Professional Documents

Culture Documents

0145E16598760151 - 1 - Def - Selecton Internal Floating Roofs v1.1 May 2014

Uploaded by

Manuel Alejandro González MarcanoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0145E16598760151 - 1 - Def - Selecton Internal Floating Roofs v1.1 May 2014

Uploaded by

Manuel Alejandro González MarcanoCopyright:

Available Formats

Selection Internal Floating Roofs

Standard

Operational Excellence

May 2014

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 1 © Vopak 2014

Document title Selection of Internal Floating Roofs

Document Number 0103-010-24-001

Document Type Standard

Status Endorsed by Operational Excellence Leadership Team

Date May 2014

Version 1.1

Project Name Vopak Standards

Owner Royal Vopak – Corporate Operational Excellence

Confidentiality and Distribution

Vopak Operational Excellence Standards contain confidential information regarding Vopak and its

relevant subsidiaries and have been prepared with a view to inform and instruct Vopak employees.

For that reason none of these standards - whether in original or copies, including but not limited to any

medium including paper or electronic formats like file copies, word documents, pdf files, on electronic

storage devices or by email - is to be shown, given or loaned to any third party, including external

companies and persons not directly employed by Vopak. No exceptions are permitted without the

written authorisation of the Director Corporate Operational Excellence.

This document has only been made available to Vopak employees who have agreed to return it to

Vopak immediately upon first request, together with any copies and any other information that was

provided. Persons who are not employed by Vopak and who have nevertheless received this

document must be aware that it is likely they have received it in breach of a confidentiality obligation.

Such persons may not rely on, use, duplicate or disclose any information contained in this document

and should forthwith return it, together with any copies if any, to Vopak.

This copy is not controlled, for the latest revision check on Vopak Intranet.

May 2014 1.1 Document number changed from 0103-010-24-001-01 to 0103-

010-24-001

January 2008 1.0 Endorsed by OpX Leadership Team

Date: Version: Description:

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 2 © Vopak 2014

TABLE OF CONTENTS

Page

1 INTRODUCTION 5

2 SCOPE AND APPLICABILITY 6

2.1 Background 6

3 ABBREVIATIONS AND DEFINITIONS 7

4 ROLES AND RESPONSIBILITIES 8

5 TYPES OF ROOFS 9

5.1 Non Contact Roof 9

5.2 Full Contact Roof 10

5.3 Comparison of Full Contact Roof with Non Contact Roof 11

6 SEALS 13

6.1 Mechanical Shoe Seals 13

6.2 Vapour Mounted Seals 14

6.3 Liquid Mounted Seals 14

7 SELECTION CRITERIA 15

7.1 General 15

7.1.1 Life Cycle Cost 15

7.1.2 Track Record 15

7.1.3 Service Life 15

7.2 Environment, Health and Safety 16

7.2.1 Retardancy 16

7.2.2 Vapour Reduction 16

7.2.3 Heat Losses 17

7.3 Constructability 17

7.3.1 Installation Time 17

7.4 Operability 17

7.4.1 Tank Cleaning 17

7.4.2 High Filling Rate 18

7.4.3 Vulnerability of Physical Damage 18

7.4.4 Loss of Storage Capacity 18

7.4.5 Dead Stock 18

7.4.6 Landing of Roof 19

7.5 Maintenance and Inspection 19

7.5.1 Maintenance 19

7.5.2 Inspection 19

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 3 © Vopak 2014

8 SELECTION OF FLOATING ROOF AND SEAL 21

9 IFR & SEAL INSTALLATION INSPECTION 23

10 DESIGN 25

10.1 Material Selection 25

10.2 Legs or Suspension 25

10.3 Calculations 26

10.4 Mountings 26

10.5 Diffuser 26

10.6 Floating Suction 27

10.7 Earthing 27

10.8 Gas Venting Capability 27

10.9 Quality Control 28

11 TYPICAL VOPAK REQUIREMENT OF IFR 29

12 INVESTMENT COST 30

12.1 CAPEX 30

12.2 OPEX 30

APPENDIX 1 – FEATURES OF DIFFERENT IFR’S 31

APPENDIX 2 – IFR INSPECTION SHEET 37

APPENDIX 3 – PRODUCT COMPATIBILITY MATERIALS 38

APPENDIX 4 – VOPAK LIST OF MINIMUM MOUNTINGS IFR 39

APPENDIX 5 – ASSESSMENT AND SELECTION TOOL FOR IFRS 40

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 4 © Vopak 2014

1 Introduction

This document is one in a series of minimum standards within the framework of the Vopak

Operational Excellence program. Implementation and compliance with these minimum

standards is part of the process of achieving Vopak’s ambitions for Operational Excellence.

This standard is intended primarily to direct terminals in the selection of internal floating roofs in

order to minimise in-service problems and extend the useful life of the floating roof.

This document describes the Vopak requirements for internal floating roofs and shall be used in

combination with the applicable national / international codes and local regulations. For this

reason, this document will also describe the aspects where the Vopak experience deviates from

the standards and / or will provide a better basis to achieve the Vopak business principles.

It is proposed that available types of roofs be evaluated against each other. In addition, material

compatibility issues will also be included. Internal floating roofs shall only be selected if benefit

has been proofed.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 5 © Vopak 2014

2 Scope and Applicability

This document describes the Vopak requirements for the selection of IFRs and seal system and

shall be used in combination with the applicable national/international codes and local

regulations. For this reason, this document will only describe the aspects where the Vopak

experience deviates from the standard and or will provide a better basis for Vopak business

principles. Vopak Minimum standard Vapour handling and control defines the selection of

different solutions on vapour control and or handling. In case an internal floating roof is

selected, this document aims to help to select the right design and type.

Covering an External Floating Roof with a fixed roof, for example by means of an Aluminium

Geodesic Dome roof is outside the scope of this document.

The selection of the IFRs shall be based on the latest editions of the following documents (in

sequence of importance):

1. Local regulations and Legislations

2. Vopak standard for Selection of IFR

3. (Inter)national codes and standards

- API 650 Appendix H

- EN 14015 Annex C

2.1 Background

IFR’s have been in use since the early 1960s and gained popularity from 1980 onwards in the

oil and chemical industry. Reasons for using a floating roof are to:

- Reduce evaporative emissions e.g. breathing and filling losses and hence air pollution.

A tank without a floating roof can have an annual vapour loss of 3% of the total tank

content;

- Reduce ingress of contaminants e.g. rust, condensed water and airborne particles;

- Minimise nuisance from odours;

- Reduce hazards of static ignition associated with highly charged liquids;

- Provide thermal insulation in fuel oil storage as an alternative of lagging;

- Local authority requirements.

This Standard applies to all existing terminals owned by Vopak and its joint venture companies.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 6 © Vopak 2014

3 Abbreviations and Definitions

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 7 © Vopak 2014

4 Roles and Responsibilities

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 8 © Vopak 2014

5 Types of Roofs

A wide variety of types of floating roofs and suppliers are on the market. However, basically

Internal Floating Roofs can be divided into two subgroups:

- Non-Contact Roofs

- Full-Contact Roofs

TYPES OF INTERNAL FLOATING ROOFS

Non-Contact roof Full contact roof

Vapour No Vapour

Various alternatives

Besides constructional differences, the big difference between the two groups is the existence

of a vapour space between the liquid and the membrane of the roof. In case of a non-contact

roof, the membrane is not in contact with the liquid enabling to form a significant amount of

vapour under the deck. In case of a full contact roof no vapour exists between the roof and the

liquid. As a result, any hole or leak in a non contact roof will result in a strong reduction of the

efficiency of the roof, while with full contact roofs in case of a leak, only the exposed area

releases vapour.

5.1 Non Contact Roof

This most common type is the Aluminium Pontoon deck type. The design is more or less

common albeit many different suppliers. The roof and pontoons can be constructed from:

- Aluminium deck and Aluminium pontoons;

- Aluminium deck and Stainless Steel pontoons (Hybrid);

- Stainless Steel deck and Stainless Steel pontoons.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 9 © Vopak 2014

5.2 Full Contact Roof

This type of roof can be installed in many varieties however the list below classifies the different

types into groups.

a. Metallic Single deck Pontoon Type (CS)

These roofs have peripheral compartments for buoyancy and a centre deck. The roofs

are made of steel

b. Metallic Double deck (CS)

These roofs consist of rings with bulkheads towards the middle between a top and

bottom deck. The roofs are made of steel.

c. Pan Type (CS or SS)

This type consists of a shallow central pan with an outer rim plate which shall float on

the liquid. The roof is subject to sinking in case of punctures or when water is collected

in case of fire fighting. In case of a fire this will result in full surface fire and on top of

that, if sunk, taking tank out-of service and clean it is very difficult. Therefore this type of

IFR is not allowed in Vopak for new roofs.

d. Pan type with buoyancy chambers (CS or SS)

Same as type c with the addition of an outer ring of pontoons or buoyancy chambers;

although the roof is an improvement of type c, it is not allowed in Vopak for new roofs.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 10 © Vopak 2014

e. Metal sandwich type

Basically two types exist:

1. Panels of Polyurethane core wrapped in Aluminium foil

This type, panels of polyurethane core wrapped in aluminium foil are vulnerable and due to the

frame, required to hold the modules, difficult to replace. Also the modules can absorb product in

case the foil would break or damage. Therefore not allowed in Vopak.

2. Aluminium panel with Aluminium honeycomb core

f. In Situ laminated (Seamless) Glass Reinforced Epoxy (GRE) or Glass Reinforced

Plastic (GRP) (with Poly Propylene honeycomb closed cell structure)

Appendix A provides an overview in more detail of pro’s and con’s of each type of roof.

5.3 Comparison of Full Contact Roof with Non Contact Roof

When a full contact roof is compared with a non contact roof, some basic features are

distinguished. Typical features of a full contact roof:

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 11 © Vopak 2014

- Flame retardant: time to form full surface fire is longer than non contact type IFR.

Having no vapour space above the liquid, meaning tendency of full service fire is lower

and only rim fires shall be taken as main risk. This is only applicable for metallic type

floating roofs, according NFPA 30. The roof must be in good condition and is applicable

only for Vopak approved full contact roofs. See also 4.2.1.;

- Better emission efficiency;

- More rigid to walk on and to cope with gas relief due to product movements*);

- Installation time is longer.

*) Product Transport lines shall be design in such a way that gas or vapour slugs introduced by

pigging, stripping or other reasons are captured or relieved before entering the tank.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 12 © Vopak 2014

6 Seals

Seals are important for IFR’s. First of all they reduce emissions complementary to the IFR and

secondly they centre the IFR. Seals also play an important role in protection against rimfires.

Basically three types of seal can be identified:

a. Mechanical shoe seal

b. Seal mounted in the vapour space

c. Seal mounted in the liquid space

Types a and c show much better emission reduction figures than the seals in type b. If only one

seal is selected this is called a primary seal. If two seals are mounted above each other, the

seal above the primary seal is called secondary seal. According BAT – Best Available

Technology it is allowed to select only one (primary) seal for IFR. When selecting a seal, using a

single seal (Primary seal only) is recommended. The type that is BAT and therefore has strong

preference is a liquid mounted Metallic (SS) shoe plate seal. If product resistance of this seal is

a problem selection of other materials or type of seal is accepted.

6.1 Mechanical Shoe Seals

Sketches below represent examples of different types of seals:

Picture of mechanical shoe seal

Some seals require the use of a bumperbar. The purpose of such a bar is to assure a minimum

gap between the tankshell and the IFR in case this IFR moves to one side. Some seals could

damage severely if not remaining this minimum distance. Ask supplier for specific requirements

on this subject.

Typical for mechanical shoe seals are the metal plates that press the shell due to a spring or

weight. The shoe plate penetrates into the liquid and forms a small vapour space which is

closed by a vapour tight fabric. If shoe does not touch the shell, only the liquid between the shell

and shoe will generate emission. Emissions form this type of seal are expected to be low

because of this small area.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 13 © Vopak 2014

6.2 Vapour Mounted Seals

Below are some examples of vapour mounted seals. If a vapour mounted seal does not touch

the tank shell at any point around the circumference, the whole circumferential vapour ring

below the seal can pass the seal. Always use bumper bars to protect the seal and make sure

earthing to tank shell is working.

Picture of vapour mounted seal

6.3 Liquid Mounted Seals

This seal is mounted in the liquid. Most of the time the seal is a bag filled with liquid or foam. In

fact it is one of the best seals from a point of emission reduction, since it can follow the

unevenness in the tank shell very well and therefore no openings are around circumference.

However at the same time the most vulnerable. Always use bumper bars to protect seal.

Picture liquid mounted seal

Seals are subject to wear and tear and should regularly be inspected. All seals have fabric or

rubber parts or components, subject to brittleness or aging over time. Therefore the lifetime

hardly ever exceeds 10 years.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 14 © Vopak 2014

7 Selection Criteria

7.1 General

7.1.1 Life Cycle Cost

Life cycle cost is the total cost during the expected life of the roof and seal. This means the sum

of CAPEX and the sum of future OPEX. When selecting and IFR and or seal one shall focus on

minimum life time cost and not primarily selection based on the lowest CAPEX.

7.1.2 Track Record

Many suppliers are on the market of which only some of them are good performers.

Investigating the track record of a supplier is essential to work together.

Subjects to be investigated:

- Reference lists outside Vopak;

- Local experience;

- Experience within Vopak;

- SHE approach (toolbox meetings, organization in the field, communication);

- Own technicians or contractor hire;

- Product resistance: supplier to confirm resistance of selected materials to defined

products;

- Manufacturer or agent/supplier;

- After sales support.

7.1.3 Service Life

The Service life of an IFR and seal is strongly related to the usage during its lifetime. The

following fields of activities are affecting the service life:

Operational

- Product Portfolio Matrix: Always check the compatibility of the materials of the floating

roof and seal (!) and the products to be stored. If a product change is intended in a tank,

take material compatibility of seal and IFR into account during Management of Change

process;

- Do not operate a tank in a way that physical overstress can occur. Typical examples:

o Never overfill a tank,

o Product circulation by jet nozzle

o Do not release gas into the tank during pigging.

o Smooth landing of a roof

o Prevent water load during cleaning

Maintenance & Inspection

- Inspect seal and roof frequently, minimum once per year. This can be done through roof

manhole if tank does not go out of service;

- Inspect settling of the tank and tank bottom frequently;

note 1;

- Perform maintenance at the right moment on the roof and seal

Repair

- Select only approved materials;

- Repair properly, so not “easy fix”-solutions: select long term solutions.

Note 1: reference is made to the inspection frequencies as defined in the Tank Maintenance and Inspection Minimum standard

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 15 © Vopak 2014

7.2 Environment, Health and Safety

7.2.1 Retardancy

For internal floating roofs a rim fire can develop into a full surface fire when the roof sinks or

catches fire and looses integrity. Therefore:

- Only use flame retardant materials in a floating roof.

- Design the roof with sufficient buoyancy according API 650, Appendix H. Take

in consideration the load on the roof due to foam (if applicable) added on top of

the roof or underneath the primary or secondary seal.

NFPA 30 states that for all metal roofs the fire fighting system shall be capable to fight a rim fire,

while for a GRE roof, according to the standards the fire fighting system in the tank must be

designed for a full service fire when choosing GRE.

7.2.2 Vapour Reduction

One of the main reasons for selecting a floating roof is to reduce emissions. Emissions are

vapours released from the tank to the environment.

The exact amount of these losses shall be calculated and reference is made to “Manual of

Petroleum Measurement Standards chapter 19, Section 1 – Evaporative losses from Fixed roof

Tanks” [2]. EPA supplies free downloadable “Tanks” software that contains the formulas of

reference [2]. In general calculating a fixed number for efficiency of a certain type Floating roof

is not possible. The true efficiency of a floating roof is dependant of many variables, such as

type of selected roof, number of turnovers per year, product stored, operational procedures

(pigging, roof landings), type of seal and level of maintenance. See table below:

Factor More emission Less emission

Stored product Volatile products Non-volatile products

Environment Warm climates, wind Cold climates

Number of turnovers High number Low number (f.e. Strategic

storage)

Landing of roof Frequently emptying tank Keep roof floating at all time

(dead stock!)

Operational procedures Pigging, gas relief in tank No gas relief in tank

Type of IFR Non-contact roof Full contact roof

Type of seal Vapour mounted seal, Mechanical shoe seal, liquid

primary seal only mounted seal, double seal

Quality of seal & IFR Damages or leaks Well designed, Maintained

and inspected roofs

Number and type of Legs & sleeves, drains, Vapour tight legs, use gaskets

mountings sample points, non gasketed

manholes,

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 16 © Vopak 2014

While operating a tank vapour losses are introduced, leaving a tank in different phases:

Filling a tank

During filling of tanks vapour is forced to leave the tank via a vent. It is not important for this

phase whether a PVV or free vent is used for the flow out of the tank. In this phase a PVV

hardly reduces emissions from the tank.

Breathing of a tank

When the tank is filled, the sun can heat the vapours above the liquid up and by the increase of

pressure the vapour can leave the tank via the free vent or PVV. This emission loss can be

reduced by the use of PVV, depending on the pressure settings. The larger the range between

the pressure settings is, the more the reduction of these losses are. The tank design limits the

PVV settings.

The opposite of breathing out will also occur during cold periods: during the night the vapour will

cool down and outside air is sucked into the tank because of the reduction of volume. This does

not have an effect on emission until it is heated up again when the outside temperature is

increasing again.

Emptying a tank

During and after emptying a tank the remaining liquid on the shell will evaporate. This vapour

can leave the tank during outbreathing of the tank. (see “breathing of a tank”)

Gas freeing in tank (pigging, blowing lines) and landing the roof are the major sources of

emission and shall be eliminated if feasible.

7.2.3 Heat Losses

Some products require heating of the product. The use of double layer roofs reduces heat

losses through the IFR. Metal roofs convey heat better than GRE roofs. An assessment of the

different types of IFRs should be made to select the best roof.

7.3 Constructability

7.3.1 Installation Time

Non contact pontoon type IFR, including the required tools comes in packages that can be

brought into the tank via the tank manhole. Rest of the floating roofs requires either a doorsheet

or hole in the fixed roof.

The steel single deck and double deck require significant more time to construct than the rest of

the IFR’s due to the engineering, labour intensive layout of the steel plates and welding. Also All

inspections shall be done in the field. All other IFR types are build in modules of which many

inspections quality related have already taken place in the workshop during construction of

these modules.

7.4 Operability

7.4.1 Tank Cleaning

Cleaning can be a high risk activity for the roof and seal. Always discuss and safeguard

cleaning activities with cleaners, focussing on the following before cleaning starts:

- Effect of chemical components on seal and floating roof materials;

- Effect of high temperatures on seal and roof (steaming tanks);

- Loads introduced due to large amounts of water on the roof;

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 17 © Vopak 2014

- Roof drains must have sufficient drainage capacity;

- Damaging the roof due to walking on the roof, especially non-contact pontoon type FR.

These roofs shall be protected by temporarily sheets or beams;

- Damaging the roof due to use of tools: high pressure cleaning, brushes, scrapers etc

can damage membranes or seals.

7.4.2 High Filling Rate

As long as the roof is not floating high filling rates must be avoided: allow maximum 1 m/s in the

pipe. Consult the supplier of the seal and/or roof for maximum flow rates on initial filling and

discharging the tank and refer to Vopak Minimum Standard on “Product Movement

Management”. The use of a diffuser will reduce the speed of the product under the roof, but

even when using a diffuser, first make sure the roof is floating. The same is valid for emptying

the tank. Reduce discharging rate when approaching the liquid level where the roof will land.

The reasons are that physical stresses are introduced at high landing speed on the bottom and

IFR.

7.4.3 Vulnerability of Physical Damage

Prevent pressurized gas release to tank

The pressure of slugs during pigging is often 3 – 7 bars. When this would be released into the

tank, the gas slugs expand this factor in order to reach atmospheric pressures at the surface of

the liquid. This expansion often results in extreme stresses introduced to the roof. Releasing

pressurized gasses into the tank, underneath an IFR shall therefore not be allowed.

After pigging, the pressure in the line shall be released from the system before new product

enters the tank. During filling of the tank with new product after pigging took place, gas will be

released into the tank until the product has arrived to the tank. For distributing the gas flow in

the tank, a diffuser shall be installed. See 7.5. A floating roof can severely be damaged during

pigging or blowing, even with a diffuser. This is especially the case when standing on its legs.

7.4.4 Loss of Storage Capacity

The use of a floating roof will always reduce the net storage capacity. The manufacturer of the

floating roof shall provide exact information on the maximum liquid level of the tank in service.

Extreme Care should be taken during a hydro test with the roof in place: Most products have a

density lower than water. The result is during hydro test that the maximum liquid level of the roof

must be compensated for the extra buoyancy.

The use of a secondary seal additionally reduces the working capacity of the tank. However, the

use of only a primary seal, except for a metallic shoe type seal, is not a good practice and

should not be recommended. Either select a double seal or a metallic shoe type seal.

Roof constructions can damage an IFR and interference shall be determined before an IFR is

selected, designed and installed.

7.4.5 Dead Stock

The space under the roof, when it is resting on its supports, is called dead stock. A large part of

the total annual tank’s emission is the release of the dead stock volume above the floating roof

during initial filling. If the floating roof can be kept floating at all times this will reduce emissions

drastically. The business of Vopak often requires completely emptying and filling of a tank

frequently, inevitably resulting in higher emissions due to this dead stock, despite the use of a

floating roof.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 18 © Vopak 2014

7.4.6 Landing of Roof

When the roof lands this shall be done with low velocity, to avoid stress peaks in supports,

bottom and construction. While the roof is resting on its supports automatic bleeder vents shall

prevent overstressing the roof during both filling and emptying a tank.

7.5 Maintenance and Inspection

During its lifetime IFR’s and seals shall be frequently inspected, and maintained. Sometimes a

repair is required. The following typical features are applicable on maintenance and inspection:

7.5.1 Maintenance

GRE

One of the benefits of GRE roofs is that they are in principle maintenance free. If repair is

required this needs special attention for temperature and humidity in the tank. Large repairs, i.e.

exchange of modules, could require openings in the fixed roof

Aluminium non contact pontoon type

Aluminium non contact pontoon type FR require hardly any maintenance. Repair is often

caused by damage of the skin (spot repair or replace whole strip) or replacement of punctured

or buckled pontoon. Repair parts can be brought into the tank easily through tank manhole.

Aluminium full contact roof

Aluminium full contact roof require hardly any maintenance. If repair has to take place due to

puncture of a module, the module shall be replaced because it can be filled with product.

Welding in that case is not allowed inside the tank and the module(s) shall be replaced or

repaired outside the tank. Delivery time of a module shall be checked with supplier but can be 2

– 4 weeks. If a module needs to be replaced, an envelope shaped opening must be made in the

fixed roof.

Steel roofs

Maintenance on steel roofs normally is to replace the coating on the topdeck after 15 – 20

years. This requires sandblasting and repainting. Repair requirements are often found in welds

that have cracked and require re-welding.

Seals

All seals require maintenance eventually. Non metallic parts age over time, getting brittle or

damaged, like vapour barriers or rubber lips touching the tank shell. Also parts undergoing wear

will require maintenance. A good example is a steel shoe plate. Although it is difficult to see, the

thickness of the shoe plates reduce over time due to friction with tank shell.

7.5.2 Inspection

IFRs are subject to sometimes extreme conditions, which can result in breakage of parts,

membranes or pontoons. Also general and pitting corrosion takes often place, as well as wear

and tear on the seals. For this and many other reasons, the IFR and seal system requires

regular inspections. Reference is made to Vopak Tank maintenance and inspection minimum

standard on inspection intervals and checklists. On top of the checklists some general additional

areas of interest are:

GRE

GRE roofs are black, due to the addition of Carbon particles for reduction static electricity build

up. This makes inspection for cracks or crevices more difficult therefore use enough light. The

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 19 © Vopak 2014

area between the touch plate of the support and the GRE floating roof can not be inspected

easily. Check for leakage there.

Non Contact aluminium pontoon roofs

History taught us that these roofs often have usage damages at pontoons and membranes.

Check for pitting and cracks in the pontoons and for cuts and damages in the aluminium

foil/membrane. Be careful when walking over the aluminium foil/skin.

Welded parts

Metal roofs with welds shall be checked for pitting, and broken welds. Often cracks in welds can

not be found by the eye and therefore require NDT techniques. Reference is made to Vopak

Tank Maintenance and Inspection minimum standard on required NDT techniques for metal

roofs.

Seals:

Primary seals can only be inspected from underside, secondary seal from upside. This means

when using double seals half of the seal area can not be inspected. It is good to understand this

is a risk. When in doubt, remove the secondary seal.

In general for integrity inspection the following measures shall be taken:

- Safety first: make sure the tank is safe to enter: legs are all vertical and touching the

floor; also the tank is gasfree. Be aware that product could be found in pontoons or

modules;

- Sufficient light. Inspection requires good light. Especially in pontoons and for GRE roof

(black colour);

- Clean roofs. Cracks, pitting holes, crevices, buckles, stressed areas etc can much

better be found at clean surfaces;

- Product can be found trapped in roof legs and shall be checked;

- Support the IFR in such a way that it’s legs can not collapse.

In IFR tanks, there are two confined spaces – below and above the roof. Entry to both locations

must be regulated or controlled under confined space requirements.

Inspect seals especially on wear and tear and aging of non metallic parts as vapour barriers for

gas tightness.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 20 © Vopak 2014

8 Selection of Floating Roof and Seal

Al above incorporated it is impossible to define one standard and preferred internal floating roof

and seal. All depends on the most important priorities of all requirements.

Seal

Preferred seal to select is a liquid mounted Metallic (SS) shoe plate seal as this is BAT – Best

Available Technique. In case product resistance is a problem for this seal, other materials or

type can be selected.

IFR

As stated before, many different suppliers are on the market, providing many different detailed

differences. For selecting an IFR that meets Vopak minimum standards, an assessment of the

above mentioned selection criteria shall be used for each project. This document presents an

assessment based on the known Best Available Techniques per type of IFR. A picture of the

assessment tool can be found in appendix E. The tool itself is available via CoOpX intranet site.

The preferred solution has minimum life time cost (CAPEX & future OPEX together) in stead of

lowest CAPEX. For that focus on:

- Good design;

- Good materials;

- Material resistancy;

- Experienced installation crew;

- Maintenance & inspection;

- Ease of repair;

- Etcetera.

On the next page the process of selection of an IFR is presented.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 21 © Vopak 2014

START

Select Acceptable

Regulations Y

Select only Full-Contact construction material for

require Full

roofs for the assessment product range in tank

Contact Roof?

Set priorities of all

requirements

(max 2 x high prio!)

Customer Y

requires Full

Contact Roof?

Assess Ratings in Tool with

N

crossfunctional Team

Other

requirements to Y

select Full

Contact Roof?

Select Best IFR option

F.e. operational

for project

END

Add Non contact roofs

to the assessment

Process of selection IFR

Appendix E shows the assessment results, which are default in the CoOpX IFR Selection tool.

In any case, apart from the above mentioned exceptions, an internal floating roof shall be

selected. In the following cases a full contact roof shall be selected:

- Customer discretion;

- Regulatory requirements;

- Other requirements (such as cleaning).

In all other cases a Pontoon type floating roof is to be assessed as well.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 22 © Vopak 2014

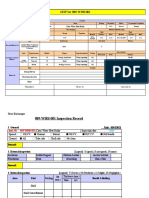

9 IFR & Seal Installation Inspection

Before an IFR and or a seal can be selected, the tank shall be inspected by the supplier of the

IFR and seal. See Appendix B for IFR Installation Inspection sheet.

For new tanks this does not apply and in that case reference is made to Repeatable Formula

BB1 – Tanks and Tank pits.

Typical points to inspect on a tank are:

- As-built dimensions of tank;

- Out of roundness of tank shell;

- Verticality of tank;

- Penetrations of roof;

- Sampling points fixed roof;

note 1;

- Column supported fixed roof

- Location of gauging systems;

- Free movement of IFR (no obstacles on tank shell);

- Framework of fixed roof (interaction IFR with rafters if tank is fully filled);

- Flow rates (in/out) for venting calculations;

- Piping / heating coils / other disturbances on the bottom for legs positions;

- Slope of the bottom for legs length;

note 1: Columns supported roofs are no longer allowed for new roofs according to Vopak Minimum Standard “Tank Design Manual”, however if

installed this must be addressed for the design of IFR.

Out of roundness measurement of tankshell

Before a seal is selected, the out of roundness of the tank must be measured. Unround tanks

can result in problems with seals and floating roofs. In some cases a seal is unable to stay in

contact with the tank shell and so releasing vapours that might form a risk. The other way is

possible too: seal is damaged or roof gets stuck due to lack of rim space, potentially causing

sparks at the tank shell. Also out of roundness can cause roof abrasion on tank shell creating

high metal loss and /or damage to internal coating.

Out of roundness is measured with a laser distance measurement device, called Theodolite,

positioned in the middle of the tank. Use of grid system as defined in EEMUA Appendix A 1-1 is

recommended.

Verticality of tank

When a tank is tilting, the liquid surface will form an oval instead of a circle. As long as the tilting

th

is limited to 1/100 of the height, this is acceptable. If the angle is more than this, seals can

sometimes not touch the tank shell anymore, with risk of vapours released above the roof.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 23 © Vopak 2014

Measurement shall be done at 4 equidistance locations (North, East, South and West of the

tank). This can be basis for further investigation on other locations. A theodolite can be used or

an easy method is to use a wire and small weight attached at the end, after which the distance

between the weight and tank shell is relevant:

Theodolite Maximum tilting

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 24 © Vopak 2014

10 Design

The Design, construction and material selection of Internal Floating Roofs and Seals shall be

fully in line with API 650 appendix H or EN 14015 Annex C. Prior to selecting an IFR and Seal,

the datasheet Appendix B shall be filled in. As well out of roundness measurement of the tank

shall be conducted. Also min. requirements on mountings shall be used See Repeatable

Formula BB1 – Tanks and Tank pits 4.2.3 BB1_3 Internal Floating roof.

10.1 Material Selection

All materials used in an IFR and seal shall be fully compatible with the proposed and future

product, vapour, cleaning products and any other mixture that comes into contact with the IFR

during service life. The selected materials shall meet EN 14015 or API 650. If not defined in

these codes, at any time the material shall be resistant against selected and expected stored

product. Appendix B shows a list with general known problem areas of different materials.

All Bolts and nuts, clampbars, rings, U-bolts etc. shall be Stainless Steel.

10.2 Legs or Suspension

In most cases a floating roof is resting on equally divided supports. If legs are connected to the

floating roof, the legs shall be adjustable in height for operational conditions (minimum dead

stock setting) and maintenance conditions (landed condition). For Steel IFRs the supports shall

land on patch plates welded on the bottom.

At the underside of the supports, PTFE end caps shall be used, well fixed to the supports.

In case a leg operated bleeder vent is used, and the roof has been designed with adjustable

legs, also the bleeder vent must have an adjustable leg.

For some floating roofs (seamless GRE), it is allowed to weld the legs to the tank bottom and

are not adjustable in height. Patch plates and reinforcements shall be used as well as a flexible

movable disc on to of the leg, carrying the roof.

Suspending a floating roof is not preferred because:

- Inspector is unable to verify “fit-for-purpose” of the suspension cables;

- Cables can get tangled and ultimately break, introducing large stresses in the roof;

- When suspending an IFR for non use cases, consideration of flows in and out of tank

with the IFR suspended from the roofs P/V of the IFR must be factored into operation to

not damage IFR with pressure or vacuum from product flows;

- The fire protection tank nozzles must provide fire suppression when the IFR is

suspended and means to provide assurance must be determined before application of

this use.

In the following two situations a suspended roof can be added to the selection process:

- For products that are extremely difficult to clean the roof when on support legs;

- For some products no floating roof is required. In that case the roof can be suspended

at the top of the roof, until another product is put in the tank, which requires again an

IFR. Stainless steel cables shall be used for suspension;

- Because of regulatory reasons from local governments related to reduced emissions

(minimise dead stock for instance in USA).

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 25 © Vopak 2014

Before selecting a suspended system, a thorough risk assessment shall be performed on

technical, safety and operational requirements.

10.3 Calculations

The supplier of the floating roof shall as a minimum hand over a set of calculation based on the

definitions and loads as defined in the applicable codes API 650 Appendix H or EN 14015

Annex C. As a minimum this means calculations must be made of:

- Buoyancy;

- Venting capacity during filling and emptying of tank with roof landed on legs;

- Stresses in construction based on several load cases;

- Buckling of legs (define maximum allowable angle of leg);

- Any point defined by Vopak as critical of which proof is required.

10.4 Mountings

All floating roofs shall be equipped with well designed mountings.

For an overview of mountings on IFRs in tanks reference is made to Repeatable Formula BB1 –

Tanks and Tank pits.

A foam dam shall extend the highest point of the seal by at least 50 mm.

For IFRs in existing tanks it is important to select the type, number and position of the

mountings in such a way that the IFR can function and move freely.

A list of minimum mountings is defined in Appendix D.

10.5 Diffuser

A diffuser shall be installed on the main inlet gas slugs can enter a tank equipped with an IFR to

prevent damage of the IFR. A diffuser needs to be designed based on the typical operational

boundaries of that tank. The figure below shows a typical example of a diffuser

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 26 © Vopak 2014

The following points shall be considered in the design:

- The diffuser is installed using a dedicated tank shell nozzle;

- During pigging, the diffuser is to be used (that is, the main tank inlet line to be shut off);

- Design for full N2 flow into tank in case the pig completely disintegrates within the

pipeline during pigging, or a mis-operation during line purging;

- Diffuser pipe should as much as possible extend over the entire diameter of the tank to

ensure that gases are evenly diffused (load spreading) over the entire IFR;

- Diffuser needs drain holes along the diffuser pipe for ease of tank cleaning and gas

freeing. The drain holes to prevent trapped products;

- Diffuser pipe needs an end flange so that any rust or debris trapped in the diffuser (over

a long period) can be cleaned out without the need for hot work;

- Diffuser pipe got to be well-supported and well-secured in the tank.

It is important to reiterate that pigging gas should be prevented from entering the tank in the first

place. The diffusers and IFR vents are acting as insurance IN CASE gases get in. The terminal

should never allow that a diffuser gives the license to allow gases into the tank.

10.6 Floating Suction

Floating suction units are connected to the underside of the floating roof. If in any case dirt like

rust, sand or water (condensation) is collected in the product it will settle to the bottom. The

floating suction unit will displace the liquid level just beneath this floating roof. The

contamination is much less likely to be pumped out of the tank this way. It is often used for jet

fuels like Kerosene and Avgas.

10.7 Earthing

Most rim fires started due to electrical discharge between IFR and shell. The potential difference

between a roof and the tank shell must be safeguarded by low electrical resistance of the roof

and the use of Stainless Steel multi-strand earthing or anti-static cables. These cables should

2

have a min cross section of 3 mm .

Diameter Tank [m] # earthing cables

< 20 2

≥ 20 4

The electrical resistance between the tank shell and any part of the roof shall be maximum 100

MΩ when measured by an approved method. The cables must be connected or installed in a

manner so that maintenance inspection and testing can be carried out while the tank is in

service.

For non metal IFR’s the roof itself shall be able to convey electricity over its entire area and not

build it up, for example by adding carbon to the composition.

10.8 Gas Venting Capability

IFRs are meant to capture vapours from leaving the tank. During initial filling, it is unavoidable

that the dead stock collected under the roof is pushed through a vent, the bleeder vent and

collect above the IFR. This vent shall however automatically close when the roof is floating. An

IFR must always have a bleeder vent.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 27 © Vopak 2014

If gas is relieved in the tank during operational use (not preferred), another type of vent is

required as well as a diffuser (see 7.5). When allowing gas slugs to enter the tank this reduces

the efficiency of the IFR dramatically and it shall be tried to avoid this, either by better

operational procedures or redesign: degas station outside tank. If this is not possible, the IFR

shall be equipped with gas relief valves, which can release the excess build up vapour space

underneath the roof. The required capacity should carefully be calculated. Rim vents, to be

installed for Mechanical type seals, should not be used for this purpose.

10.9 Quality Control

Before the start of construction the contractor shall hand over a quality document, in which

critical areas of the IFR installation which can influence the quality of the roof are described.

Examples:

- Checks on temperatures, samples;

- Performed inspections etc;

- Tests on welds, samples, materials;

- Quality checks on material & Delivery.

The contractor installing the IFR shall frequently inspect the IFR during construction. Any defect

or damage shall be solved before the hand-over to Vopak.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 28 © Vopak 2014

11 Typical Vopak Requirement of IFR

Non contact pontoon type

This type of roof is designed with the deck floating above the liquid surface and supported by

closed pontoon compartments (normally tubular pontoons). The roof deck is designed utilizing

a small light weight girder, aluminium sheeting of a minimum 0.51 mm (0.020 in.) thickness and

a rim utilizing a light weight aluminium skirt material. Pontoons are the main structural support

for the roof normally containing support gussets on the ends of the pontoons for connecting to

other pontoons and support leg assemblies.

In order to keep the vapour space captured under the membrane, vapour skirts shall penetrate

into the product minimum 100 mm. The connection between 2 pontoons shall be 1 bolt and 2

nuts, tight against each other, however enabling the pontoons to move freely.

Steel single deck and double deck type floating roofs

Reference is made to the Minimum Standard Tank Design Manual for Vopak Minimum

requirements.

Other roofs

For other roofs, supplier must follow content of this document.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 29 © Vopak 2014

12 Investment Cost

12.1 CAPEX

The following overview can be given as estimate CAPEX for 36 m tank (base date 2007). For

each project actual prices shall be received from suppliers, since material prices, location,

currency rates etc. can vary strongly over time.

Type Total, M&L, incl remark

seal

(€/m2)

Metallic Single Including

deck Pontoon Type shoeplate seal

325

(CS)

Double deck

Pontoon type FR No data

Alu Non contact FR Including

84

shoeplate seal

Alu Full Contact FR Including

242

shoeplate seal

GRE Including

238

shoeplate seal

Budget Cost Shoeplate Seal: € 200 / m circumference

12.2 OPEX

Next to the CAPEX, the sum of future OPEX is essential to analyse. Steel roofs shall be

sandblasted and painted after a period of time (average 15 – 20 years).

All seals have fabric or rubber parts or components and are therefore, subject to brittleness or

aging over time. Therefore the lifetime hardly ever exceeds 10 years.

History shows that Aluminium non contact pontoon type roofs are subject to repair more often

for pontoons and skin.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 30 © Vopak 2014

Appendix 1 – Features of different IFR’s

NON CONTACT INTERNAL FLOATING ROOFS:

Conventional or Standard Skin & Pontoon Floating IFR:

This type of roof is designed with the deck floating above the liquid surface and supported by

closed pontoon compartments (normally tubular pontoons). The roof deck is designed utilizing

a small light weight girder, aluminum sheeting of a minimum 0.020” thickness and a rim utilizing

a light weight aluminum skirt material. Pontoons are the main structural support for the roof

normally containing support gussets on the ends of the pontoons for connecting to other

pontoons and support leg assemblies.

- Lest expensive IFR;

- Installation is faster than other aluminum and steel type roofs, all components of this

roof will normally fit through a 24” shell manway. Minimal welding (anti-rotation cable

connections) is required for installation;

- Caution must be taken prior to any repairs in the tank to verify that the pontoons do not

contain product or product vapors. Even though the pontoons are sealed stress cracks

in the pontoon end caps and/or pin holes due to corrosion may have occurred;

- Roof contains bolted deck seams which become a factor in considering vapor losses

calculations;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- Roof deck is designed to float approximately 6” – 8” above the product, will provide

additional filling capacity when compared to steel type roofs but in comparison to full

contact roofs a small amount of filling capacity will be lost;

- The roof can be cable suspended from the fixed roof or geodesic dome eliminating

vapor emissions from the leg housings. Cable suspending will also high and low leg

roof adjustments from outside of the tank;

- Caution should be taken to assure that the aluminum roof will be compatible with the

stored product. 100% aluminum type roofs should not be used when such products as

Methanol, Products containing chlorides, salts and caustic, water, slop water or other

corrosive type products to aluminum will be stored;

- Aluminum type roofs should not be hydrotested in water for long periods of time and

potable water should be used during the hydrotest.

Heavy Duty Skin & Pontoon Floating IFR:

This type of roof is designed with the deck floating above the liquid surface and supported by

closed pontoon compartments (normally tubular pontoons). The roof deck is designed utilizing

a taller and wider support girders, cross girders, aluminum sheeting of a minimum 0.025

thickness and an outer rim utilizing an extruded aluminum channel. Pontoons are not the main

structural support for the roof and are not connected by support gussets or support leg

assemblies. Support legs are installed at the junction of main support girders and cross girders.

- Higher in cost than the conventional aluminum skin and pontoon IFR, cost normally falls

between a conventional skin & pontoon aluminum IFR and a full contact aluminum IFR;

- Installation is similar to the conventional aluminum and faster than other aluminum and

steel type roofs, all components of this roof will normally fit through a 24” shell manway.

Minimal welding (anti-rotation cable connections) is required for installation;

- Caution must be taken prior to any repairs in the tank to verify that the pontoons do not

contain product or product vapors. Due to possible pin holes that may occur from

corrosion;

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 31 © Vopak 2014

- Roof deck is designed to float approximately 6” – 8” above the product, will provide

additional filling capacity when compared to steel type roofs but in comparison to full

contact roofs a small amount of filling capacity will be lost;

- Roof contains bolted deck seams which become a factor in considering vapor losses

calculations;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- The roof can be cable suspended from the fixed roof or geodesic dome eliminating

vapor emissions from the leg housings. Cable suspending will also high and low leg

roof adjustments from outside of the tank;

- Caution should be taken to assure that the aluminum roof will be compatible with the

stored product. 100% aluminum type roofs should not be used when such products as

Methanol, Products containing chlorides, salts and caustic, water, slop water or other

corrosive type products to aluminum will be stored;

- Aluminum type roofs should not be hydrotested in water for long periods of time and

potable water should be used during the hydrotest.

Hybrid Skin & Pontoon Floating IFR:

This type of roof is designed with the deck floating above the liquid surface and supported by

closed pontoon compartments (normally tubular pontoons). The roof deck is designed utilizing

aluminum girders and aluminum sheeting. All wet able parts such as pontoons, pontoon straps,

leg housing assemblies, outer rim of the roof, drain tubes, column wells, float wells manway

skirts etc. will all be designed utilizing austenitic stainless steel materials. If leg support all

support legs will be of an austenitic stainless material. The overall design can be either a

conventional or heavy duty type IFR.

- Higher in cost due to the addition of the stainless steel parts;

- Installation is similar to the aluminum skin and pontoon IFRS all components of this roof

will normally fit through a 24” shell manway. Minimal welding (anti-rotation cable

connections) is required for installation;

- Roof deck is designed to float approximately 6” – 8” above the product, will provide

additional filling capacity when compared to steel type roofs but in comparison to full

contact roofs a small amount of filling capacity will be lost;

- Roof contains bolted deck seams which become a factor in considering vapor losses

calculations;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- The roof can be cable suspended from the fixed roof or geodesic dome eliminating

vapor emissions from the leg housings. Cable suspending will also high and low leg

roof adjustments from outside of the tank;

- Utilization of the stainless steel parts allows this roof to be used in products that would

not be compatible with aluminum, such as Methanol.

Stainless Steel Skin & Pontoon Floating IFR:

This type of roof is designed with the deck floating above the liquid surface and supported by

closed pontoon compartments (normally tubular pontoons). This roof is designed with all the

components being fabricated from austenitic stainless steel materials. It is higher than all of the

aluminum roofs and may fall close to the cost of a steel pontoon IFR. It is mainly used in areas

in which the stored product will be corrosive to aluminum and/or carbon steel. Also it has been

utilized in tanks in which the product will be corrosive to aluminum but a quick installation is

required ruling out the installation of a carbon steel roof. As with all the skin and pontoon

floating roofs, all the components will fit through a 24” manway.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 32 © Vopak 2014

FULL CONTACT - ALUMINUM TYPE ROOFS;

Steel Pontoon Type IFR:

Consisting of a steel deck with a inner and outer rims connected by bulkheads with steel plate

covers forming pontoons that are approximately 6 ft – 8 ft wide around the outer circumference

of the floating roof. Various designs are used with the most common type being a reversed

slopped pontoon style that will have an outer rim of approximately 15” - 18” in height and an

inner rim of approximately 24” in height to prevent excessive loss of filling capacity. All support

legs sleeves, column wells and manways should be at the same height as the outer rim.

Compatible with most stored products and the overhead (product side) can be seal welded and

coated to provide additional compatibility.

- More expensive of the steel Pan and Bulkhead Style IFR;

- Installation is longer due the construction of the pontoons;

- Requires a door sheet in the tank for installation;

- Reduces vapor emissions, except through deck support legs, gauge poles or gauge

pole/ladders and fixed roof support columns;

- Almost impossible to sinking because of the pontoons. But if for some reason two or

more of the pontoons become flooded then the roof could sink;

- Less susceptible to weld seam fatigue due to the bulkheads providing some stiffing of

the main roof deck;

- Not an IFR design that can be cable suspended;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- Reduced filling capacity of the tank due to the 15” - 18” rim height, will have

approximately 15” – 16” of free-board above the product line to the top of the pan roof.

Approximately 6” – 8” of additional loss if a secondary wiper is required.

Double Deck Type IFR;

Consisting of a continuous closed top and bottom decks, which contain bulk-headed

compartments for buoyancy and designed with an outer rim of around 18” – 24” in height?

Compatible with most stored products overhead (product side) is normally welded and the

underside can be coated to provide additional compatibility.

- Most expensive Steel IFR;

- Installation is longer due to the addition of the top deck and seal welding of the

bulkheads;

- Requires a door sheet in the tank for installation;

- Reduces vapor emissions, except through deck support legs, gauge poles or gauge

pole/ladders and fixed roof support columns;

- Almost impossible to sinking due to the design of virtually all one giant pontoon. But if a

number of areas become flooded on the inside of the roof then the roof could sink;

- Virtually no weld seam fatigue due the roof flexing;

- Not an IFR design that can be cable suspended;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- Reduced filling capacity of the tank due to the 18” – 24” rim height, will have

approximately 15” – 16” of free-board above the product line to the top of the pan roof.

Approximately 6” – 8” of additional loss if a secondary wiper is required.

Pan Type IFR:

Consisting of a steel deck and supported outer rim with a recommended height of 18”, with all

support legs sleeves, column wells and manways at approximately the same height as the outer

rim. Compatible with most stored products and the overhead (product side) can be seal welded

and coated to provide additional compatibility.

- Lest expensive of the steel IFR’S;

- Installation is faster than other steel IFR’S;

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 33 © Vopak 2014

- Requires a door sheet in the tank for installation;

- Reduces vapor emissions except through deck support legs, gauge poles or gauge

pole/ladders and fixed roof support columns;

- Contains no closed buoyancy compartments;

- Susceptible to sinking due to operational upsets especially when build with a shorter

outer rim. Product that may find its way on top of the roof will pool together, adding

additional weight, causing the roof to float lower with the possibility of sinking;

- With no additional stiffening of the roof, the possibility of fatigue in the weld seams may

occur due to the flexing of the roof during cycling;

- Not an IFR design that can be cable suspended;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- Tanks containing a Pan Type roof are considered a fixed-roof tank (having no internal

floating roof) for the requirements of NFPA 30;

- Reduced filling capacity of the tank due to the 18” rim height will have approximately 15”

– 16” of free-board above the product line to the top of the pan roof. Approximately 6” –

8” of additional loss if a secondary wiper is required.

Bulkhead Pan Type IFR;

Consisting of a steel deck, inner and outer rims connected by bulkheads that form open

compartments approximately 6 ft – 8 ft wide around the outer circumference of the floating roof.

A recommended height of the outer rim is 18”, with all support legs sleeves, column wells and

manways at approximately the same height as the outer rim. Compatible with most stored

products and the overhead (product side) can be seal welded and coated to provide additional

compatibility.

- Slightly more expensive of the steel Pan IFR;

- Installation is longer due the additional inner rim and bulkheads;

- Requires a door sheet in the tank for installation;

- Reduces vapor emissions except through deck support legs, gauge poles or gauge

pole/ladders and fixed roof support columns;

- Contains no closed buoyancy compartments;

- Less susceptible to sinking because of the individual compartments capturing any

product that may gain access to the top of the roof due to operational upsets. Prevents

the product from pooling to one area of the roof. But, should two or more compartments

become filled, roof could sink;

- Less susceptible to weld seam fatigue due to the bulkheads providing some stiffing of

the main roof deck;

- Not an IFR design that can be cable suspended;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- Tanks containing a Pan Type roof are considered a fixed-roof tank (having no internal

floating roof) for the requirements of NFPA 30;

- Reduced filling capacity of the tank due to the 18” rim height will have approximately 15”

– 16” of free-board above the product line to the top of the pan roof. Approximately 6” –

8” of additional loss if a secondary wiper is required.

Aluminum Foam Core Panel Type IFR:

Consisting of a sandwich-panel that utilizes thin aluminum foil like sheeting adhered to a

urethane foam core by adhesives. The sandwich-panel module are for buoyancy but are not

considered as compartments for purposes of inspection and buoyancy requirements.

- Less costly than steel type roofs, more in line with the cost of aluminum skin and

pontoon type IFR;

- Installation is faster than steel type roofs, foam core panels are bolted together instead

of being welded. Minimal welding (anti-rotation cable connections) is required for

installation;

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 34 © Vopak 2014

- Opening in the tank (door sheet or removed sections from a fixed roof or panels of a

Geodesic dome roof) is required for the installation of the roof in order to set the panels

into the tank;

- Caution must be taken prior to any repairs in the tank to verify that the panels do not

contain product or product vapors. Even though the panels do not contain an aluminum

honeycomb inner core, the urethane foam core can absorb product if the foil-type sheet

should break down or become damaged;

- Due to bolted panels, deck seam emissions become a factor in considering vapor

losses calculations;

- Panels normally float approximately 1” – 2” depth in product, have a small outer rim to

support the seal system and will provide additional filling capacity to the tank;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- The roof can be cable suspended from the fixed roof or geodesic dome eliminating

vapor emissions from the leg housings. Cable suspending will also high and low leg

roof adjustments from outside of the tank;

- Caution should be taken to assure that the aluminum roof will be compatible with the

stored product. 100% aluminum type roofs should not be used when such products as

Methanol, Products containing chlorides, salts and caustic, water, slop water or other

corrosive type products to aluminum will be stored;

- Aluminum type roofs should not be hydrotested in water for long periods of time and

potable water should be used during the hydrotest.

Aluminum Honeycomb Panel Type IFR:

Consisting of a sandwich-panel that utilizes aluminum sheeting adhered to a honeycomb core,

either fixed to a metal frame by adhesives or welding. The sandwich-panel module are for

buoyancy but are not considered as compartments for purposes of inspection and buoyancy

requirements.

- Less costly than steel type roofs, slightly more expensive than an aluminum skin and

pontoon type IFR;

- Installation is faster than steel type roofs, honeycomb panels are bolted together

instead of welded. Minimal welding (anti-rotation cable connections) is required for

installation;

- Opening in the tank (large manway over 24”, door sheet or removed panels from either

a fixed or Geodesic dome roof) is required for the installation of the roof in order to set

the panels into the tank. The smaller the panels the more deck seams that will come

into play when calculating emissions;

- Caution must be taken prior to any repairs in the tank to verify that the panels do not

contain product or product vapors;

- Due to bolted panels, deck seam emissions become a factor in considering vapor

losses calculations;

- Can be equipped with a mechanical shoe seal, secondary wiper seal or double wiper

seal;

- Panels normally float approximately 1” – 2” depth in product, have a small outer rim to

support the seal system and will provide additional filling capacity to the tank;

- The roof can be cable suspended from the fixed roof or geodesic dome eliminating

vapor emissions from the leg housings. Cable suspending will also high and low leg

roof adjustments from outside of the tank;

- Caution should be taken to assure that the aluminum roof will be compatible with the

stored product. 100% aluminum type roofs should not be used when such products as

Methanol, Products containing chlorides, salts and caustic, water, slop water or other

corrosive type products to aluminum will be stored;

- Aluminum type roofs should not be hydrotested in water for long periods of time and

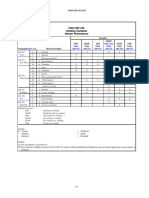

potable water should be used during the hydrotest.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 35 © Vopak 2014

GRE with Honeycomb Panel Type IFR:

Its made of a polypropylene honeycomb core sandwiched between multiple layers of glass-fibre

reinforced polyester (GRP) / epoxy (GRE), resulting in a smooth, seamless and rigid floating

roof. The GRE IFR is designed to accommodate both a mechanical shoe primary seal and a

secondary seal.

Features:

- More expensive than Aluminum Non contact IFR;

- Full contact design, therefore better emission reduction;

- Very rigid;

- Resistant to many products normally stored in floating roof tanks;

- Seamless construction, with no bolt holes through deck; legs are welded to bottom to

support “disk”;

- Maintenance free, corrosion resistant;

- Designed to accommodate both a mechanical shoe primary seal and secondary seal;

- Roofparts can be brought in the tank by only one 24" manway for access;

- Very high buoyancy, gas tight, leak proof;

- Strong enough to withstand pigging, light-end slugs and high filling rates;

- Fully engineered, tested and field proven;

- Low profile, minimal loss of storage capacity;

- Fire resistant although applicable standards say fire fighting systems for non-metallic

roofs shall be designed to cope with full service fire, while fire fighting systems of

metallic IFR’s shall only be designed to cope with rim fire;

- Roof can be cable suspended.

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 36 © Vopak 2014

Appendix 2 – IFR Inspection Sheet

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 37 © Vopak 2014

Appendix 3 – Product Compatibility Materials

Each construction material of seals and IFRs has its limits. Known problem areas are:

Material Incompatible with

Carbon Steel Acids, check chemical resistance sheets

Stainless Steel chlorides

Aluminium Very acidic or alkaline solutions, 4>pH>9;

Ethanol*, Methanol

GRE Acetone, Acrylates, methacrylates, phenol and

chlorinated products

* Some good references are available around the company with storing ethanol in aluminium

tanks. Resistance depends on concentration of ethanol with water and other contaminations.

This table is indicative only; it does not free the user from verifying the chemical resistance

against exact used materials and the stored products, during design or MOC.

For Rubber reference is made to EEMUA Table 12.3.3-1

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 38 © Vopak 2014

Appendix 4 – Vopak List of Minimum Mountings IFR

Appurtenance Number Remark

Stilling Well 1 Well for level measurements (depending

on available level measurement type)

Sampling or 1

Dipping Well

Bleeder Valve As per Sufficient venting capacity shall be

calculation guaranteed during filing and unloading

tank

Manhole 1 For diameter > 30 m, select 2 manholes;

position near tank shell manhole for easy

entry/exit and ease of gas testing of

confined space above roof

Rim vent 1 if required by seal supplier

Foam dam 1 Highest seal must be covered with foam

in case of fire.

Supporting legs As per 2 position legs, with PTFE endcaps

calculation

Earthing Cable 2 Follow design code API 650 or EN 14015,

Stainless Steel

Drains Supplier Drainage sufficient for cleaning activity

guidelines

Primairy seal 1 Liquid mounted primary seal. Secondary

seal only for regulatory purposes

Bolts, nuts, Stainless steel

clampbars, etc

Anti Rotation Min 2 Cables shall be stainless steel

poles/cables

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 39 © Vopak 2014

Appendix 5 – Assessment and Selection Tool for IFRs

Assessment of requirements of different IFR’s

This document is for Vopak internal use only and should not be distributed outside Vopak

Selection of Internal Floating Roofs l Version 1.1 l May 2014

Property of Vopak – Confidential 40 © Vopak 2014

Snap-shot of CoOpX tool for IFR selection

This document is for Vopak internal use only and should not be distributed outside Vopak