Professional Documents

Culture Documents

Saudi Aramco Test Report

Uploaded by

محمد علي النويصرOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Test Report

Uploaded by

محمد علي النويصرCopyright:

Available Formats

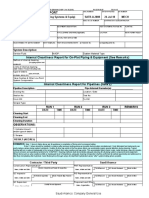

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - March 2013) Rev 8 30-June-2014

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Pressure Test Report SATR-A-2001 31-Dec-14

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION TEST SYSTEM No./Test Pack No. PLANT NO.

DRAWING NUMBER (P&ID/ISO) / REV. No. PRESSURE TEST DIAGRAM NATURE OF TEST WORK PERMIT REQD?

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME LOCATION OF TEST (PLANT NAME & NO.)

SAUDI ARAMCO TIP (SATIP) NUMBER SATIP Activity No. TEST IN ACCORDANCE WITH: a) Procedure No. b) Supporting SAIC No.

System Description: Test Details (Type):

Test/Service Fluid: MAOP: Sys Mat'l Type: Limiting Factor:

Flushing Cleaning Method Used: Accepted: Rejected:

Lay-Up Method: None: Ambient: Wet: Dry: Other :

Pressure Gages/Recorder Temp Gage/Recorder Relief Valve

Test Instruments

PG- PG- PG- PG- PR- TG- TR- RV #

Serial No/Tag No.

Make

Range

Certificate No.

Date Calibrated

Set Pressure

Re-Calibration Due

Date

ITEM Description of Test Parameters

Actual Pass Fail Remarks

No. (Complete Applicable Data Entry Prior to Test)

Test Medium Type/Quality (Indicate method of treatment if req'd in

1 Remarks, i.e., Fluid type, ph, SRB count, O2 Scavenger, etc).

2 SystemTemperature at test:

Test Pressure: Service Test/Others:________

3 Strength Test: ___________ Valve Body: ______________

Tightness Test: ___________ Valve Seat: ______________

4 Preliminary Test Conducted at __________Psig

Area of interest (Indicate flange joints, weld joints, threaded,

5

socket, body)

6 Method of leak detection (direct visual/remote)

Test Duration : a. 30 minutes min for Plant Piping

7 b. 2 hrs. Pipeline strength test/ ______ Tightness Test

c. Others_____________

REPAIRS DURING TEST:

TEST RESULTS: Test Accepted. No leak or loss in pressure observed. State reasons in

Rejected Remarks Section.

AFFIX ANY TEST TAPE TO THIS REPORT (TEST EVIDENCE)

REMARKS:

Contractor / Third-Party Saudi Aramco

Construction Representative PMT Representative

Test is ready for inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department, Name, Initials and

Company, Initials and Date: Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and

Name, Initials and Date:

Date:

QC Supervisor Proponent and Others (Optional)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - March 2013) Rev 8 30-June-2014

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Pressure Test Report SATR-A-2001 31-Dec-14

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION TEST SYSTEM No./Test Pack No. PLANT NO.

DRAWING NUMBER (P&ID/ISO) / REV. No. PRESSURE TEST DIAGRAM NATURE OF TEST WORK PERMIT REQD?

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME LOCATION OF TEST (PLANT NAME & NO.)

SAUDI ARAMCO TIP (SATIP) NUMBER SATIP Activity No. TEST IN ACCORDANCE WITH: a) Procedure No. b) Supporting SAIC No.

System Description: Test Details (Type):

Quality Record Approved: Name, T&I Witnessed QC Record Reviewed Work Verified

Name, Sign and Date: Organization,

Initials and Date:

Saudi Aramco: Company General Use

You might also like

- Consultant FeeDocument15 pagesConsultant Feesadaqat181No ratings yet

- Composite Assignment PresentationDocument19 pagesComposite Assignment PresentationJithin Devan PadincharayilNo ratings yet

- MMS Pile Foundation - R0 PDFDocument16 pagesMMS Pile Foundation - R0 PDFgohilnarendraNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Specification Guidelines For Surface Preparation of Concrete Prior To RepairDocument9 pagesSpecification Guidelines For Surface Preparation of Concrete Prior To RepairRafafuenmaNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Guidelines For Telecommunications Structures v1.0 - NSW GovernmentDocument29 pagesGuidelines For Telecommunications Structures v1.0 - NSW GovernmentruayoNo ratings yet

- Saudi Aramco Test Report: Re-Instatement Punch List Form (Punch List by The Contractor) SATR-A-2011 25-May-05 MechDocument1 pageSaudi Aramco Test Report: Re-Instatement Punch List Form (Punch List by The Contractor) SATR-A-2011 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Construction &demolition Waste RecyclingDocument20 pagesConstruction &demolition Waste Recyclingvinothpandi50% (2)

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13Document2 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 30-Apr-13PradeepNo ratings yet

- Plumbing Code SummaryDocument7 pagesPlumbing Code SummaryMon ResocoNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Amici Water Heater Catalog 2015Document44 pagesAmici Water Heater Catalog 2015pwilberj100% (1)

- IRC March 2020 ManualDocument60 pagesIRC March 2020 ManualAkash Yadav0% (1)

- MODULE 4 - Construction Cost Estimate: Ce 142-T Project Management & Construction MethodsDocument42 pagesMODULE 4 - Construction Cost Estimate: Ce 142-T Project Management & Construction MethodsNiño EvangelioNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportPradeepNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001razzak.me.enggNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test ReportGOSP3 QC MechanicalNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Satr A 2001Document8 pagesSatr A 2001ansar aliNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001GanesanNo ratings yet

- SATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Document2 pagesSATR-A-2001V Rev 6 Pressure Test Report (Valve Inspection & Field Report)Ahdal NoushadNo ratings yet

- SATR-A-2001 Pressure Test ReportDocument8 pagesSATR-A-2001 Pressure Test Reportjohn ajitNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16Document6 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 17-Mar-16GOSP3 QC MechanicalNo ratings yet

- SATR-A-2001V Pressure Test Report (Valve Inspection & Field Testing)Document8 pagesSATR-A-2001V Pressure Test Report (Valve Inspection & Field Testing)john ajitNo ratings yet

- Satr A 2001VDocument8 pagesSatr A 2001Vansar aliNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 29-Jun-17ziaNo ratings yet

- Saudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18Document8 pagesSaudi Aramco Test Report: Pressure Test Report (Valve Inspection & Field Testing) 24-Jul-18nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test Reportnadeem shaikhNo ratings yet

- Saic A 2004Document2 pagesSaic A 2004HabibNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Satr A 2006Document8 pagesSatr A 2006Shahzad HussainNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- Satr-P-3824 Rev 0Document9 pagesSatr-P-3824 Rev 0lovely mirandaNo ratings yet

- Satr A 2008Document2 pagesSatr A 2008Shahzad HussainNo ratings yet

- SATRDocument1 pageSATRAhmed BoraeyNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saic A 2004Document8 pagesSaic A 2004karthi51289No ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Temperature Gauge SATR-A-2003 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Document1 pageSaudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Anonymous S9qBDVkyNo ratings yet

- Satr B 4001Document2 pagesSatr B 4001razzak.me.enggNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 Mechnadeem shaikhNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003Thouseef MaNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Satr D 2001Document2 pagesSatr D 2001Shahzad HussainNo ratings yet

- Satr S 4002Document1 pageSatr S 4002Noor Mohamed AzeezNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 NdeDocument3 pagesSaudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 Ndenadeem shaikhNo ratings yet

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacDocument1 pageSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacNoor Mohamed AzeezNo ratings yet

- Saudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKDocument2 pagesSaudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKshaikhbwcNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbSino hydroNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Dilshad AhemadNo ratings yet

- In-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportDocument2 pagesIn-Process Inspection Report For Fire Proofing: Saudi Aramco Test ReportnadeemNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ненад КнежевићNo ratings yet

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechPradeepNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ansar Ali VemmullyNo ratings yet

- Recommendations On How GBR Can Be Prepared For Rock Tunnel ProjectsDocument15 pagesRecommendations On How GBR Can Be Prepared For Rock Tunnel Projectsjlp0529No ratings yet

- ASTM 666 - 03 Stainless SteelDocument7 pagesASTM 666 - 03 Stainless Steelisaias_esparzaNo ratings yet

- Valvulas de Bola PDFDocument9 pagesValvulas de Bola PDFChristian VegaNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- Academic Writing Task 1 Worksheet 1: PurposeDocument6 pagesAcademic Writing Task 1 Worksheet 1: PurposeNguyễn Hà MyNo ratings yet

- Upc WhiteDocument34 pagesUpc WhiteCALTRANo ratings yet

- A Case History On Design, Construction, and Performance of Stone Column ...Document10 pagesA Case History On Design, Construction, and Performance of Stone Column ...Suthan PooranampillaiNo ratings yet

- Seattle Sustainable Building ProgramDocument16 pagesSeattle Sustainable Building ProgramSustainable Neighbourhoods NetworkNo ratings yet

- Assignment CE163 - RivetsDocument3 pagesAssignment CE163 - RivetsJems MansuetoNo ratings yet

- Rvda 10 - 520 P 030220 enDocument2 pagesRvda 10 - 520 P 030220 enronald.1978No ratings yet

- D Pi 175Document2 pagesD Pi 175reza329329No ratings yet

- SOM-BMT Lab Manual FinalDocument48 pagesSOM-BMT Lab Manual FinalHarish T S Gowda100% (1)

- Requirements Concerning Gas Tankers: International Association of Classification SocietiesDocument31 pagesRequirements Concerning Gas Tankers: International Association of Classification Societiesharikrishnanpd3327No ratings yet

- Qs Communication Skills Semester 1 AssignmentDocument9 pagesQs Communication Skills Semester 1 AssignmentZahee BasheerNo ratings yet

- Ficha Sistema de Tuberia Multicapa Pex Al Pe InglesDocument3 pagesFicha Sistema de Tuberia Multicapa Pex Al Pe InglesP.M.No ratings yet

- Chang Kok Yung MSC in Civil EngineeringDocument26 pagesChang Kok Yung MSC in Civil EngineeringFareed Ahmed MemonNo ratings yet

- Abort Switch F-95111Document1 pageAbort Switch F-95111RafaqatAliNo ratings yet

- 6KramerFurnaceMaintenance PDFDocument3 pages6KramerFurnaceMaintenance PDFcarrialdiNo ratings yet

- Fielding Notching and Drilling of Glued Laminated Timber BeamsDocument1 pageFielding Notching and Drilling of Glued Laminated Timber BeamsTimothy CruseNo ratings yet