Professional Documents

Culture Documents

Design Basis

Uploaded by

Claudine Spark SerranoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Basis

Uploaded by

Claudine Spark SerranoCopyright:

Available Formats

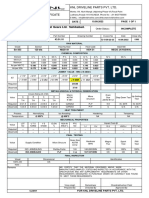

Project Name Optimization of Cement Manufacturing Process

Betterfound Cement Corporation Project Number Sheet 1

Head Office: State Center II Ortigas Avenue, Mandaluyong City REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form 52830-19-26

1 General Information

Owners Name Banton, Sherry B.; Palaje, Merciline Joy S.; Serrano, Claudine Spark M.; Valencia, Jonnabelle A.

Process Unit Name Cement Manufacturing Plant

Plant Location Purok 1, Brgy. Kilicao, Daraga, Albay

Correspondance Contacts

Address Head Office: State Center II Ortigas Avenue, Mandaluyong City

Telephone / Fax 482-0605

E-mail contactus@betterfound.com

comrel@betterfound.com

2 Measurement System

English Metric

3 Equipment Numbering System

Equipment will be identified by alphabetic AC Air cooler G Grinder, mill PRV Pressure relief valve

prefix as defined here, followed by three- B Boiler H Heater (fired or electric) R Reactor

digit serial number unless otherwise C Compressor, blower, fan J Ejector, jet, turboexpander SP Sample point

indicated CT Cooling tower M Motor T Storage tank

D Dryer ME Miscellaneous equipment V Vessel (including columns)

First digit - process section E Exchanger MX Mixer

Second & third digits - equipment count F Filter, classifier P Pump

4 Primary Products

Product Name Ordinary Portland Cement Pozzolanic Portland Cement

Product Grade OPC 53 PPC

MSDS Form Number 65997-15-1 66984-13-2

Production Rate

Metric tons per year 1839600 1526430

Metric tons per day 5,040 4,182

Other units

Product Purity (wt%) 100 100

Product shipment mode Land: Trucks and Train Land: Trucks and Train

Water: Cargo vessels Water: Cargo vessels

Additional Specifications Chemical Composi% Chemical Composit%

SiO2 19-24 SiO2 45-55

Al2O3 4.0-9.0 Al2O3 25-30

Fe2O3 1.6-6 Fe2O3 5.0-10.0

CaO 60-67 CaO 2.0-6.0

MgO not>5 MgO 2.0-3.0

SO3 not>3 SO3 0.5-3

State Solid State Solid

Density Density

Bulk Density, kg/m3 3.1 Bulk Density, kg/m3 3.15

Relative Density, kg 1,404 Relative Density, kg 1,300

Compressive strength Compressive strength

At 2 days (Mpa) 11.3 At 2 days (Mpa) 28

At 28 days (Mpa) 16.9 At 28 days (Mpa) 58

Soundness Letchate0-2 Soundness Letchatel1

Fineness % 85.4 Fineness % 86.2

pH 12 pH 12

Boiling Point 1000 C Boiling Point 1000 C

Appearance Gray Appearance Gray

5 Primary Raw Materials

(Attach additional sheets if needed)

Feedstock name Ores (from Mining Operation)

Limestone Clay Iron Ore

Feedstock grade

MSDS form number

Feedstock availability

Metric tons per year 5,787,819.60

Metric tons per day 15,857.04

Other units

Feedstock price ($/kg) N/A N/A N/A

(Default: open market price)

Feedstock Chemical Composition Name % tph Name % tph Name % tph

SiO2 5 28.080175 SiO2 37 31.780151 SiO2 3 0.396426

Al2O3 + TiO2 0.9 5.0544315 Al2O3 + TiO2 8.5 7.3008455 Al2O3 + 2.2 0.2907124

Fe2O3 + Mn2O3 0.4 2.246414 Fe2O3 + Mn2O3 5 Jan-00 TiO2

Fe2O3 + 53 7.003526

CaO 55 308.881925 CaO 25 21.473075 CaO 28 3.699976

MgO 0.3 1.6848105 MgO 5 4.294615 MgO 0.5 0.066071

K2O 0.3 1.6848105 K2O 0.5 0.4294615 K2O 3.5 0.462497

Na2O 0.1 0.5616035 Na2O 0.3 0.2576769 Na2O 0.2 0.0264284

SO3 0.1 0.5616035 SO3 3 2.576769 SO3 0.3 0.0396426

Co2 + H2O 37.9 212.8477265 Co2 + H2O 15.7 13.4850911 Co2 + H2O 9.3 1.2289206

TOTAL 100 561.6035 TOTAL 100 85.8923 TOTAL 100 13.2142

Additional specifications Primary Raw Materials will be acquired from Mining Operations

6 Site Information

Low ambient temperature (C) 25

High ambient temperature (C) 35

Hight ambient relative humidity (%) 60

Site elevation (m) 300 m above sea level

Maximum wind loading (km/h) 36

Other site design requirements

Project Name

Company Name Project Number Sheet 2

Address REV DATE BY APVD REV DATE BY APVD

DESIGN BASIS

Form XXXXX-YY-ZZ

7 Utility Information

Fuel Gas

Gas source or operation mode natural gas

Supply header temperature (C) 35

Supply header pressure (kPa (a))

Net calorific value (kJ/kg) 41858

Marginal availability (kg/h)

Marginal fuel cost ($/GJ) 2.05

Sulfur content (wppm) 1.3

Nitrogen content (wppm) 3.2

Chlorine content (wppm) 0.5

Gas composition (vol%)

H2O

O2 0.02

N2 1

CO n/a

CO2 0.5

H2S

H2 trace

CH4 95

C2H4 0.8

C2H6 3.2

C3H6 0.01

C3H8 0.2

C4H8 0.03

iC4H10 0.03

nC4H10 0.01

C5H10 0.01

C5+ 0.01

Fuel Oil

Fuel source or operation mode Rubber/tyres

Supply header temperature (C)

Supply headder pressure (kPa (a))

Net calorific value (kJ/kg) 33486.4

Marginal availability (kg/h)

Marginal fuel cost ($/GJ) 450

Fuel viscosity at C

Fuel viscosity at C

Flash point (C) 260-316

Pour point (C)

Sulfur content (wppm) .0.8

Nitrogen content (wppm) 0.3

Ash content (wt %) 2.2

Steam

Steam header classification VHP HP MP LP

Operating pressure (kPa (a))

Operating temperature (C)

Mechanical design pressure (kPa (a))

Mechanical design temperature (C)

Marginal availability (kg/h)

Marginal cost ($/metric ton)

Coolants

Coolant classification Cooling Tower Water Once-Through Water Chilled Water

Operating pressure (kPa (a))

Supply temperature (C)

Maximum return temperature (C)

Marginal availability (kg/h)

Marginal cost ($)

Marginal cost units

Process Water Feeds

Water feed stream Raw Water Process Water Boiler Feed Water Condensate

Supply pressure (kPa (a))

Supply temperature (C)

Marginal availability (kg/h)

Marginal cost ($/metric ton)

Total dissolved solids (wt%)

Hardness as CaCO3 (ppmw)

Chloride as Cl (ppmw)

Metallurgy

Electric power

Power range (kW) 2699

Voltage (V) 145000

Phase 3

Frequency (Hz)

Marginal availability (kW)

Marginal cost ($/kWh)

Plant air streams

Air stream Plant Air Instrument Air Plant Nitrogen

Header pressure (kPa (a))

Header temperature (C)

Moisture (ppmw)

Marginal availability (kg/h)

Marginal cost ($/Normal m3)

SECONDARY RAW MATERIALS

Feedstock name Correctives

Sand Iron

Feedstock grade

MSDS form number

Feedstock availability

Metric tons per year 570863.65

Metric tons per day 1,564.01

Other units

Feedstock price ($/kg) N/A N/A

(Default: open market price)

Known feedstock impurities Name % %w/w Name ppmw

SiO2 94 14.67584 SiO2 3 – 50

Al2O3 + TiO2 0 0 Al2O3 + 2 – 20

Fe2O3 + Mn2O3 3.38 52.7706 TiO2

Fe2O3 + 0.5 - 10

CaO 0.7 0.109288 Mn2O3

CaO 52-55

MgO 0.5 0.078063 MgO 0.5-5

K2O 0.5 0.078063 K2O 3.5

Na2O 0.05 0.007806 CO2 + H2O 2 – 42

SO3 0.37 0.057767 SO3 0.1 - 4

Co2 + H2O 1 0.156126

TOTAL 100 15.6126 Na2O 0.2

Additional specifications

Gypsum (CaSO4-2H2O) Fly Ash

Bauxite

13397-24-5 13397-24-5

87,600 436,143

240 1,194.91

N/A $2.00-2.27 $0.04

Name ppmw Name ppmw Name ppmw

SiO2 37-78

Al2O3 + 0.5-3

TiO2

Fe2O3 + 0.5-2

Mn2O3

CaO 0.1-3

MgO 0.5

K2O 1

CO2 + H2O 5

SO3 0.5

Na2O 0.5

You might also like

- Design BasisDocument4 pagesDesign BasisClaudine Spark SerranoNo ratings yet

- PreviewDocument1 pagePreviewJohn Cyril MusniNo ratings yet

- PP - 317005 - Tep - Qca - 0012 870310-S-1183228-CST-H99-0009Document7 pagesPP - 317005 - Tep - Qca - 0012 870310-S-1183228-CST-H99-0009Hanna MarshellaNo ratings yet

- Technical OfferDocument10 pagesTechnical OfferNishantNo ratings yet

- Homologacion Cmm-GageDocument1 pageHomologacion Cmm-GageJoan a Robledo SalasNo ratings yet

- VDRLDocument4 pagesVDRLfarazhussainkhanNo ratings yet

- Volume3A Mech PDFDocument321 pagesVolume3A Mech PDFSayee Krishnan100% (1)

- Delivery OrderDocument2 pagesDelivery OrderGayan IndunilNo ratings yet

- Duplex-Body Flowmeter Skid Commissioning ReportDocument3 pagesDuplex-Body Flowmeter Skid Commissioning ReportGeorge GuoNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Logistics Service High Pressure Co2 System Approval (20.08.06) - R1Document50 pagesLogistics Service High Pressure Co2 System Approval (20.08.06) - R1Phú ĐoànNo ratings yet

- Material Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)Document136 pagesMaterial Submittal No. 0003 r.01 For Mdpe Pipes & Fittings, Sdr-11 (Naffco Flow Control, U.a.e.)rheynavarro24No ratings yet

- Chemical Dosing Unit (Cdu) : Rabigh II Project Interconnecting Package (UO1)Document19 pagesChemical Dosing Unit (Cdu) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- Steam Control Valve - Pnumatic ValveDocument2 pagesSteam Control Valve - Pnumatic Valvepsonu92No ratings yet

- Level Transmitter MSPLDocument6 pagesLevel Transmitter MSPLPratap ShettyNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- Old Certificate TC-2796-Cerachem - CONVOLUTED MOD - 128D - TOCO-55RI-21.01.22Document2 pagesOld Certificate TC-2796-Cerachem - CONVOLUTED MOD - 128D - TOCO-55RI-21.01.22NabielNo ratings yet

- Prayagraj City Micro PlanDocument161 pagesPrayagraj City Micro PlanAnusha Kant100% (1)

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Spec Piping Material PDFDocument18 pagesSpec Piping Material PDFMuchamad FaizNo ratings yet

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- FAT Procedure & ChecklistDocument3 pagesFAT Procedure & ChecklistARSHI ASLAM100% (3)

- ITP 07-2 3LPP CS Rev.4 E0660-P10361121-H03-2001-05 (CODE 1) PDFDocument29 pagesITP 07-2 3LPP CS Rev.4 E0660-P10361121-H03-2001-05 (CODE 1) PDFBlade ChannelTvNo ratings yet

- Project Report Design of Dense Bituminous Macadam: ClientDocument11 pagesProject Report Design of Dense Bituminous Macadam: ClientHarshit MoreNo ratings yet

- # 384 / 1 (1 & 2), 3rd Stage, 4th Phase, Peenya Industrial Area, Thigalarapalya Main Road, B - 560 058, Karnataka, India 4th Area, Road, KarnatakaDocument9 pages# 384 / 1 (1 & 2), 3rd Stage, 4th Phase, Peenya Industrial Area, Thigalarapalya Main Road, B - 560 058, Karnataka, India 4th Area, Road, KarnatakaCorrosion FactoryNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- BloomLake FS 03172017Document351 pagesBloomLake FS 03172017Vivek RanganathanNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Covid 19 ofDocument4 pagesCovid 19 ofMy PhoneNo ratings yet

- Hydraulic Filter 1Document2 pagesHydraulic Filter 1OUC-SECBNo ratings yet

- IND3FB Auswahl 02 0416 PDFDocument3 pagesIND3FB Auswahl 02 0416 PDFKleberBuñayNo ratings yet

- E Series RO 2000 LPH - Final NRP 27092021Document10 pagesE Series RO 2000 LPH - Final NRP 27092021Anand_HvacNo ratings yet

- Flexible HoseDocument1 pageFlexible HoseKhánh TrầnNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 211, - , - : Heat-Treatable Steel, Low Alloy Steel, Cr-Mobaskaran ayyapparajNo ratings yet

- Pumpdesign Report: Pump ParametersDocument7 pagesPumpdesign Report: Pump Parameterscristian fernando garnicaNo ratings yet

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 pagesM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381No ratings yet

- MMBT3906: 40V PNP Small Signal Transistor in Sot23Document7 pagesMMBT3906: 40V PNP Small Signal Transistor in Sot23Abel GaunaNo ratings yet

- Strucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Document2 pagesStrucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Prince MittalNo ratings yet

- Ferromaxx 7Document2 pagesFerromaxx 7bonn99388577No ratings yet

- Tendernotice 1Document41 pagesTendernotice 1Suyog MahaleNo ratings yet

- Data Sheet For Level Transmitter Radar Non-Contact TypeDocument3 pagesData Sheet For Level Transmitter Radar Non-Contact TypeSri Kanth100% (1)

- Datasheet For FiltersDocument13 pagesDatasheet For FiltersAntonio MendesNo ratings yet

- 2005 S003 NBPG Rfi 04952 - R00Document1 page2005 S003 NBPG Rfi 04952 - R00RPDeshNo ratings yet

- Tech Bid PDFDocument234 pagesTech Bid PDFIndrajeet AldarNo ratings yet

- Inspection Report 4500806492Document2 pagesInspection Report 4500806492Stuart LemonNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- Hxh En590 Jurong Fob Icpo 富吉拉港口Document4 pagesHxh En590 Jurong Fob Icpo 富吉拉港口tsng812No ratings yet

- PCB Clearance Water & Air PDFDocument7 pagesPCB Clearance Water & Air PDFHimanshu MishraNo ratings yet

- JM 003 (Datashe PDFDocument1 pageJM 003 (Datashe PDFAmul AmnajeNo ratings yet

- ZADCO-Mechanical Equipment SpecificationDocument83 pagesZADCO-Mechanical Equipment SpecificationNAMONo ratings yet

- OICO - EDC Technical Offer - 05390-22Document2 pagesOICO - EDC Technical Offer - 05390-22MohammadNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ECC IEE ReqmntsDocument1 pageECC IEE ReqmntsClaudine Spark SerranoNo ratings yet

- CXS 177eDocument4 pagesCXS 177eIvone SulistyaNo ratings yet

- Contract of LeaseDocument9 pagesContract of LeaseClaudine Spark SerranoNo ratings yet

- Dao 2007-17 Rules and Regulations Governing Special Uses Within Protected AreasDocument11 pagesDao 2007-17 Rules and Regulations Governing Special Uses Within Protected AreasClaudine Spark SerranoNo ratings yet

- ReferencesDocument1 pageReferencesClaudine Spark SerranoNo ratings yet

- Template 3 - MATH 3-REGULAR-DIAGNOSTICDocument2 pagesTemplate 3 - MATH 3-REGULAR-DIAGNOSTIClailanie CervantesNo ratings yet

- Re 150821Document2 pagesRe 150821francis puthuserilNo ratings yet

- Automatic Control ExercisesDocument183 pagesAutomatic Control ExercisesFrancesco Vasturzo100% (1)

- Capital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisDocument16 pagesCapital Budgeting and Capital Budgeting and Risk Analysis Risk AnalysisHaris FendiarNo ratings yet

- Thursday / January 2019 Thursday / January 2019Document572 pagesThursday / January 2019 Thursday / January 2019Zie EikinNo ratings yet

- Review. Applications of Ecogeography and Geographic Information Systems in Conservation and Utilization of Plant Genetic ResourcesDocument11 pagesReview. Applications of Ecogeography and Geographic Information Systems in Conservation and Utilization of Plant Genetic ResourcesEmilio Patané SpataroNo ratings yet

- VSR Trans. PPT3Document16 pagesVSR Trans. PPT3VSR TRANSNo ratings yet

- Bhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Document37 pagesBhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Anu RsNo ratings yet

- The First-Fourth Books of The HitopadésaDocument116 pagesThe First-Fourth Books of The HitopadésaMiguel RosaNo ratings yet

- (AB-ANI) Program SpecificationDocument8 pages(AB-ANI) Program SpecificationMycah EvangelistaNo ratings yet

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Document27 pagesChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNo ratings yet

- Lab Report 1Document23 pagesLab Report 1hadri arif0% (1)

- Si2304 (Mosfet Sot 23)Document6 pagesSi2304 (Mosfet Sot 23)Alfredo Valencia RodriguezNo ratings yet

- Hamming Code - Error Detection Aim: AlgorithmDocument12 pagesHamming Code - Error Detection Aim: Algorithmkrithikgokul selvamNo ratings yet

- Anger Management: Gaurav Sharma 138Document21 pagesAnger Management: Gaurav Sharma 138gaurav_sharma_19900No ratings yet

- ENIRAM - Guide To Dynamic Trim Optimization 280611 PDFDocument14 pagesENIRAM - Guide To Dynamic Trim Optimization 280611 PDFPhineas MagellanNo ratings yet

- Ficha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux LedDocument5 pagesFicha Tecnica Reflector 2000W Led Lluminacion de Campos de Futbol Estadios Goled Philips Osram Opalux Ledluis perdigonNo ratings yet

- Concession Project List Excel 02-Aug-2019Document15 pagesConcession Project List Excel 02-Aug-2019Vishal BansalNo ratings yet

- The Research Problem: The Key Steps in Choosing A TopicDocument5 pagesThe Research Problem: The Key Steps in Choosing A TopicJoachim San JuanNo ratings yet

- Term Test Pointers For Review - 1st TermDocument2 pagesTerm Test Pointers For Review - 1st Termjessica holgadoNo ratings yet

- Theories of PersonalityDocument4 pagesTheories of PersonalityKeshav JhaNo ratings yet

- Rule Based ClassificationsDocument14 pagesRule Based ClassificationsAmrusha NaallaNo ratings yet

- PUP 200 Quizzes 6Document47 pagesPUP 200 Quizzes 6Nam TranNo ratings yet

- Empowerment TechnologyDocument15 pagesEmpowerment Technologysxhan gwenNo ratings yet

- Results 2020: Climate Change Performance IndexDocument32 pagesResults 2020: Climate Change Performance IndexTonyNo ratings yet

- INT PL 2020 Web 01-20 PDFDocument320 pagesINT PL 2020 Web 01-20 PDFAndriana Vilijencova100% (1)

- 3-Storeyed 31-3-2015-Schedule PDFDocument1 page3-Storeyed 31-3-2015-Schedule PDFSi Thu AungNo ratings yet

- Jimma UniversityDocument99 pagesJimma UniversityBekan NegesaNo ratings yet

- NeedScope On TechnologyDocument22 pagesNeedScope On TechnologyNguyen Ngo Dinh PhuongNo ratings yet

- Palmiye Leaflet 2015 enDocument4 pagesPalmiye Leaflet 2015 ensaraju_felixNo ratings yet