Professional Documents

Culture Documents

Upgrading Fine Filters at CC Water Injection Plant

Uploaded by

NAMOOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Upgrading Fine Filters at CC Water Injection Plant

Uploaded by

NAMOCopyright:

Available Formats

CLIENT: ZAKUM DEVELOPMENT COMPANY

CC WATER INJECTION PLANT

PROJECT/JOB TITLE: UPGRADE (PACKAGE 1) FINE

FILTERS MODIFICATIONS FEED

ZADCO PROJECT NUMBER: P8341

DOCUMENT TYPE: TECHNICAL SPECIFICATION

MECHANICAL EQUIPMENT

DOCUMENT TITLE:

SPECIFICATION

ZADCO DOCUMENT NUMBER: P8341-TS-260-M-0003

GENESIS JOB NUMBER: J18001

GENESIS DOCUMENT NUMBER: J18001-J02-001

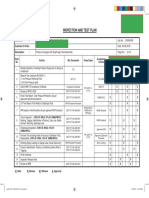

D 26/09/12 Issued for EPC GS AMH AMH

C 04/07/12 Issued for Approval GS AW AMH

B 13/04/12 Re-issued for Review GS IWH AMH

A 17/02/12 Issued for Review GS IWH AMH

Rev Date Description Issued By Checked Approved Client

By By Approval

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

HOLDS LIST

HOLD Description Section

REVISION HISTORY

Rev. Description Section

B Content and format rewritten as an amendment to All

relevant ZADCO mechanical specifications Z0-TS-M-

02010 & 02020, in line with Client comments

C Client comments incorporated 2.3, 2.5, 2.6,

3.3 & 3.6

D Issued for EPC, no change to content -

Genesis Page 2 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

ABBREVIATIONS

ADNOC Abu Dhabi National Oil Company

AISC American Institute of Steel Construction

API American Petroleum Institute

ASME American Society of Mechanical Engineers

ASTM American Society for Testing of Materials

AWS American Welding Society

BS British Standard

CC Central Complex

CRA Corrosion Resistant Alloy

CS Carbon Steel

DPI Dye Penetrant Inspection

EEMUA Engineering Equipment and Materials Users Association

EN Euronorm

EPC Engineering, Procurement, Construction.

FEED Front End Engineering Design

GTAW Gas Tungsten Arc Welding

ISO International Standards Organisation

ITP Inspection and Test Plan

IVB Independent Verification Body

LPI Liquid Penetrant Inspection

MAWP Maximum allowable working pressure

MDMT Minimum Design Metal Temperature

MPI Magnetic Particle Inspection

Genesis Page 3 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

MRB Manufacturing Record Book

MSDS Material Safety Data Sheet

MTO Material Take Off

NACE National Association of Corrosion Engineers

NB Nominal Bore

NDE Non-Destructive Examination

NPT National Pipe Thread

PIM Pre-Inspection Meeting

PMI Positive Materials Identification

ppm Parts Per Million

PWHT Post-Weld Heat Treatment

QA / QC Quality Assurance / Quality Control

RT Radiographic Testing

SDRL SUPPLIER Document Requirements List

SI Système International d’Unités (metric system)

SS Stainless Steel

SWL Safe Working Load

TEMA Tubular Exchanger Manufacturers Association

TDFT Total Dry Film Thickness

UT Ultrasonic Testing

VI Visual Inspection

WFT Wet Film Thickness

WPQR Weld Procedure Qualification Records

WPS Weld Procedure Specifications

ZADCO Zakum Development Company

Genesis Page 4 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

Table of Contents

HOLDS LIST .............................................................................................................. 2

REVISION HISTORY ................................................................................................. 2

ABBREVIATIONS...................................................................................................... 3

1 INTRODUCTION ............................................................................................... 7

1.1 BACKGROUND ........................................................................................................... 7

1.2 PROJECT DESCRIPTION ............................................................................................. 8

1.3 PURPOSE OF THE DOCUMENT.................................................................................... 8

1.4 GENERAL DESIGN OBJECTIVES.................................................................................. 8

2 AMENDMENTS TO Z0-TS-M-02010 UNFIRED PRESSURE VESSEL:

DESIGN CRITERIA ......................................................................................... 10

2.1 SECTION 5 REFERENCE STANDARDS, CODES, SPECIFICATIONS AND

REGULATIONS .................................................................................................... 10

2.2 SECTION 6 GENERAL REQUIREMENTS ............................................................. 10

2.3 SECTION 10 DESIGN REQUIREMENTS ............................................................... 10

2.4 SECTION 12 NOZZLE CONNECTIONS ................................................................. 11

2.5 SECTION 14 DESIGN OF VESSEL SUPPORTS ................................................... 11

2.6 APPENDIX B LOCAL LOADS FOR VESSELS......................................................... 12

3 AMENDMENTS TO Z0-TS-M-02020 MATERIALS, FABRICATION &

TESTING OF UNFIRED PRESSURE VESSELS FOR GENERAL SERVICE. 13

3.1 SECTION 2 REFERENCE STANDARDS, CODES, SPECIFICATIONS AND

REGULATIONS .................................................................................................... 13

3.2 SECTION 4 VENDOR’S DOCUMENTS .................................................................. 13

3.3 SECTION 5..VENDOR RESPONSIBILITIES ........................................................... 13

3.4 SECTION 6 DESIGN VERIFICATION..................................................................... 13

3.5 SECTION 7 MATERIALS ........................................................................................ 13

3.6 SECTION 8 NOZZLE CONNECTIONS ................................................................... 14

3.7 SECTION 25 SHOP PAINTING ............................................................................... 14

3.8 SECTION 29 VENDOR DOCUMENT AND DATA REQUIREMENTS ..................... 14

3.9 SECTION 30 VENDOR’S DATA REPORT.............................................................. 14

3.10 INSULATION AND PERSONNEL PROTECTION.............................................................. 14

APPENDIX – A ........................................................................................................ 15

1. DESIGN AND REFERENCE STANDARDS,SPECIFICATIONS AND

REGULATIONS .................................................................................................... 15

2. COMPANY'S SPECIFICATIONS .......................................................................... 15

3. PROJECT DOCUMENTS...................................................................................... 15

APPENDIX – B ........................................................................................................ 17

Z0-TS-M-02010 REV 2 UNFIRED PRESSURE VESSELS: DESIGN CRITERIA ............ 17

APPENDIX – C ........................................................................................................ 18

Genesis Page 5 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

Z0-TS-M-02020 REV 1 MATERIALS, FABRICATION AND TESTING OF UNFIRED

PRESSURE VESSELS FOR GENERAL SERVICE .............................................. 18

Genesis Page 6 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

1 INTRODUCTION

1.1 Background

The Zakum offshore field is located 84km from Abu Dhabi, with the Upper Zakum

portion of the field being operated by the Zakum Development Company (ZADCO), a

company in the Abu Dhabi National Oil Company Group (ADNOC), and the Lower

Zakum Field being operated by Abu Dhabi Marine Operating Company (ADMA), a

sister company in the ADNOC Group.

Upper Zakum is divided into four geographical producing areas: Central, North,

South and West. The processing facilities are located on the Central Complex (CC)

which is the focal point of the field with production being received from the three

satellite platforms situated in the North, South and West of the field. The satellite

platforms are fed by flowlines from over 90 Wellhead Platform Towers (WHPT’s).

The Central Complex houses the water injection facilities which treat and feed

injection quality seawater to the WHPT’s via the satellite platforms for reservoir

pressure maintenance.

ZADCO has initiated the Upper Zakum Full Field Development (UZFFD) project

aimed at increasing the target crude oil production rate to 750 MOBPD by the end of

2015, and sustaining this production plateau for at least 25 years.

For this increased production rate, the water injection rate will need to be increased

in order to maintain reservoir pressure. This injection water will be delivered both to

the existing WHPT’s as well as to new facilities located on a number of artificial

islands which are currently being constructed. Any shortfall in the water injection

capacity on Central Complex will be installed at the new Central Island facility.

The CC facilities will be upgraded to enable continuous injection water delivery of

900,000 BWPD, and a 400,000 BWPD injection water treatment plant installed on

the planned Central Island. Until the CI facility is operational it is necessary to

increase the capacity of the CC Water Injection Plant (WIP). The upgraded CC

facilities will be operated to produce up to approximately 1,200,000 BWPD in a

temporary “stretched” operating mode during an interim period between 2013 and

2015 to support the initial oil production expansion of the 750,000 BOPD until the

Central Island facilities are available.

ZADCO has appointed Genesis to carry out a FEED for the selected option of

upgrade of the Fine Filters 260-F-001B/C/D/E and PLC on the Zakum CC. This

follows a Conceptual Design Study also carried out by Genesis during 2009/10.

Genesis Page 7 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

1.2 Project Description

The project involves the following upgrades:

• Modification of four out of the ten existing fine filters 260-F-001A to K to

become high capacity dual media filters in order to increase capacity for

seawater injection to 1,200,000 BPD treated water

• Modification of WIP sequence control system to allow two independent back

wash cycles, ie one for modified fine filters and one for the remaining fine

filters. The WIP sequence control will be built into the new DCS system.

• Addition of temperature compensation to the fine filter backwash process.

• Allowance for all five HP injection pumps to be operated at the same time.

The current logic only allows four HP pumps to be started under automatic

control.

1.3 Purpose of the Document

The purpose of this document is to specify the recommended mechanical design

practices for changes associated with upgrading Fine Filters 260-F-001B/C/D/E.

The document supplements the general requirements of ZADCO vessel

specifications Z0-TS-M-02010 and Z0-TS-M-02020 with project-specific

requirements.

1.4 General Design Objectives

The mechanical design philosophy for the project shall be to produce Fine Filter

modifications designed to achieve the following objectives:-

Safe to operate

Non-hazardous to the health of site personnel

Best available proven technology

Equipment shall be designed for ease and simplicity of operation

Equipment shall be designed to minimise the need for maintenance

Design shall ensure that the layout and configuration of equipment allows

isolation of equipment and systems for safe maintenance

The design shall ensure that maintenance, can be accomplished with

minimum impact on production and with minimum exposure of personnel to

health and safety hazards

Equipment design based on similar field-proven technology used in off-shore

or similar locations

Genesis Page 8 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

Equipment supplied, as far as possible, complete and ready for installation at

site with minimum site-fabrication and hook-up by others

Equipment designed to permit sequential modification of the filters, to

minimise down-time during installation

Mechanical design of new process drain-down nozzles on Filter vessels in

accordance with ASME VIII Div 1

Genesis Page 9 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

2 AMENDMENTS TO Z0-TS-M-02010 UNFIRED PRESSURE VESSEL: DESIGN

CRITERIA

2.1 Section 5 REFERENCE STANDARDS, CODES, SPECIFICATIONS AND

REGULATIONS

Add the following:

5.5 The edition or revision, including addenda, of the referenced Codes,

Standards & Specifications governing, shall be the latest ruling on the

date of order, unless noted otherwise.

2.2 Section 6 GENERAL REQUIREMENTS

Section 6.5.6 Design Life

Add the following:

This is interpreted as requiring the materials selected for all major items

of piping and equipment items to be resistant to the anticipated

degradation mechanisms and remain fit-for-service for 30 years,

providing routine maintenance and inspection is carried out in

accordance with suppliers’ instructions.

It is acceptable to replace consumables during planned maintenance

interventions, such as wear parts, seals, gaskets and any other

components that cannot achieve the full service life.

2.3 Section 10 DESIGN REQUIREMENTS

10.1.9 Delete clause, since flange rigidity calculations are now mandatory

(ASME VIII Div 1 Appendix 2, section 2,14; ASME VIII Div 2 section

4.16)

Add the following:

10.3.9 The provision of suitable mechanical handling facilities shall be made in

the detail design for any component requiring removal or handling that

exceeds 25kg in weight.

Refer to Lifting & Handling Study P8341-SR-260-M-0008 for project-

specific, handling-related design requirements.

10.6 Weight Control

A Weight Control Report shall be compiled as part of the design

process, to include weight data sheets that indicate empty, hydrotest

and operational weights of the existing and modified Fine Filters 260-F-

Genesis Page 10 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

001B/C/D/E together with position of centre of gravity. Ref Weight

Control Report P8341-TR-260-S-0003.

10.7 Sparing & Spare Parts

10.7.1 Sparing of Critical Equipment

Current operating mode of existing Fine Filters is eight filters operating,

one in backwash plus one on standby.

For the modified Fine Filters, this shall be revised to nine filters on duty

plus one on backwash, so no Fine Filters will be on standby during the

interim “stretch period” of operations.

10.7.2 Spare Parts

Refer to Spare Parts Philosophy P8341-BD-260-M-0009 for project

specific, spares related design requirements for the modified Fine

Filters

10.8 Insulation and Personnel Protection

The Fine Filter vessel modifications do not give rise to any requirement

for insulation or additional personnel protection equipment.

2.4 Section 12 NOZZLE CONNECTIONS

Add the following:

12.1.40 The new process drain-down nozzles P1/P2/P3 on upgraded Fine

Filters F-260-001B/C/D/E shall be designed for loads specified in

Appendix B of Z0-TS-M-02010.

2.5 Section 14 DESIGN OF VESSEL SUPPORTS

Add the following:

14.19 Design of existing Filter vessel saddle supports and vessel internal

supports shall be carried out for modified Filters 260-F-001B/C/D/E in

accordance with Client approved procedure P8341-PB-260-M-0001

Procedure for Design of Vessel Supports.

Genesis Page 11 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

2.6 Appendix B LOCAL LOADS FOR VESSELS

Section 1. General

1.6 Revise the clause, to read:

Load combinations shall be in accordance with ASME VIII Div 2,

section 4.1.5.3. Calculations for local loads shall be carried out

according to WRC 107 and WRC 297 or FE analysis.

Genesis Page 12 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

3 AMENDMENTS TO Z0-TS-M-02020 MATERIALS, FABRICATION & TESTING

OF UNFIRED PRESSURE VESSELS FOR GENERAL SERVICE

3.1 Section 2 REFERENCE STANDARDS, CODES, SPECIFICATIONS AND

REGULATIONS

Add the following:

2.5 The edition or revision of the referenced Codes, Standards &

Specifications governing, shall be that ruling on the date of order,

unless noted otherwise.

3.2 Section 4 VENDOR’S DOCUMENTS

Amend opening sentence to read:

Vendor shall furnish the following documents where applicable to the

Filter vessel modification, for review and approval.

3.3 Section 5 VENDOR RESPONSIBILITIES

Add the following:

5.3 R stamping of the vessel nameplates is not a requirement for

modifications to the non-U-stamped Filter vessels 260-F-001B/C/D/E.

3.4 Section 6 DESIGN VERIFICATION

Add the following:

6.4 EPC Contractor shall be responsible for obtaining third party approval

of design and fabrication survey of modifications to Fine Filters 260-F-

001B/C/D/E.

3.5 Section 7 MATERIALS

7.7 Replace paragraph with:

Coating of new carbon steel bolting and threaded fasteners for

upgraded Fine Filters 260-F-001B/C/D/E shall be in accordance with

OS-FI memo #OS-FI/M.229/11 and appendices 1 & 2 attached.

Add the following

7.16 Refer to Materials Design Basis Memorandum P8341-BD-260-W-0002

for further project-specific, materials-related design requirements.

Genesis Page 13 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

3.6 Section 8 NOZZLE CONNECTIONS

8.10 Revise the clause to read:

Details (a1), (a2), (a3), (b-2), (c), (j), (k), (l), (m), (n), and (o) of FIG UG-

40 of ASME Section VIII division 1 or details (3), (4) and (5) of Table 4.2.11,

details (1), (2), (3) and (4) of Table 4.2.12 and details (1), (2), (3) and (4) of

Table 4.2.14 of ASME Section VIII division 2 shall not be used.

3.7 Section 25 SHOP PAINTING

Change section heading to SHOP AND FIELD COATING

Change section content to:

All external and internal surfaces for the Fine Filters modifications shall be

prepared, painted, coated and lined in accordance with ZADCO Manual of

Protective Coatings Specifications for Corrosion Control, Z0-TS-Y-02010.

3.8 Section 29 VENDOR DOCUMENT AND DATA REQUIREMENTS

Add the following to the end of the clause:

,where applicable to modification of Fine Filters 260-F-001B/C/D/E

3.9 Section 30 VENDOR’S DATA REPORT

Replace the opening clause with:

Vendors data report shall be complete with the following, where applicable to

modification of Fine Filters 260-F-001B/C/D/E.

3.10 Insulation and Personnel Protection

The Fine Filter modifications do not give rise to any requirement for insulation or

personnel protection equipment.

Genesis Page 14 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

APPENDIX – A

REFERENCE STANDARDS, CODES & SPECIFICATIONS

1. DESIGN AND REFERENCE STANDARDS,SPECIFICATIONS AND

REGULATIONS

Add the following:

ASME B1.1 Unified Inch Screw Threads

ASTM A153 Specification for Zinc (Hot-Dip Galvanised) Coating

of Iron and Steel Products

ASTM A193 Alloy Steel and Stainless Steel Bolting for High

Temperature

2. COMPANY'S SPECIFICATIONS

Delete the following:

Z0-TS-Y- 02020 Specification for Fluoropolymer Coated Bolting and

Threaded Fasteners

Add the following:

OS-FI/M-229/11 Technical Review and Coating Specification

dated 8 December, 2011 Update for ZADCO Paint Specification NC 21 and

Z0-TS-Y-02020 Rev A, with Appendices 1 & 2

3. PROJECT DOCUMENTS

Add the following

P8341-MR-260-V-0004 Site Survey Report

P8341-TM-260-G-0035 Basis of Design

P8341-BD-260-W-0002 Materials Design Basis Memorandum

A3-260-M-0004-001 GA’s of modified Fine Filters incl. Internals

A3-260-M-0005-001 Vessel Internal Details

P8341-DS-260-M-0002 Vessel Mechanical Data Sheet

P8341-PB-260-M-0001 Procedure for Design of Vessel Supports

Genesis Page 15 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

P8341-BD-260-M-0007 Maintenance Philosophy

P8341-SR-260-M-0008 Lifting & Handling Study

Genesis Page 16 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

APPENDIX – B

Z0-TS-M-02010 Rev 2 UNFIRED PRESSURE VESSELS: DESIGN CRITERIA

Z0-TS-M-02010 Rev

2-Unfired Press Vesse

Genesis Page 17 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

ZADCO – Upper Zakum Facilities

CC Water Injection Plant Upgrade

(Package 1) Fine Filters Modifications FEED Project

Mechanical Equipment Specifications

APPENDIX – C

Z0-TS-M-02020 Rev 1 MATERIALS, FABRICATION AND TESTING OF

UNFIRED PRESSURE VESSELS FOR GENERAL

SERVICE

Z0-TS-M-02020_Rev

_1 Mat, Fab & Test of

Genesis Page 18 of 18 Date: Sep 2012

File name: P8341-TS-260-M-0003 Rev D Mechanical Equipment Specification Rev: D

You might also like

- Tube-to-Tubesheet Joints - BaherDocument51 pagesTube-to-Tubesheet Joints - BaherNAMO100% (3)

- Rapid P016a VWM Con MST 0132 0 ApprovedDocument27 pagesRapid P016a VWM Con MST 0132 0 ApprovedVikash SharmaNo ratings yet

- 500050-00-000-PP01DB-002-DESIGN BASIS FOR 3D MODELLING REVIEW Rev CDocument33 pages500050-00-000-PP01DB-002-DESIGN BASIS FOR 3D MODELLING REVIEW Rev CSachin ShindeNo ratings yet

- Accounting and The Time Value of Money: Learning ObjectivesDocument83 pagesAccounting and The Time Value of Money: Learning ObjectivesedrianclydeNo ratings yet

- Piping Material Class Description SummaryDocument22 pagesPiping Material Class Description SummaryFabio S.No ratings yet

- Technical Specification PDFDocument101 pagesTechnical Specification PDFAsma KhanNo ratings yet

- Pipe Support ProcedureDocument21 pagesPipe Support ProcedureEfrain PonseNo ratings yet

- Technical Specification and Scope of EPC WorkDocument612 pagesTechnical Specification and Scope of EPC WorkBagadi AvinashNo ratings yet

- Index - Amendment To TBPDocument4 pagesIndex - Amendment To TBPVineet 01No ratings yet

- RFQ Pressure VesselDocument17 pagesRFQ Pressure VesselBagus SigitNo ratings yet

- LPG Blending Facilities Tender Documents ListDocument235 pagesLPG Blending Facilities Tender Documents ListManish MehtaNo ratings yet

- Sample MRB Index For ENIDocument1 pageSample MRB Index For ENIAnanthu Krishnan100% (1)

- Procedure For Positive Material Identification at Vendor'S WorksDocument7 pagesProcedure For Positive Material Identification at Vendor'S WorksAjay BaggaNo ratings yet

- Abbreviations & Definitions:: 2. General InformationDocument7 pagesAbbreviations & Definitions:: 2. General InformationHamza ShujaNo ratings yet

- IONE-AA00-MS-PI-0009 Rev. 0 - MS For Metallic Piping Spool HandlingDocument10 pagesIONE-AA00-MS-PI-0009 Rev. 0 - MS For Metallic Piping Spool HandlingYusuff YuzuakkNo ratings yet

- Pages From ONGC-SPEC-02-MS-03Document12 pagesPages From ONGC-SPEC-02-MS-03Prathamesh OmtechNo ratings yet

- 59-Qa60-R-201 - 0 - Equipment Numbering SystemDocument59 pages59-Qa60-R-201 - 0 - Equipment Numbering SystemNad EemNo ratings yet

- 1007 DISQ 0 J SS 33033 Shutdown Valve SpecificationDocument15 pages1007 DISQ 0 J SS 33033 Shutdown Valve Specificationeng20072007100% (1)

- Annexure 2 - Requisition For Pipe 4inch & AboveDocument11 pagesAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89No ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document16 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- ATTACHMENT 1 - SHJ-QMS-CS-PRO-X-5837-PreservationDocument39 pagesATTACHMENT 1 - SHJ-QMS-CS-PRO-X-5837-PreservationJoemon T Joy100% (1)

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument6 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PShanjiNo ratings yet

- Sor BPCL KochiDocument79 pagesSor BPCL KochiPrafulla PatilNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Specification For ValvesDocument24 pagesSpecification For ValvesMehdi NouriNo ratings yet

- UndergroundDocument31 pagesUndergroundJOEL ARNAO CORTEGANANo ratings yet

- Final Book - Lordegan ProjectDocument8 pagesFinal Book - Lordegan ProjectArash Sotoudeh100% (1)

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- Dodsal Engineering P&ID TransmittalDocument2 pagesDodsal Engineering P&ID TransmittalPriyam KmNo ratings yet

- Vv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationDocument30 pagesVv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationPhong ĐỗNo ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- De MisterDocument2 pagesDe MisterLaxman G GalipelliNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- General Procedure for Road and River CrossingsDocument68 pagesGeneral Procedure for Road and River Crossingsrusli bahtiarNo ratings yet

- Precommissioning Activities Reinstatement ChecklistDocument1 pagePrecommissioning Activities Reinstatement ChecklistYusufNo ratings yet

- Piping Material Specification for KG-DWN-98/2 PRE-FEEDDocument58 pagesPiping Material Specification for KG-DWN-98/2 PRE-FEEDsumit kumarNo ratings yet

- Body of Requisition - ROW Work Package PDFDocument60 pagesBody of Requisition - ROW Work Package PDFmahandhieNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- HRSG Equipment ListDocument20 pagesHRSG Equipment ListManuel Jesus Perez MelgarNo ratings yet

- Dhamra LNG Terminal Pvt. Ltd. (DLTPL)Document11 pagesDhamra LNG Terminal Pvt. Ltd. (DLTPL)balajikrishnanNo ratings yet

- Data Sheet Sight GlassDocument5 pagesData Sheet Sight GlassAdhya RazanNo ratings yet

- 1242352015di400100 D1Document6 pages1242352015di400100 D1Cristinel NechiforNo ratings yet

- Compiled Vol IIDocument69 pagesCompiled Vol IIashish.mathur1No ratings yet

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsDocument62 pagesAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaNo ratings yet

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocument38 pagesNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalNo ratings yet

- Epcm Services For Installation of "Indresid " Demonstration Plant at PanipatDocument19 pagesEpcm Services For Installation of "Indresid " Demonstration Plant at Panipatrutuja100% (2)

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- Inspection and Test Plan for Pressure GaugesDocument1 pageInspection and Test Plan for Pressure GaugesVenkatesh PethurajNo ratings yet

- Multidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) ADocument4 pagesMultidisciplinary Engineer CV For Project Engineering and Project Control (QS, Planning, Estimation, Cost Control, Contracts) AHOSAM HUSSEINNo ratings yet

- S-00-1360-002 Rev 1 (Piping Material Specification)Document53 pagesS-00-1360-002 Rev 1 (Piping Material Specification)ajmainNo ratings yet

- Bài Tập Kỹ Thuật Điện TửDocument13 pagesBài Tập Kỹ Thuật Điện TửNguyenCanhBaoNo ratings yet

- Piping Stress Analysis Calculation and Reports-2: Adnoc Gas ProcessingDocument2 pagesPiping Stress Analysis Calculation and Reports-2: Adnoc Gas Processingkbtvnr teja100% (2)

- Process Skid TrainingDocument5 pagesProcess Skid TrainingrutujaNo ratings yet

- Ione VP 14 P 102ab 001 - 1Document8 pagesIone VP 14 P 102ab 001 - 1ضياء محمدNo ratings yet

- SNO P GS 001 Rev0 EPC General RequirementDocument160 pagesSNO P GS 001 Rev0 EPC General Requirementaike_5No ratings yet

- B - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersDocument22 pagesB - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersAnitNo ratings yet

- BZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureDocument25 pagesBZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureManik KNo ratings yet

- MQ SP M 4033 PDFDocument16 pagesMQ SP M 4033 PDFjaseelNo ratings yet

- Earthworks Technical SpecificationDocument48 pagesEarthworks Technical SpecificationFeng XueNo ratings yet

- CB MX71ZZ El Rep 0001 000Document56 pagesCB MX71ZZ El Rep 0001 000alemdar.muhendislik25No ratings yet

- 12 00 Pi SPC 00022Document12 pages12 00 Pi SPC 00022Erdal CanNo ratings yet

- Carmagen 09 14Document2 pagesCarmagen 09 14NAMONo ratings yet

- Chandrayaan2 Mission - ISRODocument3 pagesChandrayaan2 Mission - ISRONAMONo ratings yet

- Chandrayaan2 Latest Updates - ISRODocument12 pagesChandrayaan2 Latest Updates - ISRONAMONo ratings yet

- Chandrayaan2 Spacecraft - ISRODocument2 pagesChandrayaan2 Spacecraft - ISRONAMONo ratings yet

- Applicability of IBR in Process PlantsDocument25 pagesApplicability of IBR in Process PlantsNAMONo ratings yet

- Commandments For AchievingDocument8 pagesCommandments For AchievingNAMONo ratings yet

- May 2014 Work Highlights Top Ten Ways to Improve Mobile Crane SafetyDocument2 pagesMay 2014 Work Highlights Top Ten Ways to Improve Mobile Crane SafetyNAMONo ratings yet

- Using Single Blend Optimizer To Quickly Maximize Bunker ProfitsDocument6 pagesUsing Single Blend Optimizer To Quickly Maximize Bunker ProfitsNAMONo ratings yet

- Local Stresses in Pressure Vessels - Carmagen EngineeringDocument2 pagesLocal Stresses in Pressure Vessels - Carmagen EngineeringNAMONo ratings yet

- Transition in Chemical IndustryDocument9 pagesTransition in Chemical IndustryNAMONo ratings yet

- 'When I Step Outside, I Step Into A Country of Men Who Stare' - Times of IndiaDocument13 pages'When I Step Outside, I Step Into A Country of Men Who Stare' - Times of IndiaNAMONo ratings yet

- Why It's Time To Reconsider ASME VIII-2 (Division 2) - CodewareDocument3 pagesWhy It's Time To Reconsider ASME VIII-2 (Division 2) - CodewareNAMONo ratings yet

- WRC470 2002 PDFDocument34 pagesWRC470 2002 PDFs100% (1)

- Ready ReckonerDocument13 pagesReady ReckonerNAMONo ratings yet

- Specifying Internals in Sour Water Strippers-Part 1Document7 pagesSpecifying Internals in Sour Water Strippers-Part 1NAMONo ratings yet

- Shell & Tube Heat Exchanger Part 1Document4 pagesShell & Tube Heat Exchanger Part 1NAMONo ratings yet

- Automated Procedure For Constructing ASME EXTERNAL PRESSURE CHARTDocument4 pagesAutomated Procedure For Constructing ASME EXTERNAL PRESSURE CHARTNAMONo ratings yet

- Retrofit - A Viable Alternative To Greenfield ConstructionDocument4 pagesRetrofit - A Viable Alternative To Greenfield ConstructionNAMONo ratings yet

- Spiral Heat Exchanger TechnologyDocument5 pagesSpiral Heat Exchanger TechnologyNAMONo ratings yet

- Preferential Baffle Reboiler Part 1Document3 pagesPreferential Baffle Reboiler Part 1NAMONo ratings yet

- Allowable Stress BasisDocument9 pagesAllowable Stress BasisNAMONo ratings yet

- API 660 Vs TEMADocument5 pagesAPI 660 Vs TEMAALONSO GOMEZNo ratings yet

- HSE Visit Walkabout ChecklistDocument4 pagesHSE Visit Walkabout ChecklistEric T100% (1)

- Course Code - 102 Course Title-Accounting For Business Decisions 2. Learning Objectives of The CourseDocument29 pagesCourse Code - 102 Course Title-Accounting For Business Decisions 2. Learning Objectives of The Courseavinash singhNo ratings yet

- Satish K Srivastava Resume LatestDocument2 pagesSatish K Srivastava Resume LatestPrashant KumarNo ratings yet

- DPS Qatar Revision Questions History Civics Class 7Document19 pagesDPS Qatar Revision Questions History Civics Class 7BNo ratings yet

- Viva Results - MAIN LIST - Fall 2021 - 2nd Intake - Notice - 9ep 21Document35 pagesViva Results - MAIN LIST - Fall 2021 - 2nd Intake - Notice - 9ep 21Shubho Dev nathNo ratings yet

- CBLM - School Food Canteen ManagementDocument76 pagesCBLM - School Food Canteen ManagementCeejaay PelinaNo ratings yet

- Industrial Machinery & Tractor TyresDocument2 pagesIndustrial Machinery & Tractor TyresFelipe HernándezNo ratings yet

- Animaccord v. Schedule A (Albright) - Order Granting PIDocument14 pagesAnimaccord v. Schedule A (Albright) - Order Granting PISarah BursteinNo ratings yet

- A Detailed Project On Secondary Market.Document40 pagesA Detailed Project On Secondary Market.Jatin Anand100% (1)

- Clariant Flyer Licomont BS 100 Sustainability Data Sheet 201804 ENDocument2 pagesClariant Flyer Licomont BS 100 Sustainability Data Sheet 201804 ENQuanNo ratings yet

- SWOT Analysis:: StrengthsDocument5 pagesSWOT Analysis:: Strengthsaq GreaterNo ratings yet

- PLDT V City of Davao August 2001Document3 pagesPLDT V City of Davao August 2001owenNo ratings yet

- How To Use This Competency-Based Learning MaterialDocument29 pagesHow To Use This Competency-Based Learning Materialaldren cedamon0% (1)

- Exam 53697Document9 pagesExam 53697Vimal Shroff55No ratings yet

- Weeks 4,5,6 - PDFDocument191 pagesWeeks 4,5,6 - PDFMehul Kumar MukulNo ratings yet

- Case 1Document19 pagesCase 1adil abidNo ratings yet

- Pauline Heurtevent's Expertise in Business Strategy and TransformationDocument3 pagesPauline Heurtevent's Expertise in Business Strategy and TransformationtrstNo ratings yet

- Standing OrdersDocument16 pagesStanding OrdersRamanah VNo ratings yet

- Corporate CultureDocument2 pagesCorporate CultureMae MarinoNo ratings yet

- Certificate of Residence formDocument2 pagesCertificate of Residence formSânziana Cristina DobrovicescuNo ratings yet

- Inventory Management Just in Time and Costing Methods Multiple Choice Questions - Accounting Quiz Answers 5 PDFDocument4 pagesInventory Management Just in Time and Costing Methods Multiple Choice Questions - Accounting Quiz Answers 5 PDFSumedha SawniNo ratings yet

- TAX - Partnership, JV, & Co-OwnershipDocument6 pagesTAX - Partnership, JV, & Co-OwnershipVon Andrei MedinaNo ratings yet

- Citi BankDocument58 pagesCiti BankVardhan SharmaNo ratings yet

- sGAN INTERNSHIP REPORTDocument16 pagessGAN INTERNSHIP REPORTShubham GuptaNo ratings yet

- Statement Summary: Run24.mx Sapi de CV Statement Date: Statement Period: Billing MethodDocument6 pagesStatement Summary: Run24.mx Sapi de CV Statement Date: Statement Period: Billing MethodnovelNo ratings yet

- Iba Cia (Data Visualization)Document7 pagesIba Cia (Data Visualization)Lakshita MehendirattaNo ratings yet

- Pcic VS Central CollegesDocument2 pagesPcic VS Central CollegesannlaurenweillNo ratings yet

- Class Presentation Be S 321971 Rafa Lga We DaDocument32 pagesClass Presentation Be S 321971 Rafa Lga We DaMlg JoséNo ratings yet

- Competing Through Capabilities: Group Assignment Case Study: Mankind PharmaDocument2 pagesCompeting Through Capabilities: Group Assignment Case Study: Mankind PharmaRN’s Food ‘N’ Travel VlogsNo ratings yet