Professional Documents

Culture Documents

Saudi Aramco Test Report

Uploaded by

nadeem shaikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Test Report

Uploaded by

nadeem shaikhCopyright:

Available Formats

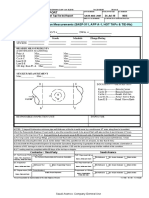

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SATR NUMBER DATE APPROVED DISCIPLINE

SAUDI ARAMCO TEST REPORT

Leak Test Report SATR-A-2010 24-Jul-18 Mech

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER EQUIPMENT DESCRIPTION TEST PACK NO. TEST SYSTEM

LAYOUT DRAWING NUMBER REV. NO. S/U SYSTEM FACILITY P.O. NUMBER

QUANTITY

TASK COMPLETED DATE RFI No. REQUESTED INSPECTION DATE MH's SPENT TRAVEL TIME

INSPECTED

System Description:

Certificate No. Date:

Location in Service: Nature of Test: Direct Pressure Bubble Leak Test

Test Procedure in Accordance With: ASME V, Art 10, Mandatory App. I Test Medium:

Pressure Gauges (PG) & Recorders (PR) Temp Gauge/Recorder Relief Valve

PG- PG- PG- PG- PR- TG- TR- RV #

1 Serial No/Tag No.

2 Make

3 Range

4 Certificate No

5 Date Calibrated

6 Set Pressure

Re-Calibration Due

7

Date

ITEM

No. Test Parameters Requirements Actual Pass Fail Remarks

Test Medium (Indicate method of Use approved clean air

1

treatment if required) or approved inert gas

Area of interest (Indicate flg joints, weld All flanges, threads,

2

joints, threaded, socket, body) welds, seal welds

Direct Pressure Bubble

3 Method of Leak Detection

Leak Test (Procedure)*

4 Test Pressure: 5-10 psig

Minimum 15 minutes

5 Duration

soak time before exam

Within temp rating of

6 System Test Temperature

App'd Bubble Solution

7 Permissible leakage None

TEST RESULTS: Test Accepted. No leaks or loss in pressure observed. List number of leaks

Rejected and location below

AFFIX ANY TEST TAPE TO THIS REPORT (TEST EVIDENCE)

Leaks/Repairs found during test: Attach any drawings to identify any construction joints found with leakage before MCC.

REFERENCE DOCUMENTS:

1. SAES-A-004, General Requirements of Pressure Testing, (28 August 2016)

2. SAES-A-007, Hydrostatic Testing Fluids and Lay-Up Procedures, (01 January 2018)

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

Saudi Aramco: Company General Use

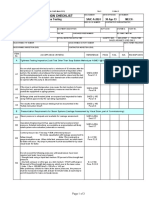

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED DISCIPLINE

SAUDI ARAMCO TEST REPORT

Leak Test Report SATR-A-2010 24-Jul-18 Mech

PROJECT TITLE WBS/BI/JO NUMBER CONTRACTOR/SUBCONTRACTOR

EQUIPMENT ID NUMBER EQUIPMENT DESCRIPTION TEST PACK NO. TEST SYSTEM

LAYOUT DRAWING NUMBER REV. NO. S/U SYSTEM FACILITY P.O. NUMBER

QUANTITY

TASK COMPLETED DATE RFI No. REQUESTED INSPECTION DATE MH's SPENT TRAVEL TIME

INSPECTED

System Description:

Certificate No. Date:

Location in Service: Nature of Test: Direct Pressure Bubble Leak Test

Test Procedure in Accordance With: ASME V, Art 10, Mandatory App. I Test Medium:

Quality Record Approved:

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001ansar aliNo ratings yet

- SATR-A-2001Document8 pagesSATR-A-2001razzak.me.enggNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportPradeepNo ratings yet

- Saudi Aramco Pressure Test ReportDocument6 pagesSaudi Aramco Pressure Test ReportGOSP3 QC MechanicalNo ratings yet

- Saudi Aramco Pressure TestDocument2 pagesSaudi Aramco Pressure Testمحمد علي النويصرNo ratings yet

- Saudi Aramco Leak Test ReportDocument1 pageSaudi Aramco Leak Test ReportAhmed BoraeyNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001GanesanNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- Calibration Test ReportDocument8 pagesCalibration Test ReportJagdishNo ratings yet

- Satr A 2001VDocument8 pagesSatr A 2001Vansar aliNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13Document2 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13PradeepNo ratings yet

- SATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Document2 pagesSATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Ahdal NoushadNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17ziaNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16Document6 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16GOSP3 QC MechanicalNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Test Report Punch List FormDocument1 pageSaudi Aramco Test Report Punch List FormAnonymous S9qBDVkyNo ratings yet

- Satr A 2008Document2 pagesSatr A 2008Shahzad HussainNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Test Report: SATR-A-2006 25-May-05 Mechanical Calibration Test Report-Test Relief ValveDocument1 pageSaudi Aramco Test Report: SATR-A-2006 25-May-05 Mechanical Calibration Test Report-Test Relief ValveAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Testing (SAEP-311 Hot Tap/Tie In) Report 24-Jul-18 NDEDocument1 pageSaudi Aramco Test Report: Ultrasonic Testing (SAEP-311 Hot Tap/Tie In) Report 24-Jul-18 NDEnadeem shaikhNo ratings yet

- Satr S 4001Document1 pageSatr S 4001Noor Mohamed AzeezNo ratings yet

- Saic A 2004Document2 pagesSaic A 2004HabibNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- Saic A 2004Document8 pagesSaic A 2004karthi51289No ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Dilshad AhemadNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacDocument1 pageSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacNoor Mohamed AzeezNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Aramco Ultrasonic Test ReportDocument3 pagesAramco Ultrasonic Test Reportnadeem shaikhNo ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDEDocument2 pagesSaudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDEnadeem shaikhNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Shahzad HussainNo ratings yet

- Leak test for water structuresDocument1 pageLeak test for water structuresNoor Mohamed AzeezNo ratings yet

- SATR-B-4001Document2 pagesSATR-B-4001razzak.me.enggNo ratings yet

- Saudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechnadeemNo ratings yet

- Satr-P-3824 Rev 0Document9 pagesSatr-P-3824 Rev 0lovely mirandaNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- Satr D 2001Document2 pagesSatr D 2001Shahzad HussainNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 Mechnadeem shaikhNo ratings yet

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbSino hydroNo ratings yet

- Saic G 2018Document1 pageSaic G 2018usmanNo ratings yet

- Saudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Document1 pageSaudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Anonymous S9qBDVkyNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Saudi Aramco Test Report: Assessment of Ultrasonic ResultsDocument4 pagesSaudi Aramco Test Report: Assessment of Ultrasonic Resultsnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDEDocument2 pagesSaudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDEnadeem shaikhNo ratings yet

- MPT Procedure No:: Saudi Aramco Test ReportDocument2 pagesMPT Procedure No:: Saudi Aramco Test Reportnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Test Report (Weld Overlay UT Examination) SATR-NDE-2006 24-Jul-18 NdeDocument9 pagesSaudi Aramco Test Report: Ultrasonic Test Report (Weld Overlay UT Examination) SATR-NDE-2006 24-Jul-18 Ndenadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)Document4 pagesSaudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)nadeem shaikhNo ratings yet

- Aramco Ultrasonic Test ReportDocument3 pagesAramco Ultrasonic Test Reportnadeem shaikhNo ratings yet

- Saudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechDocument3 pagesSaudi Aramco Test Report Re-Instatement Checklist (Form) : SATR-A-2011 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Fireproofing Inspection ReportDocument2 pagesSaudi Aramco Fireproofing Inspection ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Testing (SAEP-311 Hot Tap/Tie In) Report 24-Jul-18 NDEDocument1 pageSaudi Aramco Test Report: Ultrasonic Testing (SAEP-311 Hot Tap/Tie In) Report 24-Jul-18 NDEnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechnadeemNo ratings yet

- SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)Document2 pagesSAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)nadeem shaikhNo ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Release Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportDocument2 pagesRelease Structure For Intumescent Fireproofing (FP) : Saudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Pre-Pressure ChecklistDocument2 pagesSaudi Aramco Pre-Pressure ChecklistnadeemNo ratings yet

- Saudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Water Chemistry Report SATR-A-2014 24-Jul-18 MechnadeemNo ratings yet

- Saes T 101Document6 pagesSaes T 101nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument17 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Saes S 007Document17 pagesSaes S 007nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Saes S 020Document33 pagesSaes S 020nadeem shaikhNo ratings yet

- Saes P 127Document12 pagesSaes P 127nadeem shaikhNo ratings yet

- SAES-Q-001 - Criteria For Design and Construction of Concrete StructuresDocument24 pagesSAES-Q-001 - Criteria For Design and Construction of Concrete Structures1.202056100% (2)

- Saes S 010Document28 pagesSaes S 010nadeem shaikh0% (1)

- Saes Q 004Document25 pagesSaes Q 004nadeem shaikhNo ratings yet

- Saes S 040Document22 pagesSaes S 040nadeem shaikhNo ratings yet

- Saes R 004Document8 pagesSaes R 004nadeem shaikh100% (1)

- Science Magazine - 30 June 2023Document136 pagesScience Magazine - 30 June 2023Pablo GarcíaNo ratings yet

- 04 IPHS Primary Health CentreDocument20 pages04 IPHS Primary Health CentreKailash NagarNo ratings yet

- Airport Engineering Multiple Choice QuestionsDocument1 pageAirport Engineering Multiple Choice QuestionsengineeringmcqsNo ratings yet

- DBMS Lecture NotesDocument120 pagesDBMS Lecture NoteshawltuNo ratings yet

- Daftar PustakaDocument2 pagesDaftar PustakaRidhal FauzanNo ratings yet

- Marquez Vs Comelec GR 112889Document1 pageMarquez Vs Comelec GR 112889JFA100% (1)

- Installing Wilson Yagi Antenna 301124Document4 pagesInstalling Wilson Yagi Antenna 301124SentaNo ratings yet

- An Overview of Penetration TestingDocument20 pagesAn Overview of Penetration TestingAIRCC - IJNSANo ratings yet

- AsteriskNow Manual ConfigurationDocument24 pagesAsteriskNow Manual ConfigurationRufino Victor SaballaNo ratings yet

- MCS 150 Page 1Document2 pagesMCS 150 Page 1Galina NovahovaNo ratings yet

- Charter OCAP 4-Device Remote Control: Manufacturer'S CodesDocument2 pagesCharter OCAP 4-Device Remote Control: Manufacturer'S CodesDerek WebsterNo ratings yet

- Nestle Announcement It Is Pulling The Plug On Eldred TownshipDocument2 pagesNestle Announcement It Is Pulling The Plug On Eldred TownshipDickNo ratings yet

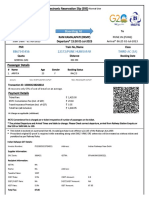

- 22172/pune Humsafar Third Ac (3A)Document2 pages22172/pune Humsafar Third Ac (3A)VISHAL SARSWATNo ratings yet

- Sante Worklist Server QSG 1Document25 pagesSante Worklist Server QSG 1adamas77No ratings yet

- Community Service ProposalDocument3 pagesCommunity Service ProposalAbdurahman AbdulhakimNo ratings yet

- Production Manager-43-4Document4 pagesProduction Manager-43-4Mohanram PandiNo ratings yet

- Qingdao ACT Auto Brake Disc Drum For Volkswagen Ford ToyotaDocument9 pagesQingdao ACT Auto Brake Disc Drum For Volkswagen Ford ToyotaQingdao act brake discNo ratings yet

- Laporan Tahunan 2009Document179 pagesLaporan Tahunan 2009zalifahshafieNo ratings yet

- Section 89 of CPC: Significance and Case LawsDocument10 pagesSection 89 of CPC: Significance and Case LawsPragna NachikethaNo ratings yet

- Income Tax Raids: Procedures and RightsDocument4 pagesIncome Tax Raids: Procedures and RightsshanikaNo ratings yet

- Ibert Concerto Tremolo Fingerings by Nestor Herszbaum PDFDocument2 pagesIbert Concerto Tremolo Fingerings by Nestor Herszbaum PDFAmedeo De SimoneNo ratings yet

- DSP1800 Temperature and Humidity ProbeDocument2 pagesDSP1800 Temperature and Humidity ProbeGerardo SanchezNo ratings yet

- DTY 4-CH Hard Disc Mobile DVR with GPS, 3G & Wi-FiDocument3 pagesDTY 4-CH Hard Disc Mobile DVR with GPS, 3G & Wi-FiAleksandar NikolovskiNo ratings yet

- Role of Business IncubatorsDocument11 pagesRole of Business IncubatorsayingbaNo ratings yet

- GrimaldiDocument104 pagesGrimaldiRicardo MartinsNo ratings yet

- Labour Welfare Management at Piaggio vehicles Pvt. LtdDocument62 pagesLabour Welfare Management at Piaggio vehicles Pvt. Ltdnikhil kumarNo ratings yet

- Group Assignment 1 - FinalDocument13 pagesGroup Assignment 1 - FinalWanteen LeeNo ratings yet

- NBC 2019 - AE Div B - Part 9 PDFDocument62 pagesNBC 2019 - AE Div B - Part 9 PDFviksursNo ratings yet

- Market Segmentation of Bata Shoe Company LTD PDFDocument1 pageMarket Segmentation of Bata Shoe Company LTD PDFkhanzakirahmad10No ratings yet

- Posteguillo The Semantic Structure of Computer Science Research ArticalsDocument22 pagesPosteguillo The Semantic Structure of Computer Science Research ArticalsRobin ThomasNo ratings yet