Professional Documents

Culture Documents

38865.sealbond Case - History

Uploaded by

paimanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

38865.sealbond Case - History

Uploaded by

paimanCopyright:

Available Formats

Case History

SealBond Cement Spacer System

Reduced Cementing Costs

System successfully avoided problems caused by lost circulation

Benefits

Reduced overall cost of surface

cement job

Effectively reduced cement losses

Eliminated need for two-stage

cement job

Minimized formation damage caused

by filtrate invasion

Background and challenges

Lost circulation zone with critical

fracture gradient

Staterequirement to ensure cement

brought to surface

Two-stage cement jobs with stage

tool typically used to achieve goals

Additional expense incurred with

A customer was cementing a surface string pumped. Although the water provided

stage tool use

and had planned on using a stage tool to good cleaning properties when used in

Baker Hughes solution and results ensure that cement was brought to surface conjunction with water-based mud, it did

Implemented Baker Hughes SealBond as required by Texas state law. Stage tools not prevent any lost circulation issues.

cement spacer system are necessary in primary cement jobs to

avoid exceeding the fracture gradient and The proposed plan was to run the SealBond

Provided a successful primary cement

job with reduced costs and rig time breaking down the formation. cement spacer system before the cement

job and complete the surface job in one

Reduced cement losses

Baker Hughes recommended using the attempt. During the actual job, SealBond

Eliminated the need for a stage tool SealBond™ cement spacer system to and 25 lbm/bbl (11 kg/bbl) of SealBond

and the second cementing stage

complete the job without using the tool. Plus were pumped followed by 715 bbl

Used rig time more efficiently The SealBond system would eliminate the (114 m3) of Class Cement at 14.8 lbm/gal,

need for the stage tool and avoid a second which was then displaced with 413 bbl

surface cement job, which would reduce the (66 m3) of mud. Approximately 27 bbl (4m3)

amount of cement the operator would need. of Class C cement successfully circulated

to surface.

The SealBond system has also been

effective in reducing cement losses The customer was able to cement the well

and enhancing whole cleaning before in one stage, which saved USD 15,000 in

the cement job. In previous work, the cement costs and approximately 5 hours

operator had frequently used fresh water of rig time at USD 2,000/hr. The SealBond

as a spacer between the mud already in cement spacer system eliminated the costs

the well and the cement that was to be associated with the second cementing stage.

The customer has been convinced of the

effectiveness of the SealBond system

when used in the proper application, and

has continued to use it for surface as well

as intermediate jobs. By incorporating

SealBond and SealBond Plus cementing

technologies, Baker Hughes has provided

the customer with successful primary

cement jobs with reduced rig time.

www.bakerhughes.com

SealBond is a trademark of Baker Hughes Incorporated.

Disclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, Baker Hughes Incorporated and

its affiliates do not make any warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent

permissible by law, including those of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided

herein. All information is furnished “as is” and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER

HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE

WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.

© 2013 Baker Hughes Incorporated. All rights reserved. 38865. 07/2013

You might also like

- SS 108 PDFDocument3 pagesSS 108 PDFHenry Dwi PuteraNo ratings yet

- Method Statement and SpecificationDocument17 pagesMethod Statement and SpecificationApai MfarNo ratings yet

- Cembrick BUILD PLASTER Shortened 2021Document17 pagesCembrick BUILD PLASTER Shortened 2021datmbathaNo ratings yet

- Subfloor Preparation GuideDocument8 pagesSubfloor Preparation GuideAlex BocicaNo ratings yet

- How To Avoid Screed Failure: Contact The Flooring SpecialistDocument7 pagesHow To Avoid Screed Failure: Contact The Flooring SpecialistSamuel WooNo ratings yet

- Field Trip QuestionsDocument4 pagesField Trip QuestionsYRA sachachNo ratings yet

- Hydrocyclone HarmonyDocument2 pagesHydrocyclone HarmonyPv RohithNo ratings yet

- Improvements in GroutingDocument4 pagesImprovements in Groutingrahuldevpatel5No ratings yet

- Installation QAQC ManualDocument100 pagesInstallation QAQC Manualkevinjun0% (1)

- Wet MillingDocument7 pagesWet MillingKiran ShettyNo ratings yet

- Mad RascalDocument23 pagesMad RascalRahul RathodNo ratings yet

- ShotcreteDocument18 pagesShotcretedartymind420No ratings yet

- Vacuum Dewaterimg: New Way For Concrete Flooring by Tremix MethodDocument7 pagesVacuum Dewaterimg: New Way For Concrete Flooring by Tremix Methodsachinkarape4844No ratings yet

- SealBond Mexico CsDocument2 pagesSealBond Mexico CshalimNo ratings yet

- Ce2071 - Repair and Rehablitation of Structures (For Viii - Semester)Document15 pagesCe2071 - Repair and Rehablitation of Structures (For Viii - Semester)Abera MamoNo ratings yet

- Grouting ManualDocument36 pagesGrouting ManualJorgeaul100% (1)

- Sandblasting Concrete Surface - Process and AdvantagesDocument6 pagesSandblasting Concrete Surface - Process and Advantagesvenkateswara rao pothinaNo ratings yet

- CGBM Revised NoteDocument10 pagesCGBM Revised NoteSunil Bose100% (1)

- OptiPort System Delivered 48-Stage Frac Job in 9 Days in Barnett Shale PDFDocument2 pagesOptiPort System Delivered 48-Stage Frac Job in 9 Days in Barnett Shale PDFMahmoud GaberNo ratings yet

- Design Procedures For Soil Modification or StabilizationDocument12 pagesDesign Procedures For Soil Modification or StabilizationBesim QelajNo ratings yet

- 26-1871-01 PaversDocument4 pages26-1871-01 Paversbanavaram1No ratings yet

- Ready Mix Concrete PPT 01Document28 pagesReady Mix Concrete PPT 01Pavan Kumar88% (16)

- Benefits of Cold Mix Technology Over Hot Mix Technology in Sustainable Road NetworkDocument7 pagesBenefits of Cold Mix Technology Over Hot Mix Technology in Sustainable Road NetworkAdvanced Research PublicationsNo ratings yet

- Index 2Document1 pageIndex 2dandekarvaibhavNo ratings yet

- NotesDocument2 pagesNotesArslaan AlamNo ratings yet

- Case - Study - 3M - Ceramic Sand Screen Deployed On Coiled TubingDocument2 pagesCase - Study - 3M - Ceramic Sand Screen Deployed On Coiled Tubingsmithyry2014No ratings yet

- Geo-Synthetic Cementitious Composite MattDocument11 pagesGeo-Synthetic Cementitious Composite MattSubhra LahiriNo ratings yet

- An Innovative Approch For Jet Grouting in Soft Clays: November 2020Document11 pagesAn Innovative Approch For Jet Grouting in Soft Clays: November 2020rigaz6366No ratings yet

- Casing Borehole Drilling Fluid Portland Cement Annulus Annular Gas Flow SlurryDocument2 pagesCasing Borehole Drilling Fluid Portland Cement Annulus Annular Gas Flow SlurryIbrahim A SaidNo ratings yet

- IATMI 20-044 Novel Low Expense Cement Slurry Design Based On Enhanced Cenosphere PropertiesDocument9 pagesIATMI 20-044 Novel Low Expense Cement Slurry Design Based On Enhanced Cenosphere Propertiesdiah ayu WulandariNo ratings yet

- Predictable and Successful Rock Injection - The First Time AroundDocument4 pagesPredictable and Successful Rock Injection - The First Time AroundStephan RossNo ratings yet

- Krystol Internal Membrane™ (KIM) : Technical Data SheetDocument3 pagesKrystol Internal Membrane™ (KIM) : Technical Data Sheetidea.statica97 idea.staticaNo ratings yet

- Cemtec 31 RDocument2 pagesCemtec 31 Rpravi3434No ratings yet

- What Is Worth?: ReliabilityDocument1 pageWhat Is Worth?: ReliabilityLoganBohannonNo ratings yet

- Sustainability: 1.1.1. BackgroundDocument15 pagesSustainability: 1.1.1. Backgroundkumar AbhishekNo ratings yet

- Method Statement Floor and Speciality JointsDocument10 pagesMethod Statement Floor and Speciality JointsJamsheed Ap KadangodNo ratings yet

- Underwater ConcretingDocument6 pagesUnderwater Concretingnepomucenoanne13No ratings yet

- Summer Internship ReportDocument17 pagesSummer Internship ReportSiddh NayakNo ratings yet

- Libro de Reforzamiento HORMIGON ARMADO 2022-5Document25 pagesLibro de Reforzamiento HORMIGON ARMADO 2022-5David Magne MamaniNo ratings yet

- Himani Bansal Jayant Negi Ritesh Kumar Uday PratapDocument7 pagesHimani Bansal Jayant Negi Ritesh Kumar Uday PratapJayant NegiNo ratings yet

- Quality Control in PlacementDocument8 pagesQuality Control in PlacementsarvadhNo ratings yet

- Cico Surface HardenerDocument2 pagesCico Surface HardenerSunil100% (1)

- BitumenDocument7 pagesBitumenArjun KumarNo ratings yet

- Precast Info Book FourDocument4 pagesPrecast Info Book FourSmaran ReddyNo ratings yet

- Ecma Admix 204: Technical Data SheetDocument2 pagesEcma Admix 204: Technical Data SheetSanthoshKumarSharmaCHNo ratings yet

- Corrogrout Admix Eb PDFDocument2 pagesCorrogrout Admix Eb PDFmanil_5No ratings yet

- Batimix Pervious Concrete SolutionDocument2 pagesBatimix Pervious Concrete SolutionAhmad SyihanNo ratings yet

- Joint Free Slabs: The ConceptDocument4 pagesJoint Free Slabs: The ConceptRoberto CarlosNo ratings yet

- Modern Advances and Applications of Sprayed Concrete: Construction ChemicalsDocument26 pagesModern Advances and Applications of Sprayed Concrete: Construction ChemicalsJorge Salomón ValdesNo ratings yet

- Cemstb 18 DecDocument45 pagesCemstb 18 DecMani KumarNo ratings yet

- 3.chemical Bonding AgentsDocument14 pages3.chemical Bonding AgentsakurilNo ratings yet

- Jet Grouting Brochure Keller UkDocument12 pagesJet Grouting Brochure Keller UkTimothy HughesNo ratings yet

- Fibra PlasticaDocument14 pagesFibra PlasticaEmiliano QuispeNo ratings yet

- Sikament - 163M PDFDocument2 pagesSikament - 163M PDFUgrasen ChaudharyNo ratings yet

- Materi Bab 10 Kelompok 8Document33 pagesMateri Bab 10 Kelompok 8Hartata Putra Mai Marta100% (1)

- Whitetopping NRRDADocument78 pagesWhitetopping NRRDAsombansNo ratings yet

- Design Methods of GeosyntheticsDocument84 pagesDesign Methods of GeosyntheticsSamuel Espartero100% (2)

- Sika Grind 200Document2 pagesSika Grind 200the pilotNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- Sect 06 Full-Opening EquipmentDocument44 pagesSect 06 Full-Opening EquipmentpaimanNo ratings yet

- Sect 10 Misc CMNTNG EquipmentDocument11 pagesSect 10 Misc CMNTNG EquipmentpaimanNo ratings yet

- Sect 01 Floating Guiding EquipmntDocument69 pagesSect 01 Floating Guiding EquipmntpaimanNo ratings yet

- ParaBow Presentation - Feb2015Document9 pagesParaBow Presentation - Feb2015paimanNo ratings yet

- Haliburton Cement AdditiveDocument33 pagesHaliburton Cement Additivepaiman0% (1)

- Sect 09 Multi-Stage FracturingDocument8 pagesSect 09 Multi-Stage FracturingpaimanNo ratings yet

- Sect 08 Plug CatchersDocument14 pagesSect 08 Plug CatcherspaimanNo ratings yet

- Transition Time of Cement SlurriesDocument3 pagesTransition Time of Cement SlurriespaimanNo ratings yet

- Sect 07 Formation Packer ShoesDocument14 pagesSect 07 Formation Packer ShoespaimanNo ratings yet

- Carrasco Teja2008Document13 pagesCarrasco Teja2008paimanNo ratings yet

- H 0357Document7 pagesH 0357paimanNo ratings yet

- Crook 1987Document6 pagesCrook 1987paimanNo ratings yet

- SealBond System in IraqDocument15 pagesSealBond System in IraqpaimanNo ratings yet

- 35905.divert S Acid System - Overview.0612Document1 page35905.divert S Acid System - Overview.0612paimanNo ratings yet

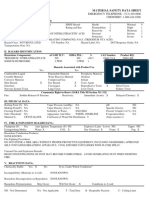

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- X-Tend Ii: DescriptionDocument2 pagesX-Tend Ii: DescriptionpaimanNo ratings yet

- Completion Fluid Services Liquid Viscosifier: DescriptionDocument2 pagesCompletion Fluid Services Liquid Viscosifier: DescriptionpaimanNo ratings yet

- N-Dril HT PlusDocument1 pageN-Dril HT PluspaimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- Ez-Core: Description EZ-CORE, A Refined Tall Oil Fatty Acid, Can Be Used As A Passive Emulsifier in All-OilDocument1 pageEz-Core: Description EZ-CORE, A Refined Tall Oil Fatty Acid, Can Be Used As A Passive Emulsifier in All-OilpaimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- EMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073Document2 pagesEMERGENCY TELEPHONE: (713) 439-8900 CHEMTREC: 1-800-424-9300 2001 Rankin Road Houston, Texas 77073paimanNo ratings yet

- Activator IDocument2 pagesActivator IpaimanNo ratings yet