Professional Documents

Culture Documents

Low Pressure Transducers - LP3 Series: Description

Uploaded by

cauvongkhongmauOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Pressure Transducers - LP3 Series: Description

Uploaded by

cauvongkhongmauCopyright:

Available Formats

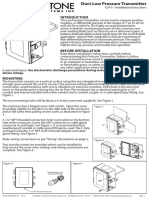

Low Pressure Transducers – LP3 Series Installation and Operating Instructions

Description

The Low Pressure Transducer can be used to measure positive, negative or differential pressure in the ranges of 1”wc to

20”wc. The highly accurate piezoresistive sensor is ideal for monitoring pressure of non-corrosive, non-ionic working fluids

such as clean dry air or other inert gases. It features field selectable pressure ranges and output signal types for the most

flexible application. Typical HVAC applications include monitoring of filter differential pressure or clean room pressure. The

output signal is factory calibrated and temperature compensated for highest startup accuracy and trouble-free operation.

Before Installation

Read these installation instructions carefully before commissioning the Pressure Transducer. Failure to follow these

instructions may result in product damage. Do not use in an explosive or hazardous environment, with combustible or

flammable gasses, as safety or emergency stop devices or in any other application where failure of the product could result in

personal injury. Use electrostatic discharge precautions during installation and do not exceed the device ratings.

Mounting

Mount the Pressure Transducer on any surface using the two holes on the base of the unit. Ensure there is enough space

around the unit to connect the pressure tubing without kinking and avoid locations with severe vibrations or excessive

moisture. Mount the enclosure with two screws but do not over-tighten. It may be mounted in any position but typically is

installed on a vertical surface with the pressure ports on the right and the cable entrance on the left. The enclosure has a

standard ½” conduit opening and may be installed with either conduit and a conduit coupler or a cable gland type fitting.

Wiring Instruction

The transmitter has standard screw block connectors and easy wire access to facilitate wiring. It is recommended that

shielded twisted pair wiring at least 22 AWG be used for all connections and that the device wires not be run in the same

conduit with wiring used to supply inductive loads such as motors. Disconnect the power supply before making any

connections to prevent electrical shock or equipment damage. Make all connections in accordance with national and local

electrical codes.

The device power (24 Vac/dc) is connected to the terminal marked PWR. This terminal is used for the positive dc voltage or

the hot side of the ac voltage. The device is reverse voltage protected and as such will not operate if connected backwards.

For voltage output signal types (3-wire) or for AC power supply operation (3-wire), the common of the power supply is

connected to the terminal marked COM. Note that this device has a half-wave type power supply which means the power

supply common is the same as the output signal common. Therefore, several devices may be connected to one power supply

and the output signals all share the same signal common. Use caution when grounding the secondary of an ac transformer or

when wiring multiple devices to ensure that the circuit ground point is the same on all devices and the controller. This

terminal is not used for loop-powered 4-20 mA output type (2-wire).

The analog output signal is available on the OUT terminal. This signal is switch selectable for either a voltage output or a

standard loop-powered 4-20 mA output signal type. When voltage mode is selected, either 0-5 Vdc or 0-10 Vdc can also be

selected. These options are clearly indicated on the device circuit board. The analog output signal is typically connected

directly to the Building Automation System (B.A.S.) and used as a control parameter or for logging purposes.

For voltage type output signal the device has a minimum load that it is able to drive, similarly for current type output signal

the device has a maximum load that it is able to drive with a particular power supply voltage. Observe and follow these

ratings in the Specification section or inaccurate reading may result. The 4-20 mA output signal can easily be converted to a

1-5 Vdc signal for controllers accepting this type of input. Simply insert a 250 ohm (0.1% is best) resistor between the “+”

and “-” inputs of the controller. This will convert the 4-20 mA signal to the desired 1-5 Vdc.

Pneumatic Connections

The two pressure ports on the end of the enclosure are labeled High and Low. The output signal reads a positive value when

the port pressure is higher on the High port than the Low port so ensure these ports are connected correctly. Use 0.170” I.D.

flexible tubing for the pressure connections. Arrange the tubing to minimize stress on the connections and ensure there are no

kinks in the tubing. For most accurate measurements, do not leave the Low port open to the atmosphere, run a return line

from the Low port to the vicinity of the point being measured.

May 17, 2011 1

Low Pressure Transducers – LP3 Series Installation and Operating Instructions

Ensure the tubing to be used is clean and do not allow material to fall into the pressure ports as contamination could damage

the sensor. When removing tubing use care to avoid breaking the ports. In some cases it is better to cut the tubing off rather

than pulling it off but be careful not to cut the fitting or an air leak may occur.

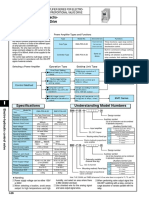

Configuration

The transmitter is configured with switches located on the circuit board as shown on the pcb drawing. These switches are

used to select the output signal type and the input pressure range.

The unit is factory configured to operate in the 4-20 mA output mode. This can be changed to the voltage mode by moving

the switch from the position marked 4-20 mA to the position marked Voltage. Once the output mode is changed to voltage,

the output scale may be changed to either 0-5 Vdc or 0-10 Vdc. This is done by moving the switch to the 5V or 10V position.

The pressure range is set with a four position DIP switch. The available ranges are marked in the MODEL section on the

circuit board. The pressure ranges are shown in the following chart:

Switch

Setting LP3-00 LP3-01 LP3-02 LP3-03 LP3-04 LP3-05

LOW 1” wc 3” wc 6” wc 10” wc 0.25 kPa 0.5 kPa

MID 2” wc 5” wc 10” wc 15” wc 0.5 kPa 1 kPa

HIGH 4” wc 8” wc 12” wc 20” wc 1 kPa 2 kPa

For example, if the LOW range is selected on the LP3-00 model, the pressure range will be 0-1” wc. If the 4th DIP switch

labeled (+/-) is also set to ON, then the pressure range will be –1 to +1” wc. This means that each model has six pressure

ranges. For the LP3-00 they will be 0-1, 0-2, 0-4, 1, 2 and 4 “wc.

Power Up Instruction

Before turning on the power, verify all wiring to ensure that it complies with one of the included wiring diagrams and verify

that the output signal type is correctly selected with the switches. Also, review the specifications to ensure the power supply

is correct and that the pressure is within the correct range. At this time, also inspect the internal pressure tubing that connects

the sensor to the external ports to ensure that the tubing did not get kinked during shipping or installation.

Proper operation can be verified by measuring the output signal. For voltage output configuration, measure the voltage

between the OUT and COM terminals. The voltmeter should read between 0-5 Vdc or 0-10 Vdc depending on the output

range selected. For current output configuration, insert a mA meter in series with the OUT terminal. The mA meter should

read between 4 and 20 mA.

Operation

If the unit is set to a unipolar range such as 0-2” wc, then the pressure applied to the High port must be higher than the

pressure applied to the Low port. In this case, if the Low port is left open to ambient pressure and the High port is used to

measure a positive pressure, then the output pressure can be calculated as follows:

4-20 mA Pressure = [(Output current – 4 mA) / 16 mA] x Range

0-5 Vdc Pressure = (Output voltage / 5 V) x Range

0-10 Vdc Pressure = (Output voltage / 10 V) x Range

In the case of 0-2” wc, 4 mA or 0 V = 0” wc and 20 mA or 5 V or 10 V = 2” wc. Since the transmitter is linear, 1” wc would

be 12 mA or 2.5 V or 5 V. If the positive pressure connection is reversed then the transmitter will always output 4 mA or 0 V.

If the unit is set to a bipolar range such as 2” wc, then the pressure applied to the High port should be higher than the

pressure applied to the Low port for a positive output response. In this case, differential pressure can be measured using both

ports. If the High port has a positive pressure with respect to the Low port, then the output indicates a positive pressure.

Negative pressure is indicated if the High pressure is less than the Low pressure. For bipolar ranges, the output pressure can

be calculated as follows:

4-20 mA Pressure = [(Output current – 4 mA) / 16 mA] x 2 x Range – Offset

0-5 Vdc Pressure = (Output voltage / 5 V) x 2 x Range – Offset

0-10 Vdc Pressure = (Output voltage / 10 V) x 2 x Range – Offset

May 17, 2011 2

Low Pressure Transducers – LP3 Series Installation and Operating Instructions

In the case of 2” wc, 4 mA or 0 V = -2” wc and 20 mA or 5 V or 10 V = +2” wc. Since the transmitter is linear, 0” wc

would be 12 mA or 2.5 V or 5 V.

Calibration

All pressure ranges are factory calibrated and no calibration is necessary. The user may adjust the zero point if desired when

changing ranges for example. Make sure the unit is warmed up for at least 10 minutes (1 hour is best) before making a zero

adjustment. With both ports open to the ambient pressure, press and hold the ZERO button for at least 3 seconds. Release the

button after at least 3 seconds and the device will calculate and store the new zero point.

Generally, it is not recommended that the span calibration be performed in the field unless a high quality calibrator with low

differential pressure ranges is available and the temperature of the sensor can be maintained. Contact the factory for

information on this type of calibration.

Specifications

Pressure Ranges (6 per model, switch selectable) . . 0-1”, 0-2”, 0-4”, 1”, 2”, 4” wc

0-3”, 0-5”, 0-8”, 3”, 5”, 8” wc

0-6”, 0-10”, 0-12”, 6”, 10”, 12” wc

0-10”, 0-15”, 0-20”, 10”, 15”, 20” wc

0-0.25, 0-0.5, 0-1, 0.25, 0.5, 1 kPa

0-0.5, 0-1, 0-2, 0.5, 1, 2 kPa

Accuracy . . . . . . . . . . . . . . . . . . . . 1% F.S.O.

Measurement Type . . . . . . . . . . . . Differential (two port)

Response Time . . . . . . . . . . . . . . . . 250 mS

Stability . . . . . . . . . . . . . . . . . . . . . < 1% F.S.O. per year

Thermal Effects . . . . . . . . . . . . . . . < 3% over compensated range

Compensated Range . . . . . . . . . . . 0 - 50 C (32 - 122 F)

Proof Pressure . . . . . . . . . . . . . . . . 40” wc all models (100” wc for 12” and 20” models)

Burst Pressure . . . . . . . . . . . . . . . . 60” wc all models (200” wc for 12” and 20” models)

Operating Conditions . . . . . . . . . . 0 - 70 C (32 - 158 F), 10 - 90 %RH non-condensing

Media Compatibility . . . . . . . . . . . Non-corrosive, non-ionic fluids such as clean dry air or inert gases

Power Supply . . . . . . . . . . . . . . . . . 20 - 28 Vac/dc (non-isolated half-wave rectified)

Supply Current . . . . . . . . . . . . . . . . < 4 mA

Input Voltage Effect . . . . . . . . . . . Negligible over specified operating range

Protection Circuitry . . . . . . . . . . . . Reverse voltage protected and output limited

Output Signal . . . . . . . . . . . . . . . . . 4-20 mA (2-wire), 0-5 Vdc or 0-10 Vdc (3-wire), switch selectable

Current Output Drive Capability . . 400 ohms max @ 24 Vdc

Voltage Output Drive Capability . . 10K ohms min

Zero Adjustment . . . . . . . . . . . . . . Pushbutton auto-zero

Wiring Connections . . . . . . . . . . . . Screw terminal block (14 to 22 AWG)

Pressure Connections . . . . . . . . . . . Barbed ports for 0.170” ID flexible tubing

Conduit Connection . . . . . . . . . . . . Access hole for ½” NPT conduit or cable gland

Optional Display . . . . . . . . . . . . . . 3 ½ digit LCD, 0.4” digit height

Enclosure . . . . . . . . . . . . . . . . . . . . High Impact Black ABS, plenum rated with optional gasket

5.00" W x 3.3" H x 2.1" D (127mm x 84mm x 53mm)

Weight . . . . . . . . . . . . . . . . . . . . . . 159 grams (5.6 oz)

May 17, 2011 3

Low Pressure Transducers – LP3 Series Installation and Operating Instructions

May 17, 2011 4

You might also like

- Digital Multimeter Instruction ManualDocument31 pagesDigital Multimeter Instruction ManualAbrahan CortezNo ratings yet

- Digital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Document15 pagesDigital/Bar-Graph Pressure Gauge Installation Instructions DPS-1591DP FORM DPS1591 II 7-02Clever Negrete NovaNo ratings yet

- Install Digital Pressure GaugeDocument15 pagesInstall Digital Pressure GaugeClever Negrete NovaNo ratings yet

- LORAIN POWER PLANT MICROPROCESSOR CONTROL PANELDocument22 pagesLORAIN POWER PLANT MICROPROCESSOR CONTROL PANELRajesh Sharma100% (1)

- Liquid Level Control Using A Pressure Senso R: Application NoteDocument9 pagesLiquid Level Control Using A Pressure Senso R: Application NoteNovian PratamaNo ratings yet

- Multifunctional Digital Multimeter: User Manual Gebruikershandleiding Manuel D'UtilisationDocument9 pagesMultifunctional Digital Multimeter: User Manual Gebruikershandleiding Manuel D'UtilisationtonielhageNo ratings yet

- AC/DC Clamp Meter User's ManualDocument20 pagesAC/DC Clamp Meter User's ManualMartin OngNo ratings yet

- Manual Multimetro Mastech My-67Document16 pagesManual Multimetro Mastech My-67WisdomBriceñoAbreuNo ratings yet

- Manual de Uso Mastech Mas838Document11 pagesManual de Uso Mastech Mas838Mario Carrasco DiazNo ratings yet

- What Is A Pressure Transmitter ?: Differential Pressure Pressure Measuring InstrumentDocument11 pagesWhat Is A Pressure Transmitter ?: Differential Pressure Pressure Measuring InstrumentPriNo ratings yet

- In Ge ElpxxxsDocument4 pagesIn Ge ElpxxxsNinh Quang TrườngNo ratings yet

- LEM Active P SeriesDocument8 pagesLEM Active P Seriesjuan manuel sierra solisNo ratings yet

- 629 IomDocument2 pages629 Iom234534No ratings yet

- InstrumentationDocument56 pagesInstrumentationavandetq15No ratings yet

- Wireless TRMS Multimeter: User's GuideDocument17 pagesWireless TRMS Multimeter: User's Guidespock_65No ratings yet

- Mam Ky02sDocument34 pagesMam Ky02sTaufan Justvands67% (3)

- DWYER - RHP-3D-11.instruções PDFDocument4 pagesDWYER - RHP-3D-11.instruções PDFMarcio Issao WatanabeNo ratings yet

- M4680GB0 D0929Document20 pagesM4680GB0 D0929Barceanu MihaiNo ratings yet

- LM2907Document21 pagesLM2907leorio88No ratings yet

- Differential Pressure TransmitterDocument14 pagesDifferential Pressure TransmitterZainab KadhemNo ratings yet

- LM392Document6 pagesLM392Brzata PticaNo ratings yet

- PRACTICAL DP TransmitterDocument5 pagesPRACTICAL DP TransmitterPATEL SWAPNEELNo ratings yet

- Johnson-Controls Informatiebrochure p216 enDocument8 pagesJohnson-Controls Informatiebrochure p216 enAhmed AzadNo ratings yet

- Mul 015Document12 pagesMul 015api-3730132No ratings yet

- Controlador de Nivel Danfoss EKC347Document12 pagesControlador de Nivel Danfoss EKC347dyeisonsiqueiraNo ratings yet

- H1000e I Ema-Emc PDFDocument4 pagesH1000e I Ema-Emc PDFNguyen Van ChungNo ratings yet

- Altronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)Document47 pagesAltronic DSG1611DUPS Gauge Install. - Oper. Instructions (FORM DSG1611DUPS II)francis_mouille_iiNo ratings yet

- DP CalibrationDocument12 pagesDP CalibrationGeorge AsuncionNo ratings yet

- Chassis CTC186 187ABDocument20 pagesChassis CTC186 187ABjujorokoNo ratings yet

- MANSON Power Supply - SPS9400 - ServiceManualDocument18 pagesMANSON Power Supply - SPS9400 - ServiceManualrangerfordNo ratings yet

- TransmittersDocument15 pagesTransmittersAarkayChandru100% (1)

- Amplifier Card For Valve With Feedback UEIK 11RSDocument4 pagesAmplifier Card For Valve With Feedback UEIK 11RSLibin100% (1)

- How A Current To Pressure Transducer (I - P) Works - Learning Instrumentation AnDocument2 pagesHow A Current To Pressure Transducer (I - P) Works - Learning Instrumentation AnLeDuNo ratings yet

- Steca Solsum VC Instruction enDocument1 pageSteca Solsum VC Instruction enMarcu TeodorNo ratings yet

- Rane Ac23Document18 pagesRane Ac23dxnxbNo ratings yet

- lm2917 NDocument24 pageslm2917 NAlejandro RojoNo ratings yet

- New EhtcDocument4 pagesNew EhtcRamakrishnan NatarajanNo ratings yet

- Operator'S Instruction Manual: 903-150NAS 903-150NBS 303-150NCS 903-150NDSDocument20 pagesOperator'S Instruction Manual: 903-150NAS 903-150NBS 303-150NCS 903-150NDSPhạm VinhNo ratings yet

- Phenix PAD10-25 Version 3.1 UMDocument25 pagesPhenix PAD10-25 Version 3.1 UMWashington VásquezNo ratings yet

- lm2907 PDFDocument20 pageslm2907 PDFArieNo ratings yet

- K-tv14m3 y K-tv21m3 Konka - KalleyDocument7 pagesK-tv14m3 y K-tv21m3 Konka - Kalleyandresriveram77No ratings yet

- AY-At Color Kit Tester ManualDocument5 pagesAY-At Color Kit Tester ManualAnais Cullon BermejoNo ratings yet

- AY-AT Color Kit Tester Manual PDFDocument5 pagesAY-AT Color Kit Tester Manual PDFJustin NgNo ratings yet

- BK130 1Document26 pagesBK130 1huychampiNo ratings yet

- AC Current TransducerDocument5 pagesAC Current TransducerOrlando MelipillanNo ratings yet

- Electronics Lab Manual Experiment 1 FamiliarizationDocument12 pagesElectronics Lab Manual Experiment 1 FamiliarizationAbdisalam A. MohamedNo ratings yet

- Milti TesterDocument5 pagesMilti Testerkdm004xxNo ratings yet

- ICA-UNIT-III - R19-CompleteDocument28 pagesICA-UNIT-III - R19-CompleteBhanu Kiran BKNo ratings yet

- DVM 68 LCD Auto Range Digital Multimeter: Operation Manual Gebruikershandleiding Manuel D'UtilisateurDocument10 pagesDVM 68 LCD Auto Range Digital Multimeter: Operation Manual Gebruikershandleiding Manuel D'UtilisateurdragelaNo ratings yet

- Magnetrol 48-635Document36 pagesMagnetrol 48-635João LuizNo ratings yet

- TX-32PM1 and TX-28PM1 Service ManualDocument28 pagesTX-32PM1 and TX-28PM1 Service ManualSean GuyNo ratings yet

- Describe How To Use Multimeters To Measure CurrentDocument25 pagesDescribe How To Use Multimeters To Measure CurrentKobby BrineNo ratings yet

- FMC 420Document6 pagesFMC 420SiavashNsiNo ratings yet

- B Precision K: Instruction ManualDocument43 pagesB Precision K: Instruction Manualedgartepe4324No ratings yet

- Ultrasonic Level SensorDocument20 pagesUltrasonic Level SensorEd CalheNo ratings yet

- Inverter Checks GuideDocument4 pagesInverter Checks GuideTarak BenslimaneNo ratings yet

- Electronics Lab MachinesDocument11 pagesElectronics Lab MachinesTiofelus H. HamutenyaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- PIFQ236L3665 BattenV-ShapeLuminairePIFQSeries2x20W6500KIP201.2mPowdercoatedaluminiumDocument1 pagePIFQ236L3665 BattenV-ShapeLuminairePIFQSeries2x20W6500KIP201.2mPowdercoatedaluminiumcauvongkhongmauNo ratings yet

- PSN40-400A Air Differential Pressure SwitchDocument2 pagesPSN40-400A Air Differential Pressure SwitchcauvongkhongmauNo ratings yet

- Selection Maintanance PF PDFDocument73 pagesSelection Maintanance PF PDFkrcdewanewNo ratings yet

- MS4104, MS4109, MS4604, MS4609, MS8104, MS8109 Fast-Acting, Two-Position ActuatorsDocument8 pagesMS4104, MS4109, MS4604, MS4609, MS8104, MS8109 Fast-Acting, Two-Position ActuatorscauvongkhongmauNo ratings yet

- EcodialAdvanceCalculation HelpDocument53 pagesEcodialAdvanceCalculation HelpcauvongkhongmauNo ratings yet

- Honeywell FDDocument1 pageHoneywell FDcauvongkhongmauNo ratings yet

- All Purpose High Limit Thermostat: THAP Series - Installation InstructionsDocument2 pagesAll Purpose High Limit Thermostat: THAP Series - Installation InstructionscauvongkhongmauNo ratings yet

- Mastering Landscape Lighting Design: Part IDocument18 pagesMastering Landscape Lighting Design: Part IcauvongkhongmauNo ratings yet

- Access Control Solutions: Designing and InstallingDocument40 pagesAccess Control Solutions: Designing and InstallingYosphe MengistuNo ratings yet

- Formulas of Power Engineering: .Dslwho BhqlqgeDocument1 pageFormulas of Power Engineering: .Dslwho BhqlqgecauvongkhongmauNo ratings yet

- AccessDocument26 pagesAccesssarjoonNo ratings yet

- Megger InsulationtesterDocument67 pagesMegger InsulationtesterNh Chuminda YapaNo ratings yet

- S8VK-C Switch Mode Power Supply SeriesDocument20 pagesS8VK-C Switch Mode Power Supply SeriescauvongkhongmauNo ratings yet

- Hochiki Detector Bases GuideDocument2 pagesHochiki Detector Bases GuidecauvongkhongmauNo ratings yet

- Access Control Planning and Installation EssentialsDocument4 pagesAccess Control Planning and Installation EssentialscauvongkhongmauNo ratings yet

- Basic Principles of Access Control P: James Botek Bluewave SecurityDocument31 pagesBasic Principles of Access Control P: James Botek Bluewave SecuritycauvongkhongmauNo ratings yet

- Installation of Fire Detectors & Manual Call Points in SystemsDocument14 pagesInstallation of Fire Detectors & Manual Call Points in SystemscauvongkhongmauNo ratings yet

- 2CSN600047D0201 MiniMac ManualDocument152 pages2CSN600047D0201 MiniMac ManualcauvongkhongmauNo ratings yet

- SafeRing SafePlus 12-24kVDocument88 pagesSafeRing SafePlus 12-24kVmakwanakundansvitNo ratings yet

- 132 Specifiers Guide Access Control SystemsDocument58 pages132 Specifiers Guide Access Control SystemsEnar PauNo ratings yet

- Editor - 1546852784 - SGS COMPANY REPORTDocument19 pagesEditor - 1546852784 - SGS COMPANY REPORTcauvongkhongmauNo ratings yet

- Tabla Awg A mm2Document1 pageTabla Awg A mm2Francisco HernandezNo ratings yet

- Sizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Document71 pagesSizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04zbyszko201234No ratings yet

- Transformers HitachiDocument10 pagesTransformers Hitachiedy985No ratings yet

- PEAD-RP71, 100, 125, 140JAA: Air-ConditionersDocument28 pagesPEAD-RP71, 100, 125, 140JAA: Air-ConditionerscauvongkhongmauNo ratings yet

- Autodesk Inventor Cable and Harness Design: Course Length: 2 DaysDocument3 pagesAutodesk Inventor Cable and Harness Design: Course Length: 2 DayscauvongkhongmauNo ratings yet

- 33kV MV Medium Voltage Switchgear ABB SafePlusDocument24 pages33kV MV Medium Voltage Switchgear ABB SafePlusJohnWilliamsNo ratings yet

- Before Installation: Meanings of Symbols Displayed On Indoor Unit And/Or Outdoor UnitDocument8 pagesBefore Installation: Meanings of Symbols Displayed On Indoor Unit And/Or Outdoor UnitcauvongkhongmauNo ratings yet

- DB Mee15k011 Asia Indoor Ap15 PDFDocument316 pagesDB Mee15k011 Asia Indoor Ap15 PDFcauvongkhongmauNo ratings yet

- DB Mees18k047 Pucy - (E) P-Y (S) KD NV18Document208 pagesDB Mees18k047 Pucy - (E) P-Y (S) KD NV18cauvongkhongmau67% (3)

- Rate AnalysisDocument46 pagesRate AnalysisbulganinganguliNo ratings yet

- F0a7c Compal LA-A994p r1.0 2014Document38 pagesF0a7c Compal LA-A994p r1.0 2014DeyProNo ratings yet

- Form WorkDocument25 pagesForm Workhina khanNo ratings yet

- Random Variate Generation-1Document21 pagesRandom Variate Generation-1Christian Delas AlasNo ratings yet

- Tejas: Practice Sheet JEE PhysicsDocument3 pagesTejas: Practice Sheet JEE PhysicsAshree KesarwaniNo ratings yet

- EE 102 Cabric Final Spring08 o Id15Document10 pagesEE 102 Cabric Final Spring08 o Id15Anonymous TbHpFLKNo ratings yet

- EniSpA - The Corporate Strategy of An International Energy Major PDFDocument24 pagesEniSpA - The Corporate Strategy of An International Energy Major PDFAnonymous 9ZMbuR75% (4)

- HEAT EFFECTS (Cha 4) : Outline of Chapter OneDocument65 pagesHEAT EFFECTS (Cha 4) : Outline of Chapter OneAdam MekonnenNo ratings yet

- Kyocera Fs-6900 Parts ManualDocument28 pagesKyocera Fs-6900 Parts ManualNic CowpeNo ratings yet

- VSD Power Supply Connections and EarthingDocument4 pagesVSD Power Supply Connections and EarthingHumaid ShaikhNo ratings yet

- Design Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment ICDocument3 pagesDesign Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment IClagnajit dasNo ratings yet

- Bentley Bentayga BrochureDocument9 pagesBentley Bentayga BrochureGerry CalàNo ratings yet

- Fault Codes: STO U AndriivDocument3 pagesFault Codes: STO U AndriivAtochkavNo ratings yet

- Effect of Pregnancy Induced Hypertension on Mothers and Babies Hematological ProfilesDocument3 pagesEffect of Pregnancy Induced Hypertension on Mothers and Babies Hematological ProfilesAbdifatah AhmedNo ratings yet

- Seminar Application of Nitrous Oxide in AutomobilesDocument20 pagesSeminar Application of Nitrous Oxide in AutomobilesSaikat BadyakarNo ratings yet

- Stereochemistry MSCDocument29 pagesStereochemistry MSCBapu Thorat50% (2)

- Common Mistakes in Dimensional Calibration MethodsDocument16 pagesCommon Mistakes in Dimensional Calibration MethodssujudNo ratings yet

- Manufacturing Airbrushes Since 1904Document20 pagesManufacturing Airbrushes Since 1904Sa MiNo ratings yet

- 1 Proforma of Allotment LetterDocument32 pages1 Proforma of Allotment LetterGovind SandhaNo ratings yet

- Guillain Barre 3Document6 pagesGuillain Barre 3YON LEANDRO VILLAMIL ROJASNo ratings yet

- QRP Yu1lm SDR-RX TXDocument299 pagesQRP Yu1lm SDR-RX TXD BNo ratings yet

- Chapter 14 Chemical EquilibriumDocument29 pagesChapter 14 Chemical EquilibriumlynloeNo ratings yet

- Pasture FatteningDocument15 pagesPasture FatteningKartika PurnamasariNo ratings yet

- 9709 s15 QP 12Document4 pages9709 s15 QP 12Abrar JahinNo ratings yet

- 9701 w09 QP 41Document20 pages9701 w09 QP 41Hubbak KhanNo ratings yet

- Free Printable House Cleaning Schedule Template PDFDocument1 pageFree Printable House Cleaning Schedule Template PDFclear100% (1)

- Resource Guide: Three Phase PowerDocument8 pagesResource Guide: Three Phase PowerddNo ratings yet

- Sabp X 002Document18 pagesSabp X 002Hassan MokhtarNo ratings yet

- Wily Walnut BRAIN SQUEEZERS Vol.1Document116 pagesWily Walnut BRAIN SQUEEZERS Vol.1tarzaman88% (8)

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet