Professional Documents

Culture Documents

RDB 535 Fault Finding Chart

Uploaded by

Francisco DuranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RDB 535 Fault Finding Chart

Uploaded by

Francisco DuranCopyright:

Available Formats

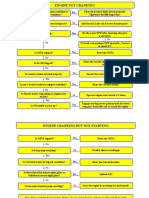

Fault Finding Logic For Control Box Type 535 SE/LD RDB Series Oil Burners

Burner Yes Lock out No Lock Out Yes Ignition Yes Pump Yes Nozzle Yes Combustion Yes Combustion

Motor within After 12 sec Spark Produces Atomising Air Set Head Set

Runs 1 second Purge Proved Pressure Fuel Correct Correct

No No No No No Yes

Yes

Check L & N Motor or Repair/ Check and Washing Yes Solenoid Replace Flame

To Control Pump Yes Replace set the Pressure operating Nozzle Off and

Box seized Motor/Pump Electrodes 1-2 Bar raise pressure Re-Lights

No No No No No No

Check Replace Replace Drive Replace the Contaminated Boiler or

Boiler Motor the control Coupling Coil &/ or Fuel Flue

Controls Capacitor box Broken Stem Valve Filter Blocked

No

Repair or

NOTES: Replace

Oil Pump

Solenoid coil test for resistance

of 100 Ohms (+-5) or continuity

Accurate Photocell testing is very difficult Motor Gives Yes Coil of Yes Photo Yes Replace If B/F application

without a lux meter so it is best to 50 Volt to Solenoid Cell Control remove burner snorkel

replace the photocell if suspect. white wire functional functional Box tube & retest

Motor white wire returns 50-53 No No No OK

Volt AC to control box

Replace Replace Replace Reseal B/F flue

Burners on Balanced flue systems Burner Solenoid Photo or re position

Can recirculate flue products Motor Coil Cell

resulting in burner recycling

if this happens check flue position & sealing

Approx: Coil Voltage

27-30v DC at ignition

3vDC on running

Permanent L/O Light

Check Polarity Approx: Photocell Resistance: Fuel Pump supply line pressure Fuel Pump By-Pass screw

Check no feedback on 2 Kohms with a strong Light no more than 0.5 bar and fitted in the return Port - Only

Remote L/O line OL in Dark vacuum pressure no more than when using a two pipe system.

then Cx Box (0.8 mA) 0.4 bar.

You might also like

- 3054 3056electronicDocument110 pages3054 3056electronicMohmed Abo Elftoh100% (5)

- Volvo BL 71 4 Power TransmissionDocument62 pagesVolvo BL 71 4 Power TransmissionVygintas Balcius50% (2)

- Hyundai D6GA Fuel System PDFDocument53 pagesHyundai D6GA Fuel System PDFTonny Nguyen100% (3)

- Neptune (Packet) V6.0 System SpecificationsDocument229 pagesNeptune (Packet) V6.0 System SpecificationsThe Quan BuiNo ratings yet

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Test Motor Transmisie Volvo Ec140Document4 pagesTest Motor Transmisie Volvo Ec140Michael DavenportNo ratings yet

- Engine: Workshop ManualDocument360 pagesEngine: Workshop ManualAutomotriz JTMotorsNo ratings yet

- Vdocuments - MX - Naza Ria MPV PDFDocument93 pagesVdocuments - MX - Naza Ria MPV PDFalangku09100% (2)

- Grúa Tadano Faun ATF 130 G5Document171 pagesGrúa Tadano Faun ATF 130 G5Reinaldo Zorrilla100% (2)

- 4 JB 1Document60 pages4 JB 1Rex Palmitos100% (1)

- VOLVO BL71 PLUS BACKHOE LOADER Service Repair ManualDocument12 pagesVOLVO BL71 PLUS BACKHOE LOADER Service Repair ManualMostafa75% (4)

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- 02-Engine Mechanical System PDFDocument129 pages02-Engine Mechanical System PDFSigit Indrawan100% (1)

- Isuzu 4JA1 Section 6Document249 pagesIsuzu 4JA1 Section 6Niti KlinKaew100% (1)

- C 152Document3 pagesC 152Diego Zamora0% (1)

- Service Manual (ES-F1408X)Document14 pagesService Manual (ES-F1408X)mdiyas aw0% (1)

- 05 Fuel SystemDocument109 pages05 Fuel SystemUtomo BudidarmoNo ratings yet

- 03-Engine Electrical System PDFDocument32 pages03-Engine Electrical System PDFAditiana SukadarusmanNo ratings yet

- Importance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)Document23 pagesImportance of Sub-Station Equipment Maintenance: Presented by MD - Golam Mowla XEN (G&P)rajshahieeeNo ratings yet

- Trouble ShootingDocument16 pagesTrouble ShootingVinay Singh100% (1)

- PPM TFC45 - HaishiDocument280 pagesPPM TFC45 - Haishicristian100% (3)

- Troubeshootings 8 Wheeler DHTC Detc-1Document27 pagesTroubeshootings 8 Wheeler DHTC Detc-1khan11k100% (1)

- Engine Performance TroubleshootingDocument4 pagesEngine Performance Troubleshootingfranklinrobin78No ratings yet

- Kawasaki Fa 210d 4 Stroke Trouble ShootingDocument6 pagesKawasaki Fa 210d 4 Stroke Trouble ShootingChris KrassNo ratings yet

- Cazafallas 2Document4 pagesCazafallas 2oscarNo ratings yet

- Engine Electrical EeDocument17 pagesEngine Electrical EePedro LopezNo ratings yet

- Diagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardDocument11 pagesDiagnose Engine Malfunctions: Symptom Problem Solution Engine Will Not Start or Starts HardAlejandro HernandezNo ratings yet

- Troubleshooting, RE80: Machine RE80 Serial Number Build Year Customer Customer Number Invoice Number Shipment DateDocument4 pagesTroubleshooting, RE80: Machine RE80 Serial Number Build Year Customer Customer Number Invoice Number Shipment DateFelipe Ambrocio GranadinoNo ratings yet

- 1.8L FP EngineDocument327 pages1.8L FP EngineKamil Charmik LužaNo ratings yet

- Engine ServiceDocument18 pagesEngine ServiceDhanu MalarNo ratings yet

- Engine FuelDocument24 pagesEngine FuelЮра Петренко100% (1)

- Engine Mechanical SystemDocument181 pagesEngine Mechanical Systemsled novaNo ratings yet

- Genpowerusa Generator TroubleshootingDocument2 pagesGenpowerusa Generator TroubleshootingKarthyc PillaiNo ratings yet

- TBM Gen GS01Document2 pagesTBM Gen GS01rohit tiwariNo ratings yet

- Genesis 3.8L Section 9Document52 pagesGenesis 3.8L Section 9Nacho MowjiNo ratings yet

- Varriable Speed Motor TroubleshootingDocument3 pagesVarriable Speed Motor Troubleshootingmattyg35No ratings yet

- Hydroserv Gen HS ELG 42Document2 pagesHydroserv Gen HS ELG 42rohit tiwariNo ratings yet

- Emission Control SystemDocument18 pagesEmission Control SystemLacatusu MirceaNo ratings yet

- Grúa Tadano Faun ATF 130 G5Document37 pagesGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNo ratings yet

- Trouble Shooting Suggestions Gas, Oil or Gas/Oil Burner: GeneralDocument12 pagesTrouble Shooting Suggestions Gas, Oil or Gas/Oil Burner: GeneralDody SukocoNo ratings yet

- Apu Troubleshoot Tree: Abbreviations & DefinitionsDocument8 pagesApu Troubleshoot Tree: Abbreviations & DefinitionsAde YahyaNo ratings yet

- 07.2-110 Testing, Adjusting EngineDocument16 pages07.2-110 Testing, Adjusting EngineMariusz NowakowskiNo ratings yet

- CazafallasDocument7 pagesCazafallasoscarNo ratings yet

- Adobe Scan 04 Aug 2023Document1 pageAdobe Scan 04 Aug 2023Samuel DinkuNo ratings yet

- KIA Carnival 04-Emission Control SystemDocument10 pagesKIA Carnival 04-Emission Control SystemHenryHutabarat100% (1)

- Panda AGT-DC 4000 Trouble ShootingDocument4 pagesPanda AGT-DC 4000 Trouble Shootingjerrywen08No ratings yet

- TBM Gen GS09Document2 pagesTBM Gen GS09rohit tiwariNo ratings yet

- HHP Trouble ShootingDocument13 pagesHHP Trouble ShootingSarin John SkariaNo ratings yet

- 4 Tec Troubleshooting ChartDocument11 pages4 Tec Troubleshooting ChartnelsoncoNo ratings yet

- MTU OE EX-MK-8-7 - Gen - Systems - Insp - Prev - Maint - ChecklistDocument1 pageMTU OE EX-MK-8-7 - Gen - Systems - Insp - Prev - Maint - ChecklistabdiNo ratings yet

- Volvo 850 Troubleshoot GuideDocument56 pagesVolvo 850 Troubleshoot Guidedaniel veraNo ratings yet

- Machine Test & Inspeciton ReportDocument8 pagesMachine Test & Inspeciton Reportvenkatesh kollisettiNo ratings yet

- Eue-Lab Final See2Document29 pagesEue-Lab Final See2Harsha SamagaraNo ratings yet

- SANTAFE (DMA) 2013 G 2.4 GDI Engine Electrical SystemDocument57 pagesSANTAFE (DMA) 2013 G 2.4 GDI Engine Electrical SystemHircel Leonardo GonzálezNo ratings yet

- Power Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky MovementsDocument1 pagePower Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky Movementsbetabet GeorgeNo ratings yet

- Fault Finding: Section F - TransmissionDocument1 pageFault Finding: Section F - TransmissionIonut GrozaNo ratings yet

- Industrial Resources, Inc.: Solar Taurus 60 Gas TurbineDocument28 pagesIndustrial Resources, Inc.: Solar Taurus 60 Gas TurbineIsabel PaixaoNo ratings yet

- Engine FuelDocument19 pagesEngine FuelJohn fredy cuervoNo ratings yet

- AlternatorsDocument8 pagesAlternatorsViệt LêNo ratings yet

- Troubleshooting - Dp50Document17 pagesTroubleshooting - Dp50Julinho Otiniano MauricioNo ratings yet

- Suntec Fuel Unit Test ManualDocument17 pagesSuntec Fuel Unit Test ManualsunnygyadavNo ratings yet

- GDC 800H Handset Eng User GuideDocument35 pagesGDC 800H Handset Eng User Guideadyta_roNo ratings yet

- Assignment No. 3 - Eng Maj 11Document4 pagesAssignment No. 3 - Eng Maj 11Mark GutierrezNo ratings yet

- Instant Download Strategic Market Management 11th Edition Aaker Solutions Manual PDF Full ChapterDocument7 pagesInstant Download Strategic Market Management 11th Edition Aaker Solutions Manual PDF Full Chapteramityleightonwfp9z100% (6)

- Ahu BoqDocument6 pagesAhu BoqBavakar ScribdNo ratings yet

- How To Import Satellite Image From Google Earth To ArcGISDocument10 pagesHow To Import Satellite Image From Google Earth To ArcGISMehmood AlamNo ratings yet

- Computer Science Textbook Solutions - 28Document30 pagesComputer Science Textbook Solutions - 28acc-expert0% (1)

- Product GroupsDocument2 pagesProduct GroupsDiego CanasaNo ratings yet

- Formulary - Aerodynamic Design of Turbomachinery: PV NRT, H HDocument2 pagesFormulary - Aerodynamic Design of Turbomachinery: PV NRT, H HZhifengNo ratings yet

- Social Media Rhetorical AnalysisDocument2 pagesSocial Media Rhetorical Analysisapi-548490632No ratings yet

- Lukas Erzett - Catalog - 2018 GBDocument443 pagesLukas Erzett - Catalog - 2018 GBGabriel DobrescuNo ratings yet

- Demo Junit Test: Introduction To Software TestingDocument21 pagesDemo Junit Test: Introduction To Software TestingNguyên HưngNo ratings yet

- 3D Catalog HG11 31 enDocument47 pages3D Catalog HG11 31 enqwkerbk090909No ratings yet

- Control Stepper Motor Using A NEXTION Display and 8Document45 pagesControl Stepper Motor Using A NEXTION Display and 8Kifah ZaidanNo ratings yet

- Die Design FeaturesDocument46 pagesDie Design FeaturesMohamed Abdel FattahNo ratings yet

- Backup Depth and Speed Display ALS6A200: Operations and Maintenance ManualDocument27 pagesBackup Depth and Speed Display ALS6A200: Operations and Maintenance ManualDiego CorderoNo ratings yet

- Kennvood DMF9020 SMDocument29 pagesKennvood DMF9020 SMbetmenn45No ratings yet

- Porcelain VS PolymersDocument6 pagesPorcelain VS PolymersLisa Harrington100% (1)

- A Knowledge-Based Master Modeling Approach To System Analysis and DesignDocument10 pagesA Knowledge-Based Master Modeling Approach To System Analysis and DesignHeribertoNo ratings yet

- Sony HCD Az2d PDFDocument110 pagesSony HCD Az2d PDFPranil RathodNo ratings yet

- Sesy Puspita Wulandari Putri A.Md - Ak CAP: Curriculem VitaeDocument1 pageSesy Puspita Wulandari Putri A.Md - Ak CAP: Curriculem VitaeAngelica FariadiNo ratings yet

- Machine GuardingDocument13 pagesMachine GuardingSwayam SARIT SatpathyNo ratings yet

- PowlVac-ND Metal-Clad SwitchgearDocument2 pagesPowlVac-ND Metal-Clad Switchgearalfayha sciNo ratings yet

- External Fire Design Standard For Vegetative Roofs: Ansi/Spri Vf-1Document10 pagesExternal Fire Design Standard For Vegetative Roofs: Ansi/Spri Vf-1Abdul Hadi AdriansyahNo ratings yet

- Chap-2 2 (RegularExpression)Document46 pagesChap-2 2 (RegularExpression)Mohmed IbrahimNo ratings yet

- KK Line-Topographic Survey report-TS02Document25 pagesKK Line-Topographic Survey report-TS02Aparna CkNo ratings yet

- IM AZ20M-EN D.bookDocument56 pagesIM AZ20M-EN D.bookHammad AshrafNo ratings yet

- Enhancement of Time-Based One-Time Password For 2-Factor AuthenticationDocument6 pagesEnhancement of Time-Based One-Time Password For 2-Factor AuthenticationInternational Journal of Innovative Science and Research TechnologyNo ratings yet