Professional Documents

Culture Documents

Saudi Aramco Leak Test Report

Uploaded by

Ahmed BoraeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Leak Test Report

Uploaded by

Ahmed BoraeyCopyright:

Available Formats

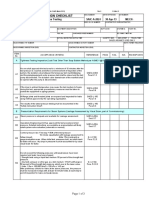

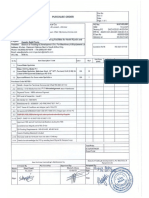

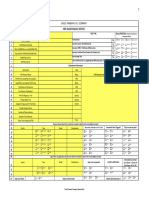

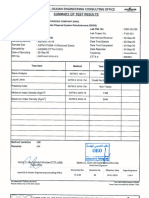

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff -March 2013) Rev 7 31-Mar-13

SATR NUMBER DATE APPROVED DISCIPLINE

SAUDI ARAMCO TEST REPORT

Leak Test Report SATR-A-2010 30-Apr-13 S-NHC-MEC-054

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

REFINED PRODUCT INTERFACE FACILITIES FOR NORTH

RIYADH AND 10-13269 NHC

QASSIM BULK PLANTS

EQUIPMENT ID NUMBER EQUIPMENT DESCRIPTION TEST PACK NO. TEST SYSTEM

LAYOUT DRAWING NUMBER REV. NO. S/U SYSTEM FACILITY P.O. NUMBER

AA-036886 , SHT-001 ,

TASK COMPLETED DATE RFI No. REQUESTED INSPECTION DATE QUANTITY MH's SPENT TRAVEL TIME

10-MAY-2022 , 11:00 AM 10-MAY-2022 , 11:00 AM

System Description:

Certificate No. Date:

Location in Service: Nature of Test: Direct Pressure Bubble Leak Test

Test Procedure in Accordance With: ASME V, Art 10, Mandatory App. I Test Medium: AIR

Pressure Gauges (PG) & Recorders (PR) Temp Gauge/Recorder Relief Valve

PG- PG- TG- TR- RV #

1 Serial No/Tag No. 422100312

2 Make MICHELIN

3 Range 0-150 PSIG

4 Certificate No UIC-SAF-20201676

5 Date Calibrated 13-APRIL-2022

6 Set Pressure

Re-Calibration

7 12-OCT-2022

Due Date

ITEM

No.

Test Parameters Requirements Actual Pass Fail Remarks

Test Medium (Indicate method of Use approved clean air

1

treatment if required) or approved inert gas

CLEAN AIR

Area of interest (Indicate flg joints, All flanges, threads,

2

weld joints, threaded, socket, body) welds, seal welds

WELD JOINTS

Direct Pressure Bubble

3 Method of Leak Detection

Leak Test (Procedure)*

VISUAL

4 Test Pressure: 5-10 psig 10 PSIG

Minimum 15 minutes

5 Duration

soak time before exam

15 MIN

Within temp rating of

6 System Test Temperature

App'd Bubble Solution

AMBIENT

7 Permissible leakage None NO LEAKAGE

Test Accepted. No leaks or loss in pressure observed. List number of leaks

TEST RESULTS: Rejected

and location below

AFFIX ANY TEST TAPE TO THIS REPORT (TEST EVIDENCE)

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements of Pressure Testing, (30 January, 2011)

2. SAES-A-007, Hydrostatic Testing Fluids and Lay-Up Procedures, (24 July 2011)

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Name, Title, Department, Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Company, Initials and Name, Initials and Date:

Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Page 1 of 1

You might also like

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportPradeepNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001GanesanNo ratings yet

- Saudi Aramco Pressure Test ReportDocument6 pagesSaudi Aramco Pressure Test ReportGOSP3 QC MechanicalNo ratings yet

- Saudi Aramco Pressure TestDocument2 pagesSaudi Aramco Pressure Testمحمد علي النويصرNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- SATR-A-2001Document8 pagesSATR-A-2001razzak.me.enggNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001ansar aliNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- SATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Document2 pagesSATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Ahdal NoushadNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13Document2 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13PradeepNo ratings yet

- Saic e 2010Document3 pagesSaic e 2010sureshNo ratings yet

- Saic A 2004Document2 pagesSaic A 2004HabibNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- Test PackDocument17 pagesTest PackMuhammad Bilal Arif100% (3)

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16Document6 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16GOSP3 QC MechanicalNo ratings yet

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17ziaNo ratings yet

- Satr A 2001VDocument8 pagesSatr A 2001Vansar aliNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument7 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurepookkoya thangalNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- Calibration Test ReportDocument8 pagesCalibration Test ReportJagdishNo ratings yet

- Saudi Aramco LV Panelboard TestingDocument4 pagesSaudi Aramco LV Panelboard TestingheikelNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- SAIC-A-2022 Rev 6 Depressure PnematicDocument1 pageSAIC-A-2022 Rev 6 Depressure Pnematicpookkoya thangalNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- Saic A 2004Document8 pagesSaic A 2004karthi51289No ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbSino hydroNo ratings yet

- SATR-B-4001Document2 pagesSATR-B-4001razzak.me.enggNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005karthi51289No ratings yet

- Saudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEDocument2 pagesSaudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEWaleed MedhatNo ratings yet

- 9-Material Treacibility PDFDocument64 pages9-Material Treacibility PDFmamounsdNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- Pressure Testing Report SummaryDocument1 pagePressure Testing Report SummarymomoitachiNo ratings yet

- HT FormDocument1 pageHT FormMohd Effiezool YaserNo ratings yet

- Certificate of Relief Valve Capacity (PROCA) 7 PDFDocument1 pageCertificate of Relief Valve Capacity (PROCA) 7 PDFAdeoye OkunoyeNo ratings yet

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacDocument1 pageSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacNoor Mohamed AzeezNo ratings yet

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Dilshad AhemadNo ratings yet

- Saudi Aramco System Lay-up ReportDocument2 pagesSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- SAIC-A-2005 Rev 8Document4 pagesSAIC-A-2005 Rev 8Syed ImranNo ratings yet

- Verify Saudi Aramco Test Equipment SafetyDocument6 pagesVerify Saudi Aramco Test Equipment SafetyEagle SpiritNo ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- Vendor document review cover sheetDocument9 pagesVendor document review cover sheetvelmurug_balaNo ratings yet

- Annexure - 11.1 Code of ConductDocument3 pagesAnnexure - 11.1 Code of ConductAhmed BoraeyNo ratings yet

- Annexure - 1 Part D Subcontract Agreement (Sample Copy)Document6 pagesAnnexure - 1 Part D Subcontract Agreement (Sample Copy)Ahmed BoraeyNo ratings yet

- Skilled WorkerDocument68 pagesSkilled WorkerAhmed BoraeyNo ratings yet

- Annexure - 11.2 Nda For SubcontractorDocument1 pageAnnexure - 11.2 Nda For SubcontractorAhmed BoraeyNo ratings yet

- Safety Requirements for ScaffoldsDocument16 pagesSafety Requirements for ScaffoldschassasNo ratings yet

- BS 4 - Grade 7Document2 pagesBS 4 - Grade 7Ahmed BoraeyNo ratings yet

- CVJ 79126225 20231031083643Document5 pagesCVJ 79126225 20231031083643Ahmed BoraeyNo ratings yet

- SPDRequestfor Bids GOODS1 Envelope OCT2017Document139 pagesSPDRequestfor Bids GOODS1 Envelope OCT2017Ahmed BoraeyNo ratings yet

- QA/QC Requirements for Sprinkler NozzlesDocument4 pagesQA/QC Requirements for Sprinkler NozzlesAhmed BoraeyNo ratings yet

- Risk LectureDocument75 pagesRisk LectureAhmed BoraeyNo ratings yet

- Rading Development-Reda-Nozzles - AckDocument5 pagesRading Development-Reda-Nozzles - AckAhmed BoraeyNo ratings yet

- 603 Stairways and LaddersDocument40 pages603 Stairways and LaddersAhmed BoraeyNo ratings yet

- CertificateOfCompletion - SAP ERP Essential TrainingDocument1 pageCertificateOfCompletion - SAP ERP Essential TrainingAhmed BoraeyNo ratings yet

- CPVC MentDocument5 pagesCPVC MentAhmed BoraeyNo ratings yet

- Coating FultsDocument4 pagesCoating FultsAhmed BoraeyNo ratings yet

- Diameter Ofof NozzelDocument16 pagesDiameter Ofof NozzelAhmed BoraeyNo ratings yet

- Manual-Performing PNS SecurityDocument60 pagesManual-Performing PNS SecurityAhmed BoraeyNo ratings yet

- Ford Flow ViscosityDocument8 pagesFord Flow ViscosityAhmed BoraeyNo ratings yet

- Batching Plant Document Requirement Front PageDocument1 pageBatching Plant Document Requirement Front PageAhmed BoraeyNo ratings yet

- Sand Test Report Azmil SourseDocument4 pagesSand Test Report Azmil SourseAhmed BoraeyNo ratings yet

- Signed Manifold PackageDocument117 pagesSigned Manifold PackageAhmed BoraeyNo ratings yet

- S NHC CT 005Document7 pagesS NHC CT 005Ahmed BoraeyNo ratings yet

- Quiz6 PDFDocument6 pagesQuiz6 PDFEdwar YesidNo ratings yet

- Series Sensitivity Reader: C O N V E N T I O N A L D E T E C T I O NDocument2 pagesSeries Sensitivity Reader: C O N V E N T I O N A L D E T E C T I O NArgile-assholeNo ratings yet

- Model FA Anti Lock Brake System 77-1Document45 pagesModel FA Anti Lock Brake System 77-1Komatsu Perkins HitachiNo ratings yet

- Calibration All PDFDocument42 pagesCalibration All PDFMubasher91% (11)

- Airlocks and Accessories For MPSN 25/15 and 25/23.: Original Spare Parts For Longer LifetimesDocument2 pagesAirlocks and Accessories For MPSN 25/15 and 25/23.: Original Spare Parts For Longer LifetimesA4blackNo ratings yet

- Secondary Storage DevicesDocument36 pagesSecondary Storage DevicesVinayKumarSinghNo ratings yet

- CSS G10 Q1 - Wk4 - Creating Ethernet CableDocument11 pagesCSS G10 Q1 - Wk4 - Creating Ethernet CableBryce PandaanNo ratings yet

- ISO 9001 Certified Company Technical SheetDocument6 pagesISO 9001 Certified Company Technical SheetSagarNo ratings yet

- What Are Computers - Prova Ingles Tecnico Subsequente - 1 BimestreDocument2 pagesWhat Are Computers - Prova Ingles Tecnico Subsequente - 1 BimestreMaria Cristina PereiraNo ratings yet

- CAT-4003 MRI-M500 Series Intelligent ModulesDocument2 pagesCAT-4003 MRI-M500 Series Intelligent ModulesJordan Varona MazaNo ratings yet

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-55Hardiansyah Simarmata100% (1)

- Standardised "EN 733" Centrifugal Pumps 50 HZ N 2900 MinDocument7 pagesStandardised "EN 733" Centrifugal Pumps 50 HZ N 2900 MinCost RootsNo ratings yet

- Installation Manual IO Module EN-125Document12 pagesInstallation Manual IO Module EN-125GabrielNo ratings yet

- ATC-300+ and ATC-800 Bypass Isolation Contactor Based ATS PDFDocument56 pagesATC-300+ and ATC-800 Bypass Isolation Contactor Based ATS PDFPILAR MARTINEZNo ratings yet

- OmniBAS - IDU - Installation and Cabling - Manual - en - Ed 6.0Document112 pagesOmniBAS - IDU - Installation and Cabling - Manual - en - Ed 6.0gabis100% (3)

- CARBON MONOXIDE (CO) DETECTOR SPECIFICATIONS AND FEATURESDocument4 pagesCARBON MONOXIDE (CO) DETECTOR SPECIFICATIONS AND FEATURESalay-okNo ratings yet

- LW160-1 S - N 1001-Up - Boom Angle Sensor PDFDocument2 pagesLW160-1 S - N 1001-Up - Boom Angle Sensor PDFBillNo ratings yet

- 07 - Pilot Lights & PushbuttonsDocument4 pages07 - Pilot Lights & PushbuttonsEDUANG20No ratings yet

- Ring Blower CatalogueDocument22 pagesRing Blower CatalogueCesar MedinaNo ratings yet

- English Manual of V208 PKE Alarm System: Operation and UseDocument8 pagesEnglish Manual of V208 PKE Alarm System: Operation and Useeduardo gomezNo ratings yet

- High-Strain-Rate Test Apparatus for Split Hopkinson Pressure BarDocument6 pagesHigh-Strain-Rate Test Apparatus for Split Hopkinson Pressure BarMubarak AliNo ratings yet

- SopranoDocument11 pagesSopranoBagus SaputroNo ratings yet

- EE-260 Lecture 19 Synchronous Generators IntroductionDocument24 pagesEE-260 Lecture 19 Synchronous Generators IntroductionRehan BasharatNo ratings yet

- Signalling Relay Spec PDFDocument2 pagesSignalling Relay Spec PDFIndranilNo ratings yet

- Manual VX 500Document16 pagesManual VX 500Felipe oliveira guimarãesNo ratings yet

- Electrical Installation and MaintenanceDocument9 pagesElectrical Installation and Maintenanceartjill printingNo ratings yet

- Bosch Siemens WFMC WFXD Training ManualDocument83 pagesBosch Siemens WFMC WFXD Training ManualDusmantha AnandaratneNo ratings yet

- Spanish Layout Keyboard StockDocument1 pageSpanish Layout Keyboard StockBlas PerezNo ratings yet

- Dosing and Disinfection: Search Part NumberDocument48 pagesDosing and Disinfection: Search Part NumberataoulalimtNo ratings yet

- Fuel Rack Solenoid - TestDocument6 pagesFuel Rack Solenoid - TestAdolfo Dario SaavedraNo ratings yet