Professional Documents

Culture Documents

Pressure Control Loop Wiring Connections

Uploaded by

Ammar Instrument0 ratings0% found this document useful (0 votes)

3 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views3 pagesPressure Control Loop Wiring Connections

Uploaded by

Ammar InstrumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Pressure Control Loop Wiring Connections

Prepared By : AMMAR MIRANI

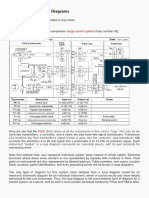

This pictorial diagram shows the wiring connections for a

simple pressure control loop, where a loop- powered 4-20 mA

pressure transmitter sends a signal to a Honeywell controller, which in

turn sends another 4-20 mA signal to a control valve:

Answer the following questions on the above shown pressure

control loop.

Sketch all directions of current, using conventional flow notation.

Identify which electrical devices in this system act as sources and which

act as loads.

If an operator informs you that the pressure indicated by the Honeywell

controller is below range (“pegged” full downscale, reading −25%), what

types and locations of electrical faults might you suspect? Are there any

non-electrical faults which might also cause this to happen?

If an operator informs you that the control valve remains fully shut no

matter the output value of the controller (even in “manual” mode), what

types and locations of electrical faults might you suspect? Are there any

non-electrical faults which might also cause this to happen?

Suppose that a short-circuit developed between the transmitter wires in

the four-conductor cable. Explain what effect this would have on the

operation of the system, as well as how you could determine that this fault

was in the cable (and not in the transmitter) with your only piece of test

equipment being a voltmeter.

Solution:

Even though the loop-powered transmitter does exert control over the

amount of current sent to the controller’s input, the transmitter acts as a

load rather than a source. In other words, it functions as a current

regulator while relying on the 24 VDC power supply to be the source of

motive power in the circuit.

Current Flow Direction in Pressure Control Loop

A full-downscale (−25%) reading at the controller suggests a 0 volt signal

at the controller’s input terminals. This could be caused by an open fault in

the transmitter wiring somewhere, because this correlates with a zero

current signal. It could also be caused by a short across the 250 ohm

resistor. The fault must be electrical in nature, as no other kind of problem

will cause the controller to lose all signal.

An unresponsive control valve suggests a lack of air pressure reaching

its diaphragm. This may be caused by any kind of electrical fault in the

output circuit (open or short) preventing current from reaching the I/P

transducer. It might also be the consequence of an air supply failure, or

perhaps a mechanical failure inside the I/P.

A short-circuit fault in the transmitter wiring will cause full current (> 20

mA) to be sent to the controller, making it “peg” full upscale. Normally, an

ammeter would be a helpful tool to isolate the location of this fault, but

here we only have access to a voltmeter.

In order to locate shorted faults using a voltmeter, we must break the

circuit and then measure voltage “upstream” (toward the source) to see

whether or not the shorted fault is “downstream” (toward the load)

You might also like

- Troubleshooting Current LoopsDocument14 pagesTroubleshooting Current LoopsrozzillaNo ratings yet

- Analog Electronics Instrumentation - Current LoopsDocument23 pagesAnalog Electronics Instrumentation - Current LoopsAnonymous WokAmg4jNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 270 EHC Sec 2a EHC Actuators and ValvesDocument19 pages270 EHC Sec 2a EHC Actuators and Valvesmendel Santa Fe ArenasNo ratings yet

- MS5908 English ManualDocument33 pagesMS5908 English ManualferruzziNo ratings yet

- Voltage Drop Test 122718Document3 pagesVoltage Drop Test 122718Abdul JabbarNo ratings yet

- LORAIN PP PresentationDocument22 pagesLORAIN PP PresentationRajesh Sharma100% (1)

- Re 95023Document8 pagesRe 95023Rafael Torres SabalzaNo ratings yet

- F003 AtosDocument4 pagesF003 Atoschandushar1604No ratings yet

- How A 4-20 Ma Transmitter WorksDocument3 pagesHow A 4-20 Ma Transmitter WorksVraja KisoriNo ratings yet

- Intro TwoWire Transmitters 4 20ma Current LoopDocument8 pagesIntro TwoWire Transmitters 4 20ma Current Loopchandushar1604No ratings yet

- 4 To 20 Ma Transmitter WorkingDocument7 pages4 To 20 Ma Transmitter WorkingVenkata Suresh MandavaNo ratings yet

- Series: Power Amplifier For Electro-Pneumatic Proportional ValveDocument3 pagesSeries: Power Amplifier For Electro-Pneumatic Proportional ValvejavierdepzNo ratings yet

- CMC P 530 Rms ManualDocument17 pagesCMC P 530 Rms ManualVicente GarciaNo ratings yet

- Acc Measure Nanoamperes AppNotesDocument3 pagesAcc Measure Nanoamperes AppNotesRabshaqaNo ratings yet

- Half Wave and Full Wave RectifierDocument10 pagesHalf Wave and Full Wave RectifiersunilsathishNo ratings yet

- Chapter 5Document39 pagesChapter 5Portia ShilengeNo ratings yet

- 4-20ma Current LoopDocument1 page4-20ma Current LoopYasir JamilNo ratings yet

- Pass Laboratories Aleph 5 Service ManualDocument8 pagesPass Laboratories Aleph 5 Service ManualShakarak1No ratings yet

- EDN Design Ideas 2004Document155 pagesEDN Design Ideas 2004chag1956100% (2)

- LM108, LM117: Application Note 178 Applications For An Adjustable IC Power RegulatorDocument7 pagesLM108, LM117: Application Note 178 Applications For An Adjustable IC Power RegulatornickynandanamNo ratings yet

- ApNote810 Wiringa4 20mALoopDocument3 pagesApNote810 Wiringa4 20mALoopEduardo_77No ratings yet

- APC200 ECM-ECI Error Codes Ver1.0Document9 pagesAPC200 ECM-ECI Error Codes Ver1.0Jose Tranquilino Renteria83% (6)

- Instrumentation Loop DiagramsDocument4 pagesInstrumentation Loop DiagramsVraja KisoriNo ratings yet

- Loop Checking Basic ProcedureDocument4 pagesLoop Checking Basic ProcedureHamada Elsharawy100% (1)

- Low Pressure Transducers - LP3 Series: DescriptionDocument4 pagesLow Pressure Transducers - LP3 Series: DescriptioncauvongkhongmauNo ratings yet

- Fuel Delivery (DEPR) : Electrical System Diagnostic Trouble CodesDocument5 pagesFuel Delivery (DEPR) : Electrical System Diagnostic Trouble CodesEsjoNo ratings yet

- LH SeriesDocument4 pagesLH Seriesge_bdNo ratings yet

- Measurement of Current With A Voltage DAQDocument3 pagesMeasurement of Current With A Voltage DAQKh SabNo ratings yet

- Thyristor Based HVDC SystemDocument5 pagesThyristor Based HVDC SystemAnonymous hzXy93FAE0% (1)

- Unit2 MSDocument43 pagesUnit2 MSchandramohan murugan100% (1)

- MPC-20 MPC-50 Indirect Earth Simulator ManualDocument30 pagesMPC-20 MPC-50 Indirect Earth Simulator ManualAnonymous 4kYNmixNo ratings yet

- LM393 DDocument10 pagesLM393 DPardeep KumarNo ratings yet

- Sequencer Compressor Module (STD) - 100016166 & ZS1066046Document9 pagesSequencer Compressor Module (STD) - 100016166 & ZS1066046abdur rohman100% (1)

- Fire Detection Systems GuideDocument28 pagesFire Detection Systems Guideleanh121No ratings yet

- Failiure Codes DANADocument8 pagesFailiure Codes DANAHasan Hamit AydınNo ratings yet

- Pass Aleph 3Document11 pagesPass Aleph 3eletropcNo ratings yet

- How Harmonic Mitigating TransformersDocument5 pagesHow Harmonic Mitigating TransformersRa ArNo ratings yet

- EB 57 EWLC TroubleshootingDocument7 pagesEB 57 EWLC TroubleshootingFrenkyFaking FourFingersNo ratings yet

- Man02817y 0Document34 pagesMan02817y 0GustavoNo ratings yet

- Troubleshooting Pulse Meters Part 2Document8 pagesTroubleshooting Pulse Meters Part 2bauro mikaereNo ratings yet

- Voltage Sag Analysis Case StudiesDocument7 pagesVoltage Sag Analysis Case Studiesmonirul_ahmedNo ratings yet

- 2505 Tips TricksDocument5 pages2505 Tips TricksaalvarcaNo ratings yet

- Aplicacion Practica Fluke 360Document3 pagesAplicacion Practica Fluke 360mci_ingNo ratings yet

- Vax21 31 Mvaxm Commisionin GDocument6 pagesVax21 31 Mvaxm Commisionin GSumit VermaNo ratings yet

- 1 Fluke87 U2L3S TXTDocument11 pages1 Fluke87 U2L3S TXTPablo Gaspar D'Agostini AmengualNo ratings yet

- Power Supply Testing On Danfos bd35 50 SystemsDocument2 pagesPower Supply Testing On Danfos bd35 50 SystemsMuhammad PandorNo ratings yet

- Altronic Stepper Motor Controller Operating Manual 691156-1 Form SMC Om 12-04Document4 pagesAltronic Stepper Motor Controller Operating Manual 691156-1 Form SMC Om 12-04Esau Jose PabloNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Learn To Interpret Single Line Diagram (SLD)Document4 pagesLearn To Interpret Single Line Diagram (SLD)M Luthfi FathoniNo ratings yet

- CL1060A ManualDocument9 pagesCL1060A Manualtito983No ratings yet

- Understanding Voltage Regulators - Smart Grid Solutions - SiemensDocument5 pagesUnderstanding Voltage Regulators - Smart Grid Solutions - SiemenstusarNo ratings yet

- Electrical Symbols and Line DiagramDocument37 pagesElectrical Symbols and Line DiagramMatthew GarciaNo ratings yet

- LM25005, LM25010: Buck Regulator Topologies For Wide Input/Output Voltage DifferentialsDocument10 pagesLM25005, LM25010: Buck Regulator Topologies For Wide Input/Output Voltage DifferentialsBejoy ThomasNo ratings yet

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Normally-Open and Normally-Closed Switch ContactsDocument10 pagesNormally-Open and Normally-Closed Switch ContactsAmmar InstrumentNo ratings yet

- ICS Control System SecurityDocument7 pagesICS Control System SecurityAmmar InstrumentNo ratings yet

- Fail Open (FO) - Air To Close&Fail Closed (FC) - Air To OpenDocument3 pagesFail Open (FO) - Air To Close&Fail Closed (FC) - Air To OpenAmmar InstrumentNo ratings yet

- Basics of Vibration MeasurementDocument8 pagesBasics of Vibration MeasurementAmmar Instrument100% (1)

- Powerful Communication Tools For Successful Acupuncture PracticeDocument4 pagesPowerful Communication Tools For Successful Acupuncture Practicebinglei chenNo ratings yet

- Material Safety Data Sheet: Wonder Gel™ Stainless Steel Pickling GelDocument2 pagesMaterial Safety Data Sheet: Wonder Gel™ Stainless Steel Pickling GelTrần Thùy LinhNo ratings yet

- Schedule NDocument3 pagesSchedule Nmittal kelaNo ratings yet

- Schematic Diagram For Pharmaceutical Water System 1652323261Document1 pageSchematic Diagram For Pharmaceutical Water System 1652323261Ankit SinghNo ratings yet

- 2-Product Spec PDFDocument10 pages2-Product Spec PDFMhooMOoChaappHteenNo ratings yet

- BKM 10e Ch07 Two Security ModelDocument2 pagesBKM 10e Ch07 Two Security ModelJoe IammarinoNo ratings yet

- What Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Document5 pagesWhat Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Rica machells DaydaNo ratings yet

- Vital Statistics: Presented by Mrs - Arockia Mary Associate ProfDocument17 pagesVital Statistics: Presented by Mrs - Arockia Mary Associate ProfraghumscnNo ratings yet

- NCR RepairDocument4 pagesNCR RepairPanruti S SathiyavendhanNo ratings yet

- Vaccination Schedule in Dogs and CatsDocument3 pagesVaccination Schedule in Dogs and CatsAKASH ANANDNo ratings yet

- 220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsDocument34 pages220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsJVMNo ratings yet

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Document4 pages(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungNo ratings yet

- Operational Safety and Health Procedures, Practices and RegulationsDocument20 pagesOperational Safety and Health Procedures, Practices and RegulationsDionisa ErnacioNo ratings yet

- (Engine International Air Pollution Prevention) : EIAPP CertificateDocument2 pages(Engine International Air Pollution Prevention) : EIAPP CertificateTan DatNo ratings yet

- Cyber Safety PP Presentation For Class 11Document16 pagesCyber Safety PP Presentation For Class 11WAZ CHANNEL100% (1)

- DR Hoon Park III - Indigenous Microorganism (IMO)Document33 pagesDR Hoon Park III - Indigenous Microorganism (IMO)neofrieda79100% (1)

- Earth Loop ImpedanceDocument5 pagesEarth Loop ImpedanceKaranjaNo ratings yet

- Catalogue CV. Traka Abadi UniversalDocument15 pagesCatalogue CV. Traka Abadi UniversalHackers StevenNo ratings yet

- AA-036322-001 - Anchor Bolt DetailsDocument1 pageAA-036322-001 - Anchor Bolt DetailsGaurav BedseNo ratings yet

- CP 1Document22 pagesCP 1api-3757791100% (1)

- Borelog CP.101Document1 pageBorelog CP.101radixkusumaNo ratings yet

- LECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentDocument32 pagesLECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentmusabNo ratings yet

- BV DSG eDocument18 pagesBV DSG eIulianIonutRaduNo ratings yet

- SA 8000 Audit Check List VeeraDocument6 pagesSA 8000 Audit Check List Veeranallasivam v92% (12)

- Business PlanDocument17 pagesBusiness PlanChester Cortez50% (2)

- Biology - Cell City AnswersDocument5 pagesBiology - Cell City AnswersDaisy be100% (1)

- Bitumen BasicsDocument25 pagesBitumen BasicsMILON KUMAR HORENo ratings yet

- Chapter 03Document35 pagesChapter 03david jenil nabuaNo ratings yet

- Pressure Vessels SHO ProgrammeDocument42 pagesPressure Vessels SHO Programmehew ka yeeNo ratings yet

- Literary Portraiture & Modern Spain: Dr. Rebecca M. Bender (Document6 pagesLiterary Portraiture & Modern Spain: Dr. Rebecca M. Bender (Pedro PorbénNo ratings yet