JosolNo ratings yet

- Kinetics Mastery AnswersDocument5 pagesKinetics Mastery AnswersAnonymous vRpzQ2BLNo ratings yet

- Assignment L01 (Friday, 9.30) Marking SchemeDocument14 pagesAssignment L01 (Friday, 9.30) Marking SchemeMawareNo ratings yet

- CP 48 Water 2005Document13 pagesCP 48 Water 2005nicky1213aNo ratings yet

- Urzs - D - Ulzs - DB - wk422980 - en - 01-2020-1VALVULAS LOGICASDocument10 pagesUrzs - D - Ulzs - DB - wk422980 - en - 01-2020-1VALVULAS LOGICAS13177566No ratings yet

- Facts at Your Fingertips-200903-Membrane ConfigurationsDocument1 pageFacts at Your Fingertips-200903-Membrane Configurationsonizuka-t2263No ratings yet

- Fluid Engineering Flow in P.Document6 pagesFluid Engineering Flow in P.sunilkumar2685No ratings yet

- Weil Pump CurvesDocument5 pagesWeil Pump CurvesseriouscallerzonlyNo ratings yet

- Modified Point Mass Trajectory SimulationDocument51 pagesModified Point Mass Trajectory SimulationnanocardosoNo ratings yet

- Assignment 2 (334421)Document5 pagesAssignment 2 (334421)AB RehmanNo ratings yet

- GNG HoseDocument3 pagesGNG HoseMehdi SoltaniNo ratings yet

- 4th and 5th WeeksDocument57 pages4th and 5th WeeksnaverfallNo ratings yet

- Vc-90200.01.03-En Ecoline DJDocument6 pagesVc-90200.01.03-En Ecoline DJGary IrawanNo ratings yet

- CTV Compressor Component WeightsDocument1 pageCTV Compressor Component WeightsTrane De Colombia SANo ratings yet