Professional Documents

Culture Documents

Saic G 2018

Uploaded by

usmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic G 2018

Uploaded by

usmanCopyright:

Available Formats

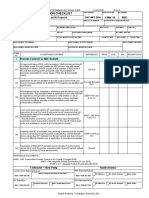

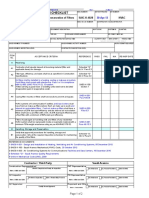

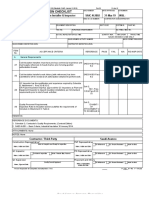

SAUDI ARAMCO ID/PIEU-31-December-2018 - REV.2018.12.00 (Standards Cutoff - December 31,2018) Rev.2018.12.

00 31-Dec-18

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Final Cleanliness Inspection After Cleaning and Flushing of

SAIC-G-2018 4-Mar-19 MECH

Lube and/or Seal Oil System.

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Inspection Requirement

A final cleanliness check shall be made after 24 hours continuous

flushing, a final cleanliness check shall be made. The inspection screens SAES-G-116,

A1

shall be cleaned and reinstalled and the flushing oil shall be circulated for Sec. 8

an additional period of 12 hours the following acceptance criteria.

History / Report / Log of lube/seal oil and fluid power systems

SAEP-1028,

A2 cleaning /flushing / chemical cleaning has been reviewed. (SAEP-

Para. 5.4.2

1028.Para.9)

B. CLEANLINESS RESULT

(Refer to Notes 1 & 2 if result is not acceptable.)

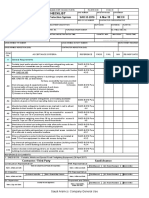

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-G-116 -- Cleanliness Standard for Lube/Seal Oil and Fluid Power Systems, 27 May 2014

2. SAEP-1028 -- Chemical Cleaning and Flushing of Lube/Seal Oil and Fluid Power Systems, 17 January 2018

NOTES:

After approximately two days of flushing, perform an acceptance check to verify whether it meets the cleanliness requirements specified in SAES-G-

116, Section 7. If it does not, continue flushing for another 48 hours and repeat the cleanliness check. If the system is not clean after 7 days with slag,

scale, paint, rust or other abrasive or adherent material continuing to appear on the inspection screens, circulation shall be stopped. Steps shall be

taken to identify and isolate contaminated sections of the system. The contaminated parts of the system shall be mechanically or chemically cleaned

again.14.2 If chemical cleaning is required:1. Drain the flushing oil. 2. Degrease with steam or surfactants to remove the flushing oil from the system,

and then proceed as in Section 12.

(Reference: SAES-G-116, Para. 7.4) The cleanliness of the system is acceptable to the Saudi Aramco proponent organization's Operations

personnel.

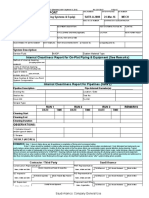

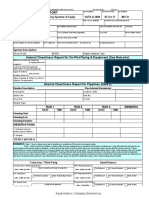

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Saic LPT 2010Document4 pagesSaic LPT 2010Arjun RawatNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Aramco ChecklistDocument1 pageAramco ChecklistTayyab AchakzaiNo ratings yet

- The AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesFrom EverandThe AS9100C, AS9110, and AS9120 Handbook: Understanding Aviation, Space, and Defense Best PracticesNo ratings yet

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ansar Ali VemmullyNo ratings yet

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTArjun RawatNo ratings yet

- Saic A 2004Document8 pagesSaic A 2004karthi51289No ratings yet

- Satr D 2001Document2 pagesSatr D 2001Shahzad HussainNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 24-Jul-18 Mechnadeem shaikhNo ratings yet

- Saic A 1015Document1 pageSaic A 1015Ненад КнежевићNo ratings yet

- SAUDI ARAMCO ID/PIEU-30-Nov-2018Document2 pagesSAUDI ARAMCO ID/PIEU-30-Nov-2018Moghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 22-Jan-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 22-Jan-18 MechaneeshNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Jul-18 Mechnadeem0% (1)

- Satr A 2008Document2 pagesSatr A 2008Shahzad HussainNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 24-Mar-16 MechSajid ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Satr H 1003Document2 pagesSatr H 1003Thouseef MaNo ratings yet

- Aramco Ultrasonic Test ReportDocument3 pagesAramco Ultrasonic Test Reportnadeem shaikhNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Shahzad HussainNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- Saudi Aramco Fireproofing Inspection ReportDocument2 pagesSaudi Aramco Fireproofing Inspection ReportnadeemNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic A 1010Document1 pageSaic A 1010usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaNo ratings yet

- Satr H 1003Document1 pageSatr H 1003Moghal AliNo ratings yet

- Saudi Aramco Inspection Checklist: Storage, Handling & Preservation of Relief Valves SAIC-J-2007 24-Jul-18 MechDocument6 pagesSaudi Aramco Inspection Checklist: Storage, Handling & Preservation of Relief Valves SAIC-J-2007 24-Jul-18 Mechnisha_khan100% (1)

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechJagdishNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009Dilshad AhemadNo ratings yet

- Saic A 2004Document2 pagesSaic A 2004HabibNo ratings yet

- SATR-D-2001Document2 pagesSATR-D-2001razzak.me.enggNo ratings yet

- Saudi Aramco Test Report Punch List FormDocument1 pageSaudi Aramco Test Report Punch List FormAnonymous S9qBDVkyNo ratings yet

- Saic B 2002Document1 pageSaic B 2002usmanNo ratings yet

- Satr-P-3824 Rev 0Document9 pagesSatr-P-3824 Rev 0lovely mirandaNo ratings yet

- Leak test for water structuresDocument1 pageLeak test for water structuresNoor Mohamed AzeezNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Saic-N - 2002Document1 pageSaic-N - 2002SUNIL RAJPUTNo ratings yet

- Saudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: System Lay-Up Report (Certificate) SATR-A-2009 24-Jul-18 MechnadeemNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- Saic H 2010Document1 pageSaic H 2010Ansar Ali VemmullyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistHaroon odoodNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatDocument2 pagesSaudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatnasirNo ratings yet

- Saudi Aramco Inspection Checklist: Completion of Form 3099A SAIC-J-2010 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Completion of Form 3099A SAIC-J-2010 24-Jul-18 Mechnisha_khanNo ratings yet

- Final Cleanliness InspectionDocument2 pagesFinal Cleanliness Inspectionkarthi51289No ratings yet

- Saic M 1062Document1 pageSaic M 1062Hussain Nasser Al- NowiesserNo ratings yet

- Liquid Penetrant Test Report for Kapsarc ProjectDocument2 pagesLiquid Penetrant Test Report for Kapsarc ProjectshaikhbwcNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportnadeemNo ratings yet

- Saic B 2016Document2 pagesSaic B 2016usmanNo ratings yet

- Saic B 2010Document2 pagesSaic B 2010usmanNo ratings yet

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- Saic A 1004Document2 pagesSaic A 1004usmanNo ratings yet

- Saic A 2025Document3 pagesSaic A 2025usmanNo ratings yet

- Saic B 2014Document4 pagesSaic B 2014usmanNo ratings yet

- Double GameDocument1 pageDouble GameusmanNo ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- Hollow Metal Doors and FramesDocument1 pageHollow Metal Doors and FramesusmanNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001usmanNo ratings yet

- Saic B 2002Document1 pageSaic B 2002usmanNo ratings yet

- Sky Light HeightDocument1 pageSky Light HeightusmanNo ratings yet

- Satr A 2007Document2 pagesSatr A 2007usmanNo ratings yet

- Reporting FormatDocument10 pagesReporting FormatusmanNo ratings yet

- Hollow Metal Doors and FramesDocument1 pageHollow Metal Doors and FramesusmanNo ratings yet

- 1st TimeDocument1 page1st TimeusmanNo ratings yet

- South Dahran Home Ceiling RFIDocument1 pageSouth Dahran Home Ceiling RFIusmanNo ratings yet

- Hollow Metal Doors and FramesDocument1 pageHollow Metal Doors and FramesusmanNo ratings yet

- Ashi and Bushnag Co. LTD: Windows Missing in Admin Staff & L.R.C RoomDocument1 pageAshi and Bushnag Co. LTD: Windows Missing in Admin Staff & L.R.C RoomusmanNo ratings yet

- Hollow Metal Doors and FramesDocument1 pageHollow Metal Doors and FramesusmanNo ratings yet

- Ashi and Bushnag Co. LTD: South Dhahran Home Ownership ProjectDocument1 pageAshi and Bushnag Co. LTD: South Dhahran Home Ownership ProjectusmanNo ratings yet

- 185 Doors Type D2Document1 page185 Doors Type D2usmanNo ratings yet

- Rfi 230 Wall Finishing in StairsDocument1 pageRfi 230 Wall Finishing in StairsusmanNo ratings yet

- Ashi and Bushnag Co. LTD: Water FountainDocument1 pageAshi and Bushnag Co. LTD: Water FountainusmanNo ratings yet

- THERMAL INSULATION FOR WALL, TestDocument1 pageTHERMAL INSULATION FOR WALL, TestusmanNo ratings yet

- Hollow Metal Doors and FramesDocument1 pageHollow Metal Doors and FramesusmanNo ratings yet

- AC Footing Height Issue on School RoofDocument1 pageAC Footing Height Issue on School RoofusmanNo ratings yet

- Hollow Metal Doors and FramesDocument1 pageHollow Metal Doors and FramesusmanNo ratings yet

- Export Import Practices - SylabusDocument3 pagesExport Import Practices - SylabusHải ĐăngNo ratings yet

- Chapter 2 - Cyber SecurityDocument16 pagesChapter 2 - Cyber SecurityShivanshuSingh80% (5)

- Types of Bailment: Compressive Study Special Contract: Parinsha Sharma Division B Roll No 53 Class 2013-18 ofDocument13 pagesTypes of Bailment: Compressive Study Special Contract: Parinsha Sharma Division B Roll No 53 Class 2013-18 ofNiyati BagweNo ratings yet

- Certificate of Non-Coverage: (CNC-OL-CAR-2020-09-00520)Document1 pageCertificate of Non-Coverage: (CNC-OL-CAR-2020-09-00520)Jennie AmandoNo ratings yet

- Warranty Conditions: Clause Accreditation Employee Enabled by ALSTOM GRID CUSTOMER Service Villeurbanne (France)Document2 pagesWarranty Conditions: Clause Accreditation Employee Enabled by ALSTOM GRID CUSTOMER Service Villeurbanne (France)Shafiqul IslamNo ratings yet

- Global Financial Crisis and Kerala EconomyDocument16 pagesGlobal Financial Crisis and Kerala EconomycalamurNo ratings yet

- Edillon v. Manila Bankers Life, 1982Document1 pageEdillon v. Manila Bankers Life, 1982Randy SiosonNo ratings yet

- Kalahi-Cidss Additional Financing Briefer: Project Component 1: Capacity Building and Implementation Support. Under ThisDocument4 pagesKalahi-Cidss Additional Financing Briefer: Project Component 1: Capacity Building and Implementation Support. Under ThisNolan GaraNo ratings yet

- Carlos TRABAJO FINAL INGLES 1 1Document7 pagesCarlos TRABAJO FINAL INGLES 1 1Greis sayuri Arellano AvendañoNo ratings yet

- Untitled DocumentDocument8 pagesUntitled DocumentKiều MaiNo ratings yet

- Technological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityDocument10 pagesTechnological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityJheo TorresNo ratings yet

- Mercado v. VitrioloDocument1 pageMercado v. VitrioloCy Panganiban100% (1)

- Drill 2Document6 pagesDrill 2trexy jeane sumapigNo ratings yet

- Actuant Payroll BR100 PDFDocument3,678 pagesActuant Payroll BR100 PDFsuyog thakareNo ratings yet

- United Nations SuccessDocument4 pagesUnited Nations Successanin_boboNo ratings yet

- Bureau Veritas Materials and WeldingDocument227 pagesBureau Veritas Materials and Weldingscofiel1No ratings yet

- Bonds Payable ProblemsDocument12 pagesBonds Payable ProblemsHAKUNA MATATANo ratings yet

- ASW ConnectionDocument7 pagesASW ConnectionNicoNo ratings yet

- External Audit ThesisDocument8 pagesExternal Audit ThesisLisa Riley100% (2)

- History of Education TimelineDocument13 pagesHistory of Education Timelineapi-557136175No ratings yet

- Gate Valve: Typical Use Valve ConstructionDocument4 pagesGate Valve: Typical Use Valve ConstructionCegrow Ber BersabalNo ratings yet

- Duties of A Lawyer Lecture Notes 3 PDFDocument12 pagesDuties of A Lawyer Lecture Notes 3 PDFSaidatulnajwaNo ratings yet

- Assignment 2 Fin110Document6 pagesAssignment 2 Fin110Soh Meng Tat EdmundNo ratings yet

- Reds and Our Churches - J B MatthewsDocument12 pagesReds and Our Churches - J B MatthewsHal ShurtleffNo ratings yet

- Chapter 2 Taxes, Tax Laws and Tax AdministrationDocument7 pagesChapter 2 Taxes, Tax Laws and Tax AdministrationElisa Jane AbellaNo ratings yet

- WHD20162022a Pérez Vs Puerto Rico Police Department DemandaDocument8 pagesWHD20162022a Pérez Vs Puerto Rico Police Department DemandaEmily RamosNo ratings yet

- Goquiolay vs. Sycip - Real CaseDocument43 pagesGoquiolay vs. Sycip - Real CaseLeizl A. VillapandoNo ratings yet

- SC upholds hierarchy of courts in dismissing directly filed certiorari petitionDocument277 pagesSC upholds hierarchy of courts in dismissing directly filed certiorari petitionKris NageraNo ratings yet

- Wilmington Trust Filing Retry 3-25-21Document25 pagesWilmington Trust Filing Retry 3-25-21Delaware Public MediaNo ratings yet

- Quiz Badminton Basic SkillsDocument1 pageQuiz Badminton Basic Skillsgeraldine.miclatNo ratings yet