Professional Documents

Culture Documents

Saic e 2010

Uploaded by

sureshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic e 2010

Uploaded by

sureshCopyright:

Available Formats

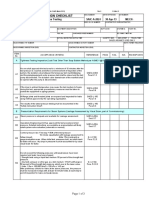

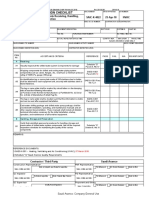

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Situ Strength Test of Fin Fan Coolers (Preparation) SAIC-E-2010 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Preparation for Pressure testing:

StrengthTest Pressure is the test pressure (NEW) indicated in the SAES-A-004,

A1

approved Safety Instruction Sheet. (SAES-A-005, Attach E-1) Para. 9.3

Fin fan exchangers shall be strength tested as specified below:

7.4.5.1 New Construction, refer to Appendix III of SAES-A-004

SAES-A-004,

A2 standard.7.4.5.2 Operating facilities

Para. 7.4.5

Strength tested in situ if the equipment has been transported. Refer

to Attachment 1

Temperature of water during hydrostatic testing is maintained at not 32-SAMSS-011,

A3

less than 17°C throughout the testing cycle. Para. 10.3.11

Hydrostatic test pressure hold for a minimum of one hour per 25 mm

32-SAMSS-011,

A4 of exchanger header thickness & in no case < than 1 hr. API 661

Para.1

Para. 10.3.2

Ensure that the Use of shellacs, glues, lead, etc., on gaskets during 32-SAMSS-011,

A5

testing is not used. Para.10.3.8

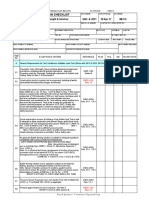

Fluids used for pressure testing are as follows:

1) Clean potable water, treated for control of bacteria and corrosion

2) For exchangers with stainless steel, monel or non-ferrous tubes,

the water does not contain more than 50 ppm chlorides. 32-SAMSS-011,

A6

3) For lube-oil and seal-oil exchangers the fluid to be used for Para. 10.3.3

pressure testing is the system fluid.

Strength testing preparation, pressurizing and inspection shall be

performed per SATIP-A-004-04. UTILIZE SAIC-A-2025 as a Pre-

A7 SATIP-E-007-01

Test Checklist & evaluate effectiveness of Fin Fan Cooler care

using Attachment 1.

NOTE: 1- Strength testing preparation, pressurizing & inspection shall be performed per SATIP-A-004-04. USE SAIC-A-2025. As the

opportunity affords itself, this pressure test & evaluation may be performed during the activities of chemical cleaning if pressures used in the

cleaning process will be close enough to that listed on the mfg stamp. Proponent shall be consulted to make this determination & shall concur

with using this method. 2- Use of shellacs, glues, lead, etc., on gaskets during testing is prohibited.

REMARKS:

REFERENCE DOCUMENTS:

1. 32-SAMSS-011, Manufacture of Air-Cooled Heat Exchangers, (19 February 2013)

2. SAES-A-004, General Requirements for Pressure Testing, (30 January 2011)

3. SAES-A-005, Safety Instruction Sheet, (21 March 2010)

4. SATIP-E-007-01, Saudi Aramco Typical Inspection and test Plan for Air Cooled Heat Exchanger (Fin Fan Cooler),

5. SATIP-A-004-04, Saudi Aramco Typical Inspection and Test Plan for Pressure testing of Pressure Vessels & Fin Fan Coolers,

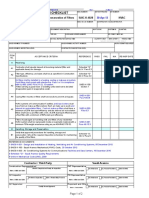

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

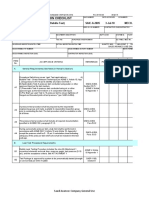

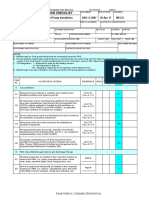

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

In-Situ Strength Test of Fin Fan Coolers (Preparation) SAIC-E-2010 30-Apr-17 MECH-

Attachment 1 - IN-SITU TESTING & CARE OF FIN FAN COOLERS

1. Follow these simple guidelines to assure good test results.

2. Make certain Fin Fans (on arrival) were treated very carefully.

3. Inspect the load on arrival for proper preservation & damage

The internals of exchangers shall be protected from corrosion by use of a non-toxic vapor phase corrosion inhibitor such as CORTEC VCI-309

or 307 or equivalent, applied at a rate of 0.1 kg/m³ fogged into the space. The inhibitor selected must be appropriate for the metallurgy of the

exchanger. Exchangers must be sealed vapor tight for the inhibitor to be effective. Alternatively, nitrogen blanketing or temporary coatings in

accordance with MIL-C-16173-D Grade IV (example Tectyl 846) may be used. Corrosion inhibitors for use on exchangers with stainless steel

& monel tubes must be chloride free, suitable for its intended use & not result in crevice corrosion. 32-SAMSS-011, Sect. 11

Stainless steel exchangers shall be protected from salt water and salt water spray during shipment. 32-SAMSS-011, Sect. 11

4. Fin Fan Coolers can "twist" if improperly lifted. BEWARE!!!

5. First thing, before it leaves the truck it arrives on! Inspection (camera)

6. Transit & erection clips & fasteners are checked closely for damage.

*PLAN Proactive supervision at handling points to assure they arrive ok.

7. UNLOAD & STORE ON HARD & EXTREMELY LEVEL SITES ALWAYS.

8. Plan staging areas close to Units to minimize handling

9. Corrosion Inhibitors can solidify, beware of opening these up.

10. Limit opening for "fit up" & piping work to good dry weather.

11. Keep system closed except when absolutely necessary.

12. Plan Test at test pressure on Manufacturer's Stamp.

If Chemical Cleaning (usually around 90 psi) is req'd, utilize this opportunity to meet the reqmt. (it's usually close enough)

Perform testing in accordance with good lay-up practices. Be Prepared to pull plugs and allow Proponent a visual exam.

Water removal after testing at low points can be assured by spool dropouts. Test as close to start-up as practical.

ALWAYS HAVE EXTRA PLUGS ON HAND (OR OVERNIGHT ACCESS AVAILABLE) IN THE EVENT OF TUBE/TUBESHEET LEAKS.

Saudi Aramco: Company General Use

You might also like

- SAIC E 2010 in Situ Test OfAirCoolersDocument1 pageSAIC E 2010 in Situ Test OfAirCoolersAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saic A 2004Document8 pagesSaic A 2004karthi51289No ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument7 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurepookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization of Pneumatic Test (Perform Leak Test) SAIC-A-2022 30-Apr-17 Mechkarthi51289No ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saic A 2004Document2 pagesSaic A 2004HabibNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAIC-A-2009 Rev 6 Test EquipmentDocument5 pagesSAIC-A-2009 Rev 6 Test Equipmentpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Relief Valves SAIC-J-2006 24-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Relief Valves SAIC-J-2006 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 30-Apr-17 Mechkarthi51289No ratings yet

- SAUDI ARAMCO PNEUMATIC TEST INSPECTIONDocument4 pagesSAUDI ARAMCO PNEUMATIC TEST INSPECTIONpookkoya thangalNo ratings yet

- SAIC-A-2009 Rev 7Document4 pagesSAIC-A-2009 Rev 7sajidazmi.amuNo ratings yet

- SAIC-L-2041 Rev 6 Storge & Inspection of ValvesDocument2 pagesSAIC-L-2041 Rev 6 Storge & Inspection of ValvesAhdal NoushadNo ratings yet

- SAIC-A-2024 Rev 2Document2 pagesSAIC-A-2024 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2022 Rev 6 Depressure PnematicDocument1 pageSAIC-A-2022 Rev 6 Depressure Pnematicpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Saic A 2005Document10 pagesSaic A 2005karthi51289No ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- Verify Saudi Aramco Test Equipment SafetyDocument6 pagesVerify Saudi Aramco Test Equipment SafetyEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaNo ratings yet

- SAIC-A-2009 - Verify Test Equipment (Safety Assessment)Document4 pagesSAIC-A-2009 - Verify Test Equipment (Safety Assessment)walidNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- SAIC-A-2005 Rev 5 Leak TestDocument4 pagesSAIC-A-2005 Rev 5 Leak Testpookkoya thangalNo ratings yet

- SATR-B-4001Document2 pagesSATR-B-4001razzak.me.enggNo ratings yet

- Saudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Insp of Air Test On Repads & Weld-Plus-Ends Cplgs SAIC-A-2016 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic S 4054Document2 pagesSaic S 4054Jahanzeb MaharNo ratings yet

- Saudi Aramco Inspection Checklist: Storage, Handling & Preservation of Relief Valves SAIC-J-2007 24-Jul-18 MechDocument6 pagesSaudi Aramco Inspection Checklist: Storage, Handling & Preservation of Relief Valves SAIC-J-2007 24-Jul-18 Mechnisha_khan100% (1)

- SAIC-A-2005 Rev 8Document4 pagesSAIC-A-2005 Rev 8Syed ImranNo ratings yet

- Saic A 1009Document2 pagesSaic A 1009mohammadNo ratings yet

- Leak test for water structuresDocument1 pageLeak test for water structuresNoor Mohamed AzeezNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- Satr H 1003Document1 pageSatr H 1003Moghal AliNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 10-Jun-19 PlumbSino hydroNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistshahzadaNo ratings yet

- Saudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacDocument1 pageSaudi Aramco Test Report: Refrigerant Pipe Vacuum Test SATR-K-4004 15-Dec-09 HvacWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Soil Sampling ChecklistDocument3 pagesSaudi Aramco Soil Sampling ChecklistTayyab KhanNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 30-Oct-17 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestJagdishNo ratings yet

- Satr A 2001Document7 pagesSatr A 2001GanesanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- Saic A 1005Document2 pagesSaic A 1005Hussain Nasser Al- Nowiesser0% (1)

- Saic B 1004Document2 pagesSaic B 1004jerinNo ratings yet

- Saudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbDocument2 pagesSaudi Aramco Test Report: Emergency Eyewash/Shower Functional Test Report SATR-B-4001 24-Jul-18 PlumbnadeemNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Saudi Aramco Pressure Test ReportDocument6 pagesSaudi Aramco Pressure Test ReportGOSP3 QC MechanicalNo ratings yet

- SAIC-W-2071 Selection of Welds For NDE (Vessels)Document2 pagesSAIC-W-2071 Selection of Welds For NDE (Vessels)KirubhakarPooranamNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Saudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 PipeDocument10 pagesSaudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 Pipesuresh100% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saes o 204Document7 pagesSaes o 204suresh100% (1)

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saic G 2007Document5 pagesSaic G 2007sureshNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- Saudi Aramco Fence Pre-Pour ChecklistDocument2 pagesSaudi Aramco Fence Pre-Pour ChecklistjerinNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Saic G 2007Document5 pagesSaic G 2007sureshNo ratings yet

- Saic K 4031Document2 pagesSaic K 4031sureshNo ratings yet

- Saep 321Document28 pagesSaep 321brecht1980No ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- 01-SAMMS-046 Stainless PipeDocument11 pages01-SAMMS-046 Stainless PipesureshNo ratings yet

- Saic F 2021Document11 pagesSaic F 2021jerinNo ratings yet

- Saep 99Document31 pagesSaep 99sureshNo ratings yet

- Saep 15Document22 pagesSaep 15biplabpal2009No ratings yet

- SAEP-22 Tank Calibration Requirement PDFDocument15 pagesSAEP-22 Tank Calibration Requirement PDFjerinNo ratings yet

- 04 SAMSS 001 Gate ValveDocument10 pages04 SAMSS 001 Gate Valveshganesh81gmailcom100% (1)

- Saep 20 PDFDocument43 pagesSaep 20 PDFTizio TizioNo ratings yet

- SAEP-26 Capital Project Bench Marking GuidelinesDocument31 pagesSAEP-26 Capital Project Bench Marking Guidelinessuresh0% (1)

- MSDS White GreaseDocument10 pagesMSDS White GreaseAndini Nur Paujiah100% (1)

- ENDOTOXIN (E. Coli O113:H10) Control Standard Endotoxin (CSE)Document2 pagesENDOTOXIN (E. Coli O113:H10) Control Standard Endotoxin (CSE)deepanmb007No ratings yet

- Insulating Oil Technical Data SheetDocument2 pagesInsulating Oil Technical Data SheetXavier DiazNo ratings yet

- Fast Curing Epoxy Adhesive with High Shear StrengthDocument3 pagesFast Curing Epoxy Adhesive with High Shear StrengthEl KhanNo ratings yet

- Alucobond ContemporaryColorChart Jan 2016 PDFDocument2 pagesAlucobond ContemporaryColorChart Jan 2016 PDFcathes231No ratings yet

- IR Absorption Table PDFDocument3 pagesIR Absorption Table PDFDavid QuinteroNo ratings yet

- Chapter 3Document38 pagesChapter 3Teddy Matthew AudleyNo ratings yet

- Mega BlueDocument9 pagesMega Bluepollito AmarilloNo ratings yet

- End of Topic Questions: Chapter 9: Chemical Periodicity of Elements 8Document1 pageEnd of Topic Questions: Chapter 9: Chemical Periodicity of Elements 8Baraa KhaledNo ratings yet

- Caiga - Experiment 2Document15 pagesCaiga - Experiment 2Simon Mathew CaigaNo ratings yet

- Flood Assessment MethodsDocument219 pagesFlood Assessment MethodsCvetkoNo ratings yet

- Enzyme Catalysis RatesDocument12 pagesEnzyme Catalysis RatesSiddharth KumraNo ratings yet

- Nano CompositeDocument26 pagesNano Compositenandan akNo ratings yet

- ARC SD4i Datasheet - ENDocument1 pageARC SD4i Datasheet - ENnorsahiramaslazimNo ratings yet

- PH3 30 Iron SteelDocument142 pagesPH3 30 Iron SteelMouna GuruNo ratings yet

- Lasercut WB 100 enDocument0 pagesLasercut WB 100 enfbp81No ratings yet

- Prorox SL 580 PDFDocument1 pageProrox SL 580 PDFgowtham_venkat_4No ratings yet

- Concure WB309Document2 pagesConcure WB309Tori Small100% (1)

- Chimestry ProjectDocument28 pagesChimestry Projectpsyxs4tsv9No ratings yet

- Enthalpy Change WorksheetDocument4 pagesEnthalpy Change WorksheetRose Belle A. GarciaNo ratings yet

- Skoog - Solucionário Capítulo 10 PDFDocument20 pagesSkoog - Solucionário Capítulo 10 PDFThais Dos SantosNo ratings yet

- Example of Research ProposalDocument4 pagesExample of Research ProposalBlankSyaNo ratings yet

- Evs PPT Final 1Document18 pagesEvs PPT Final 1KaranNo ratings yet

- Fiber Optic Nitrite Sensor for Cancer ScreeningDocument15 pagesFiber Optic Nitrite Sensor for Cancer ScreeningSabiran GibranNo ratings yet

- FerrousDocument538 pagesFerrousPutoy Itoy100% (1)

- CBSE Sample Paper Class 8 Science SA1 Set 1Document4 pagesCBSE Sample Paper Class 8 Science SA1 Set 1Vijayalakshmi Senthil100% (1)

- Biochemistry (DR Jhamad)Document90 pagesBiochemistry (DR Jhamad)dbchoudhary77No ratings yet

- Vacuum Technology Book II Part 1 PDFDocument88 pagesVacuum Technology Book II Part 1 PDFMuhammad Maratab Ali ZiaiNo ratings yet

- MDT Multisample Module PsDocument1 pageMDT Multisample Module PsariosabzNo ratings yet