Professional Documents

Culture Documents

Tech Spec - HTVCB

Uploaded by

saravananOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tech Spec - HTVCB

Uploaded by

saravananCopyright:

Available Formats

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECIFICATION FOR HT/LT SYSTEM

PROJECT DETAILS: HT/LT SYSTEM

CLIENT:

TAGORE MEDICAL COLLEGE & HOSPITAL

Rathinamangalam, Melakottaiyur,

Chennai- 600127

MEP CONSULTANTS:

M/s. ENERSAVE SOLUTIONS

No.19, KK Nagar, 10th STREET,

NGO COLONY, BV NAGAR, NANGANALLUR,

CHENNAI- 600 061.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 1

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECTION FOR HT/LT SPEC. Page 2

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

1.00 GENERAL SCOPE OF WORK

The scope of work shall cover internal and external electrical works for CONSTRUCTION

OF TAGORE HOSPITAL -CHENNAI. The scope of workcovers electrical equipments as per

BOQ. Also, supply, installation, testing and commissioning of electrical works of the project

including the following main items/systems:

H.T. Sub-station including VCB panel, Transformers, bus ducts, HT cables etc

Main LT , Capacitor panels (APFC), Rising mains, MV Panels.

DG sets including AMF panels / Synchronizing panel etc.

LT Cabling.

Earthling, safety equipments and misc items required for electrical installation

complete in all respect.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 3

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECIFICAITON

OF

11KV VCB

TECHNICAL SPECTION FOR HT/LT SPEC. Page 4

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

1.0TECHNICAL SPECIFICATIONS FOR 11KV VACUUM CIRCUIT BREAKER

PANEL

1.0 GENERAL:

All equipment shall be designed, manufactured and tested in accordance with the

latest IS/IEC standards. Equipment conforming to any other standard, which ensures

equal or better specifications & quality, may be accepted on production of proof.

Electrical installation shall meet the requirement of current edition of Indian

Electricity Rules, 1956 & Indian Electricity Act, 1910 & 2003. In addition other rules

and regulations applicable to the work shall be followed. In case any discrepancy the

most stringent one shall be binding.

The HT switchgear shall comply with the latest standards (including amendments)

mentioned below, but not limited to :

IEC 62271- Part 1,3 & 4: HV Switchgear & Controlgear

IEC 62271- 100 & 200 series: HV Switchgear & Controlgear

IEC 60129 Ed. 3: Alternating current dis-connectors and earthing switches

IS/IEC 60529: Degree of protection provided by enclosures:

-IP 67 for tank with high voltage components

-IP 3X for the front covers of the mechanism

-IP 3X for the cable connection covers

-IP 54 for the outdoor enclosure (kiosk)

IEC 60265-1, Ed. 3 High voltages switches for rated voltage > 1kV, up to 52 kV

IEC 60255-1: Measuring Relays & protection equipment- Common requirement

TECHNICAL SPECTION FOR HT/LT SPEC. Page 5

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

1.1 Design Criteria:

Shall be suitable for operations at a height up to 2000 meters above sea level with

the following temperature range:

- Maximum ambient temperature : + 40 ° C

- Minimum ambient temperature: - 15 ° C.

Manufacturer shall declare whether RMG is able to operate at temperature above

+ 40 °C and if current de-rating is necessary. Shall be able to control from remote

commands. RMG shall be suitable for future motorization and capable of being

exposed to high relative humidity and polluted environments & shall be suitable for

outdoor use.

1.2. System Parameters:

Network 3 phase, 3 wires

Rated Voltage 12 kV

Service Voltage 11 kV

System Frequency 50 Hz

Lightning Impulse withstand Voltage (1.2/50 uS)

Phase to phase, phase to earth 170 kV peak

Across the isolating distance 195 kV peak

Power Frequency withstand voltage (50 Hz for 1 min) 70 kV rms

Rated Normal Current Line switches / VCB 800 A

Rated Short time current withstand ( 1 sec ) 25 kA

Internal Arc 1 sec 20 kA

Rated Short circuit making capacity of line switches & breaker 62.5 kA

Number of operations at rated short circuit current on 20 O/C

TECHNICAL SPECTION FOR HT/LT SPEC. Page 6

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

breaker

Number of Mechanical operations at full rated current for 2000 O/C

breaker

1.3. Configuration requirements:

Feeders :

1. Incoming VCB : 800 Amps, 11,000V – 1No.

2. Outgoing VCB : 630 Amps, 11,000V,500Kva (EXISTING )– 1 No.

3. Outgoing VCB : 630 Amps, 11,000V,1250kVA – 1 No.

4. Outgoing VCB : 630 Amps, 11,000V for FUTURE – 1 No.

The following chambers are to be provided.

• Incoming feeders – HT VBS - 1 Chambers

• Outgoing control HTVCB - 3 Chamber

• Bus bar chamber, a set of 3 Nos. – Copper bus bar - 1 Chamber

• Provision suitable for terminating 3 core 300 Sq.mm - 11 KV grade

XLPE-(E) Aluminium cable using heat shrinkable type termination kit.

a. Incoming - 1Chambers

b. Outgoing - 3 Chamber

• Potential transformer - 1 Chamber

• Current transformer - 1 Chamber

• Instruments and Control Panel - 1 Chamber

Each Circuit Breaker shall have the following:

1 Circuit breaker 11 kV, 630 A, 25 kA

1 Mechanism for manual operation.

1 Self Powered protection relay providing over-current & earth fault protection.

3 Ring core CT for protection depending upon the transformer ratings

(Rating shall be X/1 A, 1.0 VA, Accuracy Class during detailed engineering).

1 Capacitive voltage indication fixed type

TECHNICAL SPECTION FOR HT/LT SPEC. Page 7

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

1 ON, OFF, TRIP indication on the front mimic of the panel.

1 Cable box for termination of cable up to 300 sq. mm.

1 Emergency Trip Push Button.

1 Set of 36kV Cable boots.

TECHNICAL DATA:

1 SWITCHGEAR PANEL

Basic Design

a Applicable Standards IEC 62271-100/200 & IS-13118-1991

VCB-800A & 630A Single bus bar duly

b Type interlocked, Horizontal isolation &

Horizontal draw out Switchboard

Metal Clad, Metal Enclosed, Floor

c Classification

mounted,Free standing indoor type VCB Panel

CRCA Steel Sheet

Breaker, CT Plate, Spout Plate-3mm

d Type of Steel Sheet

Side Sheet, Base Sheet, Front mounted, Free

standing Indoor type VCB Panel

e Degree of Protection IP5X

Internal arc withstands on Type tested for Internal Arc 26.3kA for

f

3HV compartments 0.1sec

Voltage and Insulation

a Rated Voltage 12kV

Power Frequency withstand

b 28kV

Voltage

1.2/50micro sec impulse

c 75kV

withstand Voltage

Current and Temperature

Rise

a Rated Current 800A for Incomer and 630A Outgoing

Rated short circuit withstand

b 25kA rms for 3sec

current

c Rated Making Current 2.5 times short time withstand current i.e

62.5kA

Temperature rise at rated

d Within limits as specified in IS/IEC

current

Bus Bar Compartment(IS-375)

a Bus Bar Material Electrolytic grade copper

b Bus Bar Current Rating 800A

TECHNICAL SPECTION FOR HT/LT SPEC. Page 8

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

c Bus Bar Shape Rectangular

d Bus Bar Sleeving PVC Sleeve

Current Transformer(IS- 2705(1992), IEC 60185)

a Type Epoxy Resin Cast

b Voltage 12kV

c Frequency 50Hz

Incomer, Outgoing, CAP Fdr for 26.3kA for

Rated short circuit withstand

d 3sec and Stn Transformer for 18.4kA for 3

current

sec

For Incomer-

A) 150-75/5-5A,

Core1:15VA CL-5P20, Core2:

15VA CL-0.2S

e Ratio & Class of Accuracy

For OUTGOING-

A) 150-75/5-5A,

Core1:15VA CL-5P20, Core2:

15VA CL-0.2S

Potential Transformer—for Incomer(IS- 3156(1992), IEC 60186)

a Type Resin Cast, Dry Draw Type Out

b Class of Accuracy For I/C Core :200VA/CL-0.2

c Rated Voltage Factor & Time 1.2 for continuous and 1.9 for 8hrs

1min Power Frequency withstand

d 28kV

Voltage test

1.2/50micro sec impulse withstand

e 75kV

Voltage

Particulars of Instrument & Meters

1) Digital Programmable Ammeter, CL -

0.5

2) Digital Programmable Voltmeter, CL -

0.5

Type 3) Digital Power Factor Meter, CL -0.5

4) SCADA Compatible Trivector Meter,

CL- 0.5DLMS compliant, Class A with

RS485 communication port

Relays(IS- 3231(1987), IEC 60255)

TECHNICAL SPECTION FOR HT/LT SPEC. Page 9

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

Front draw out type:

1) Incomer, Outgoing Transformer-

SCADA Compatible Numerical Non

Directional 50-50/50-51N Protection

Relay with IEC 61850 Protocol

Over Current & Earth Fault

a O/C Relay Setting -1% to 3200% step size

Protection Shunt Trip Relay

1%

E/F Relay Setting -1% to 3200% step size

1% With Programmable Self and Hand

Reset Option. Low transient over reach

shall not exceed 5% in O/C &E/F relays

30V DC Electromechanical Type

b Master Trip & Lockout Relay Electrically

reset high speed tripping relay

Trip Circuit Supervision Relay, Contacts

c Trip Circuit Supervision Relay 2NO

+ 2C/O Self Reset, Aux Supply 30V DC

d 2CO Relay for Antipumping 30V DC PLA Relay with 2 C/O

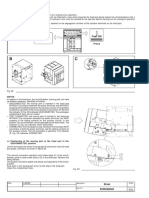

2 CIRCUIT BREAKER

2.2 Basic Design

a Applicable Standards IEC 62271-100/200 & IS-13118-1991

b Type Vaccum Circuit Breaker

c Isolation/Draw Out Horizontal isolation & Horizontal draw out

with three distinct position-Service Test &

Isolated

d Frequency 50Cycles/Sec

e Spring Charge Motor 230V AC

f Closing & Tripping mechanism 30V DC

g Breaking Time <60ms

h Making time <60ms

Interrupting Capacity at Normal

i 500MVA, i.e 25kA

System Voltage

2

. Voltage and Insulation

2

a Rated Voltage 12kV

TECHNICAL SPECTION FOR HT/LT SPEC. Page 10

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

Power Frequency withstand

b 28kV

Voltage

1.2/50micro sec impulse withstand

c 75kV

Voltage

2

. Current and Temperature Rise

3

a Operating Duty O-0.3sec-CO-3min-CO

b Rated Current 1250A for Incomer /Outgoing/Stn

Transformer/CAP Fdr

Rated short circuit withstand

c 25kA rms for 3sec

current

d Rated Making Current 2.5 times short time withstand current i.e

62.5kA

d Temperature rise at rated current Within limits as specified in IS/IEC

Rated short circuit breaking

e

current

i

Symmetrical SC breaking current 25kA rms

)

i

i Asymmetrical SC breaking current With DC Component <40%

)

f Cable Charging breaking current 25A

2

. Vaccum Interrupter

4

a Type/ designation VGE-4

b Rated Current 800A

Rated Symmetrical SC breaking

c 26.3kA rms

current

2.5 times rated short circuit breaking

d Rated making current current

i.e 65.75kA

e Opening Speed Avg 1.2-1.5m/sec

f Closing Speed Avg 0.7-0.9m/sec

g Total Break time < 3 cycles( 60ms)

h Total make time < 3 cycles( 60ms)

i Contact gap in open condition 8+/- 1mm

j Max Contact erosion permissible 2mm, Contact Wear indicator shall be

provided

k Life of interrupter

TECHNICAL SPECTION FOR HT/LT SPEC. Page 11

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

i

At no load 50000 operations

)

i

i At 100% rated current 30000 operations

)

i

i At 100% rasted short circuit 100 operations at 26.3kA and <100

i current operations at 18.4kA

)

Operating Mechanism

a Type Spring Charged, Stored Energy

Details of motor- For motor

b Universal 6 motor, 230V AC , 80W

operated

Auxiliary voltage for closing and tripping

c Voltage Required 30V

DC

d Range of voltage for tripping 70% to 110% of rated voltage

e Power required for tripping <200W

f Range of voltage for Closing 85% to 110% of rated voltage

g Power required for Closing <200W

h Number of Auxiliary Contacts 6NO+6NC

TESTS

Each type of H.V. Switchgear shall be completely assembled, wired, adjusted and

tested at the factory as per the relevant standards and during manufacture and

on completionZ4.15.1 Type test reports:

The following type test certificates shall be supplied :

Impulse withstand test,

Temperature-rise test,

Short-time withstand current test,

Mechanical operation test,

TECHNICAL SPECTION FOR HT/LT SPEC. Page 12

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

Checking of degree of protection,

Switch, earthing switch making capacity.

Switch, breaking capacity.

Internal arc withstand

Checking of partial discharge on complete unit.

1.4 Routine tests :

Withstand voltage at Power Frequency for all current carrying parts including

wiring

Measurement of resistance of the main circuit RMU

Leakage test

Withstand power frequency voltage on auxiliary circuits

Operation of functional locks, interlocks, signaling devices and auxiliary devices

Suitability and correct operation of protections, control instruments and

electrical connections of the circuit breaker operating mechanism (primary &

secondary injection)

Verification of wiring

Visual Inspection shall be carried out on all equipment such as circuit breakers,

current transformers, relays, etc. as per relevant standards.

Switches: Rated breaking & making capacity.

Earthing switches: Making capacity, short-time withstand current & peak short-

circuit current.

Shall also include the following:

Conformity with drawings and diagrams,

Measurement of closing and opening speeds,

Checking of filling pressure,

TECHNICAL SPECTION FOR HT/LT SPEC. Page 13

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

Checking of gas-tightness,

Dielectric testing.

Main circuit resistance measurement.

1.5. Acceptance Test:

Shall include all the routine tests mentioned above and also demonstration of

tripping through the relay by secondary injection tests.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 14

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECIFICAITON

OF

HT CABLES

TECHNICAL SPECTION FOR HT/LT SPEC. Page 15

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

HT XLPE CABL

2.1 SCOPE :

This specification covers the Design, Manufacture, Testing, Inspection & delivery at

site.

Shall withstand all mechanical & thermal stresses under steady state & transient

conditions.

2.2 STANDARDS:

IS 3975 : Mild Steel Wires, strips and tapes for armouring of cable.

IS 8130 : Conductor for insulated electric cables and flexible cords.

IS 5831 : PVC Insulation and Sheath of Electric Cables

IS 7098 : Cross Linked Poly-ethylene Insulated FRLS PVC Sheathed cable.

2.3 CONDUCTOR:

Shall be Aluminium / Copper as specified in BOQ.

Shall be smooth, uniform in quality & free from scale/other defects.

The Aluminium conductor for 10sq.mm and above (6sq.mm for copper) shall

be stranded and shall be clear and uniform in size and shape.

Shall be circular or Sector Shaped.

Stranded conductor shall be compacted to reduce dimension and to give

smoother profile.

2.4 CONDUCTOR SCREEN:

Shall be semi conducting compound & extruded in the same operation as the

Insulation

2.5 INSULATION:

Shall be cross linked polyethylene and gas cured.

2.6 INSULATION SHIELD/SCREEN

Shall be strippable and triple extruded thermo set type.

.7 CORE SCREENING

Shall be provided with copper tape screen over cores for full coverage (6.6 kV &

above).

TECHNICAL SPECTION FOR HT/LT SPEC. Page 16

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

The number and thickness of tape shall be suitable for the short circuit rating of the

cables.

5.8 INNER SHEATH

The inner sheath shall be extruded PVC; Polypropylene filler shall be provided.

5.9 ARMOUR

GI wire / strips armour shall be provided over the inner sheath & its coverage shall

be> 95%

to achieve better mechanical protection and low armour resistance.

5.10 OUTER SHEATH.

Shall be extruded PVC and shall be resistant to termite and rodent attack.

Progressive sequential marking, size marking, voltage grade, manufacture name at

every one meter shall be made.

5.11 TEMPERATURE RISE:

Shall not exceed 90 °C during continuous operation at full rated current.

Temperature after short circuit for 1 sec shall not exceed 250 °C (initial conductor

temp of 90 °C).

Bidder shall give the following information in the Bid for each conductor cross

section specified.

a. Rated continuous current

b. Rated 1.0 second current Rating factor shall be given by the Bidder for the

following:

c. Variation in ground temperature

d. Variation in soil thermal resistivity

e. Variation of Ambient temperature

f. For the cables laid side by side, at ID spacing and in Tier formation.

The Bidder shall also indicate the percentage overload that the cable can carry and

its duration, when operating initially at 90 °C , with final conductor temperature of

130 °C .

5.13 CABLE DRUMS:

Cables shall be supplied in non-returnable drums of sturdy construction.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 17

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

All ferrous and other metal parts of drum shall be treated with a suitable rust

preventive finish or coating to avoid rusting during transit or storage.

The length of cable on each drum shall be determined by manufacturer

considering the transport limitations from manufacture's works to the site.

5.14 ROUTINE TESTS (To be performed on each drum length)

These shall include, among others normally performed by the manufacturer, the

following:

a. Conductor D.C. resistance test

b. Capacitance

c. Partial discharge level measurement at Power frequency

d. High voltage test

5.1 TECHNICAL DATA:

PARTICULARS DESCRIPTION

1.0 ENVIORMENT DETAILS:

1.1 Ambient Temp - 45 Degree Celsius

1.2 Ground Temp - 40 Degree Celsius

1.3 Relative Humidity - 85 % at 35 Degree Celsius

1.4 Altitude - < 1000 m above MSL

1.5 Atmosphere - Corrosive, Humid and Dusty

2.0 SYSTEM DETAILS:

2.1 System Voltage - 11KV, ± 10%

2.2 System Frequency - 50 Hz., ± 3%

2.3 Grounding - Solidly Earthed

3.0 CABLE

3.1 No Of Cores - 3 (Three)

3.2 CABLE CONDUCTOR

TECHNICAL SPECTION FOR HT/LT SPEC. Page 18

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

3.2.1 Size Of Conductor - As per BOQ

3.2.2 Material - High Purity Aluminium

3.2.3 Construction - Stranded

3.2.4 Shape - Compacted Circular

3.2.5 Confirming To - IS-8130

3.3 Conductor Screen - Extruded Semiconducting Material

3.4 Conductor insulation - (XLPE) Using Gas Curing Process

3.5 Thickness - > = 5.5mm

3.6 Insulation screen -

Extruded semiconductor having copper tape over it

3.6 Core identification tape - Required

3.7 Core laying - Right Hand Direction

3.8 Inner sheath / cover - Extruded

3.9 ARMOURING

3.9.1 Material - Flat/Round Steel GI Strip

3.9.2 No of strips - 4

3.9.3 Size Of Strip - 0.8 mm

3.10 Outer sheath

3.10.1 Material - FR/FRLS

3.10.2 Type - St-2 As Per IS-5831

Thickness - > = 2.4 mm

TECHNICAL SPECTION FOR HT/LT SPEC. Page 19

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECIFICAITON

OF

1200KVA 11KV / 0.433KV OIL COOLED

TRANSFORMER SPECFICATION

TECHNICAL SPECTION FOR HT/LT SPEC. Page 20

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

1.0 SCOPE

This specification covers the requirements of design, manufacture, testing and

supply of Outdoor type 1x1200 KVA, 11/0.433 KV Oil Cooled Distribution

transformer (BIS 1180 - LEVEL 2) complete with all accessories for efficient and

trouble - free operation

2.0 CODES & STANDARDS

The equipment covered by this specification shall, unless other wise stated to be

designed, constructed and tested in accordance with latest revisions of relevant IEC

publications/BS Standards.

BS 171 - Power transformers

BS 148 - Unused Mineral insulating oil for

Transformers.

BS 2562 - Cable box for Transformer.

IEC 76Part-1 - Power Transformer – General

IEC 76Part-2/

IS 2036 - Power Transformer – Temperature rise.

IEC 76 Part-3/

IS 2026 - Power Transformer – Insulation level

and dielectric test.

IEC 616 / IS 2026 - Power Transformer – Terminals and

tapping marking.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 21

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

3.0 GENERAL DESIGN FEATURES

3.1 All transformers shall be of the latest design, oil cooled only.

3.2 The type of cooling shall be Oil immersed, natural cooled core type double

wound construction and the corresponding ratings for each transformer

shall be as indicated in the specific requirements.

3.3 Each transformer shall be suitable for operation at full rated power on all tapings

without exceeding the applicable temperature rise.

3.4 It shall be possible to operate the transformer satisfactorily, up to overloads of 150% of

the rated value in confirmation with the loading guide specified in relevant IEC/BS

Standards. There shall be no limitations imposed by bushings, tap changers, auxiliary

equipment to meet this requirement. The manufacturer shall confirm that the

transformer shall cater the starting KVA requirement of motors up to 150% of the rated

capacity with the period of starting as 20 secs. There shall be a minimum of 6 such starts

in one hour.

3.5 The transformers shall be designed to be capable of with-standing, without injury,

the thermal and mechanical effects of short-circuits between phases or between

phase and earth at the terminals of any winding with full voltage applied across the

other winding for periods given in relevant standards.There shall be no limitations

imposed by any part/component of the transformer/off load tap changer to meet

the short circuit level Specified. The maximum short circuit current shall be

determined by computing the through fault current using the formula:

Short circuit current = (Rated Current x 100)/% Impedance

3.6 The Transformer shall be designed to suppress harmonic content, especially

the third, fifth and seventh harmonics, so as to eliminate distortion in the waveform and

TECHNICAL SPECTION FOR HT/LT SPEC. Page 22

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

consequent additional insulation stress, noise on communication system and

undesirable circulating currents between the neutrals at different transformer stations.

3.7 Transformer shall be designed for minimum no-load and load losses within the

economic limit and shall be able to have minimum loss at the rated load condition

during different period of the day.

3.8 All electrical connections and contacts shall be of ample cross sections for carrying

the rated current without excessive heating.

3.9 The transformer shall be capable of continuous operation at full load rating under

the following conditions.

a) Voltage variation = 10%

b) Frequency variation = 5%

c) Combined voltage and frequency variation (Absolute sum) = 10%

4.0 CONSTRUCTION

4.1 The transformer shall be ONAN cooled suitable for Outdoor installations.

Transformer and the enclosure shall be suitably reinforced to prevent distortion

during handling. Base channels shall be provided with skids and pulling eyes to

facilitate handling.

4.2 The core-clamping frame shall be provided with lifting eyes having ample strength

to lift the complete core and winding assembly.

4.3 The core assembly of the transformer enclosure shall be electrically connected to

the transformer tank for effective core earthing. Also copper flexible for earth

continuity purpose shall connect different parts of transformers.

4.4 Transformer with all accessories shall be of free standing type.

Transformer/accessories shall be designed in such a way that no supporting/post

structure shall be required other than rail.

4.5 The transformer shall have suitable ON load tap changing on the HV windings.

4.6 The lifting lugs and rollers shall be provided.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 23

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

4.7 The transformer shall be provided with protection class of IP-65 protection class

enclosure for outdoor applications. The thickness of the enclosure shall be minimum

2 mm.

4.8 WINDINGS

4.8.1 Windings shall be of electrolytic copper conductors (circular in shape) of high

conductivity and 99.9% purity.

4.8.2 Windings shall be designed to withstand the specified thermal and dynamic

short circuit stresses.

4.8.3 The windings shall be duly sectionalised. Accessible joints brazed or welded

and finished smooth shall connect similar sections. No corona discharge shall result

on the winding upon testing the transformer for induced voltage test as specified in

the relevant standards.

4.8.4 The end turns of the high voltage windings shall have reinforced insulation

to take care of the voltage surges likely to occur during switching or any other

abnormal condition.

4.8.5 The high voltage and low voltage winding shall be made of copper conductors.

4.8.6 The double wound Core shall be constructed from non-ageing cold rolled grain

oriented steel sheets. The built core shall be painted with high temperature

resistant paint to prevent corrosion at the edges of core plates and to

withstand high temperatures. By using different core material optimisation of

core losses shall be achieved. The yokes shall be firmly clamped between yoke

channels or plates. The top & bottom yoke frames shall be secured to each

other by means of tie-rods, which help in securing the winding in place.

4.9. ON-LOAD TAP CHANGER

4.9.1 High-speed on-load tap changing gear with number of steps as specified, shall be

provided and mounted on the transformer.

4.9.2 The OLTC gear shall have diverter resistance and the current diverting

contacts shall be housed in a separate oil chamber segregated from the

TECHNICAL SPECTION FOR HT/LT SPEC. Page 24

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

main tank of the transformer.

4.9.3 The design of the assembly shall be such that oil of OLTC compartment

does not mix with the oil in the main transformer tank.

4.9.4 The contacts shall be accessible for inspection and their tips shall be

replaceable.

4.9.5 The tap changer shall be suitable for connection to tappings brought from

HV winding covering the range as specified. Tap changer cubicle shall be located at a

convenient operating level (ie., 1200 mm from rail level). The tap changer shall be

supplied with the following components in the driving mechanism cubicle.

a) High torque electric motor suitable for 415 volts three phase, 50 Hz AC

supply

b) Motor drive and energy accumulator

c) Motor isolating device with over load and single phasing protection

d) Contactors for forward and reverse operation of motor

e) 'Raise/Lower' limit switches

f) Retainer switch

g) Local/Remote control selector switch

h) Raise/lower control for remote operation

i) Out of step relay

j) Auxiliary transformer

k) Anti-condensation heater with switch

l) Interlock between manual and electrical operation

m) Mains isolating switch

n) A set of fuses

o) Insulated terminal board (with connectors for transformer tap leads)

p) Mechanical(local) tap position indicator

q) Handle for manual operation

r) Tap changer operation counter

TECHNICAL SPECTION FOR HT/LT SPEC. Page 25

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

s) Mechanical stops to prevent over cranking of the mechanism beyond

extreme tap Positions. However the tap switch shall in no case get stranded at

these extreme positions which may cause over voltages & consequently

damage the connected equipment.

t) Rating plate

u) Driving mechanism chamber locking arrangement

v) Undrilled gland plate for cable entry

w)Terminal strips

x) Lubrication chart

y) Drain cum filter valve

z) Potentiometer for remote tap position indicator

4.9.6 The OLTC shall be supplied with the first fill of oil conforming to relevant

standards.

4.9.7 An Indoor Floor Mounted CRCA sheet steel Remote Tap changer Control

Cubicle (RTCC) with rear access door with wiring and with the following components

shall be provided.

a) Remote tap position indicating meter (digital meter)

b) 'Tap change in progress' signal lamp

c) Auto/Manual selector switch

d) 'Raise/Lower' push buttons for remote operation

e) AVR

f) Cubicle illuminating lamp with door switch with fuse.

g) Terminal strips

h) Supply 'ON' signal lamp

i) Undrilled gland plate for cable entry

j) A.C. fail lamp (thru D.C. supply)

4.10 MARSHALLING BOX

TECHNICAL SPECTION FOR HT/LT SPEC. Page 26

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

4.10.01 A marshalling box made with sheet steel of 2.5 mm thick, (CRCA) conforming to

IP23 degree of protection shall be located near each transformer. The marshalling

box shall contain all accessories that are required for the transformer except those

that are mounted on the transformer itself. The wiring of all devices shall be

brought to stud type

terminal block. 15% spare terminals shall be provided. Control wiring shall be done

by 2.5 sq.mm. Stranded copper wires. Labels shall be provided for ease of

identification. Capillaries for WTI shall be taken in GI flexible and the same shall be

terminated on the marshalling ox/thermometer pockets with weatherproof glands.

Following items, apart from regular marshalling box instruments shall be

equipped:

- Triple pole line isolating switch

- HRC fuses / MCCB

- Strip heaters, thermostat controlled with switch

- Cubicle lamp with door switch

- Control circuit MCB

- Adjustable wire wound rheostat for winding temperature Indicator

- Mushroom type 'RED' emergency stop Push button with acrylic Shroud.

- One set of winding temperature shall be fitted locally in the marshalling box of the

transformer so as to be readable at a standing height from the ground level. Each

winding temperature indicator shall be provided with necessary

contacts for alarm on a high set point and for trip on a higher set point. The contacts

shall have adequate rating, if used directly in the control circuit, otherwise auxiliary

relay shall be provided for the purpose.

The following accessories shall be provided.

- Two temperature-sensing devices in each limb.

- Temperature sensing relay with one contact for alarm and one for trip.

- Indicating platinum resistance type thermo meter with alarm and trip

contacts.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 27

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

4.11 TERMINATION ARRANGEMENT:

The HV terminal arrangement shall be as per specific requirements. The phase

sequence in the LV bus duct flange shall be as per the purchaser’s choice and the

same shall be decided during the detailed engineering stage. The cable box shall be

complete with gland plate/bushings,cable armour clamps etc., The arrangement

shall be such as to permit removal of transformer without dismantling bus

duct/cable installation.

4.12 NEUTRAL BUSHINGS/NCT'S

4.12.01 Neutral bushing,wherever applicable shall be identical to the phase

bushing in all respects ie., voltage, current rating etc.,

4.12.02 LV Neutral terminal for the purposes of earthing shall be brought down,

totally insulated by means of epoxy insulator supports, up to the skid

level. The rating of the earth bushing shall be similar to the phase

bushing.

4.12.03 NCT, as specified elsewhere,shall be mounted in the exclusive neutral to

earth circuit only. NCT shall not sense any unbalance current, which will

flow through the neutral.

4.12.04 Further NCT’s shall be located in a weatherproof enclosure with both sides

of the primary (neutral) as well as secondary connections shall be

accessible for primary injection testing. Suitable bolting type connections

shall be provided on either side Of NCT primary to facilitate external

connections. The degree of protection for the NCT housing shall be as

per requirements.

4.12.05 The material for LV neutral & LV earth bushing shall be minimum

Porcelain only.Epoxy bushings will not be accepted

4.13 PAINTING

4.13.01 All steel surfaces shall be thoroughly cleaned by sand blasting or chemical

Agents as required to produce a smooth surface free of scale, grease and rust.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 28

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

4.13.02 The external surface, after cleaning, shall be given a cost of high quality

red Oxide or yellow quoted primer,followed by filler coats.

4.13.03 The transformer shall be finished as per IS requirement for outdoor applications.

4.14 CLEARANCES

4.14.01 The electrical clearances shall be maintained as per IEC/BS standards.The design of

the transformer/the height of the bushing/location of the conservator shall be

chosen/carried out considering the electrical clearances stipulated.

4.14.02 There shall not be any structure/piping etc., which may foul with the

vertical uptake of the LV bus duct. LV bus duct, in no case shall be

deviated from vertical direction.

5.0 NOISE

The audible sound level measured at one Meter from the external surface of the

transformer shall not be exceed 65dB.

6.0 TESTS: -

All routine tests as per standards and type tests (as per IEC-726 and BS)/ Acceptance

tests as referred in the specific requirement shall have to be conducted.

7.0 TECHNICAL PARTICULARS/INFORMATIONS REQUIRED

TECHNICAL SPECTION FOR HT/LT SPEC. Page 29

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

7.01 Complete technical particulars as per Appendix E of IS: 2026 as applicable and data as

required on data sheet shall be furnished with the quotation.

7.02 Confirmation for compliance to all requirement of specification/tender documents,

deviations if any should be clearly indicated in schedule of deviation. Any deviation not

specifically indicated in schedule of deviations shall not be considered.

7.03 Schedule of maintenance spares,commissioning spares,special maintenance tools and

equipments.

7.04 The Bidder shall furnish separately man-day rates for supervision of erection, testing

and commissioning. The owner retains the option of availing the services for this

purpose.

7.05 Make, type and catalogue of various accessories and protective devices/bought out

items like ON load tap changer, Buchhloz relay, oil preservation system, radiator,

temperature indicator, pressure relief device.

7.06. Type Test report of similar transformer and major items.

7.07 General arrangement drawing of transformer with plan, elevation, end view indicating

overall shipping dimensions, weights, clearances and all fittings.

7.08 The bidder shall furnish the details of design capabilities; manufacturing facilities, test

facilities etc. Furnish a list of similar transformers manufactured, installed and

commissioned, with details regarding voltage, class, KVA Ratings, the name of the

Purchaser(s),location, quantity supplied and date(s) of commissioning etc.,

7.09 In addition to above the successful bidder shall provide:

i. Foundation plan showing reaction at points of support and

TECHNICAL SPECTION FOR HT/LT SPEC. Page 30

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

location of jacking pad.

ii. GA, schematic and wiring diagram of marshalling box.

iii. Drawing of rating and diagram plate.

iv. Bill of material.

v. Instruction manuals.

7.10 Prior to the despatch of the equipment, requisite copies of instruction manuals shall

be furnished. These manuals shall be sturdily bound volumes and shall contain every

write-up, drawing, data sheets and information required for installation, testing,

setting and adjustment of all components after installation, operation and

overhauling/maintenance of the equipment and all its components.

7.11 Marked erection prints identifying the component parts of the equipment, as

transported, with the assembly drawings.

7.12 Detailed dimensioned assembly and cross-section drawings and description of all the

auxiliaries and drawings identifying all spare parts of re-order.

8.0 DOCUMENTATION

8.01 Correspondence, drawings, progress reports, schedules, test reports and instruction

manuals shall be mailed as per the Distribution Schedule.

9.0 DELIVERY SCHEDULE

9.01 All design, drawing, components and sub-assemblies details shall be furnished within

four (2) weeks of order for Consultants/owners comments.

SPECIFIC REQUIREMENT SHEET FOR DISTRIBUTION TRANSFORMERS

1. Capacity : 1 x 1200 KVA (BIS 1180 - LEVEL 2)

2. TYPE OF TRANSFORMER

a) Indoor/Outdoor : Outdoor

b) Winding : Double

TECHNICAL SPECTION FOR HT/LT SPEC. Page 31

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

c) Winding material : Electrolytic Copper

d) Cooling method : Oil immersed natural cooled (ONAN), to

filled with oil as per IS

e) Core/Shell type : Core type

3. Number of phases : Three

4. Supply frequency : 50 HZ +/- 5%

5. Voltage ratio : 11000 / 433V or as per local electricity

board requirement at normal tap

6. Frequency Variation : 5%

7. Voltage variation : 10%

8. Combined voltage and

frequency variation : 10%

9. Connections:

a) High voltage : Delta

b) Low voltage : Star With Neutral Solidly grounded

10. Vector Group : Dyn11

11. Type of Tap Changer : On load with RTCC on the HV side

12. No. of taps, range : +5% to – 15% in steps of 1.25%

Voltage variation per tap

13. Temperature rise over an

ambient of 50C.

a) Windings by resistance : 50C

method.

14. Insulation class : Class A

15. Trafo. Protection Class : IP 55

16. Enclosure thickness : 2mm

17. Percentage impedance : As reqd. for varying loads as per IS

TECHNICAL SPECTION FOR HT/LT SPEC. Page 32

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

18. Design flux density at : Rated operating flux density shall be Rated

Voltage at 0 tap shall be 15% less than Saturation density

19. Insulation level:

Impulse (KV peak) : As per IS

20. Power frequency HV rms. : As per IS

LV rms. : As per IS

21. Fault level of the system : HV – 18 KA

(Solidly Grounded.) : LV – 50 KA

22. TERMINAL ARRANGEMENT:

a) H.V Cable box to terminate 11KV,3C 185 mm. XLPE cable.

b) L.V LV bus duct flange to terminate 2500A rating Al. Bus duct.

c) L.V Neutral Neutral bushing with rating same as the phase

bushing.

d) L.V Neutral Bushing Suitable for connection by

2Nos. for earthing 50x10mm. Cu.flat (additional neutral bushing) with NCT.

e) Neutral CT Ratio 1250/5AMPS, 15VA

Accessories

23.1 Thermometer pockets

with thermometer : Yes

23.2 Lifting lugs : Yes

23.3 On load tap changing

switch on tank with : Yes

tap position indicator,

23.4 Rating and terminal : Yes

marking plate

TECHNICAL SPECTION FOR HT/LT SPEC. Page 33

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

23.5 Earthing terminals Two nos. each for

(i) Transformer body.

(ii) HV Cable box/LV Bus duct.

(iii) Marshalling box

23.6 Base channel with towing :Yes

holes/lugs

23.7 Jacking lugs/Skid. :Yes

23.8 Inspection Hole :Yes

23.9 Manufacturers' name plate :Yes

23.10 Bidirectional flat/flanged rollers: Flat rollers

23.11 Marshalling box

i) Thickness of sheet steel : 2.5 mm.

ii) Painting : In line with main tank

iii) Degree of protection : IP55

iv) Gland plate : Undrilled, 3 mm thick

v) Spare terminals : 15%

23.12 150mm. dial winding & Oil

temperature indicator

with maximum reading

pointer and alarm & trip

contacts with additional

contacts for remote : Required

annunciation.

23.13 Buchholz relay : Required

23.14 Conservator with drain valve: Required

23.15 Magnetic oil level guage : Required

23.16 Drain cum bottom filter valve

with plug :Required

23.17 Oil level indication :Required

TECHNICAL SPECTION FOR HT/LT SPEC. Page 34

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

23.18 Loss figures to be considered

by the bidder (subject to IS tolerance)

a) No load loss at rated

Voltage & frequency at

Principal tap :

b) Load loss at 75c at

Principal tap :

23.19 Neutral CT Ratio : 1250/5AMPS

23.20 HV Cable Box : Required

23.21 LV Bus Duct Flange : Required

23.22 10% extra oil for topping up : Required

24. Service Conditions

a) Location : Outdoor

b) Mounting : Floor

c) Special Conditions : Moderate

d) Max ambient temperature : 50 C

25. Acceptance tests and

type tests : Temperature rise test shall be conducted

in the presence of Client/PMC/Consultant’s

side.

26. Inspection : Transformer inspection before despatch.

27. Painting : RAL 7032.

28. Impedance : In accordance with IS 2026

--------------

TECHNICAL SPECTION FOR HT/LT SPEC. Page 35

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECIFICAITON

OF

LT BUS DUCT

TECHNICAL SPECTION FOR HT/LT SPEC. Page 36

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

SPECIFIC REQUIREMENTS FOR AIRINSULATED BUSDUCT

ALUMINIUM BUS DUCT

1. System Nominal Voltage - 415 V

2. System Frequency - 50

3. Number of Phases - TPN ( 3 Phases + 100% Neutral)

4. Rated Continuous - As per Single line

diagram/BOQ.

5. Minimum Clearance in Air - As per IS 8623, Part – II

a). Phase to Phase Clearance (clear) - 26mm

b). Phase to Body Clearance (clear) - 20mm

c). Phase to Neutral (clear) - 26mm

6. Neutral Grounding - Solidly earthed

7. Insulation Level - As per standard

8. Short time rating - 50 kA for 1 Sec / as per

BOQ

9. Dynamic withstand current - 100 kA peak

10.Cooling - Self Cooled

11.Design Ambient temperature - 50°C

12.Location/Services - Indoor

TECHNICAL SPECTION FOR HT/LT SPEC. Page 37

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

13.Degree of protection - IP 42 (indoor) and IP 55 (outdoor)

14.Maximum temperature rise

(Over 50 deg. C ambient) - 45°C

15.Material

a). Bus bar - Highly conductivity electrolytic

aluminium alloy GR. 63401

b). Impedance - As per IS 5082

c). Enclosure - 2 mm thick CRCA sheet

steel with powder coated.

16.a). Bus bar joints - Aluminium Laminated

flexible joint at bus duct

run and termination

b). Flexible / expansion - to be provided at all joints

equipment terminations and

between bus section

i). Material - Aluminium

ii). Short circuit and

Continuous rating - As per Master Single line

diagram.

c). Change over chamber - Required

17.Enclosure Points - Circumferential neoprene

rubber Gaskets shall be provided for dust tight

joints

18.Disconnecting Links - Required

TECHNICAL SPECTION FOR HT/LT SPEC. Page 38

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

19.Insulators - 2 Layers of class F Mylar

between

Conductors or better

20.Supports within bus duct - Every 250mm interval

21.Bus duct Support - Required as per site

condition.

22.Flexible bellows - Required in both

Transformer and

Breaker end Termination.

23.Straight run of bus duct - Not exceeding 5 meter

24.Creep age distance - As per standards

25.Seal off Bushing at wall entries - Required

26.a). Ground bus/ Bus duct earthing - Two runs of 50x6mm aluminium

flat

on either side

b). Grounding terminal - To be provided to suit

above ground bus

27.Paint finish - ANS149 Grey Powder

coated finish

28.Acceptance tests - As per IEC / IS

29.Preferred makes/Vendor - Vendor Shall be of CPRI

certified

Manufacturer

TECHNICAL SPECTION FOR HT/LT SPEC. Page 39

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

TECHNICAL SPECIFICAITON

OF

MV PANEL

TECHNICAL SPECTION FOR HT/LT SPEC. Page 40

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

1. GENERAL

This section covers the detailed requirements of Low voltage switchboard for 415

volts, 3 phase, 50 Hz, 4 wire system.

2. STANDARDS AND CODES

Updated and current Indian Standard Specifications and Codes of Practice will apply

to the equipment and the work covered by the scope of this contract.

Low Voltage Switchgear Assemblies IEC61 439-1 & 2

Low Voltage switchgear & control gear IEC 60 947 /IS 13947: 1993

Part I : General rules

Part II : Circuit Breakers

Part III : Switches, disconnectors, switch disconnectors and fuse combination units

TECHNICAL SPECTION FOR HT/LT SPEC. Page 41

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

Part IV : Contactors and Motor starters

Part V : Control circuiFt devices and switching elements Degree of Protection of

enclosures for low voltage switchgear. IEC60529 /IS 2147: 1962

Internal arc – IEC 61641 V2

3. SWITCHBOARDS

The LV switchboards shall be as per the standards and shall conform to IS

8623 / IEC 60439

The designs of the switchboards should be with switchgear manufacturer,

and all the mechanical drawings must be available in the factory beforehand.

Switchboards shall have a short circuit level withstand as per Schedule of

Quantities and drawings.

The enclosures shall be designed to take care of normal stress as well as

abnormal electro-mechanical stress due to short circuit conditions. All covers

and doors provided shall offer adequate safety to operating persons and

provide ingress protection of IP 42 unless otherwise stated. Ventilating

openings and vent outlets, if provided, shall be arranged such that same

ingress protection of IP 42 is retained. Suitable pressure relief devices shall be

provided to minimize danger to operator during internal fault conditions. Panel

shall also be tested for min. IK 08 Protection against mechanical impacts.

The switchboard should have been being type tested design at

CPRI/NABL/ERDA/Independent international test house for short circuit,

temperature rise, protective earth short circuit test and dielectric tests of the

ratings required.-

For operator safety IP2 X (touch proof) protection to be available even after

opening the feeder compartment door. The compartmentalization to be

achieved by using metal separators, use of PVC sheet / Hylem sheets shall not

be allowed.

LT Panel shall be form 3b, for form of separation only for Main PCC panels

Switchboard Configuration

TECHNICAL SPECTION FOR HT/LT SPEC. Page 42

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

The Switchboard shall be configured with Air Circuit Breakers, MCCB's, MCB’s

and other equipment as called for in the schedule of quantities. The MCCBs

shall be arranged in multi-tier formation whereas the Air Circuit Breakers shall

be arranged in Single or Double tier formation only to facilitate operation and

maintenance.

The Switchboards shall be of adequate size with a provision of spare space to

accommodate possible future additional switch gear.

Company name should be mentioned on Top of each all columns of

switchboard.

Constructional Features

The Switchboards shall be metal clad totally enclosed, floor mounted free

standing type of modular extensible design suitable for indoor mounting.

Switchboards construction shall employ the principle of compartmentalized

and segregation for each circuit.

Incomer and bus section panels or sections shall be separate and independent

and shall not be wired with sections required for feeder. The incomer panel

shall be suitable for receiving b us trunking or MV cable of size specified.

Switchboards shall be made up of requisite vertical sections, which when

coupled together, shall form continuous dead front switchboards.

Switchboard shall be readily extensible on both sides by addition of vertical

sections after removal of the end covers.

The switchboards shall be designed for use in ambient temperature and humid

tropical conditions as per Chennai environment. Ease of inspections, cleaning

and repairs while maintaining continuity of operation shall be provided in the

design.

Metal based neoprene gaskets between all adjacent units and beneath all

covers shall be provided to render the joints dust and vermin proof to provide

a degree of protection of IP 42 as stipulated in schedule of quantities. The

unused openings within the switchboards shall be closed using suitable

grommets.

Special care to be taken to ensure effective earthing of the frame and doors of

the switchboards

Each vertical section shall be provided with a rear or side cable chamber

housing the cable end connections and power/control cable terminations.

There should be generous availability of space for ease of installation and

maintenance with adequate safety for working in one vertical section without

TECHNICAL SPECTION FOR HT/LT SPEC. Page 43

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

coming into contract with any live parts. The design of the switchboard shall

allow standard extension chambers if required to accommodate cables.

Switchboard panels and cubicles shall be fabricated with CRCA Sheet Steel of

thickness not less than 2.0 mm and shall be folded and braced as necessary to

provide a rigid support for all components. The doors and covers shall be

fabricated from CRCA sheet steel of thickness not less than 1.6 mm.

All panels and covers shall be properly fitted and square with the frame. The

holes in the panel shall be correctly positioned.

Switchboard shall be provided with “Danger Notice Plate” conforming to

relevant Indian Standards.

Switchboard Dimensional Limitations

The overall height of the switchboard shall be limited to 2400 mm for all the

Busbar ratings and type of switchboards. Panel should have integral base frame

of 75mm, hence total panel height should not be more than 2475mm.

The height of the operating handle, push buttons etc shall be restricted

between 300 mm and 1800 mm from finished floor level.

Other dimensional limits if any are specified separately.

Switchboard Compartmentalization

For compartmentalized switchboards, separate totally enclosed compartments

shall be provided for horizontal busbars, vertical busbars, ACBs, MCCBs, and

cable alloys.

The main board shall be with Form 3b Construction

Earthed metal or insulated shutters shall be provided between drawout and

fixed portion of the switchgear such that no lives parts are accessible with

equipment drawn out. Degree of protection within compartments shall be

atleast IP 2X.

Sheet steel hinged lockable doors for each separate compartment shall be

provided and duly interlocked with the breaker in "ON" and "OFF" position.

For all Circuit Breakers separate and adequate compartments shall be provided

for accommodating instruments, indicating lamps, control contactors and

control MCB etc. These shall be accessible for testing and maintenance without

any danger of accidental contact with live parts of the circuit breaker, busbars

and connections.

For Some MCCB feeders for critical loads like UPS it may be required to have

operation only after opening the door, all other facilities like pad lockable

rotary handle to be provided for such feeder. It shall be possible to do this

TECHNICAL SPECTION FOR HT/LT SPEC. Page 44

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

change during execution of order Each switchgear cubicles shall be fitted with

label in front and back identifying the circuit, switchgear type, rating and duty.

All operating device shall be located in front of switchgear only.

A horizontal wire way with screwed cover shall be provided at the top to take

interconnecting control wiring between vertical sections.

Separate cable compartments running the height of the switchboard in the

case of front access boards shall be provided for incoming and outgoing cables.

Cable compartments shall be of adequate size for easy termination of all

incoming and outgoing cables entering from bottom or top as per site

condition. The construction shall include necessary and adequate and proper

support shall be provided in cable compartments to support and clamping the

cable in the cable alley / cable chamber.

Switchboard Bus Bars

Busbars shall be made of high conductivity, and high strength Aluminum E91

grade Busbars shall be of rectangular cross sections, suitable for full load

current for phase bus bars and half/ full rated current for neutral bus bar or as

stipulated in schedule of quantities. Busbar shall be suitable to withstand the

stresses of fault level as specified in schedule of quantities.

Main Horizontal bus bar and neutral should be in same compartment.

The bus bar system may comprise of a system of main horizontal bus bars and

auxiliary vertical bus bars run in bus bar alloy on either side in which the circuit

could be arranged with front access for cable entrances

The bus bars shall be supported on non-breakable, non-hygroscopic epoxy

resin or glass fiber reinforced polymer insulated supports able to withstand

operating temperature of 110O C at regular intervals, to withstand the forces

arising from a fault level as stipulated in schedule of quantities. The material

and the spacing of the Busbar supports should be same as per the type tested

assembly

Auxiliary buses for control power supply, space heater power supply or any

other specified service shall be provided. These buses shall be insulated,

adequately supported and sized to suit specific requirement. The material for

auxiliary supply bus will be insulated electrolytic copper wires.

TECHNICAL SPECTION FOR HT/LT SPEC. Page 45

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

Clearances between phases should be in line with IEC.

Switchboard Interconnection

All connection and tap offs shall be through adequately sized connectors

appropriate for fault level at location. This shall include tap off to feeders and

instrument/control transformers.

For unit ratings upto 250 amps, PVC insulated 105degC withstand, copper

conductor wires of adequate size to carry full load current shall be used. The

terminations of such interconnections shall be crimped. Solid connections shall

be used for all rating of above 250 amps.

All connections, tappings, clamping, shall be made in an approved manner to

ensure minimum contact resistance. All connections shall be firmly bolted and

clamp with even tension. Before assembly joint surfaces shall be filed or

finished to remove burrs, dents and oxides and silvered to maintain good

continuity at all joints. All screws, bolts, washers shall be zinc plated. Only 8.8

grade nuts and bolts shall be used for busbar connections.

Drawout Features

Air Circuit Breakers shall be provided in fully drawout cubicles, unlessotherwise stated.

These cubicles shall be such that drawout is possible without disconnection of the wires

and cables. The power and control circuits shall have self-aligning and self-isolating

contacts. Mechanical latches shall be integrated in ACB at service, test and isolated

position to ensure that Breaker is firmly latched in respective position. It shall not be

possible to move the breaker from the position unless latch is manually operated.

Instrument Accommodation

All voltmeter, ammeter, MFM and other instruments shall be flushed mounted

type of size 96 sq. mm. All instruments shall be protected with MPCBs.

Instruments and indicating lamps shall not be mounted on the Circuit Breaker

Compartment door for which a separate and adequate compartment shall be

provided and the instrumentation shall be accessible for testing and

TECHNICAL SPECTION FOR HT/LT SPEC. Page 46

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

maintenance without danger of accidental contact with live parts of the

Switchboard.

For MCCBs, instruments and indicating lamps can be provided on the

compartment doors.

The current transformers for metering and for protection shall be mounted on

the solid aluminium bus bars with proper supports.

On all the incomers of switch boards ON/OFF indicators lamps shall be

provided suitable for operation on AC 230 volts supply. All lamps shall be

protected by MCBs.

Wiring

All wiring for relays and meters shall be with PVC insulated copper conductor wires. The

wiring shall be coded and labeled with approved ferrules for identification. The minimum

size of copper conductor control wires shall be 2.5 sq. mm. Runs of wires shall be neatly

bunched and suitably supported and clamped. Means shall be provided for easy

identification of wires. Identification ferrules shall use at both end of wires. All control

wires meant for external connections are to be brought out on a terminal board. The

cables and control wires shall be suitable for withstanding 105 deg C.

GUARANTEED TECHNICAL PARTICULARS OF LT Switchgears:

415V MCC / PCC PANEL

GENERAL-

1. Manufacturer’s Name : M/s. Apparent Power Control systems

(a) Symmetrical short circuit

withstand at rated voltage

of switchgear cubicle : 20 KA FOR 1 SEC.

(b) Peak short circuit

withstand current : 42 KA

2. Degree of protection

TECHNICAL SPECTION FOR HT/LT SPEC. Page 47

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

as per IS:13947

(a) Breaker/MCC AC & DC

Distribution Cubicles : IP 42/IP 55

(b) Busbar chamber : IP 42

3. Cubicle sheet metal details

(a) Cold rolled/hot rolled : COLD ROLLED

(b) Thickness (structural frames

and load bearing members) : 2.0 mm

(c) Thickness (Front and rear) : 1.6 mm

(d) Thickness (Sides and top) : 1.6 mm

4. Painting shade as per IS:5

(a) External surfaces : RAL 7035

(b) Internal surfaces : - DO -

5. Gasket type : Neoprene

6. Width of cable alley : 350 mm (Minimum)

7. Earth busbar size and material : 50 x 6 mm (GS)

8. Approx. weight of one panel with

circuit breaker : 300 KGS.

9. Cable entry : From Bottom

10. Material and applicable standards : Copper / Aluminium

11. Bare/P-ainted epoxy

insulated / sleeved : Sleeved

12. Bus Joints silver faced : No

13. Minimum clearance

(a) Phase to phase (mm) : 25 mm (minimum)

14. Continuous current rating

(a) At 400C ambient (Amps.) : As applicable

(b) At 500C ambient (Amps.) : As applicable

15. Current Density Factor : 0.8Sq.mm for Aluminium & 1.2A

Sq.mm Copper

16. Temperature rise over design

TECHNICAL SPECTION FOR HT/LT SPEC. Page 48

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

ambient temperature at 500C

for continuous current rating 0C. :400C (maximum)

17. One second current rating (kA) : 25 KA

18. Dynamic current withstand

rating (kA) : 45 KA

19. Material of the support insulators : FRP

20. 1min. power freq.withstand -

i. For power circuit : 2.5KV(rms)

ii. For control circuit : 1.5KV(rms)

AIR CIRCUIT BREAKER -

21. Type : Air Break electrical draw-out

22. No. of Poles : 3

115. Voltage : 415±10%

116. Control voltage : 220V DC

117. Frequency : 50Hz±5%

118. Rated operational duty : B-3min, M-B-3min-MB

119. Symmetrical Breaking capacity : 25kA rms for 1sec.

120. Short circuit Making capacity : 62.5kAp

121. Nos. of Aux. contacts : 4NO & 4NC

MCCB

21. Make : L&T/ABB/SIEMENS/SCHNEIDER/ EQUVT.

22. Type : Thermal-magnetic / Microprosser

23. Applicable standard : IS 13947 (Part 3)

24. Rated Current at design

ambient temp. (Amps.) : 630A/400A/100A/63A

25. Design ambient

temperature 0C : 50°C

26. No of poles & Frequency : 4P, 50 Hz.

27. Voltage : 415V ± 10%

28. Rated operating duty : P2

TECHNICAL SPECTION FOR HT/LT SPEC. Page 49

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

29. Derating factor for use

under site ambient

conditions : Not required

30. Rated breaking

current (kA) : 25 KA (min)

31. Maximum through fuse

current withstand (kA) : 45KA

32. Maximum size of fuse

recommended : N.A.

33. Temperature rise of

contacts when carrying

continuous rated current (0C) : 40ºC over 50ºC ambient

34. Door interlock as specified

has it been provided : Yes

CURRENT TRANSFORMER

44. Make : IE/Equvt.

45. Type : Cast Resin, Bar Primary

46. Applicable standard : IS 2705

47 Ratio : Primary/1A

48. Accuracy class : Protection CT - 5P10, 7.5VA

Metering CT - 1 , 7.5VA

Diff protection- PS, KPV = 300V

49. Voltage Class & frequency : 650V, 50Hz

50. Accuracy limit factor :5

51. Instrument security factor :<5

52. Short time current for

1 Sec. (kA) :25 KA

53. Dynamic rating :50 KA

54. Class of Insulation :E or Better

TECHNICAL SPECTION FOR HT/LT SPEC. Page 50

Apparent Power Control Systems

AVA Heritage, Karunakaran Street, Pachiyammai Nagar, Gerugambakkam, Chennai – 600122.

Mail: apparentcs@gmail.com, Web: www.appcs.in,Mob: +919841387065

AUXILIARY CONTACTOR

55. Make : Schneider/L&T/ABB/Equvt.

56. Type : Air-Break

57. Coil Voltage : 220V DC ±5%

58. Coil Burden : 3VA

59. 0Operating Time : 30 ms

60. No of contacts :

(a) Normally open : 2 (two)

(b)Normally closed : 2 (two)

61. Contact rating : 6A

TECHNICAL SPECTION FOR HT/LT SPEC. Page 51

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 6243-ELECTRICAL DRG. R2 - Approved As NotedDocument41 pages6243-ELECTRICAL DRG. R2 - Approved As NotedsaravananNo ratings yet

- 2.6.3 Practice - Quadratic Functions (Practice)Document10 pages2.6.3 Practice - Quadratic Functions (Practice)HyounJoun KangNo ratings yet

- 11 KV Ring Main Units and AccessoriesDocument35 pages11 KV Ring Main Units and AccessoriesAbdus Salam0% (1)

- Gas Insulated SwitchgearDocument33 pagesGas Insulated SwitchgearsudhirguduruNo ratings yet

- Analysis of Permanent Magnet Synchronous MotorDocument15 pagesAnalysis of Permanent Magnet Synchronous Motormalini72No ratings yet

- LT APFC Manual PDFDocument0 pagesLT APFC Manual PDFVp SreejithNo ratings yet

- Vacuum Circuit BreakerDocument12 pagesVacuum Circuit Breakerherovhung12100% (1)

- Geometry FormulasDocument5 pagesGeometry FormulasAlyzza Rose Pampliega LedesmaNo ratings yet

- Boq With BusductDocument9 pagesBoq With BusductsaravananNo ratings yet

- AEG Protect 8 33 End UPSDocument6 pagesAEG Protect 8 33 End UPSomarNo ratings yet

- Partbii IIIDocument388 pagesPartbii IIIsaravananNo ratings yet

- 400 KV Swyd FOR DOJDocument49 pages400 KV Swyd FOR DOJSam0% (1)

- LV PDFDocument44 pagesLV PDFGyanesh BhujadeNo ratings yet

- General Description: Project: Mb#26 Perawang ProjectDocument26 pagesGeneral Description: Project: Mb#26 Perawang ProjectSurianshah shahNo ratings yet

- 12 KV 25 Ka VCB - Rev2Document25 pages12 KV 25 Ka VCB - Rev2Mochamad TaufikNo ratings yet

- AHLSTAR Process PumpsDocument71 pagesAHLSTAR Process PumpsPascal Cote100% (2)

- 62-00 ICAO+doc+9137 Airport+Services+Manual Part+9+-+Airport+Maintenance+Practices FR 110228 GanDocument56 pages62-00 ICAO+doc+9137 Airport+Services+Manual Part+9+-+Airport+Maintenance+Practices FR 110228 GanAnibal Jacek Quirós P.No ratings yet

- 22kV GTPDocument41 pages22kV GTPSundaresan Sabanayagam100% (1)

- Pss TenderDocument26 pagesPss TenderKEYSTONE INFRA PVT LTDNo ratings yet

- Okken Solution GuideDocument26 pagesOkken Solution GuideShailesh ChettyNo ratings yet

- Fire Damaged StatemetDocument11 pagesFire Damaged StatemetsaravananNo ratings yet

- Porcelain Clad VCBDocument2 pagesPorcelain Clad VCBvenkateswararaoNo ratings yet

- FAR Series Outdoor Auto Circuit RecloserDocument11 pagesFAR Series Outdoor Auto Circuit RecloserJoe ChuengNo ratings yet

- 12 KVDocument25 pages12 KVMethilesh DaraNo ratings yet

- Viper - S Solid Dielectric, Three Phase Reclosers: Typical SpecificationsDocument5 pagesViper - S Solid Dielectric, Three Phase Reclosers: Typical SpecificationsErick MoraNo ratings yet

- AC Combiner Box Specification 400vac)Document7 pagesAC Combiner Box Specification 400vac)emilNo ratings yet

- SHP US DS en 22Document2 pagesSHP US DS en 22Mahmoud EL-SayedNo ratings yet

- 275kv Inverter DatasheetDocument2 pages275kv Inverter Datasheetvidhisuthar1162No ratings yet

- AEG Protect8.33 InfoDocument4 pagesAEG Protect8.33 InfoAllan T.No ratings yet

- APFC Panel 23.06.23Document11 pagesAPFC Panel 23.06.23rambhool singh ChohanNo ratings yet

- PC8AHXS Buyers GuideDocument6 pagesPC8AHXS Buyers GuidekkrishnamoorthyNo ratings yet

- LV Catalog ENGDocument11 pagesLV Catalog ENGAbd KHEMIRINo ratings yet

- Switchgear PDFDocument4 pagesSwitchgear PDFgsirinNo ratings yet

- Green Recloser: Chardon KoreaDocument6 pagesGreen Recloser: Chardon KoreatusarNo ratings yet

- Basler BE1-87B DatasheetDocument8 pagesBasler BE1-87B DatasheetstuartsjgNo ratings yet

- 卷二Document572 pages卷二ashraful tanvirNo ratings yet

- Rectiverter Power Core 110VDC 6kVA 1ph MB (DS - CIOR0405110.DS3 - 1 - 1) - 1Document4 pagesRectiverter Power Core 110VDC 6kVA 1ph MB (DS - CIOR0405110.DS3 - 1 - 1) - 1PeterNo ratings yet

- SMA-Sunny Highpower Peak3Document2 pagesSMA-Sunny Highpower Peak3Omar ChaconNo ratings yet

- AlfanarDocument44 pagesAlfanarpratham sutharNo ratings yet

- Sunny Highpower Peak3 125-Us / 150-UsDocument2 pagesSunny Highpower Peak3 125-Us / 150-UsBen Clark100% (1)

- 100 00 Metal Enclosed Capacitor Bank LiteratureDocument8 pages100 00 Metal Enclosed Capacitor Bank LiteratureDany Frisma DhesaNo ratings yet

- Section-7.3 Substation EquipmentDocument84 pagesSection-7.3 Substation EquipmentBRB CABLENo ratings yet

- Air Circuit Breaker: Catalogue 2012Document20 pagesAir Circuit Breaker: Catalogue 2012Addin Galih PrakosoNo ratings yet

- Acb VCBDocument4 pagesAcb VCBAbhay KumarNo ratings yet

- Llaves Termicas S200 80 A y 100 ADocument8 pagesLlaves Termicas S200 80 A y 100 AabrahambarcazaNo ratings yet

- Ali Djuraev SVDocument4 pagesAli Djuraev SVRassl Amrullaevich100% (1)

- APFC TheoryDocument13 pagesAPFC TheoryAnwar HussainNo ratings yet

- SUNPOWER Sp-Oasis-Datasheet-Rv2 - 0Document2 pagesSUNPOWER Sp-Oasis-Datasheet-Rv2 - 0ER BEN SAIDNo ratings yet

- ATSDocument8 pagesATSserban_elNo ratings yet

- sttn6050h 12m1yDocument18 pagessttn6050h 12m1yRahul SinghNo ratings yet

- Technical Specification For 145 KV Circuit BreakersDocument4 pagesTechnical Specification For 145 KV Circuit BreakersraviNo ratings yet

- Datasheet Minipack 48-800 WIR PDFDocument2 pagesDatasheet Minipack 48-800 WIR PDFWellington EspinozaNo ratings yet

- Rectiverter Power Core 18 KVA 3ph MB (DS - CIOR1207.DS3 - 1 - 1) - 1Document4 pagesRectiverter Power Core 18 KVA 3ph MB (DS - CIOR1207.DS3 - 1 - 1) - 1SCRBMark3No ratings yet